Advertisement

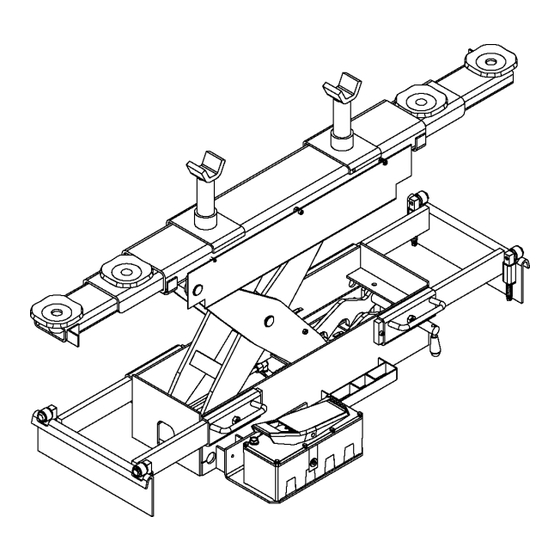

X14/XA14 Rolling Jack

General Description......................................................................................................... 3

Specifications ................................................................................................................... 4

Installation......................................................................................................................... 5

Maintenance Instructions .............................................................................................. 9

Safety Instructions........................................................................................................... 11

Operating Instructions .................................................................................................... 11

Maintenance Instructions .............................................................................................. 12

Trouble Shooting .............................................................................................................. 13

Parts Breakdown ............................................................................................................. 16

© June 2019 by Rotary Lift. All rights reserved.

7,000 Lb. Capacity

Table of Contents

CO10951.3

I

I

N

N

S

S

T

T

A

A

L

L

L

L

A

A

T

T

I

I

O

O

N

N

-

-

S

S

A

A

F

F

E

E

T

T

Y

Y

-

-

O

O

P

P

E

E

R

R

A

A

T

T

I

I

O

O

N

N

-

-

M

M

A

A

I

I

N

N

T

T

E

E

N

N

A

A

N

N

C

C

E

E

IN20843

Rev. B 6/3/2019

Advertisement

Summarization of Contents

1. GENERAL DESCRIPTION

1.1 Description of the machine

Hydraulic wheel free jack with mechanical stop.

1.2 Purpose of the machine

Designed to support and lift vehicles already on a lift.

1.3 Wheel free jack controls

Identifies mechanical stop (A) and elevation pedal (B) controls.

1.4 Main technical specifications

Lists key technical features like overload valve and sliding rollers.

2. AFTER UNPACKING

2.1 Moving to site

Procedure for moving the machine to the installation area using a fork-lift.

2.2 Disposal of the packaging

Instructions for safely disposing of packaging materials.

3. INSTALLATION

3.1 Checking that all the parts are present

Verify all parts are received before starting assembly and installation.

3.2 Checking the minimum requirements for the place of installation

Check area for light, weather, and pollution for proper installation.

3.3 Pneumatic connection

Ensure air supply pressure does not exceed 10 bar; use filtered air.

3.4 Instructions for installation

Step-by-step guide for positioning the jack onto the lift platform.

Holder brackets adjustment

Procedure for adjusting holder brackets, including shims and checking clearances.

3.5 First start up of the machine

Process for initial machine start-up and testing by authorized staff.

4 INSTRUCTIONS FOR USE

4.1 Precautions for use and training of operating staff

Emphasizes trained personnel, safety procedures, and prohibitions for operation.

4.2 Description of controls

Details the operation of safety pin, vehicle positioning, and jack controls (Up/Down).

5. DESCRIPTION AND FUNCTION OF THE SAFETY COMPONENTS

5.1 Warning

Highlights the importance of safety components for proper operation and warns against modifications.

5.2 Mechanical stop device

Explains the threaded ring nut for blocking accidental load descent.

5.3 Device for overload protection

Describes the calibration valve to prevent lifting beyond set capacity.

7. MAINTENANCE

7.1 Changing the oil

Procedure and frequency for changing hydraulic oil, including level check.

7.2 Cleaning the valve and filter

Instructions for cleaning the air filter and valve using specific methods.

7.3 Replacement of the piston gaskets

Advises replacing all piston gaskets simultaneously when one needs changing.

7.4 Air drainage

Procedure for draining air from the piston and pump systems.

OPERATING INSTRUCTIONS

1. Before loading a vehicle onto lift

Ensure jacks are lowered, adapters inbound, and rear jack centered.

2. After vehicle has been loaded

Chock tires on the opposite side of the rolling jack to be raised.

3. Place jack under vehicle

Position jack at pick-up points, extend arms, and take up clearance with rubber blocks.

4. To Raise Rolling Jack

Connect air, depress pump lever until desired lock position, lift lever to latches.

5. To Lower Rolling Jack

Raise jack off latches, lift latch release, lift pump lever to lower.

4. Be sure the jack is fully lowered

Ensure jack is lowered, adapters low, bridge pushed forward before vehicle removal.

MAINTENANCE INSTRUCTIONS

Daily: Inspect rolling jack adapters

Daily inspection of adapters for damage or wear; replace with original parts.

Daily: Inspect air/hydraulic system

Daily check of the air/hydraulic system for any signs of leaks.

Daily: Inspect for loose bolts

Daily inspection for loose bolts and damaged components.

Daily: Inspect linkage curtain guard

Daily check of linkage curtain guard for damage or wear.

Monthly: Inspect the roller assemblies

Monthly inspection of the machine's roller assemblies.

Semi-Annually: Check fluid level

Semi-annual check of the hydraulic reservoir fluid level.

11. SPARE PARTS TABLES

11.1 How to order spare parts

Information needed when ordering spare parts, including model and serial number.

11.2 Spare parts summary

Summary of machine main units and references to relevant spare parts tables.

Need help?

Do you have a question about the XA14 and is the answer not in the manual?

Questions and answers