Table of Contents

Advertisement

Quick Links

®

Bendix

M-21

®

™

SOLENOID

CONNECTOR

DELIVERY

(CAST-IN ID #2)

DELIVERY

MOUNTING

HOLES

M-21

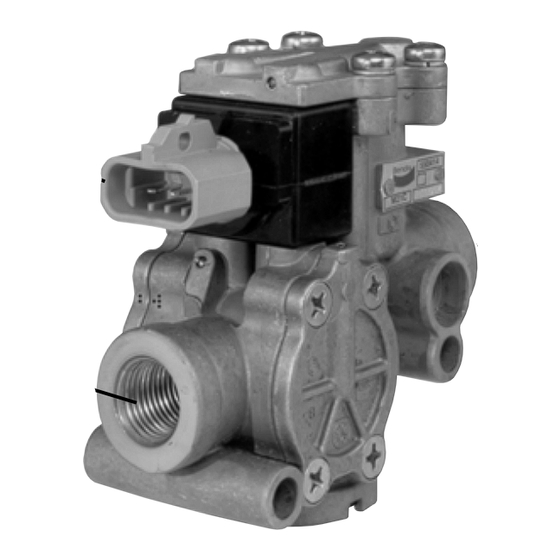

FIGURE 1 - M-21

AND M-22

™

DESCRIPTION

There are two Bendix antilock modulators available from

Bendix Commercial Vehicle Systems LLC, the older M-21

modulator and the newer M-22

functionally the same.

The M-21

™

and M-22

™

antilock system modulators (Figure

1) are essentially high capacity, on/off air valves that

incorporate a pair of electrical solenoids for control. The

solenoids provide the electro-pneumatic interface or link

between the antilock controller electronics and the air brake

system. The modulator can be used to control the braking

function on an individual wheel or two service actuators. When

used to control both service chambers on an axle or two

chambers on the same side of a tandem axle, the modulator

is sometimes mounted ahead of a quick release valve, which

and M-22

AntiLock Modulator Assembly

™

(CAST-IN ID #1)

MODULATOR

™

MODULATOR

™

modulator. Both are

™

SUPPLY

SUPPLY

EXHAUST

(CAST-IN ID #3)

SUPPLY

(CAST-IN ID #1)

SUPPLY

SOLENOID

CONNECTOR

EXHAUST

(CAST-IN ID #3)

provides quick exhaust of service applications during normal

braking. (Figure 2) In the case of individual wheel control

applications, the modulator is always the last control valve

™

through which air passes on its way to the service brake

actuator and a solenoid assembly which contains one

normally open solenoid (NOS), one normally closed solenoid

(NCS), and two inlet and exhaust diaphragm valves. A

Packard, three pin, 280 series weather resistant electrical

connector is an integral part of the modulator solenoid

assembly and serves to carry control commands from the

antilock controller to the modulator. Two, .35 inch diameter,

mounting holes are provided for frame or cross member

mounting. The single supply, delivery and exhaust port on

both modulators is identified with a cast, embossed numeral

for positive identification.

DELIVERY

(CAST-IN ID #2)

MOUNTING

HOLES

M-22

MODULATOR

™

DELIVERY

1

Advertisement

Table of Contents

Summary of Contents for BENDIX M-21-M-22 ANTILOCK MOD ASSY

- Page 1 (Figure 2) In the case of individual wheel control There are two Bendix antilock modulators available from applications, the modulator is always the last control valve Bendix Commercial Vehicle Systems LLC, the older M-21 ™...

- Page 2 FRONT AXLE SYSTEMS REAR AXLE SYSTEM WHEEL CONTROL AXLE CONTROL WHEEL CONTROL ANTILOCK CONTROLLER ANTILOCK CONTROLLER ANTILOCK CONTROLLER M-21 OR M-22 MODULATOR ™ ™ M-21 OR M-22 ™ ™ MODULATOR CONTROLLER/ RELAY ASSEMBLY QUICK RELEASE VALVE M-21 OR M-22 ™ ™...

- Page 3 EXHAUST EXHAUST SOLENOID DIAPHRAGM EXHAUST PORT BRAKE VALVE SUPPLY SOLENOID SPRING BRAKE SUPPLY SPRING CHAMBER DIAPHRAGM FIGURE 3 - M-21 , M-22 MODULATOR NON-ANTILOCK APPLICATION OF SERVICE BRAKES ™ ™ EXHAUST EXHAUST SOLENOID DIAPHRAGM EXHAUST PORT BRAKE VALVE SUPPLY SOLENOID SPRING BRAKE SUPPLY...

- Page 4 EXHAUST EXHAUST SOLENOID DIAPHRAGM EXHAUST PORT BRAKE VALVE SUPPLY SOLENOID SPRING BRAKE SUPPLY SPRING CHAMBER DIAPHRAGM FIGURE 5 - M-21 , M-22 MODULATOR NON-ANTILOCK EXHAUST OF SERVICE BRAKES (NORMAL) ™ ™ NON-ANTILOCK EXHAUST The manner in which air exhausts through the modulator exhaust and out the modulator exhaust port.

- Page 5 EXHAUST EXHAUST SOLENOID DIAPHRAGM EXHAUST PORT BRAKE VALVE SUPPLY SOLENOID SPRING BRAKE SUPPLY SPRING CHAMBER DIAPHRAGM FIGURE 6 - M-21 , M-22 MODULATOR NON-ANTILOCK EXHAUST OF SERVICE BRAKES (RAPID) ™ ™ ANTILOCK HOLD ANTILOCK EXHAUST (FIGURE 7) The antilock controller will place the modulator in the hold When wheel lock is detected, or imminent, the antilock position when it senses that the correct wheel speed (braking controller simultaneously energizes both the supply and...

- Page 6 If the modulator fails to function as promptly. described, or leakage is excessive, it should be replaced with a new or genuine Bendix remanufactured unit, available 3. Build system pressure to governor cut-out and turn the at any authorized parts outlet.

- Page 7 C. Apply a soap solution around each diaphragm cover. VALVE REMOVAL Leakage should not exceed a 1" bubble in less than 3 1. Park the vehicle on a level surface and block the wheels seconds. If leakage exceeds the specified maximum, and/or hold the vehicle by means other than the air tighten the diaphragm cap screws and re-test.

- Page 8 EXHAUST EXHAUST SOLENOID DIAPHRAGM EXHAUST PORT BRAKE VALVE SUPPLY SOLENOID SPRING BRAKE SUPPLY SPRING CHAMBER DIAPHRAGM FIGURE 8 - M-21 ™ , M-22 ™ MODULATOR ANTILOCK APPLICATION HELD POSITION CONNECTOR CONNECTOR SOURCE EXHAUST HOLD SOURCE EXHAUST HOLD M-22 MODULATOR M-21 MODULATOR ™...

- Page 9 7. Never connect or disconnect a hose or line containing pressure; it may whip. Never remove a component or plug unless you are certain all system pressure has been depleted. 8. Use only genuine Bendix replacement parts, ® components and kits. Replacement hardware, tubing, hose, fittings, etc.

- Page 12 BW1664 © 2004 Bendix Commercial Vehicle Systems LLC All rights reserved. 6/2004 Printed in U.S.A.

Need help?

Do you have a question about the M-21-M-22 ANTILOCK MOD ASSY and is the answer not in the manual?

Questions and answers