Advertisement

Quick Links

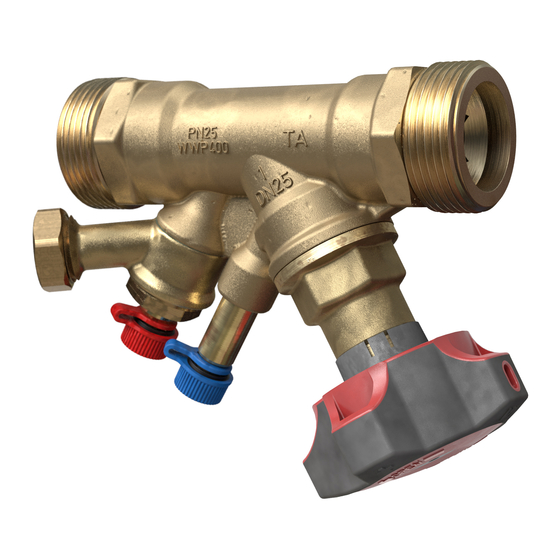

Technical description

Application: Heating- and cooling

installations (glycol/brine). Potable

water installations (hot/cold). Seawater

(cold).

Functions:

With internal threads:

STS

Shut-off, draining (optional)

STA

Shut-off, draining (optional),

presetting of flow, internal

threads

STAD

Shut-off, draining (optional),

presetting of flow, flow

measuring, pressure reading

STA-DR Shut-off, draining (optional),

presetting of flow, flow

measuring, pressure reading

With external threads:

STADA

Shut-off, draining (optional),

presetting of flow, flow

measuring, pressure reading

Nominal pressure: PN 20

Max. working pressure:

2.0 MPa = 20 bar ≈ 300 psi

Max. working temperature: 120°C

For higher temperatures (but not

exceeding 150°C), contact TA.

Min. working temperature: -20°C

Material:

The valves are made completely of

®

AMETAL

and are fitted with a red nylon

handwheel and a protection cap. Seat

seal: Stem with EPDM O-ring.

Spindle seals: EPDM O-rings.

Moulded polyurethane insulation with

PVC cover, for heating and cooling

systems.

Marking:

Body: PN 20/150, DN and inch size

Handwheel: Valve type and DN

Threads:

Internal:

G3/8 - G2

External:

G1/2 - G2 1/2

STS, STA, STAD, STADA, STA-DR

Balancing valves

Einregulierungsventile

Vannes d'équilibrage

Technische Beschreibung

Anwendungsbereich: Heiz- und Kühl-

systeme (Glykol, Brine). Brauchwasser-

systeme (warm/kalt). Salzwasser (kalt).

Funktionen:

Version: Innengewinde:

STS

Absperren (Entleerung

wahlweise)

STA

Absperren, Voreinstellung

(Entleerung wahlweise)

STAD

Absperren, Voreinstellung,

Differenzdruck- und Durch-

flußmessung (Entleerung

wahlweise)

STA-DR Absperren, Voreinstellung,

Differenzdruck- und Durch-

flußmessung (Entleerung

wahlweise)

Version: Außengewinde für lose

Verschraubung:

STADA

Absperren, Voreinstellen,

Differenzdruck- und Durch-

flußmessung.

Nenndruck: PN 20

Max. Betriebsdruck:

2,0 MPa = 20 bar

Max. Betriebstemperatur: 120°C

(Wegen höherer Temperaturen, max.

jedoch 150°C, bitte bei TA anfragen)

Min. Betriebstemperatur: -20°C

Material: Gehäuse, Oberteil, Spindel,

Drosselkegel: AMETAL

®

.

Handrad: Polyamid-Kunststoff.

Sitzdichtung: Kegel mit O-Ring aus

EPDM.

Spindeldichtungen: O-Ring aus EPDM.

Vorgefertigte Isolierung aus Polyurethan

mit PVC-Oberflächenbeschichtung für

Wärme- und Kälteanlagen.

Kennzeichnung:

Gehäuse: PN 20/150, DN- und

Zollkennzeichnung

Handrad: Ventiltyp und DN

Gewinde:

Innen:

G3/8 - G2

Außen:

G1/2 - G2 1/2

Menu

5-5-10

1995.02

ISO 9001

Certification of Registration

Number FM 1045

Certified by BSI

Caractéristiques techniques

Applications: Installations de chauffa-

ge et de conditionnement d'air (eau

normale, glycolée et saumure). Installa-

tions de distribution d'eau sanitaire

(chaude ou froide). Eau de mer froide.

Fonctions: (vidange en option)

Taraudage interne:

STS

Vanne d'arrêt.

STA

Vanne d'arrêt, préréglage.

STAD

Vanne d'arrêt, préréglage,

prises de pression.

STA-DR Vanne d'arrêt, préréglage,

prises de pression, orifice

interne réduit.

Taraudage externe:

STADA

Vanne d'arrêt, préréglage,

prises de pression.

Pression nominale: PN 20

Pression de service maxi:

2,0 MPa = 20 bar

Température de service maxi: 120°C

Températures plus élevées (mais infér-

ieures à 150°C): prenez contact avec TA.

Température de service mini: -20°C

Matériaux: Vannes entièrement

®

fabriquées en AMETAL

, poignée en

nylon rouge. Étanchéité du siège: cône

avec joint torique en EPDM.

Joints de tige: joint torique en EPDM.

Calorifuge préformé en polyuréthanne

avec revêtement en PVC, prévu pour

les installations de chauffage et de

climatisation.

Marquage:

Corps: PN 20/150 (DN/pouce).

Volant: Type de vanne et DN.

Taraudages:

Interne:

G3/8 - G2

Externe:

G1/2 - G2 1/2

1

Advertisement

Summarization of Contents

Technical Description

Application and Functions

Details the intended use, operational capabilities, and basic functions of the valves.

Technical Data

Covers pressure, temperature, materials, marking, and thread connection specifications.

Pre-setting Procedure

STA, STAD, STADA Pre-setting Steps

Step-by-step guide for setting the valves to a specific pressure drop using an Allen key.

General Information and Features

Draining Options

Explains the availability and function of optional draining banjos for hose connections.

Measurement Points

Describes the self-sealing measurement points for pressure testing and how to use them.

STA-DR Renovation Valves

Details the purpose and benefits of STA-DR valves for renovation and small flow applications.

STS Valve Specifications

STS with Draining Option

Technical data and part numbers for STS valves with draining banjo connection.

STS without Draining Option

Technical data and part numbers for STS valves without draining banjo connection.

STA and STAD Valve Specifications

STA Valve Details

Technical data and part numbers for STA valves, with and without draining options.

STAD Valve Details

Technical data and part numbers for STAD valves, with and without draining options.

Accessories and Components

Measurement Point Accessories

Details specific accessories for measurement points, including extensions for STAD and STA-DR models.

Handwheel Replacement

Information on replacing handwheels for STA, STAD, STA-DR, and STADA valves.

Prefabricated Insulation

Describes the prefabricated insulation options for STS, STA, STAD, and STA-DR valves.

Connection Sets and Draining Kit Installation

STADA Connection Sets

Details connection sets for STADA valves, including options for welding, soldering, and compression.

Miscellaneous Components

Covers rating plates and Allen keys used with TA valves.

Draining Kit Installation Guide

Instructions for installing a draining kit on STAD valves and for STS, STA, STAD, STADA models.

Balancing Procedures and Measurement Accuracy

Balancing Manual References

Lists manuals for various balancing adjustment methods for control circuits, distribution systems, and radiators.

Handwheel Calibration and Flow Deviation

Covers handwheel zero position calibration and factors affecting flow measurement accuracy.

Correction Factors and Valve Sizing

Liquid Correction Factors

Details how to adjust flow rates for liquids other than water based on specific density.

Formulas and Software for Sizing

Mentions TA-Calc software and formulas for presetting and sizing valves.

Calculation and Measurement Tools

Conversion Disc and CBI Instrument

Describes conversion disc and CBI instrument for flow, pressure, and setting calculations.

Example Calculation and Kv Values

Provides an example calculation and a table of Kv values for valve presetting.

Valve Performance Diagram

Pressure Drop Graph

Illustrates the relationship between flow rate, Kv, and pressure drop for valve performance.

STAD Valve Preset and Draining Instructions

STAD Presetting Procedure

Detailed steps for closing, opening, and adjusting the inner spindle for STAD valve presetting.

STAD Draining Procedure

Instructions for draining the STAD valve using the Allen key recess and turning the valve.

STAD Draining Kit Installation

Steps for fitting a draining kit to a STAD valve, including removing covers and nipples.

Handwheel Replacement Guide

English Handwheel Exchange

Instructions for removing the existing handwheel and fitting a new one to the valve.

Need help?

Do you have a question about the STAD and is the answer not in the manual?

Questions and answers