Table of Contents

Advertisement

M Series July 2020

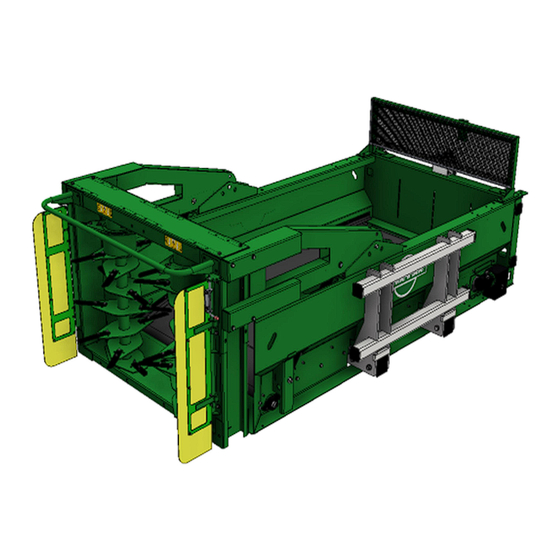

Mini

Mini RB1.8

Midi

Maxi

From Serial Number: SAB200

SAFETY FIRST!

Most accidents that involve product operation, maintenance and repair are caused by failure

to observe basic safety rules or precautions. An accident can often be avoided by

recognising potentially hazardous situations before an accident occurs. A person must be

alert to potential hazards. This person should also have the necessary training, skills and

tools to perform these functions properly.

Advertisement

Table of Contents

Summarization of Contents

Machine Identification

Machine Identification Details

Fields for recording serial number, model, dates, and accessories.

Introduction

Foreword and Manual Purpose

Explains the manual's aim to provide clear operation and maintenance instructions.

Warranty Guidelines and Claims

Outlines warranty period, exclusions, and the claims submission process.

Safety Data

Safety Symbols and General Precautions

Explains the meaning of various safety alert symbols used in the manual.

Operational Safety Requirements

Details qualifications for operators and essential safety precautions during use.

Accident Prevention and Safe Working

Covers accident prevention regulations, changing equipment safely, and working practices.

Working Safely Procedures

Covers safe working practices.

Installation

Unit Attachment Procedure

Step-by-step guide for connecting the Spread-a-Bale to the loader.

Technical Data

Machine Dimensions and Weights

Provides approximate dimensions and weight for different models.

Hydraulic System and Noise Levels

Details hydraulic flow rates, pressures, and machine noise level.

Adjustment and Operation

Unit Description and Components

Identifies and describes the main parts of the Spread-a-Bale unit.

Control, Modes, and Operations

Explains unit control, operating modes, bale loading, and spreading.

Moving, Detachment, and Adjustments

Covers moving, detachment, adjustments, and checks for performance.

Servicing and Maintenance

Routine Servicing and Cleaning

Outlines regular tasks for keeping the machine in good condition.

Component Replacement Procedures

Instructions for changing hydraulic hoses, belts, motors, and bearings.

Lubrication and Lubricant Handling

Details lubrication points, intervals, and safe handling of oils and greases.

Operator Support and Intervals

Information on seeking dealer support and recommended maintenance intervals.

Faults and Remedies

Troubleshooting Common Issues

Lists common problems and checks for diagnosing and resolving issues.

Hydraulic Circuit Schematic

Hydraulic System Flow Diagram

Visual representation of the hydraulic system's flow paths.

Need help?

Do you have a question about the Mini and is the answer not in the manual?

Questions and answers