Summarization of Contents

Supersedure Notice

Effective Changes for this Manual

Details revisions and updates to the manual content.

List of Effective Pages

Lists all pages included in the current manual revision.

Introduction to Operations and Maintenance

Manual Scope and Purpose

Outlines the manual's purpose, sections, and general instructions for mechanics.

Required Tools and Parts

Lists necessary tools, parts procurement, and quality control aspects for maintenance.

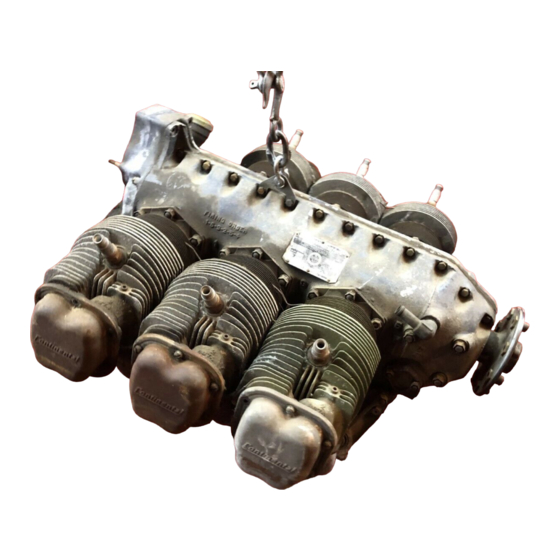

Engine Model Differences Overview

Explains key distinctions between C-125, C-145, and O-300 engine variants.

Engine Specifications and Data

Characteristics and Dimensions Table

Provides detailed physical and performance characteristics of engine models.

Purchased Accessories List

Lists engine accessories, manufacturers, and part numbers for procurement.

Ignition System Specifications

Specifies ignition system parameters like firing order and spark plug gap.

General Engine Description

Engine Model Differences Explained

Details differences between C-125, C-145, and O-300 engine variants.

Cylinder Construction Details

Describes the design and materials of cylinder heads and barrels.

Piston and Piston Pin Construction

Explains the design and materials of pistons and piston pins.

General Engine Description

Connecting Rods Construction

Details the design and materials of connecting rods and bearings.

Crankshaft Construction Overview

Explains the crankshaft design, including its six-throw configuration and bearings.

Crankcase and Oil Sump Design

Describes the two-piece crankcase and the attached oil sump design.

Crankcase Cover Components

Details the components housed within the rear crankcase cover.

Valve Operating Mechanism

Covers hydraulic tappets, push rods, and rocker arms for valve actuation.

General Engine Description

Lubricating System Function

Explains the engine's oil circulation, pump, screens, and pressure relief valve.

Operating and Maintenance Instructions

Introduction to Operations

Outlines the manual's purpose, definitions, tools, and part procurement for operations.

Engine Model Numbering System

Explains how Continental engine models are numbered and identified.

Packing, Storage, and Preparation Procedures

Shipping Boxes and Packing Process

Details engine packaging for shipment and securing it on an assembly stand.

Engine Unpacking Guide

Provides steps for safely removing the engine from its shipping container.

Engine Preparation for Storage

Outlines procedures for preparing engines for periods of storage, including oil treatment.

Post-Storage Engine Preparation

Details checks required before putting a stored engine back into service.

Engine Installation and Removal Procedures

Engine Mounting and Control Connections

Covers connecting controls and mounting the engine onto the aircraft structure.

Fuel and Carburetor System Connections

Details connecting the fuel system and mounting the air intake to the carburetor.

Oil System Connections Guide

Describes connecting the oil temperature capillary to the oil pressure screen cap.

General Engine Operating Instructions

Pre-Starting Checks and Procedures

Lists pre-flight checks including oil, fuel, and ignition switch status.

Engine Starting Procedures

Provides step-by-step instructions for starting the engine, including priming.

Warm-up and Ground Test Procedures

Details engine warm-up procedures, oil pressure checks, and magneto tests.

Take-Off and Climb Operations

Guides on procedures for taking off and climbing, including temperature limits.

Cruising Flight Procedures

Covers recommended practices for cruising flight to ensure engine longevity.

General Engine Operating Instructions

Landing Procedures Guide

Outlines steps for landing, including mixture control and carburetor heat usage.

Engine Stopping Procedure

Details the correct procedure for shutting down the engine safely.

Carburetor Heat Control Usage

Explains when and how to use the carburetor heat control for optimal performance.

Engine Troubles and Service Repairs

Failure to Start Troubleshooting

Lists potential causes and troubleshooting steps for an engine that fails to start.

Low Oil Pressure Diagnosis

Covers checks and potential causes for low oil pressure readings.

High Oil Temperature Diagnosis

Addresses issues related to high oil temperatures and their causes.

Low Power Output Troubleshooting

Provides troubleshooting steps for engines experiencing reduced power.

Rough Running Engine Diagnosis

Lists checks for engine roughness, including propeller and spark plug conditions.

Engine Acceleration Problems

Outlines checks for engines that do not accelerate properly.

Service Inspection and Maintenance Procedures

Daily Inspection Checklist

Details essential daily checks for oil, fuel, controls, and external engine condition.

100-Hour Inspection Guide

Covers thorough inspection points for engines after 100 hours of operation.

Adjustment, Replacement, and Minor Repairs

Carburetor Adjustment Steps

Explains how to adjust the carburetor, including fuel lines and air intake.

Magneto Installation and Timing

Details the process for installing and timing magnetos to the engine.

Ignition Wiring Diagrams

Refers to diagrams for complete ignition wire system setup.

Starter Installation Process

Covers the mounting and securing of the starter motor to the engine.

Adjustment, Replacement, and Minor Repairs

Generator Installation Process

Explains how to install the generator onto the engine's crankcase cover.

Overhaul Instructions: Disassembly, Cleaning, and Inspection

General Overhaul Preparations

Covers engine mounting, exterior cleaning, and initial disassembly steps.

Preliminary Disassembly Operations

Details steps for removing ignition cables, magnetos, starter, and generator.

Engine Disassembly Steps

Provides a systematic guide for disassembling engine components like manifolds and oil sumps.

Overhaul Instructions: Disassembly, Cleaning, and Inspection

Cleaning Engine Components Guide

Outlines cleaning procedures for various engine parts using kerosene and compressed air.

Component Inspection Methods Overview

Covers visual inspection, etching, and dimensional checks for engine parts.

Visual Inspection of Parts

Guides on inspecting parts for damage like cracks, corrosion, or wear.

Etching for Crack Detection

Details the process of etching aluminum parts to reveal hidden cracks.

Repair and Replacement of Engine Parts

General Repair Techniques

Covers general repair methods for nicks, burrs, and flat surfaces on engine parts.

Stud Replacement Procedures

Details how to remove damaged studs and install new ones, including helical coil inserts.

Helical Coil Insert Installation

Explains the process for installing helical coil thread inserts for repairing threads.

Repair and Replacement of Engine Parts

Cylinder Repair Methods

Covers repairing cylinder bores, refacing valve seats, and replacing valve guides.

Piston and Ring Replacement

Details inspection and replacement of pistons, rings, and piston pins.

Reassembly, Final Assembly, Timing, and Testing

Major Subassembly Reassembly Guide

Guides on reassembling cylinder, connecting rods, crankshaft, and pistons.

Final Assembly Procedures

Details the step-by-step process for assembling the crankcase and installing gears.

Air Intake System Installation

Covers connecting intake manifolds, elbows, and hoses to the engine.

Ignition System Installation and Timing

Provides instructions for installing spark plugs and timing magnetos.

Reassembly, Final Assembly, Timing, and Testing

Engine Run-In and Test Procedure

Outlines the process for running in and testing the engine after overhaul.

Reassembly, Final Assembly, Timing, and Testing

Test Operating Limits Data

Lists the operational limits for various engine parameters during testing.

Reassembly, Final Assembly, Timing, and Testing

Standard Acceptance Test Procedure

Details the steps and parameters for the standard engine acceptance test.

Marvel-Schebler MA-3SPA Carburetor

Carburetor Installation Steps

Covers mounting the carburetor, throttle arm orientation, and fuel line connections.

Carburetor Construction Overview

Describes the main components of the carburetor, including the throttle body and bowl cover.

Carburetor Operation: Idle System

Explains how the idle system functions to provide fuel at low engine speeds.

Marvel-Schebler MA-3SPA Carburetor

Carburetor Operation: Metering and Main Nozzle

Details fuel metering and the function of the main nozzle in the carburetor.

Carburetor Operation: Accelerating Pump

Explains the role and adjustment of the accelerating pump for throttle response.

Carburetor Operation: Mixture Control

Describes the mixture control lever and its effect on fuel-air ratio.

Marvel-Schebler MA-3SPA Carburetor

Carburetor Operation: Mixture Control Usage

Guides on using the mixture control for optimal performance at different altitudes.

Carburetor Adjustment Procedure

Provides steps for adjusting the carburetor's idle speed and mixture settings.

Carburetor Float Height Check

Explains how to check and set the float height for proper fuel delivery.

Starting Cold and Hot Engines

Details procedures for starting both cold and hot engines, including priming.

Bendix S6LN-21 Magneto Installation and Maintenance

Magneto Description and Features

Describes the Bendix S4 and S6 series magnetos and their components.

Magneto Installation and Initial Timing

Covers mounting the magneto and performing initial timing checks using a timing light.

Magneto Inspection and Maintenance

Details routine inspection of breaker points, cleaning, and replacement criteria.

Hydraulic Tappets Service Instructions

Handling and Operation Essentials

Covers key points for handling hydraulic tappets and their operational requirements.

Tappet Body and Check-ball Function

Explains the need for a free tappet body and a leak-free check-ball for proper operation.

Plunger Freedom and Leakdown Rate

Details the requirement for a free plunger and the specified leakdown rate for hydraulic units.

Hydraulic Tappets Service Instructions

Tappet Handling and Initial Operation

Provides guidance on handling tappets during engine assembly and initial run-in.

Hydraulic Tappet Noise Causes

Discusses causes of noisy hydraulic tappets, including oil supply and air in the system.

Hydraulic Tappets Service Instructions

Types of Hydraulic Tappet Failures

Classifies tappet failures into noise categories and discusses potential causes.

Summarizing Hydraulic Tappet Issues

Summarizes common causes of noisy tappets and emphasizes proper maintenance.

Delco-Remy Starter Service Instructions

Starter General Description

Describes the Delco-Remy starter's design, drive type, and specifications.

Starter Installation Procedures

Details the steps for installing the starter, including gasket placement and bolt tightening.

Starter Shift Lever Adjustment

Explains the importance of return spring tension and clearance for the starter shift lever.

Delco-Remy Starter Service Instructions

Cranking Motor Maintenance Procedures

Covers normal maintenance and checks for improperly operating cranking motors.

Starter No-Load and Torque Tests

Details procedures for performing no-load and torque tests on the starter motor.

Interpreting Starter Test Results

Explains how to interpret results from no-load and torque tests to diagnose starter issues.

Delco-Remy Generator Service Instructions

Generator Description and Specifications

Provides a description and key specifications for the Delco-Remy aircraft generator.

Generator Installation Steps

Covers assembling drive parts and mounting the generator to the engine housing.

Generator Maintenance and Checks

Outlines normal maintenance and procedures for checking inoperative generators.

Delco-Remy Generator Service Instructions

Checking Inoperative Generator Output

Details checks for no output, unsteady output, excessive output, and noisy generator conditions.

Delco-Remy Generator Regulator Service Instructions

Regulator Description and Function

Describes the combined function of the cutout relay, current regulator, and voltage regulator.

Regulator Mounting and Servicing

Covers mounting the regulator and servicing procedures for normal operation.

Delco-Remy Generator Regulator Service Instructions

Checking Regulator Operation

Details checks for low charging rate, high charging rate, and troubleshooting regulator faults.

Regulator Contact Points Cleaning

Explains the importance and procedure for cleaning contact points in the regulator.

Starter and Adapter Service Instructions

Starter and Adapter General Description

Describes the starter's mounting, drive adapter, and worm gear mechanism.

Starter and Adapter Removal Process

Provides steps for removing the starter and adapter assembly from the crankcase cover.

Starter and Adapter Disassembly Steps

Details the process for disassembling the starter, adapter, and associated components.

Cleaning Starter and Adapter Parts

Outlines cleaning procedures for starter and adapter parts, recommending specific solvents.

Starter and Adapter Inspection Methods

Covers visual inspection and methods for checking parts for wear and damage.

Starter and Adapter Service Instructions

Repair and Replacement of Starter Parts

Details repair and replacement procedures for starter adapter components like needle bearings and bushings.

Starter and Adapter Service Instructions

Starter and Adapter Table of Limits

Lists service limits and new part dimensions for starter and adapter components.

Need help?

Do you have a question about the O-300 and is the answer not in the manual?

Questions and answers