Advertisement

Quick Links

Advertisement

Summarization of Contents

I. APPLICATION

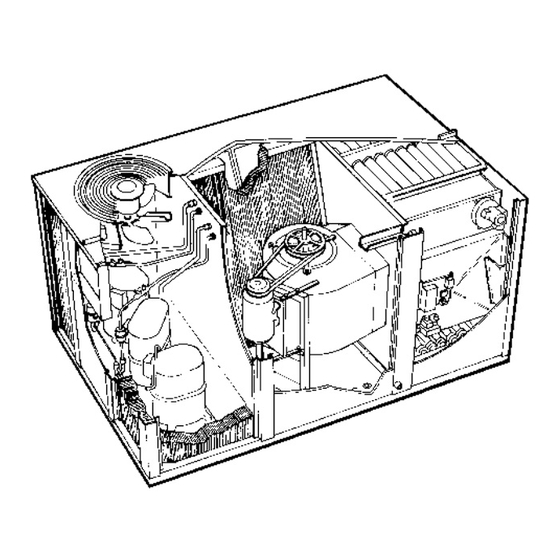

GCS16 2-5 ton units

Overview of GCS16 units available in three models and three cabinet sizes.

II. UNIT COMPONENTS

A-Control Box Components

Description of the control box, its location, and access for GCS16H and GCS16.

1-Terminal Strip TB1

Describes Terminal Strip TB1 for indoor thermostat and outdoor unit low voltage control wiring.

2-Transformer T1

Describes Transformer T1 used in GCS16 series units for 24VAC to control circuits.

3-Transformer Fuse F1

Details Transformer Fuse F1 for 460/575 volt units, providing overcurrent protection.

4-Transformer T3

Describes Transformer T3 used in 460/575 volt units for combustion air blower.

5-Transformer T4

Details Transformer T4 for 460 volt units, powering the indoor blower.

6-Cooling Contactor K1

Explains Cooling Contactor K1, its function with the thermostat and compressor.

7-Indoor Blower Relay K20 (Cooling Speed)

Describes Indoor Blower Relay K20 for cooling speed control.

8-Potential Relay K31

Explains Potential Relay K31 used in higher-end units to control compressor operation.

9-Combustion Air Blower Relay K13

Describes Combustion Air Blower Relay K13, controlling combustion air blower operation.

10-Indoor Blower Relay K20 (Heating Speed)

Details Indoor Blower Relay K20 for heating speed control.

IV. ELECTRICAL CONNECTIONS

A-Power Supply

Details power supply requirements, including voltage and wiring connections.

V. REFRIGERATION SYSTEM SERVICE CHECKS

A-Gauge Manifold Attachment

Details connecting gauge manifolds for pressure checks.

B-Charging

Outlines procedures for charging the unit with refrigerant, including temperature checks.

VII. HEATING SYSTEM SERVICE CHECKS

A. G.A./C.G.A. Applications and Requirements

Refers to manual for A.G.A. and C.G.A. applications and requirements.

B-Gas Piping

Provides guidelines for gas supply piping installation and safety.

C-Testing Gas Piping

Explains manual gas shut-off valve operation for safety during testing.

D-Testing Gas Supply Pressure

Details testing gas supply pressure at the field (field provided).

E-Check and Adjust Manifold Pressure

Explains how to check and adjust manifold pressure using the gas valve.

F-Proper Gas Flow

Describes how to check gas flow and calculate CFM per hour.

VIII. INDOOR BLOWER OPERATION / ADJUSTMENT

A-Blower Operation

Describes blower operation modes based on thermostat settings.

B-Determining Unit CFM

Explains how to measure static pressure and air filters for CFM determination.

D-Blower Speed Adjustment 460V and 575V Units Only

Details how to adjust blower speed using pigtails on 460V/575V units.

B-Filters

Discusses field-provided filters, installation, and maintenance.

C-Heat Exchanger

Guides on checking and cleaning the heat exchanger and checking gaskets.

D-Burner

Details periodic inspection and cleaning of the burner assembly.

E-Combustion Air Blower

Describes inspection and cleaning procedures for the combustion air blower.

XI. ACCESSORIES

A-Lifting Lug Kit

Describes optional lifting lug kits for unit installation.

B-RMF16 Mounting Frame

Details the RMF16 roof mounting frame for downflow discharge.

C-Economizers

Introduces economizer types and their applications with GCS16 units.

2-REMD16 Downflow Economizer

Describes the REMD16 downflow economizer and its damper operation.

3-EMDH16 Horizontal Economizer

Details the EMDH16 horizontal economizer and its damper operation.

4-Economizer Operation

Explains economizer operation modes: setpoint control, minimum positioner, enthalpy sensor.

h-Warm Up Kit

Describes the warm-up kit for enhancing heating performance.

i-Night Relay

Details the night relay for reducing energy consumption.

E-RDE16 Duct Enclosure for REMD16-41 and REMD16M-41 Economizer Limited Application GCS16 Series Units Only

Explains the RDE16 duct enclosure for economizer installation.

F-LPG Gas Kit

Describes the LPG gas kit for converting Natural Gas units to LPG.

G-Condenser Coil Guard Kit

Details the optional condenser coil guard kit for unit protection.

H-High Altitude Kit (CGA only)

Mentions the high altitude kit is not available at this time.

I-Compressor Crankcase Heater

Describes the optional crankcase heater for field installation.

J-DF16 Downflow Filter Kit

Details the optional DF16 downflow filter kit for economizer operation.

K-Timed-Off Control Kit (Figure 68)

Explains the timed-off control kit to prevent compressor short cycling.

L-Optional Compressor Monitor (Figure 69)

Describes the optional compressor monitor for low ambient protection.

M-Low Ambient Kit

Details the optional low ambient kit for outdoor operation.

N-Roof Curb Power Kit

Describes the roof curb power kit for mounting.

O-Firestats

Explains firestat wiring and controls for safety.

P-Transitions

Describes optional supply/return transitions for economizer mounting.

Q-Supply and Return Diffusers

Details optional flush mount diffusers and return air diffusers.

R-Status Panels SP11 and SP11

Describes status panels for system monitoring.

4-Installation and Wiring

Guides on installing and wiring control kits and status panels.

XII. WIRING DIAGRAMS AND OPERATION SEQUENCE

Installation of Plug-In Kits

Details the installation of plug-in kits for economizer control.

D-Warm-up Kit

Explains warm-up kit operation with different control systems.

E-W973 Control System

Describes the W973 control system for programmable operation.

Need help?

Do you have a question about the GCS16H-311-75 and is the answer not in the manual?

Questions and answers