Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Awite AwiFLEX Cool+

- Page 1 Original Instruction Manual (Version 10.02)

- Page 2 Contact and Imprint Please find the latest information online at www.awite.de. For any questions, comments or suggestions, please send an email to info@awite.de. Awite Bioenergie GmbH Grünseiboldsdorfer Weg 5 85416 Langenbach/Niederhummel, Germany Phone +49 8761 72 162-0 +49 8761 72 162-11 Email info@awite.com...

-

Page 3: Table Of Contents

1 Table of Contents Table of Contents ......................... 3 Preface ..........................6 Identification ......................... 7 Safety instructions ......................... 8 Product Description ......................13 Intended Usage ....................13 Device Category According to ATEX Classification ........... 14 5.2.1 Device category not intended for installation in an Ex-zone ......14 5.2.2 Device category intended for installation in an Ex-zone 2 ......... - Page 4 6.2.2.1 Terminal Box AwiFLEX Cool+ and AwiFLEX Cool+ XL ........32 6.2.2.2 Terminal box AwiECO ..................33 6.2.2.3 Connection Cable 100–240 V for Power Supply ..........34 6.2.2.4 Connection cable for DI (digital inputs) and DO (digital outputs) ...... 34 6.2.2.5 Connection cable AI (analogue inputs) and AO (analogue outputs) ....

- Page 5 Technical Data ....................55 Accuracy, Service Life and Calibration of the Sensors ........55 AwiDESULF Combined Package for Microbiological Desulphurization ....... 57 Intended Usage ....................61 Assumptions for Interpreting ................61 Required Space ....................62 Mechanical Connection ..................64 Electrical Connection ..................64 Maintenance ......................

-

Page 6: Preface

Manual. Please operate and service your gas analysis system based on the information in this Instruction Manual. The Instruction Manual for the Awite The Instruction Manual for the Awite – Gas Analysis System consists of two parts: Gas Analysis System consists of two parts: Part A: Product Description, Installation and Opera... -

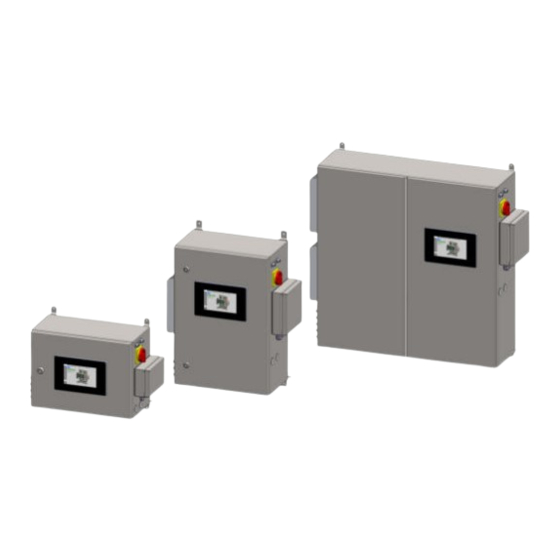

Page 7: Identification

This Instruction Manual is valid for the Series 10 gas analysis systems (AwiFLEX Cool+, AwiFLEX Cool+ XL and AwiECO models) of Awite Bioenergie GmbH. The type plate on the right hand side panel of the device indicates the device type, the required voltage supply, and the rated output. -

Page 8: Safety Instructions

Safety instructions 4 Safety instructions The device is only designed for situations of intended use. A non-intended use can lead to personal injury and property damage. Only use the device as intended. The device measures combustible or explosive gases and is installed in their environment. There is a potential risk of spread or ignition of a hazardous atmosphere. - Page 9 Safety instructions the risk of a possibly even fatal hydrogen sulphide poisoning due to gas leakage has to be assessed on an individual basis. Appropriate measures must be taken. Avoid small volumes of space and low air exchange rates. Hydrogen sulphide is toxic. Watch out for smell of rotten eggs. Ventilate and not enter the room.

- Page 10 "risk of explosion" as well as with loose hose ends, porous hoses or other leaks that lead to an explosion hazard, disconnect the device from the gas supply and shut it down. Contact Awite or an Awite contract partner.

- Page 11 Safety instructions Optionally, the device has alarm outputs with an additional service switch which can be disabled during maintenance. This cancels the alarms regarding possible hazards. The service switch must be turned off again after maintenance in order to reactivate the alarm function.

- Page 12 Safety instructions Gas warning sensors can deliver too low readings or even become unusable due to nsors can deliver too low readings or even become unusable due to nsors can deliver too low readings or even become unusable due to hydrogen sulphide in the air.

-

Page 13: Product Description

The suitability for use in safety-critical applications must be assessed by the user critical applications must be assessed by the user for each case. Reliability data can be provided by Awite if required. for each case. Reliability data can be provided by Awite if required. -

Page 14: Device Category According To Atex Classification

Product Description 5.2 Device Category According to ATEX Classification Applies only within the EU and in countries in which the ATEX Directive (94/9/EG) also applies. The ATEX marking is located on the left outside of the casing. 5.2.1 Device category not intended for installation in an Ex-zone Marking per ATEX with II 2/- G IIA Gas-carrying pipes with inflammable or explosive gas of explosion group IIA (e.g. -

Page 15: Safety Device For The Monitoring Of The Interior Space

The measuring head is integrated in Awite Process Analysis. The evaluation unit which delivers the shutdown signal must be installed outside of an Ex-zone. The disconnection of the power supply to the Awite process analysis device takes place on site. The gas warning device is supplied with 24V DC on site. - Page 16 Product Description The analysis gas lines are routed to the system from the left hand side via the condensate traps for the manual emptying of the system. Pressure-resistant pipes are recommended as analysis gas lines: Diameter 4/6mm or “/¼“ ⅛ Material: stainless steel 1.4401 or highly resistant plastic (depending on the site of operation, stainless steel pipes might be obligatory) All connections on the condensate traps and on the gas analysis system are implemented as...

- Page 17 17: Connections for measuring points 8: Panel PC 18: Connection for exhaust air 9: Measuring gas cooler AwiCool 19: Connection for condensate from gas cooler 10: Exhaust air Illustration 1: Awite gas analysis system AwiFLEX Cool+ including condensate traps on the outside.

- Page 18 > Exhaust air 9: Measuring gas cooler AwiCool (optional) > Calibration gas 10: Exhaust air > Condensate from gas cooler 11: External supply of analysis gas Illustration 2: Awite gas analysis system AwiFLEX Cool+ XL including condensate traps on the outside.

- Page 19 5: Profibus IN 13: Supply of fresh air 6: Profibus OUT 14: Connections for measuring points 7: Potential equalization 15: Connection for exhaust air 8: Panel PC Illustration 3: Awite gas analysis system AwiECO including condensate traps on the outside.

- Page 20 Product Description 1: Main switch 14: Measuring gas cooler AwiCool 2: Line filter 15: Mounting brackets sensors 3: Fuse terminal 100–240 VAC 16: Multi-gas sensor InfraFRED 4: Terminals 100–240 VAC 17: Temperature sensor 5: Relay feedback motor protection 18: AwiConnect incl. pressure sensor 6: Relay AwiDESULF 19: Membrane pump 7: Power supply unit...

- Page 21 Product Description 1: Main switch 18: AwiConnect incl. pressure sensor 2: Line filter 19: diverse electrochemical sensor 3: Fuse terminal 100–240 VAC 20: diverse electrochemical sensor 4: Terminals 100–240 VAC 21: Filter AwiClean 5: Power supply unit 22: Thermal conductivity sensor 6: Fuse terminal 24 VDC 23: Temperature sensor 7: AwiProtect...

- Page 22 Product Description 1: Main switch 11: Terminals shielding sensors 2: Line filter 12: Water sensor AwiH2O 3: Fuse terminal 100–240 VAC 13: Membrane pump 4: Terminals 100–240 VAC 14: Filter AwiClean 5: Power supply unit 15: Valves 6: Fuse terminal 24 VDC 16: Oxygen sensor 7: AwiProtect 17: Hydrogen sulphide sensor...

-

Page 23: Ambient Conditions And Limits For Operation And Storage

Ambient Conditions and Limits for Operation and Storage Ambient Conditions and Limits for Operation and Storage Although the Awite gas analysis systems are designed for use under rough conditions, some Although the Awite gas analysis systems are designed for use under rough conditions, some... -

Page 24: Humidity And Dust

With higher or lower pressure, corresponding measures and measured values may be changed. With higher or lower pressure, corresponding measures must be taken (pressure regulator, precision pressure regulator, available from Awite). (pressure regulator, precision pressure regulator, available from Awite). -

Page 25: Calibration Gas Connection

A comprehensive risk assessment according to the machinery directive is available from Awite. according to the machinery directive is available from Awite. Technical data can be adapted to Technical data can be adapted to new technological advances in the area of biogas by the manufacturer without any prior notice. -

Page 26: Zone Division

Product Description 5.5.1 Zone division Inside the measuring gas pipes and inside the gas analysis system there are only very small amounts of gas, whose volume is far below hazardous amounts. Therefore no Ex-zone obtains in this case. Whether there is an Ex-zone around the gas analysis system or its pipes or not depends on the probability of the occurrence of an explosive gas mixture. -

Page 27: Leaks In The Gas Analysis System

Product Description 5.5.5 Leaks in the Gas Analysis System Despite the slow reaction of methane with oxygen compared to other gases (55 bar*m/s compared to 550 or 1,415 bar*m/s with hydrogen and acetylene) at a similar maximum pressure (7.1 bar under normal conditions), the danger for persons at a control box volume of 60 l cannot be completely eliminated if only due to a deflagration, in the event that an explosive mixture would form inside due to a potentially occurring tightness error and a subsequent ignition due to unfavorable conditions or an escape of the gas from the gas... -

Page 28: Release Of Potentially Toxic And Harmful Gases

Preparing the Gas Analysis System for Use 5.5.6 Release of Potentially Toxic and Harmful Gases The device itself releases no gases, only the gases contained in the measuring gas can be released. In accordance with its intended use, the device is used for the analysis of biogas and upgraded biogas and the gases contained therein may be released correspondingly. -

Page 29: Preparing The Gas Analysis System For Use

Preparing the Gas Analysis System for Use Preparing the Gas Analysis System for Use 6 Preparing the Gas Analysis System for Use Gas Analysis System for Use WARNING This is a complex measuring and control system. Incorrectly performe This is a complex measuring and control system. Incorrectly performed installation, d installation, electrical installation, initial operation and maintenance can lead to hazards and possibly electrical installation, initial operation and maintenance can lead to hazards and possibly... -

Page 30: Main Switch Mains Disconnection Facility

Preparing the Gas Analysis System for Use Preparing the Gas Analysis System for Use CAUTION In the event of a malfunction, the device ca In the event of a malfunction, the device can be brought into a safe state by de n be brought into a safe state by de- energizing it. -

Page 31: Terminal Boxes For Electrical Connections

Check the connections afterwards. the electric diagram provided as part of the system. Check the connections afterwards. The Awite gas analysis system includes a terminal box for external connection. The Awite gas analysis system includes a terminal box for external connection. -

Page 32: Terminal Box Awiflex Cool+ And Awiflex Cool+ Xl

Preparing the Gas Analysis System for Use 6.2.2.1 Terminal Box AwiFLEX Cool+ and AwiFLEX Cool+ XL 1: Conductor connection X11 4: Conductor connection X14 2: Conductor connection X12 5: Conductor connection X15 3: Conductor connection X13 6: Conductor connection X16 Illustration 7: Terminal Box Gas Analysis System AwiFLEX Cool+ and AwiFLEX Cool+ XL. -

Page 33: Terminal Box Awieco

Preparing the Gas Analysis System for Use 6.2.2.2 Terminal box AwiECO 1: Conductor connection X11 4: Conductor connection X13 2: Conductor connection X12 5: Conductor connection X14 Illustration 8: Terminal box Gas Analysis System AwiECO. The terminal box illustrated here serves as an example only, as the number of feed-through terminals depends on the setup of the system. -

Page 34: Connection Cable 100-240 V For Power Supply

Preparing the Gas Analysis System for Use Preparing the Gas Analysis System for Use 6.2.2.3 Connection Cable 100 Connection Cable 100–240 V for Power Supply 3-pin (3 x 1.5²) feed line 100 pin (3 x 1.5²) feed line 100–240 V Specifications Connection Cable: Specifications Connection Cable: AWG16 (metric equivalent 1.5mm²) -

Page 35: Data Transmission Signals

Preparing the Gas Analysis System for Use Preparing the Gas Analysis System for Use 6.2.4 Data transmission signals Data transmission signals There are various possibilities for data transmission. If the connection to the process c There are various possibilities for data transmission. If the connection to the process c There are various possibilities for data transmission. -

Page 36: Analogue Outputs

Preparing the Gas Analysis System for Use Set terminating resistor ON/OFF (see below) Open device door Pull connector from Profibus module (see no. 8 on Illustration 4) Set switch on connector to ON/OFF. Plug connector back into Profibus module, tighten safety screws, close device door 6.2.4.2 Analogue outputs The voltage supply for the analogue outputs takes place via the gas analysis system. -

Page 37: Gas Inlets Awiflex Cool

Preparing the Gas Analysis System for Use condensate lines are also connected by hose screw or pipe screw connections. Illustration 10, Illustration 11 and Illustration 12 show the allocation of the gas inlets. 6.2.6.1 Gas Inlets AwiFLEX Cool+ Connection no. Description Connection to measuring point 1 or optionally connection to measuring point switch-over when there are more than 4 measuring points... -

Page 38: Gas Inlets Awiflex Cool+ Xl

Preparing the Gas Analysis System for Use 6.2.6.2 Gas Inlets AwiFLEX Cool+ XL Due to the high variability of AwiFLEX Cool+ XL, there is no fixed allocation of the gas connections. Please refer to the included gas flow diagram for individual allocations. Illustration 11: Gas Inlets, exhaust air and condensate outlets for AwiFLEX Cool+ XL... -

Page 39: Gas Inlets Awieco

Preparing the Gas Analysis System for Use 6.2.6.3 Gas Inlets AwiECO Connection no. Description Connection to measuring point 1 2 (optional) Connection to measuring point 2 Exhaust air connection – Exhaust air has to be led out of the gas analysis system into the open. -

Page 40: Awisamplex - Measuring Point Switch-Over

Preparing the Gas Analysis System for Use 6.2.6.4 AwiSamplex – Measuring Point Switch-Over If the measuring gas connections on the gas analysis device are not sufficient, a measuring point switch-over (Illustration 13, Illustration 14), must be integrated into the gas analysis system. - Page 41 Preparing the Gas Analysis System for Use Preparing the Gas Analysis System for Use CAUTION Electrical voltage is present in the measuring point switch Electrical voltage is present in the measuring point switch-over. A water ingress may over. A water ingress may cause a short circuit.

-

Page 42: Extraction Points For Analysis Gas

Preparing the Gas Analysis System for Use 6.2.6.5 Extraction Points for Analysis Gas Please take into account the following when designing and setting up the extraction points for biogas: Position: If possible, mount them on top or at the side of the gas line, so that no condensate can permanently flow into the analysis gas lines. - Page 43 Pressure: If the system pressure at the extraction point exceeds 20 mbar of relative high pressure, then additional fine pressure regulators have to be used (provided by Awite) which produce a stable output pressure of approx. 5 mbar of relative high pressure at a maximum of 400 mbar of relative high pressure at input.

-

Page 44: Laying Of Analysis Gas Lines

Preparing the Gas Analysis System for Use Preparing the Gas Analysis System for Use 6.2.6.6 Laying of Analysis Gas Lines ying of Analysis Gas Lines Conductor material: Durable plastic (4/6mm or Conductor material: Durable plastic (4/6mm or or stainless steel (6mm or or stainless steel (6mm or ¼“) ⅛“/¼“) - Page 45 Preparing the Gas Analysis System for Use Preparing the Gas Analysis System for Use 1: Wall outer side 2: Wall interior side 3: Exhaust pipe from gas analysis system Exhaust pipe from gas analysis system Illustration 17: Installation of the exhaust pipe : Installation of the exhaust pipe DANGER The device measures/rinses alternately with measuring gas and ambient air.

-

Page 46: Installation Of Humidity And Flow Sensor Awiflow

Preparing the Gas Analysis System for Use 6.2.7 Installation of Humidity and Flow Sensor AwiFLOW 1: Gas pipe 5: Humidity sensor incl. temperature sensor 2: Fitting sleeves (Rp ½”) 6: Evaluation unit with display for humidity sensor 3: Ball valve (R ½”) L1: Inlet section (Upstream) 4: Flow sensor incl. - Page 47 For details and prices please contact Awite. There must also be sufficient space (approx. 600 mm from the pipe) for installation or removal of the sensor. The sensor should be positioned in such a way that the measuring tips are centered in the pipe, the flow direction arrow points in the flow direction of the gas, and the flattenings on the sensor shaft are parallel to the pipeline.

- Page 48 Preparing the Gas Analysis System for Use < 150mm 20 x pipe Ø 10 x pipe Ø ≥ 150mm 15 x pipe Ø 7.5 x pipe Ø with flow conditioner 6 x pipe Ø 2 x pipe Ø Figure Recommendation for 45° or 90° angle on one level Pipe inner diameter Inlet section L1 Outlet section L2...

-

Page 49: Initial Operation

Preparing the Gas Analysis System for Use 6.2.8 Initial Operation Prior to the initial operation of the gas analysis system, it needs to be checked whether the operating conditions comply with the guidelines provided in this manual. When starting up the process analysis system, the following points have to be noted: The gas analysis system has to be fully installed and connected. -

Page 50: Operation Of The Gas Analysis System

Operation of the Gas Analysis System Operation of the Gas Analysis System 7 Operation of the Gas Analysis System of the Gas Analysis System The gas analysis system may only be The gas analysis system may only be operated by personnel who have been authorized and operated by personnel who have been authorized and instructed by the operator of the system. -

Page 51: Cleaning

Operation of the Gas Analysis System Operation of the Gas Analysis System WARNING Wear of parts can lead to leakage and malfunction. This may even cause an explosion. arts can lead to leakage and malfunction. This may even cause an explosion. arts can lead to leakage and malfunction. -

Page 52: Calibration

If you require a higher accuracy of results, or in case of heavy use, a calibration interval of 3–6 months is recommended. The calibration can be carried out directly on-site by Awite or an Awite partner. Please contact Awite for further information. -

Page 53: Condensate Traps

Operati Operation of the Gas Analysis System 7.1.6 Condensate Traps The condensate traps are installed in the measuring gas supply line to the gas analysis system The condensate traps are installed in the measuring gas supply line to the gas analysis system The condensate traps are installed in the measuring gas supply line to the gas analysis system for each measuring point. -

Page 54: Spare Parts List

Spare parts lists are available at Awite. 7.4 Disposal For a small fee, Awite is prepared to take back any Awite devices that need to disposed off and use them for further industrial processing. 7.5 Product Liability Awite does not assume liability for damages caused by faulty measuring values. -

Page 55: Technical Data And Sensor Accuracy

Table 3. From these figures it is possible to calculate the measurement uncertainties based on the uncertainty of the calibration gases, the calibration intervals, and the ambient temperature. If required, more comprehensive material on the subject of measurement accuracy is available at Awite. - Page 56 Technical Data and Sensor Accuracy Table 3: Measuring uncertainties without uncertainty of the calibration gas. The uncertainty was determined at the calibration point. Values that have been conservatively extrapolated to the measuring range end value are indicated in brackets (worst case). Calibration Standard Standard...

-

Page 57: Awidesulf Combined Package For Microbiological Desulphurization

The electric connection for the compressor incl. motor protection switch is located in a terminal box. The valves are controlled directly from the Awite gas analysis system. Depending on the hourly biogas production, different compressors are offered (Table 4). - Page 58 AwiDESULF Combined Package for Microbiological Desulphurization 1: Compressor 3: Solenoid valve, closed in a de- 5: Check valves energized state 2: Bracket compressor 4: Outlet to fermenter 6: Terminal box Illustration 20: Schematic setup of AwiDESULF 100 (A), AwiDESULF 200 CE (B), and AwiDESULF 200 UL/CSA (C) –...

- Page 59 AwiDESULF Combined Package for Microbiological Desulphurization 1: Compressor 4: Solenoid valve, open in a 7: Outlet to fermenter de-energized state 2: Bracket compressor 5: Exhaust air 8: Solenoid valve, closed in a de- energized state 3: Air intake/filter 6: Check valves 9: Terminal box with motor protection switch Illustration 21: Schematic setup of AwiDesulf 300/500 (C) and AwiDesulf 1000 (D) –...

- Page 60 AwiDESULF Combined Package for Microbiological Desulphurization 1: Terminal box 3: Solenoid valve, closed in a de- 5: Check valves energized state 2: Connection pure oxygen 4: Outlet to fermenter 6: Console Illustration 22: Schematic setup of AwiDESULF PureOxygen – Exemplary representation...

-

Page 61: Intended Usage

Check valve to solenoid valve(s): Zone 2 Interior space of compressor to valves: no zone Max. reachable pressure with compressor: < 500 mbar An exemplary risk assessment for the addition of pure oxygen and air is available from Awite on request. -

Page 62: Required Space

AwiDESULF Combined Package for Microbiological Desulphurization 9.3 Required Space For information on the required space, please refer to the following illustrations. For details on the functioning of the desulphurization unit, please refer to Part B of the Instruction Manual. Illustration 23: Required space for AwiDESULF 100 and AwiDESULF 200 – Exemplary representation Illustration 24: Required space for AwiDESULF 200 UL/CSA –... - Page 63 AwiDESULF Combined Package for Microbiological Desulphurization Illustration 25: Required space for AwiDESULF 300/500 – Exemplary representation Illustration 26: Required space for AwiDESULF 1000 – Exemplary representation Illustration 27: Required space for AwiDESULF PureOxygen – Exemplary representation...

-

Page 64: Mechanical Connection

Pipe lengths of 100m and more are possible at the specified cross-sections (please sections (please inform Awite in advance about the pipe lengths and the expected biogas volume flows ance about the pipe lengths and the expected biogas volume flows... - Page 65 AwiDESULF Combined Package for Microbiological Desulphurization AwiDESULF Combined Package for Microbiological Desulphurization AwiDESULF Combined Package for Microbiological Desulphurization please refer to the electric diagram provided as part of the system. Check the please refer to the electric diagram provided as part of the system. Check the please refer to the electric diagram provided as part of the system.

-

Page 66: Maintenance

Dirty filter pads lead to a reduced air flow, whereby the motor can be damaged. Only the original filter pads may be used (available at Awite). The inspection and exchange intervals differ depending on the device:... -

Page 67: Awilab Gas Analysis

AwiLAB Gas analysis 10 AwiLAB Gas analysis The product family AwiLAB was developed especially for laboratory applications in the biogas sector. In combination with the AwiFLEX gas analysis device, gas production and gas composition can be automatically controlled and investigated during the substrate fermentation. -

Page 68: Required Space

AwiLAB Gas analysis 10.1 Required Space For information on the required space for the AwiLAB extension, please refer to the following illustrations. Illustration 29: Required space for AwiLAB... -

Page 69: Mechanical Connection

AwiLAB Gas analysis 10.2 Mechanical Connection Mechanical Connection The reactors are connected to the The reactors are connected to the milligas counters or the drum gas meters (4/6 mm stainless s or the drum gas meters (4/6 mm stainless steel hose connections). From there, the 4/6 mm hose lines lead into the AwiLAB via a steel hose connections). -

Page 70: Document And Change History

Document and Change History 11 Document and Change History Date Change Dates and Editor Versions 2013-10-31 First version 00-00 Rager 2014-07-18 5.1 Intended usage extended 01-00 Rager 5.2 Device Category for Installation in an Ex-Zone 2 added 5.5.2 Special Devices Hydrogen Measurement 6.2.6.6 Warning Notice Regarding Introduction of the Exhaust Gas into a Gas... - Page 71 Document and Change History 5.3 AwiClean and pressure filter AwiFLEX 6.2.4.2 Analogue outputs 6.2.7 AwiFLOW flow sensor 7.1 Maintenance 7.2 Replacing a Fuse 9 AwiDesulf PurOxygen 12.1 CE Declaration of Conformity updated Formatting and bug-fixing entire document 2017-09-12 07-00 Murnleitner 5.5.2 Footnote (10% hydrogen) added.

-

Page 72: Appendix

Appendix 12 Appendix 12.1 CE Declarations of Conformity The gas analysis system can optionally be designed to be installed in the potentially explosive zone 2. Which declaration applies to the respective device can be determined using the marking on the left side of the device. 12.1.1 CE Declaration of Conformity for Devices Not Intended to be Installed in an Ex-Zone... -

Page 73: Ce Declaration Of Conformity For Devices Intended To Be Installed In An Ex

Appendix 12.1.2 CE Declaration of Conformity for Devices Intended to be Installed in an Ex- Zone... -

Page 74: Iec Declaration Of Conformity

Appendix 12.2 IEC Declaration of Conformity... -

Page 75: Certificate Tüv Süd (Ul / Csa 61010-1:2012)

Appendix 12.3 Certificate TÜV SÜD (UL / CSA 61010-1:2012)

Need help?

Do you have a question about the AwiFLEX Cool+ and is the answer not in the manual?

Questions and answers