Table of Contents

Advertisement

Manual

Plate heat exchanger

ID number:

Order number:

thermowave

Gesellschaft für Wärmetechnik mbH

Eichenweg 4

06536 Berga

BA EN 12.2019 Modification 02 from 01.12.19. Copies are not subject to the change service.

Type:

Position:

Project:

Telefon:

+49 34651 418 0

Fax:

+49 34651 418 13

E-mail:

info@thermowave.de

Web:

www.thermowave.de

Advertisement

Table of Contents

Summary of Contents for Thermowave TL650

- Page 1 Manual Plate heat exchanger Type: ID number: Order number: Position: Project: thermowave Telefon: +49 34651 418 0 Gesellschaft für Wärmetechnik mbH Fax: +49 34651 418 13 Eichenweg 4 E-mail: info@thermowave.de 06536 Berga Web: www.thermowave.de BA EN 12.2019 Modification 02 from 01.12.19. Copies are not subject to the change service.

- Page 2 GmbH cannot be held responsible for faults that emerge as a result of these operating instructions having been ignored. In case your plate heat exchanger encounters problems that have not been addressed in these operating instructions, we request you to promptly contact thermowave GmbH or its respective representative.

-

Page 3: Table Of Contents

Table of contents Important basic information ....................5 Following the operating instructions ................5 Limits of the apparatus ....................5 Technical data ......................5 Prescribed environmental conditions ................5 Other limits ......................5 Interfaces ......................... 6 Responsibilities ......................6 The manufacturer’s responsibilities ..................6 1.7.1 Responsibilities of the operator or owner ................ - Page 4 Connection, activation and shutdown ................24 Connection......................24 Activation ......................25 Shutdown ......................26 Reactivation after shutdown ..................26 Operations ........................27 Safety ........................27 General ........................27 Troubleshooting ....................... 28 Safety ........................28 Service address ....................... 28 Performance loss ....................29 Lack of leak-tightness .....................

-

Page 5: Important Basic Information

Important basic information Following the operating instructions ➢ Please read the operating instructions thoroughly and in full. ➢ Ensure that the operating instructions are read and understood by all users who perform activities associated with the plate heat exchanger. ➢ Always store the operating instructions in a manner that ensures that they can be accessed by all users at any time. -

Page 6: Other Limits

Other limits After the life cycle comes to an end, it is necessary to properly dispose of the materials that have been built into the PHE [► chapter 10]. The existing standards, guidelines, laws and regulations must be complied with. Interfaces The connections for the mediums and potential ventilation and emptying facilities can be found on one or both plates and/or on a special intermediate frame. -

Page 7: Legal Information

The operating instructions or parts thereof may not (either electronically or mechanically) be copied, distributed, modified, provided to third parties, translated or used in any other manner unless thermowave GmbH has explicitly approved of such a course of action in writing. Service address thermowave Gesellschaft für Wärmetechnik mbH... -

Page 8: Safety

Safety Depiction of information 2.1.1 Warning notices Warning against injuries resulting in death. Denotes an immediate and impending hazard. If such a hazard is not avoided, it results in death or the most severe injuries. ➢ The arrow flags a precautionary measure that must be implemented in order to avert the risk. Warning against serious injuries. -

Page 9: Diagrams And Figures

Customer service The customer service domain consists of service technicians who have demonstrably been trained and authorised by thermowave for work pertaining to the PHE. 2.3.2 Safety-relevant environmental conditions Operate the PHE in hazard-free surroundings. -

Page 10: Safety-Relevant Instructions For Specific Life Phases

2.3.3 Safety-relevant instructions for specific life phases Transport and storage Crushing hazard! The PHE often has a high weight. The PHE can slip and fall away from the transport equipment. Use suitable lifting means to secure it [► chapter 5.3]. The consequences could be serious injuries, or even death. -

Page 11: Technical Data

Technical data These operating instructions apply to all plate heat exchangers manufactured by thermowave. The name of your PHE can be found on its name plate – [► chapter 4.1.2]. Apparatus type Refer to order-related documents in the annexe ID number... -

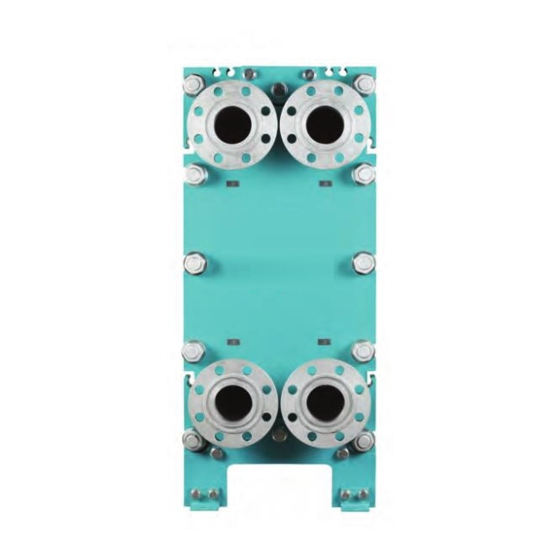

Page 12: Structure And Function

Structure and function Structure 4.1.1 Main components The following section depicts the main components and the fundamental structure. Figure 1: Overview of the PHE Apparatus part no. Apparatus part no. 1. Upper support rod 9. Heat exchanger plate 2. Profile support rod (optional) 10. -

Page 13: Marking On The Apparatus

4.1.2 Marking on the apparatus 4.1.2.1 Sign as per PED (pressure equipment directive) The head plate of every single PHE is equipped with a name plate. It provides important information such as: • Identification number of the specified spot • Apparatus type •... -

Page 14: Screw Locking Varnish

The medium signs can be found at the connections; they denote the entry and exit of the mediums. Figure 3: Medium sign 4.1.2.2 Screw locking varnish Screw locking varnish can be found on two of the tensioning screws on the frame cover (Figure 4). The varnish primarily serves to ensure that the tensioning screws are sealed at delivery. -

Page 15: Frames

Frames The plate heat exchanger is available in conjunction with various frame designs. Along with the maintenance-friendly and optimised K and N frame models, a frame type featuring a very low design height (model T) is also available. Apparatus types TL 50/TL 90/TL 150 (which have a low number of heat exchanger plates) are also produced, along with a frame type that does not have a rear-side support (model Special variants of stainless steel are used in all processes pertaining to the cooling and heating operations associated with the food and beverage sector. -

Page 16: Function

Function The PHE consists of shaped heat exchanger plates featuring installed gaskets, which are clamped together (such that they remain detachable) between a stationary and moving pressure plate with the help of tensioning screws, and which are arranged between the upper and lower support rods. Plates featuring gaskets and welded modules featuring various stampings are available for the most diverse application areas. -

Page 17: Heat Exchanger Plates And Modules

Heat exchanger plates and modules 4.5.1 Gasketed heat exchanger plates All thermoline plate heat exchangers are available with gasketed plates. The advantage of using gasketed plates is that after the plate packet has been opened, all the flow channels are directly accessible for the purposes of inspection. -

Page 18: Delivery, Transport, Installation

Please check whether your delivery is complete. Please raise prompt complaints regarding missing or damaged parts by contacting the following address: thermowave Gesellschaft für Wärmetechnik mbH Eichenweg 4 06536 Berga Tel.: +49 34651 418 9980... -

Page 19: Installing The Apparatus At The Installation Site

Mortal danger due to high dead weight of the PHE The PHE can tip over or fall down when it is being transported using a ground conveyor or crane. This can lead to life-threatening accidents. ➢ If possible, ensure that a horizontal PHE is erected for the first time at the installation site. ➢... -

Page 20: Horizontal Delivery - On The Side

Remove the lifting means. Use the order-related documents or the information specified on the name plate to check the tensioning dimension. If these values are not in line with each other, contact thermowave’s customer service department. Check whether the screw locking varnish is ruptured [► chapter 4.1.2.2]. In case of damage, contact thermowave’s customer service department. -

Page 21: Horizontal Delivery - On The Head Plate

Remove the lifting means. Use the order-related documents or the information specified on the name plate to check the tensioning dimension. If these values are not in line with each other, contact thermowave’s customer service department. Check whether the screw locking varnish is ruptured [► chapter 4.1.2.2]. In case of damage, contact thermowave’s customer service department. -

Page 22: Vertical Delivery

Carefully lower the PHE onto the base of the apparatus. Use the order-related documents or the information specified on the name plate to check the tensioning dimension. If these values are not in line with each other, contact thermowave’s customer service department. -

Page 23: Vertical Delivery With Base Of The Apparatus

Carefully lower the PHE onto the base of the apparatus (at the installation site). Use the order-related documents or the information specified on the name plate to check the tensioning dimension. If these values are not in line with each other, contact thermowave’s customer service department. -

Page 24: Connection, Activation And Shutdown

Connection, activation and shutdown Connection Mortal danger due to tipping over of the PHE The PHE can tip over due to its high dead weight; this can result in deaths or serious injuries. ➢ Anchor or bolt the PHE firmly at the installation site before you undo the lifting means. ➢... -

Page 25: Activation

Temperature changes of up to 1 K/s and pressure change rates of up to 2 bar/s are considered to be harmless. This limitation does not apply to brief process-induced temperature changes, such as those associated with CIP cleaning operations of the plate heat exchanger. thermowave must be consulted in case of other deviations. -

Page 26: Shutdown

12. In case of a lack of tightness, the plate packet can be re-tightened up to a level that is 3% above the specified initial dimension. Never tension the PHE beneath the specified final dimension. thermowave customer service The customer service department will provide high-quality expert assistance in case of any and all questions and problems. -

Page 27: Operations

If it is necessary to change the pressure and temperature levels, such changes should only be made after consulting thermowave. Temperature changes of up to 1 K/s and pressure change rates of up to 2 bar/s are considered to be harmless. -

Page 28: Troubleshooting

➢ Faults may only be rectified by appropriately-trained personnel. Service address thermowave’s customer service department will always be glad to help you correct faults and avoid inappropriate activities and their consequences. thermowave Gesellschaft für Wärmetechnik mbH... -

Page 29: 8.3 Performance Loss

Viscosity Check the viscosity and set it to the order-related operating data, get it checked by thermowave if necessary Flow rate too high Set the PHE to the order-related operating data and get it checked by thermowave if necessary Use the parts list [►... -

Page 30: 8.4 Lack Of Leak-Tightness

Gaskets are contaminated Open the PHE, clean the gaskets and heat exchanger plates and get the system checked by thermowave if necessary Gaskets are defective Open the PHE and replace the gaskets, get the system checked by... -

Page 31: Maintenance, Servicing And Cleaning

➢ Always wear suitable protective equipment (PPE). ➢ If hot or very cold mediums are used, there is a risk of burning or freezing. Service address thermowave Gesellschaft für Wärmetechnik mbH Eichenweg 4 06536 Berga Tel.: +49 34651 418 9980 Fax: +49 34651 418 9924 service@thermowave.de... -

Page 32: Maintenance Schedule

Information regarding the types of gaskets can be found in the order-related documents. We recommend that all plate gaskets be replaced at the same time. Only use original plate gaskets by thermowave. Clip-on system for gasketed heat exchanger plates and modules The system guarantees optimal and slip-free seating. -

Page 33: Repairing Leakages

12. Ensure that the pressure-free PHE is not tensioned beyond the final dimension specified on the name plate. Follow the sequence while tightening the tensioning screws [► chapter 9.5.2]. 13. If leakages persist, contact thermowave’s customer service department. Opening and closing the plate packet 9.5.1... -

Page 34: Closing The Plate Packet

Carry out the following work steps: After the PHE has been emptied and the protective covers have been removed, the pipes at the frame cover (if present) should be disassembled in a manner that ensures that there is enough space for the cover to be pushed up to the support. - Page 35 9.5.2 Closing the plate packet Check once again whether the plates have been installed in the correct order. Push the moving frame cover as close to the plate packet as possible, and place the tensioning screws in the tensioning screw slots. The seating of the gaskets should be checked once again after light straining. In this regard, the fundamental rule is that the plate packet should have a uniform appearance.

-

Page 36: Removal And Installation Of The Plate Packet

Removal and installation of the plate packet Risk of injury There is a risk of injury while the heat exchanger plates are being installed. Be mindful of the following points: ➢ Always wear suitable protective equipment (PPE). 9.6.1 Removal of the heat exchanger plates and the modules in case of K, L, T and F (without intermediate frame) frames Open [►... -

Page 37: Installation Of The Heat Exchanger Plates

9.6.4 Installation of the heat exchanger plates Risk of injury There is a risk of injury while the heat exchanger plates are being installed. Be mindful of the following points: ➢ Always wear suitable protective equipment (PPE). Perform the following work steps: 1. -

Page 38: Cleaning The Laser-Welded Modules

(cleaning) fluid in the laser-welded gap is unobjectionable. Firmly-adhering dirt should be removed by thermowave’s service personnel in accordance with case-by-case specifications. Please direct queries to thermowave’s customer service department. Damage to the modules Ensure that no cleaning agents or detached pieces of dirt get into the laser-welded plate gap. -

Page 39: Manual Cleaning

6. The plate packet should be re-closed properly after the cleaning activities have been completed [► chapter 9.5.2]. Firmly-adhering dirt should be removed by thermowave’s service personnel in accordance with case-by-case specifications. Please direct queries to thermowave’s customer service department. -

Page 40: Disassembly And Disposal

The PHE must be sent to final recycling at the end of its service life in accordance with the local disposal guidelines. If requested, thermowave shall dispose of your PHE. The PHE shall be disassembled, transported away and disposed of in a technically correct manner; our employees shall provide these services for a fee. -

Page 41: Annexe

Annexe 11.1 Parts list 11.2 Technical data sheet 11.3 Diagram 11.4 Declaration of conformity 41 of 41 BA EN 12.2019 Modification 02 from 01.12.19. Copies are not subject to the change service..

Need help?

Do you have a question about the TL650 and is the answer not in the manual?

Questions and answers