Table of Contents

Advertisement

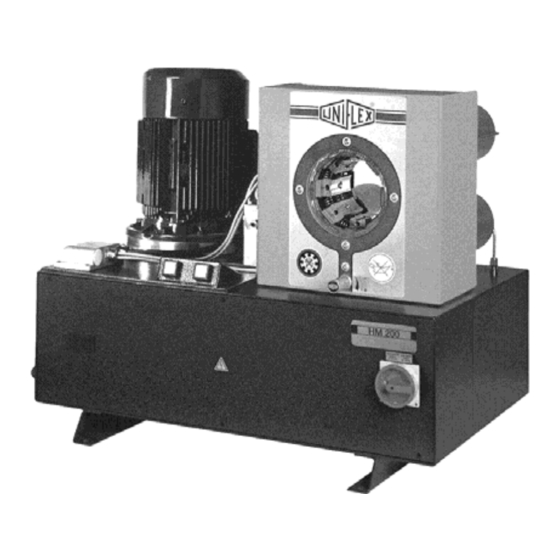

OPERATING MANUAL

- HM 200

- HM 200 Ecoline

- HM 200 Ecoline DC

- HM 250

- HM 260

Technical Details subject to change

EN

Copying and distributing this document and the use or communication of the contents thereof are forbidden without

expressed authority. Offenders are liable to the payment of damages. All rights are reserved in the event of the grant of a

patent or the registration of a utility model or design.

Advertisement

Table of Contents

Summarization of Contents

CE Declaration of Conformity

Machine Compliance and Applicable Standards

Details machine identification, manufacturer, and relevant directives for compliance.

Chapter 1: Introduction to UNIFLEX Operation

Manual Overview and Safety Information

Provides general information about the manual and an overview of safety aspects.

Understanding Warning Pictograms

Explains the meaning of various symbols and icons used in the manual.

Chapter 2: Safety Precautions

Operator Responsibilities and Machine Hazards

Outlines owner and personnel obligations, and hazards during machine operation.

Safe Usage and Machine Integrity

Covers intended use, machine safety, and general operating rules.

Safety Guidelines and Procedures

Intended Use, Warranty, and Training

Defines intended purpose, warranty conditions, and personnel training requirements.

Operational Safety and Hazard Management

Details safety measures for operation, electrical, and hydraulic hazards.

Machine Modifications and Cleaning Safety

Restrictions on Machine Modifications

Specifies prohibitions on unauthorized changes and the use of non-original parts.

Safe Cleaning and Waste Disposal Practices

Provides guidelines for cleaning the machine and disposing of materials safely.

Safety Installations and Personal Protection

Safety Systems and Path Limitation

Describes safety installations, emergency switches, and path limitation settings.

Personal Safety Measures and Danger Awareness

Lists essential personal safety rules and highlights specific dangers like crushing.

Chapter 3: System Design and Components

Identification of System Components

Illustrates and labels the main parts of the machine system.

Technical Specifications and Model Comparison

Detailed Machine Specifications Table

Presents a comparative table of technical data for different UNIFLEX machine models.

Chapter 4: Commissioning and Setup

Unpacking and Workbench Installation

Guides on how to unpack the machine and set it up on a suitable workbench.

Hydraulic System Setup and Filling

ECOLINE DC Hydraulic Power Unit Requirements

Details the external hydraulic power unit needed for the HM 200 Ecoline DC.

Hydraulic Oil Filling and System Ventilation

Instructions for filling the hydraulic oil and ventilating the system.

Electrical Connection and Motor Verification

Connecting the Main Power Supply

Procedure for connecting the machine to the electrical power supply.

Electric Motor Rotation Direction Check

Method for verifying the correct rotation direction of the electric motor.

HM200Ecoline Electrical Setup

Power Connection and Motor Rotation Check

Specific instructions for connecting HM200Ecoline power and checking motor rotation.

Ecoline DC Electrical Connection

Vehicle Power Unit Connection Details

Guides on connecting the hydraulic power unit to the vehicle battery.

Chapter 5: Crimping Procedures

Quick Die Change (QDC 239.5)

Step-by-step guide for changing crimp dies using the QDC system.

Crimp Die Insertion and Removal

Instructions for inserting and removing crimp dies from the machine.

Setting the Crimp Diameter

Crimp Die Table and Diameter Selection

Details how to select the correct crimp diameter using the provided die table.

Crimping Best Practices

General Crimping Guidelines and Control

Provides general notes on crimping quality and controlling the hose crimper.

Chapter 6: Maintenance Schedule and Tasks

Daily and Monthly Maintenance

Lists routine maintenance tasks to be performed daily and monthly.

Six-Month and Annual Maintenance

Details maintenance tasks required every six months and annually, including oil change.

Crimp Micrometer Calibration

Procedure for Micrometer Recalibration

Explains how to recalibrate the crimp micrometer for accurate settings.

Slide Bearing Replacement Procedure

Exchanging Slide Bearings

Step-by-step instructions for replacing the slide bearings in the crimping tool.

Appendix: Spare Parts Information

Component Identification and Diagrams

Overview of spare parts with visual identification and numbered diagrams.

Spare Parts Diagrams (Part 2)

Detailed Component Illustrations

Further diagrams illustrating specific machine components for spare parts.

Spare Parts Diagrams (Part 3)

Micrometer and Tool Holder Illustrations

Illustrations of the micrometer and tool holder for spare parts reference.

Detailed Spare Parts List

Part Number and Description Details

Lists part numbers, quantities, names, and descriptions in multiple languages.

Detailed Spare Parts List (Hydraulic Components)

Hydraulic Components and Fittings List

Provides a list of hydraulic components and fittings with their part numbers.

Detailed Spare Parts List (Aggregates & Valves)

Hydraulic Aggregates and Valve List

Lists hydraulic aggregates, valves, and other related parts with part numbers.

Electric Motor Specifications

Motor Voltage and Frequency Options

Details motor specifications, including voltage and frequency for different configurations.

Pins for Standard Dies

Die Pin Compatibility Chart

Chart showing compatibility of different pin types with various die profiles.

Ordering Spare Parts

Contact Information and Order Requirements

Provides contact details for ordering parts and lists essential information needed for orders.

Circuit Diagrams: HM 200 Ecoline

Hydraulic Circuit Diagram

Schematic representation of the hydraulic system for the HM 200 Ecoline.

Circuit Diagrams: Power Unit

Aggregate Electric Circuit Diagram (440V)

Electrical circuit diagram for the hydraulic power unit operating at 440V.

Circuit Diagrams: Control Systems

HM 200 Control Circuit Diagram

Electrical diagram detailing the control part of the HM 200 machine.

Circuit Diagrams: Power Sections

HM 200 Power Circuit Diagram

Electrical diagram showing the power section of the HM 200 machine.

Circuit Diagrams: 480V Operation

HM 250/260 480V Electric Circuit

Electrical circuit diagram for HM 250 and HM 260 operating at 480V.

Circuit Diagrams: 220/239V Operation

HM 250/260 220/239V Electric Circuit

Electrical circuit diagram for HM 250 and HM 260 operating at 220/239V.

Hydraulic Diagram: HM 200/250/260

System Hydraulic Layout Schematic

Schematic representation of the hydraulic system for HM 200, 250, and 260 models.

Control System Diagrams

PLC Input/Output and Configuration

Diagrams related to PLC inputs, outputs, and configuration for the control system.

Maintenance Logbook Entries

Service Record and Checklist

Template for recording maintenance activities, including checks for bearings, springs, and oil.

Trained Personnel Declaration

Operator Training and Safety Acknowledgment

Form for personnel to declare attendance of training and understanding of safety procedures.

Need help?

Do you have a question about the HM 260 and is the answer not in the manual?

Questions and answers