Table of Contents

Advertisement

Advertisement

Table of Contents

Summarization of Contents

WATERBLAST SAFETY

Recognizing Safety Information

Details on how to identify and understand safety warnings and decals.

Understanding Signal Words

Explanation of DANGER, WARNING, CAUTION, and ATTENTION signal words.

Waterblast Safety Manual

Information on the importance and availability of the safety manual.

WARRANTY

Limited Warranty

Defines the warranty period and conditions for Jetstream products.

Exclusive Remedy

Outlines the sole and exclusive remedy for product failure.

Warranty Exclusions

Lists conditions and parts not covered by the Jetstream limited warranty.

COMPONENT IDENTIFICATION

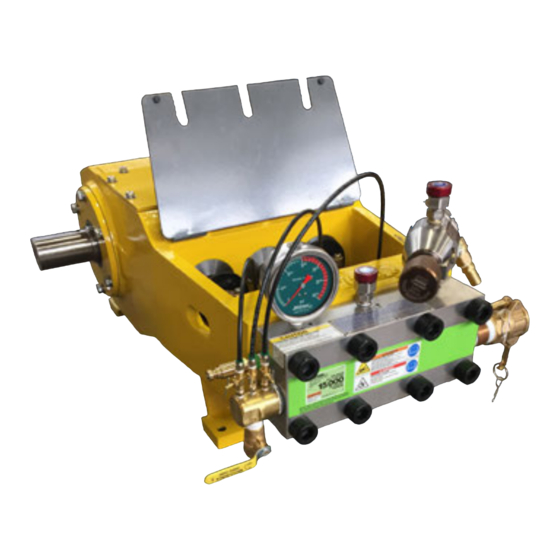

Pump Main Components

Identifies the UNx pump, its power and fluid ends, and the manifold assembly.

Fluid Handling Components

Describes rupture discs, bypass/regulator valves, and discharge fittings.

Ancillary Components

Covers supply couplings, secondary filters, and fluid end identification.

Jetstream 3000/3600/4200 Installation

Models and Specifications

Details available horsepower ranges and gear ratios for 3000/3600/4200 series.

Water Supply Requirements

Specifies water quality, temperature, and hose ID for 3000/3600/4200 series.

Pulsation and Lubrication

Explains pump pulsation and power end lubrication for 3000/3600/4200 series.

Jetstream 6000 Installation

Water Supply and Lubrication

Details water supply needs and lubrication requirements for the 6000 series.

Technical Notes

Driver and Coupling Selection

Discusses requirements for selecting appropriate drivers and couplings.

Inlet Pressure Considerations

Addresses minimum and maximum allowable inlet water pressure.

OPERATION

Recommended Equipment

Lists essential components recommended by Jetstream for safe operation.

Hose and Water Supply Requirements

Specifies requirements for supply and discharge hoses and water temperature.

Start-up Preparation

Steps to prepare the unit for operation, including inspections and connections.

Flushing the System

Procedure for flushing debris from the system before operation.

Checking Water Lubrication

Instructions for verifying and adjusting the water lubrication system.

Raising System Pressure

Guidance on safely increasing system pressure to operating levels.

Breaking in New Packing

Procedure for properly breaking in new pump packing.

Monitoring Weep Holes

How to identify seal failures through weep hole observation.

MAINTENANCE

Maintenance Schedules

Overview of daily, 50, 100, 500, and 1000-hour maintenance tasks.

Winterizing the Pump

Procedure to protect the unit from freezing damage during storage.

WATER

Water Quality Requirements

Recommended water quality levels for optimal pump performance.

Fluid Compatibility

Information on using fluids other than water and its warranty implications.

Secondary Filter Operation (40k)

Details on monitoring and maintaining the secondary filter for 40K operation.

PRESSURE CONVERSION

Converting Pump Pressure Ratings

Procedure for changing the pump's operating pressure range.

40K Hose Connections

Specific hose connection instructions for 40K operation.

SERVICE

Fluid End Service Procedures

Covers procedures for the pump's fluid end components.

Power End Service Procedures

Covers procedures for the pump's power end components.

Uni-Valve Service

Procedures for servicing uni-valves, including disassembly and assembly.

Packing Replacement

Step-by-step guide for replacing pump packing.

Rod Journal Bearings

Inspection and installation procedures for rod journal bearings.

TROUBLESHOOTING

High and Low Discharge Pressure

Troubleshooting steps for issues related to high or low discharge pressure.

Pulsation, Vibration, and Noise Issues

Addresses common problems like excessive pulsation, vibration, and pump noise.

Leakage and Oil Contamination Issues

Troubleshooting for leaks from manifold/fittings and oil contamination.

TRAINING

Safety Training

Overview of essential safety training for operating waterblast equipment.

Start-up and FS Solutions Training

Information on new unit start-up training and FS Solutions certified courses.

Additional Training Opportunities

Details on other available certified training classes from Jetstream.

Need help?

Do you have a question about the 3600 series and is the answer not in the manual?

Questions and answers