Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

Summarization of Contents

Safety

Important provisions for all products

General guidelines and information for safe product usage.

Correct use of all products

Defines the intended use and limitations of the product.

Personnel and organizational requirements

Specifies qualifications and responsibilities for personnel involved.

Initial start-up and operation – Safety regulations

Safety procedures for initial engine start-up and operation.

Assembly, maintenance, and repair work – Safety regulations

Safety guidelines for assembly, maintenance, and repair tasks.

Fire and environmental protection, fluids and lubricants

Procedures for fire prevention, environmental protection, and handling fluids.

Standards for warning notices in the text and highlighted information

Explanation of warning notice symbols and highlighted information.

Transport

Guidelines for the safe transport and handling of the engine.

General Information

Tightening specifications for screws, nuts and bolts

Provides detailed tightening torques for various screws and connections.

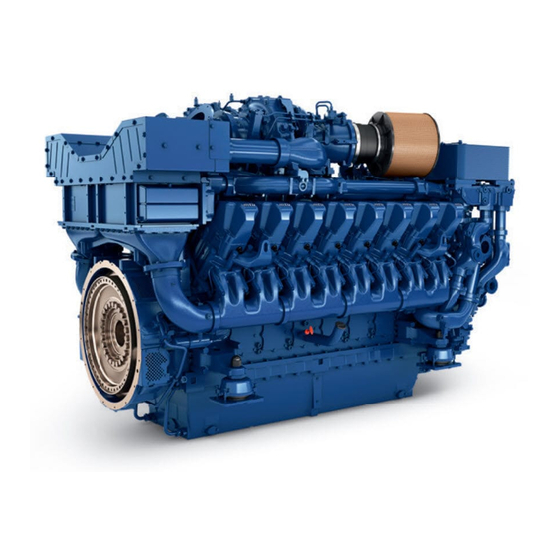

Engine – Overview

Diagram and identification of major engine components.

Product description

Detailed description of engine systems and components.

Engine side and cylinder designations

Explains engine side and cylinder designation conventions.

Sensors and actuators – Overview

Diagrams showing the location of sensors and actuators.

Engine wiring harness – Overview

Overview of engine wiring harness designations and terminal assignments.

Technical Data

ENGINE DATA 12V4000M93, heat exchanger installed, EPA stage 2

Technical specifications for 12V4000M93 engine (EPA Stage 2).

ENGINE DATA 12V4000M93, heat exchanger installed, IMO

Technical specifications for 12V4000M93 engine (IMO).

ENGINE DATA 12V4000M93L, heat exchanger installed, EPA stage 2

Technical specifications for 12V4000M93L engine (EPA Stage 2).

ENGINE DATA 12V4000M93L, heat exchanger installed, IMO

Technical specifications for 12V4000M93L engine (IMO).

ENGINE DATA 16V4000M93, heat exchanger installed, EPA stage 2

Technical specifications for 16V4000M93 engine (EPA Stage 2).

ENGINE DATA 16V4000M93, heat exchanger installed, IMO

Technical specifications for 16V4000M93 engine (IMO).

ENGINE DATA 16V4000M93L, heat exchanger installed, EPA stage 2

Technical specifications for 16V4000M93L engine (EPA Stage 2).

Product data 16V4000M93L

Product data specifications for the 16V4000M93L model.

Engine – Main dimensions

Table of engine dimensions (Length, Width, Height).

Firing order

Specifies the firing order for different engine cylinder configurations.

Operation

LOP – Controls

Description of controls and functions on the Local Operation Panel (LOP).

Putting the engine into operation after extended out-of-service periods (>3 months)

Procedure for restarting the engine after extended periods of inactivity.

Putting the engine into operation after scheduled out-of-service-period

Steps for returning the engine to operation after scheduled downtime.

Re-starting the engine following an automatic safety shutdown

Procedure for safely re-starting the engine after an automatic shutdown.

Starting the engine

Preconditions and methods for starting the engine.

Operational checks

Routine checks to perform during engine operation.

Fuel treatment system control cabinet – Controls

Overview of controls and indicators on the fuel treatment system cabinet.

Tasks after extended out-of-service periods (>3 weeks)

Tasks to perform after the engine has been idle for several weeks.

Checks prior to start-up

Pre-start checks for the fuel treatment system.

Fuel treatment system – Initial start-up

Step-by-step guide for the initial start-up of the fuel treatment system.

Fuel treatment system – Switching on

Procedure for switching on the fuel treatment system.

Stopping the engine

Methods for stopping the engine.

Emergency engine stop at BlueLine automation system (control stand)

Procedure for emergency engine stop via the automation system.

Clutch – Engagement at LOP

Steps for engaging the clutch using the Local Operation Panel (LOP).

Coupling – Disengaging from LOP

Steps for disengaging the coupling using the Local Operation Panel (LOP).

Waterjet – Flushing from LOP (optional)

Procedure for flushing the waterjet from the LOP.

Stopping the engine from LOP

Procedure for stopping the engine using the Local Operation Panel (LOP).

Stopping the engine at the BlueLine automation system (control stand)

Procedure for stopping the engine via the BlueLine automation system.

Emergency stop from LOP

Instructions for performing an emergency stop from the LOP.

Emergency engine stop

General instructions for emergency engine stop.

After shutting down the engine

Tasks to perform after the engine has been shut down.

Fuel treatment system – Shutdown

Procedure for shutting down the fuel treatment system.

Plant – Cleaning

Guidelines for cleaning the plant and its components.

Maintenance

Maintenance schedule task reference table [QL1]

Table referencing maintenance tasks and their corresponding page numbers.

Troubleshooting

Fuel treatment system – Troubleshooting

Troubleshooting guide for the fuel treatment system.

Troubleshooting

General troubleshooting for engine operational issues.

Engine governor ADEC (ECU 7) fault messages for Series 4000 engines, marine application

List and explanation of fault messages from the ADEC ECU 7.

ADEC engine governor – Fault codes

Troubleshooting guide for ADEC engine governor fault codes.

Task Description

SOLAS

Information related to SOLAS (Safety Of Life At Sea) requirements.

SOLAS shielding as per MTN 5233 – Installation

Step-by-step guide for installing SOLAS shielding.

Installation locations for SOLAS shielding

Diagrams showing the correct installation locations for SOLAS shielding.

Adhesive tape for SOLAS shielding – Application

Instructions for applying adhesive tape for SOLAS shielding.

Engine

Engine – Barring manually

Procedure for manually barring the engine crankshaft.

Barring engine with starting system

Procedure for barring the engine using the automation system.

Cylinder Liner

Cylinder liner – Endoscopic examination

Procedure for performing an endoscopic examination of the cylinder liner.

Cylinder liner – Instructions and comments on endoscopic and visual examination

Terms and explanations for interpreting endoscopic and visual cylinder liner examination.

Valve Drive

Valve gear – Lubrication

Procedure for lubricating the valve gear components.

Valve clearance – Check and adjustment

Steps for checking and adjusting valve clearance.

Cylinder head cover – Removal and installation

Procedure for removing and installing the cylinder head cover.

Injection Pump / HP Pump

HP fuel pump – Filling with engine oil

Procedure for filling the HP fuel pump with engine oil.

HP fuel pump – Relief bore check

Checking the relief bore on the HP fuel pump for fuel discharge.

Injection Valve / Injector

Injector – Replacement

Procedure for replacing the injector.

Injector – Removal and installation (jacketed fuel system)

Detailed steps for removing and installing injectors.

Fuel Filter

Fuel filter – Replacement

Procedure for replacing the fuel filter element.

Fuel prefilter – Differential pressure gage check and adjustment

Checking and adjusting the differential pressure gauge for the fuel prefilter.

Fuel prefilter – Draining

Procedure for draining the fuel prefilter.

Fuel prefilter – Flushing

Procedure for flushing the fuel prefilter.

Fuel prefilter with water separator – Filter element replacement

Replacing the filter element in the fuel prefilter with water separator.

Charge-Air Cooling

Intercooler – Checking condensate drain for coolant leakage and obstruction

Checking the intercooler's condensate drain for leaks and blockages.

Air Filter

Air filter – Replacement

Procedure for replacing the air filter element.

Air filter – Removal and installation

Steps for removing and installing the air filter.

Air Intake

Contamination indicator – Signal ring position check

Checking the signal ring position on the contamination indicator.

Starting Equipment

Starter – Condition check

Procedure for checking the starter's condition.

Lube Oil System, Lube Oil Circuit

Engine oil level – Check

Procedure for checking the engine oil level.

Engine oil – Change

Detailed steps for changing the engine oil.

Engine oil – Sample extraction and analysis

Procedure for extracting and analyzing engine oil samples.

Oil Filtration / Cooling

Automatic oil filter – Overview

Diagram and list of components for the automatic oil filter.

Oil indicator filter – Cleaning

Procedure for cleaning the oil indicator filter.

Oil indicator filter – Cleaning and check

Procedure for cleaning and checking the oil indicator filter.

Centrifugal oil filter – Cleaning and filter-sleeve replacement

Steps for cleaning and replacing the filter sleeve of the centrifugal oil filter.

Coolant Circuit, General, High-Temperature Circuit

Venting points

Identifies venting points for the coolant circuit.

Engine coolant – Level check

Procedures for checking the engine coolant level.

Engine coolant – Change

Steps for draining and filling the engine coolant.

Engine coolant draining

Detailed procedure for draining engine coolant.

Engine coolant – Filling

Procedure for filling the engine coolant system.

Engine coolant pump – Relief bore check

Checking the relief bore on the engine coolant pump.

Engine coolant – Sample extraction and analysis

Procedure for sampling and analyzing engine coolant.

Raw Water Pump with Connections

Raw water pump – Relief bore check

Checking the relief bore on the raw water pump.

Battery-Charging Generator

Battery-charging generator drive – Coupling condition check

Checking the condition of the coupling for the battery-charging generator drive.

Engine Mounting / Support

Engine mounting – Check

Procedure for checking the resilient elements of the engine mounting.

Auxiliary PTO

Bilge pump – Relief bore check

Checking the relief bore on the bilge pump.

Fuel Supply System

Water drain valve – Check

Procedure for checking the water drain valve.

Differential pressure gage – Alarm function check

Checking the alarm function of the differential pressure gauge.

Water level probe (3-in-1 rod electrode) – Check

Procedure for checking the water level probe.

Pump capacity – Check

Procedure for checking the pump's capacity.

Coalescer filter element – Replacement

Steps for replacing the coalescer filter element.

Wiring (General) for Engine/Gearbox/Unit

Engine cabling – Check

Procedure for checking engine cabling and connections.

Accessories for (Electronic) Engine Governor / Control System

CDC parameters – Reset with DiaSys®

Procedure for resetting CDC parameters using DiaSys®.

EMU and connectors – Cleaning

Instructions for cleaning EMU and its connectors.

Limit switch for start interlock – Check

Procedure for checking the limit switch for start interlock.

Engine governor and connector – Cleaning

Instructions for cleaning the engine governor and its connectors.

Engine Control Unit ECU 7 – Checking plug connections

Checking plug connections on the Engine Control Unit ECU 7.

Engine Monitoring Unit EMU 8 – Plug connections check

Checking plug connections on the Engine Monitoring Unit EMU 8.

Interface module EIM plug connections – Check

Checking plug connections on the Engine Interface Module EIM.

Engine governor ECU 7 – Removal and installation

Procedure for removing and installing the Engine Governor ECU 7.

Engine Monitoring Unit EMU 8 – Removal and installation

Procedure for removing and installing the Engine Monitoring Unit EMU 8.

Engine Interface Module EIM 2 – Removal and installation

Procedure for removing and installing the Engine Interface Module EIM 2.

Engine Interface Module EIM 2 – Diagnostic features

Overview of diagnostic features for the EIM 2.

Emergency Instrumentation (Local Operating Panel)

LOP and connectors – Cleaning

Instructions for cleaning the Local Operating Panel (LOP) and its connectors.

Appendix A

List of abbreviations

Glossary of abbreviations used in the manual.

Appendix B

Index

Alphabetical index of topics and their corresponding page numbers.

Need help?

Do you have a question about the 12V4000M93L and is the answer not in the manual?

Questions and answers