Summary of Contents for kala Starter 1400

- Page 1 STARTER USER MANUAL STARTER 1080 – 1400 – 1600 USER MANUAL TRANSLATED FROM ORIGINAL VERSION: EDITION 1...

- Page 2 USER MANUAL STARTER INTRODUCTION We thank you for your purchase of a Kala laminator. It has been designed by our team of engineers for intensive use with the guarantee of quality outputs. Made from the best material and under tough quality control in the successive steps of its manufacture, this laminator has been produced in our factory to fulfill all your production requirements for many years.

-

Page 3: Table Of Contents

USER MANUAL STARTER SUMMARY ………….…………………………………………………………….……… Conformity Declaration & Warranty The reception of your laminator……………………………………………………………………………….……. ………………………………………………………………………….…...….. Definition of your working space ……………………………………..………………………………………………..… Unpacking the laminator Laminator stand assembly……………………………………………………………………………..…………… …………………………………………………………………..…….. Positioning of the laminator on the stand ……...……………………………………………………………………..Caution when installing the machine ………………………...……………………………………………………….……... -

Page 4: Conformity Declaration & Warranty

USER MANUAL STARTER 1. CONFORMITY DECLARATION & WARRANTY Kala S.A.S Parc de l’Ecotay 35410 Nouvoitou France – Declares that following product STARTER 1080 1400 1600 conforms to the following requirements : Voltage 230-240V 50-60hz : • Machines Directive (2009) : 2006/42/CEE including : •... -

Page 5: The Reception Of Your Laminator

USER MANUAL STARTER THE RECEPTION OF YOUR LAMINATOR Definition of your working space Before unpacking your machine, it is necessary to determine your working space area. You should have easy access to all the parts of the machine. When mounting onto rigid boards, make sure that you will have at least one meter free space on top of the maximal length of your boards in front and in rear of the... -

Page 6: Caution When Installing The Machine

USER MANUAL STARTER 3. CAUTION WHEN INSTALLING THE MACHINE 3.1 Electrical power requirement Do not leave the electric lead in contact with a Before connecting the machine to the power, warm surface. check that : - The machine should be installed in a well- - The tension of the machine corresponds ventilated place. -

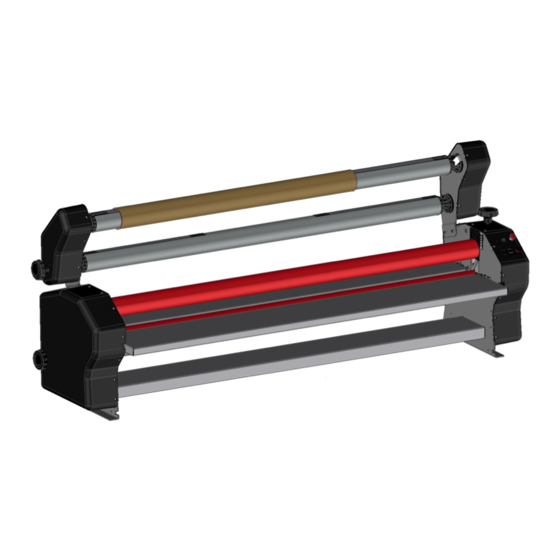

Page 7: Components Of The Laminator, Control Board

USER MANUAL STARTER 4. COMPONENTS OF THE LAMINATOR, CONTROL BOARD Components of the laminator and accessories rés Alim entat Alim enta rés éle rése tion rése tati rés élect éle tati rique élec rése Alime rés Alime Véri triqu éle ntatio rése ér... -

Page 8: Control Board

USER MANUAL STARTER 4. COMPONENTS OF THE LAMINATOR, CONTROL BOARD 4.2 Control board A Handle for roller elevation and pressure D Emergency switch adjustment of the upper roller E Working mode selection switch B Speed adjustment - Forward C LED indicator for the machine working mode - Stop : GREEN : Forward - Reverse... -

Page 9: Adjustments And Recommendations

USER MANUAL STARTER 5. ADJUSTMENTS AND RECOMMENDATIONS 5.1 Switching on the laminator Plug the machine to the power and turn it on by pressing the switch located at the rear of the machine (Rep 13). The LED indicator showing the working mode on the control board turns red (Rep.C). -

Page 10: Roller Pressure Adjustment

USER MANUAL STARTER 5.ADJUSTMENTS AND RECOMMENDATIONS Reverse : Select the working mode selection switch to reverse (Rep.E). The LED indicator (Rep.C) should turn to orange. Press on the foot pedal to start operating the machine into reverse motion. 5.3 Roller pressure adjustment The laminator Starter has got a manual pressure adjustment... -

Page 11: Film Tension Adjustment

USER MANUAL STARTER 5. ADJUSTMENTS AND RECOMMENDATIONS When maximum pressure level is reached, the LED pressure indicator light (Rep.12) turns to red and the mechanism is locked to prevent any damages due to trying to apply to mu ch pressure on the mechanism. To decrease pressure, turn the roller elevation handle (Rep. -

Page 12: Switching Off The Machine

USER MANUAL STARTER 5. ADJUSTMENTS AND RECOMMENDATIONS Use of the safety reset button : If the emergency button has been pushed, the rollers would not start rotating. The working mode LED indicator (Rep. C) would be red, meaning that safety is active. To reset the safety, check the the emergency button is disengaged (Rep.D) and press on the safety reset button (Rep.F) to start operating the machine.. -

Page 13: Application

USER MANUAL STARTER 6. APPLICATIONS 6.1 Single side lamination with waste paper or simultaneous adhesive mounting 1. Turn on the machine (ref. §5.6). Remove the feeding tray (Rep.14). If the machine is installed on a stand, you can store the feeding tray (Rep.14) on the base of the stand, below the machine while installing the media. - Page 14 USER MANUAL STARTER 6. APPLICATIONS 4. Place the shaft with the film reel on position (A) of the machine (film release paper facing up). Place the shaft with the carton mandrel on position (B) of the machine. 5. Centre the film reel on the shaft using the graduated measurement.

- Page 15 USER MANUAL STARTER 6. APPLICATIONS 8. Stick the release paper onto the cardboard mandrel using an adhesive tape gun. 9. Lay the film onto the upper laminating roller (sticky side facing toward you). 10 Installing the double side adhesive or the waste paper on the lower shaft.

- Page 16 USER MANUAL STARTER 6. APPLICATIONS 11. Place the assembly on position (C) of the machine. 12. Centre the reel on the shaft using the graduated measurement. 13. Stick the paper onto the adhesive film. 14. Use a thin board (carton, pvc, metal…) to insert paper and film between the rollers.

-

Page 17: Use Of Application Tape

USER MANUAL STARTER 6. APPLICATIONS 14. Once the board is out or the machine, adjust the pressure by using the roller elevation handle (Rep. 3) according to the kind of operation you will have to achieve. For pressure adjustment recommendation, please refer to §... - Page 18 USER MANUAL STARTER 6. APPLICATIONS 3. Place the assembly on position (A) of machine (adhesive side application tape facing toward the user). 4. Centre the reel on the shaft using the graduated measurement. 5. Raise the upper roller (refer to § 5.3). Tear off the application tape toward the back of the machine so that there are no fold on the surface of the application...

-

Page 19: Mounting Onto Rigid Boards

USER MANUAL STARTER 6. APPLICATIONS 7. To avoid the application tape to stick onto the lower roller, run a vinyl width of the same size or wider than the application tape. 8. Lower the upper roller (refer to § 5.3) and adjust pressure based on the width of the print and regarding our pressure adjustment recommendations (refer to... - Page 20 USER MANUAL STARTER 6. APPLICATIONS 3. Raise the upper roller high enough regarding to the thickness of the board. (refer to § 5.3). 4. Place the board with the print on the feeding tray between the rollers. 5. Adjust the roller pressure (refer to #5.3) based on the width of the board and regarding our pressure adjustment recommendations (refer to §...

-

Page 21: Options

USER MANUAL STARTER 6. APPLICATIONS 6.4 Options A - Paper guide and roll scrolling bar : (optional) The removable paper guide can be installed on the feeding tray to make the insertion of print into the laminator easier. To install it on the feeding tray, slide the guide through the feeding tray ends. - Page 22 USER MANUAL STARTER 6. APPLICATIONS B - Electrical laminated prints rewinder : (Optional and only to be mounted on the stand (Refer to §D below)) Usefull for processing long print runs, it can be mounted on the back of the machine.

-

Page 23: Working Parameters Adjustments

USER MANUAL STARTER 6. APPLICATIONS D - Optional stand : Machine can be installed onto the optional stand with castors. Electrical print rewinder (§B above) and film reels holder (§C above) can be added to it. To mount it onto the machine, please refer to the assembly instruction delivered with the kit. -

Page 24: Maintenance And Safety

USER MANUAL STARTER 8. MAINTENANCE AND SAFETY 8.1 Maintenance PART FREQUENCY ACTION Immediately Ink waste on the rollers or on the feeding tray Soap and water Laminating rollers * Weekly Soap and water Feeding tray Soap and water Back tray Soap and water Plastic side covers Soap and water... -

Page 25: Technical Data

USER MANUAL STARTER 9. TECHNICAL DATA STARTER 1080 STARTER 1400 STARTER 1600 Maximum working width 1128 (44.4’’) 1440 (56.7’’) 1612 (63.5’’) (in mm/inch) Maximum opening of the 50 (2’’) 50 (2’’) 50 (2’’) rollers (in mm / inch) Pressure on the roller in... -

Page 26: Lamination Incidents

USER MANUAL STARTER 11. LAMINATION INCIDENTS ROBLEME OSSIBLE CAUSE CTION The print is fed too quickly Hold the print more firmly when The print folds or waves The print has not been fed flat feeding it during lamination. Paper too light or not dry enough a) Use the brake to remove the fold... -

Page 27: Wiring Diagram

/ LED (MP843602) Motor foot switch control for operation information (MP292103) (MP843602) Moteur 24DC / Motor 24DC (STARTER 1080-1400: MP413500) (STARTER 1600: MP433500) Interrupteur 0-I / Alimentation / Fusible (1A/230V) Main switch 0-I Power supply 230V – 240 V...

Need help?

Do you have a question about the Starter 1400 and is the answer not in the manual?

Questions and answers