Siemens S7-300 Manual

- Manual (676 pages) ,

- Reference manual (574 pages) ,

- Installation and operating manual (356 pages)

Advertisement

-

1

SM 321 digital input module

- 1.1 Order number

- 1.2 Characteristics

- 1.3 Terminal connection diagram and block diagram of the SM 321; DI 16 DC 24 V

- 1.4 Terminal assignment diagram for the redundant supply of sensors

- 1.5 Terminal assignment diagram of the resistor wiring of the sensors

- 1.6 Technical specifications of the SM 321; DI 16 DC 24 V

- 1.7 Clock synchronization

- 1.8 Parameterizing the SM 321; DI 16 DC 24 V

- 1.9 Behavior and diagnostics of the SM 321; DI 16 DC 24 V

- 1.10 Interrupts of the SM 321; DI 16 DC 24 V

-

2

Analog input module SM 331

- 2.1 Order number

- 2.2 Characteristics

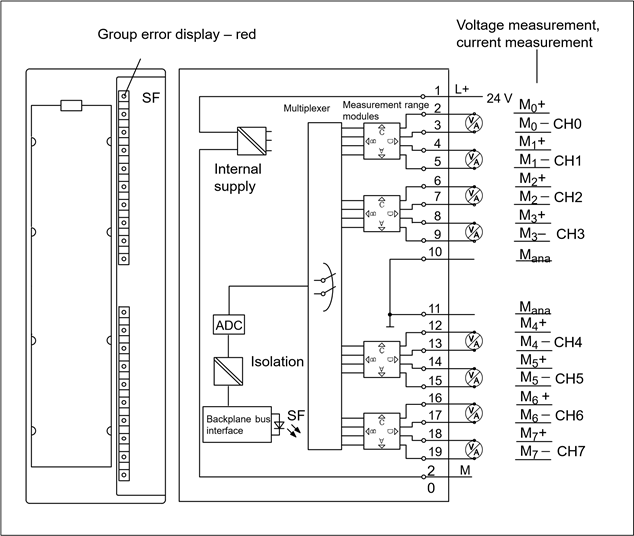

- 2.3 Terminal connection diagram and block diagram of the SM 331; AI 8 14 Bit High Speed

- 2.4 Technical specifications of the SM 331; AI 8 14 Bit High Speed

- 2.5 Clock synchronization

- 2.6 Commissioning the SM 331; AI 8 14 Bit High Speed

- 2.7 Measuring methods and measuring ranges of the SM 331; AI 8 14 Bit High Speed

-

3

Analog Output Module SM 332

- 3.1 Order number

- 3.2 Characteristic

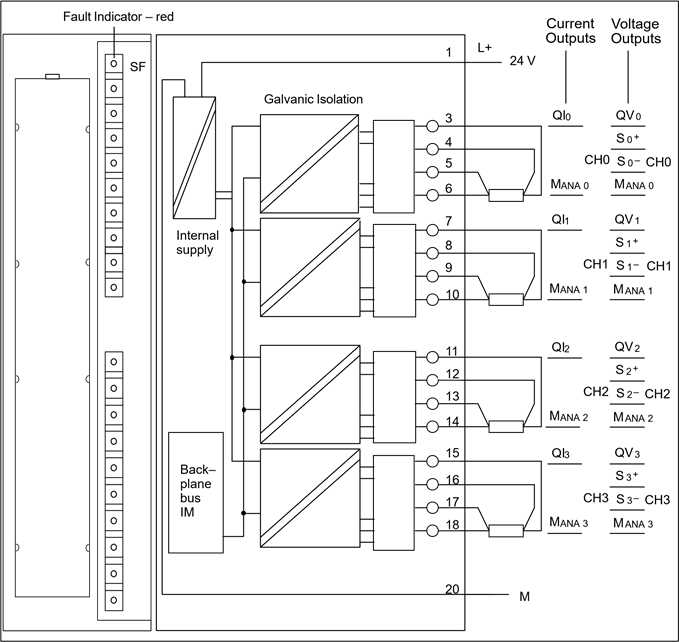

- 3.3 Terminal connection diagram and block diagram of the SM 332; AO 4 × 16 Bit

- 3.4 Technical specifications of the SM 332; AO 4 16 bits

- 3.5 Clock synchronization

- 3.6 Commissioning the SM 332; AO 4 16 bits

- 3.7 Output Ranges of the Analog Output Module SM 332; AO 416 bits

- 4 Documents / Resources

The S7-300 product family has been enhanced and improved. This document contains details of the features and technical specifications of the modules.

SM 321 digital input module

DI 16 DC 24 V; with hardware interrupt and diagnostic interrupt, clocked; (6ES7 321-7BH01-0AB0)

Order number

6ES7 321-7BH01-0AB0

Characteristics

The SM 321; DI 16 DC 24 V; with hardware and diagnostic interrupts has the following features:

- 16 inputs, isolated in groups of 16

- 24 VDC rated input voltage

- Input characteristic curve according to IEC 61131, Type 2

- Suitable for switches and two / three / four-wire BEROs (proximity switches)

- 2 short-circuit-proof sensor supplies for 8 channels each

- External redundant power supply possible to supply sensors

- "Sensor supply (Vs)" status display

- Group error display

- Supports clocked operation

- Supports the function "Reparameterization in RUN mode"

- Programmable diagnostics

- Programmable diagnostic interrupt

- Programmable hardware interrupt

- Programmable input delays

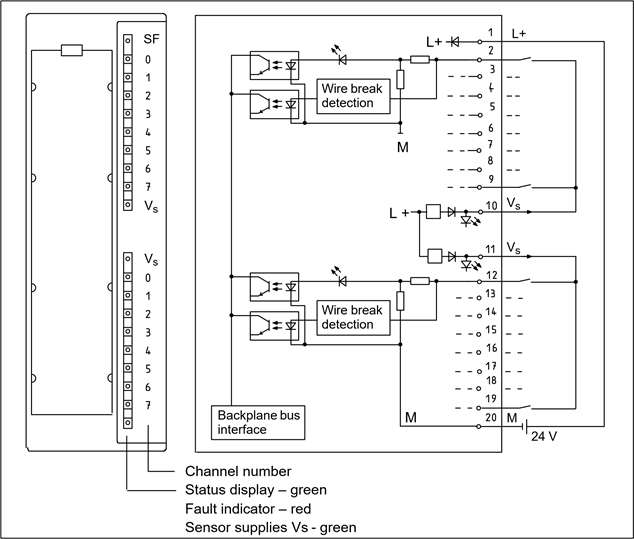

Terminal connection diagram and block diagram of the SM 321; DI 16 DC 24 V

Figure 1 Module view and block diagram of the SM 321; DI 16 DC 24 V

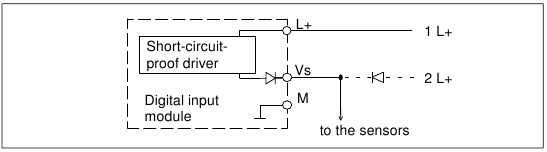

Terminal assignment diagram for the redundant supply of sensors

The figure below shows how sensors can additionally be supplied by means of Vs with a redundant voltage source – for example, via another module.

Figure 2 Terminal assignment diagram for the redundant supply of sensors of the SM 321; DI 16 DC 24 V

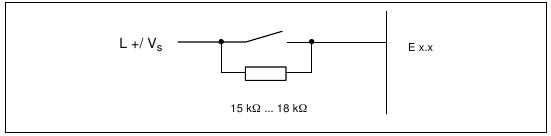

Terminal assignment diagram of the resistor wiring of the sensors

To detect a wire break, it is necessary to wire sensor contacts with a resistor.

Figure 3 Terminal assignment diagram of the resistor wiring of the sensors of the SM 321; DI 16 DC 24 V

Technical specifications of the SM 321; DI 16 DC 24 V

Dimensions and Weight

| Dimensions W H D (in millimeters) | 40 125 117 |

| Weight | Approx. 200 g |

Data for Specific Module

| Supports clocked operation | Yes |

| Reparameterization in RUN mode possible | Yes |

|

|

| Number of inputs | 16 |

| Length of cable | |

|

|

Voltages, Currents, Potentials

| Power rated voltage of the electronics and sensor L+ | 24 VDC |

| Yes |

| Number of inputs that can be triggered simultaneously | |

|

|

| Isolation | |

| Yes |

| Permitted potential difference | |

| 75 75 VDC / 60 VAC |

| Insulation tested with | 500 VDC |

| Current consumption | |

|

|

| Power dissipation of the module | typ. 4 W |

Status, interrupts, diagnostics

| Status display | |

|

|

| Interrupts | |

|

|

| Diagnostic functions | Parameters can be assigned |

|

|

| Monitoring for | |

| Yes, for I < 1 mA |

Sensor Power Supply Outputs

| Number of outputs | 2 |

| Output voltage | |

| min. L+ (–2.5 V) |

| Output current | |

|

|

| Additional (redundant) supply | Permitted |

| Short-circuit protection | Yes, electronic |

Data for Selecting a Sensor

| Input voltage | |

|

|

| Input current | |

| typ. 7 mA |

| Input characteristic curve | According to IEC 61131, type 2 |

| Connection of Two-Wire BEROs | Possible |

| max. 2 mA |

| Resistor wiring of the sensor for wire break monitoring | 10 to 18 kOhm |

Time/Frequency

| Internal preparation time for status processing (in non-clocked operation) | |

| max. 40 ms |

| Input delay | |

|

|

Clock synchronization

Characteristics

Reproducible response times (i.e. times of the same length) are achieved in SIMATIC by means of an equidistant DP bus cycle and the synchronization of the following free-running individual cycles:

- Free-running cycle of the user program. On account of cyclic program branches the length of the cycle time may vary.

- Free-running, variable DP cycle on the PROFIBUS subnet.

- Free-running cycle on the DP slave backplane bus.

- Free-running cycle at signal conditioning and conversion in the electronic modules of the DP slaves.

With equidistance the DP cycle runs with the same clock pulse and for the same length. The priority classes of a CPU (OB 61 to OB 64) and the clocked I/Os are synchronized with this clock pulse. The I/O data are thus transferred at defined, fixed intervals (clock synchronization).

Prerequisites

The DP master and DP slave must support clock synchronization. STEP 7 as of Version 5.2 is required.

Mode: clock synchronization

The following conditions apply to clocked mode:

| Filter and processing time TWE between the actual values being read in and made available in the transfer buffer (the specified value for TWE applies regardless of the activation of the hardware interrupt or diagnosis) | 255 to 345 s |

| Includes an input delay of | 100 s |

| TDPmin | 2.5 ms |

| Diagnostic interrupt | max. 4 x TDP |

In clocked mode, the input delay of the inputs is always 100 s, regardless of the input delay parameterized in STEP7.

Further information

You will find further information on clock synchronization in the online help system of STEP 7, in the manual ET 200M Distributed I/O System and in the manual Clock Synchronization.

Parameterizing the SM 321; DI 16 DC 24 V

Parameter assignment

Section "Output Ranges of the Analog Output Module SM 332; AO 4x16 bits" of the reference manual describes how digital modules are generally parameterized.

Parameters of the SM 321; DI 16 DC 24 V

You will find an overview of the parameters that can be set for the SM 321; DI 16 DC 24 V, together with the default settings, in the following table.

The default settings apply if you have not performed parameter assignment in STEP 7.

Table 1: Parameters of the SM 321; DI 16 DC 24 V

| Parameter | Value Range | Default Settings | Parameter Type | Scope |

| Enable | ||||

|

|

| Dynamic | Module |

| Input delay/voltage type | 0.1 ms (DC) 0.5 ms (DC) 3 ms (DC) 15 ms (DC) 20 ms (DC/AC) | (DC) | Static | Module |

| Diagnosis | ||||

|

|

| Static | Channel group |

| Trigger for hardware interrupt | ||||

|

|

| Dynamic | Channel group |

Assignment of the sensor supplies to channel groups

The module's two sensor supplies supply two channel groups: inputs 0 to 7 and inputs 8 to 15. In these channel groups you also parameterize the diagnosis for the sensor supply.

Assigning interrupt parameters to channel groups

The table below shows the channels that can be combined to form a channel group if you would like to parameterize interrupt processing.

You will need the channel group number to set the parameters in the user program with an SFC.

Table 2: Assignment of the interrupt parameters to the inputs of the SM 321; DI 16 DC 24 V

| Parameter... | Can Be Set in Following Channel Groups | Channel Group Number |

| Hardware interrupt (for falling, rising or both types of pulse edges) | 0 and 1 2 and 3 4 and 5 6 and 7 8 and 9 10 and 11 12 and 13 14 and 15 | 0 1 2 3 4 5 6 7 |

| Diagnostic interrupt (if there is no sensor supply) | 0 to 7 8 to 15 | - |

| Wire break | 0 and 1 2 and 3 | 0 1 : |

Tolerances of the programmable input delays

Table 3: Tolerances of the input delays of the SM 321; DI 16DC 24 V

| Programmed Input delay | Tolerance |

| 0.1 ms | 60 to 140 s |

| 0.5 ms | 400 to 900 ms |

| 3 ms (preset) | 2.6 to 3.3 ms |

| 15 ms | 12 to 15 ms |

| 20 ms | 17 to 23 ms |

Behavior and diagnostics of the SM 321; DI 16 DC 24 V

Effect of operating and mode supply voltage on the input values

The input values of the SM 321; DI 16 DC 24 depend on the operating mode of the CPU and the supply voltage of the module.

Table 4: Dependencies of the input values of the operating mode of the CPU and the supply voltage L+ of the SM 321; DI 16 DC 24 V

| CPU Operating State | Power Supply L+ to Digital Module | Input Value of Digital Module | |

| POWER ON | RUN | L+ exists | Process value |

| L+ missing | 0 signal | ||

| STOP | L+ exists | Process value | |

| L+ missing | 0 signal | ||

| POWER OFF | – | L+ exists | – |

| L+ missing | – | ||

Diagnostic messages of the SM 321; DI 16 DC 24 V

The table below provides an overview of the diagnostic messages of the SM 321; DI 16 DC 24 V.

Table 5: Diagnostic messages of the SM 321; DI 16 DC 24 V

| Diagnostics Message | LED | Scope of the Diagnostics | Parameters can be assigned |

| Sensor supply missing | SF | Channel group | Yes |

| Wire-break | SF | Channel group | |

| Module not parameterized | SF | Channel group | |

| External auxiliary supply missing | SF | Module | No |

| Internal auxiliary power missing | SF | Module | |

| Fuse blown | SF | Module | |

| Incorrect parameter on module | SF | Module | |

| Watchdog timeout | SF | Module | |

| EPROM error | SF | Module | |

| RAM error | SF | Module | |

| Hardware interrupt lost | SF | Module |

A prerequisite for detecting the errors indicated by programmable diagnostic messages is that you have assigned parameters to the digital module accordingly in STEP 7.

Behavior upon failure of the supply voltage

The failure of the supply voltage of the SM 321; DI 16 DC 24 is always indicated by the SF LED on the module. Furthermore, this information is made available on the module.

The input value is initially held for 20 to 40 ms before the 0 signal is transferred to the CPU. Supply voltage dips < 20 ms do not change the process value (see Table 4).

Triggering of the diagnostic interrupt depends on the parameter assignment (see "Interrupts of the SM 321; DI 16 x DC 24 V" Section).

Failure of the supply voltage with redundant incoming supply for the sensor supply

If an external redundant source is applied simultaneously to the sensor supply (Vs), a failure in the internal sensor supply causes a failure of the internal and/or external sensor supply and/or a blown fuse to be indicated instead of a regular sensor supply failure.

Short-circuit of sensor supply Vs

Irrespective of the parameter assignment, the corresponding Vs LED goes out if a short-circuit of the sensor supply Vs occurs.

Causes of errors and remedial action

Table 6: Diagnostic messages of the SM 321; DI 16 DC 24 V, causes of errors and remedial action

| Diagnostics Message | Possible Error Cause | Remedy |

| Missing sensor supply | Overload of sensor supply | Eliminate overload |

| Short circuit of sensor supply to M | Eliminate short circuit | |

| External auxiliary supply missing | Power supply L+ to module missing | Feed supply L+ |

| Internal auxiliary supply missing | Power supply L+ to module missing | Feed supply L+ |

| Fuse in module defective | Replace module | |

| Fuse blown | Fuse in module defective | Replace module |

| Incorrect parameters in module | One parameter or the combination of parameters is not plausible | Reassign module parameter |

| Time monitoring triggered (watch dog) | Temporary high electromagnetic interference | Eliminate interference |

| Module defective | Replace module | |

| EPROM error | Temporary high electromagnetic interference | Eliminate interference and switch on/off power supply of CPU |

| Module defective | Replace module | |

| RAM error | Temporary high electromagnetic interference | Eliminate interference and switch on/off power supply of CPU |

| Module defective | Replace module | |

| Hardware interrupt lost | The module cannot send an interrupt, since the previous interrupt was not acknowledged; possible configuration error | Change interrupt processing in CPU and reconfigure module parameters, if required The error continues until the module is configured with new parameters |

| Module not parameterized | Problem at startup | Reassign module parameter |

Interrupts of the SM 321; DI 16 DC 24 V

Introduction

This section describes the interrupt behavior of the SM 321; DI 16 DC 24 V. The following interrupts exist:

- Diagnostic interrupt

- Hardware interrupt

The OBs and SFCs mentioned below can be found in the online Help for STEP 7, where they are described in greater detail.

Enabling interrupts

The interrupts are not preset – in other words, they are inhibited without appropriate parameter assignment. Assign parameters to the Interrupt Enable in STEP 7 (refer to "Parameterizing the SM 321; DI 16 x DC 24 V" Section).

Diagnostic interrupt

If you have enabled diagnostic interrupts, then active error events (initial occurrence of the error) and departing error events (message after troubleshooting) are reported by means of an interrupt.

The CPU interrupts the execution of the user program and processes the diagnostic interrupt block (OB 82).

In the user program, you can call SFC 51 or SFC 59 in OB 82 to obtain more detailed diagnostic information from the module.

The diagnostic information is consistent until such time as OB 82 is exited. When OB 82 is exited, the diagnostic interrupt is acknowledged on the module.

Hardware interrupt

The SM 321; DI 16 DC 24 V can trigger a hardware interrupt for every channel group at a rising edge, a falling edge, or at both edges of a signal status change.

Perform parameter assignment one channel group at a time. It can be modified at any time (in RUN mode using the user program).

Pending hardware interrupts trigger hardware interrupt processing in the CPU (OB 40). The CPU interrupts the execution of the user program or of the priority classes with low priority.

You can set in the user program of the hardware interrupt OB (OB 40) how the programmable logic controller has to react to an edge change. When the hardware interrupt OB is exited, the hardware interrupt is acknowledged on the module.

The module can buffer one interrupt per channel. If no higher priority run-time levels are waiting to be processed, the buffered interrupts (of all modules) are serviced one after the other by the CPU according to the order in which they occurred.

Hardware interrupt lost

In an interrupt has been buffered for a channel and another interrupt occurs on that channel before it has been processed by the CPU, a diagnostic interrupt "hardware interrupt lost" is triggered.

More interrupts on this channel are not acquired until processing of the interrupt buffered on this channel has been executed.

Interrupt-triggering channels

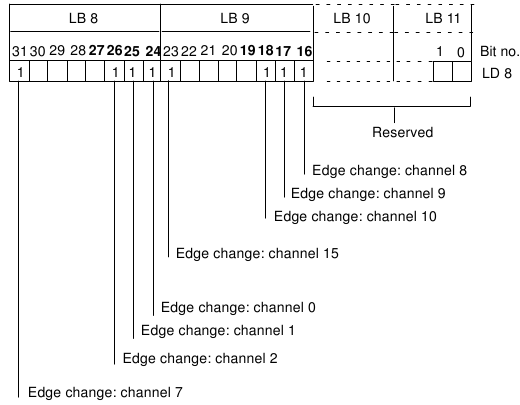

The start information of OB 40 in the OB40_POINT_ADDR variable indicates which channel triggered the hardware interrupt. Figure 4 shows the assignment to the bits of the local data double word 8.

| Byte | Variable | Data type | Description | |

| 6/7 | OB40_MDL_ADDR | WORD | B#16#0 | Address of the interrupt-triggering module |

| As of 8 | OB40_POINT_ADDR | DWORD | See Figure 4 | Indication of the interrupt-triggering inputs |

Figure 4 Start information of OB 40: which event triggered the hardware interrupt

Analog input module SM 331

AI 8 14 Bit High Speed, clocked; (6ES7 331-7HF00-0AB0)

Order number

6ES7 331-7HF00-0AB0

Characteristics

The SM 331; AI 8 14 Bit High Speed has the following features:

- 8 inputs in 4 channel groups

- Measured-value resolution 13 bits + sign

- Measuring method selectable per channel group:

- Voltage

- Current

- Arbitrary measuring range selection per channel group

- Programmable hardware interrupt

- Programmable diagnostics

- Programmable diagnostic interrupt

- Supports clocked operation

- Isolated against the backplane bus interface

- Isolated from the load voltage (not in the case of the 2-wire transmitter)

Terminal connection diagram and block diagram of the SM 331; AI 8 14 Bit High Speed

Figure 5 Module view and block diagram of the SM 331; AI 8 14 Bit High Speed

Technical specifications of the SM 331; AI 8 14 Bit High Speed

Dimensions and Weight

| Dimensions W H D (in millimeters) | 40 125 117 |

| Weight | Approx. 230 g |

Data for Specific Module

| Supports clocked operation | Yes |

| Number of inputs | 8 |

| Length of cable | |

| max. 200 m |

Voltages, Currents, Potentials

| Rated supply voltage of the electronics L + | 24 VDC |

| Yes |

| Power supply of the transmitters | |

|

|

| Isolation | |

|

|

| Permitted potential difference | |

| 11 VDC / 8 VAC |

|

|

| Insulation tested with | |

| 500 VDC |

| Current consumption | |

|

|

| Power dissipation of the module | typ. 1.5 W |

Analog value generation

| Measuring principle | Instantaneous value conversion |

| Integration time/conversion time/ resolution (per channel) | |

|

|

Suppression of interference, Limits of Error

| Noise suppression for f = n x (f1 " 1%), (f1 = interference frequency) n= 1,2... | ||

|

| |

| Crosstalk between the inputs | > 65 dB | |

| Operational limit (in the entire temperature range, with reference to the input range) | ||

| ±1 V ±5 V ±10 V 1 to 5 V | ±0.3 % ±0.4 % ±0.3 % ±0.4 % |

| ±20 mA 0 to 20 mA 4 to 20 mA | ±0.3 % ±0.3 % ±0.3 % |

| Basic error limit (operational limit at 25 _C, with reference to the input range) | ||

| ±1 V ±5 V ±10 V 1 to 5 V | ±0.2 % ±0.25 % ±0.2 % ±0.25 % |

| ±20 mA 0 to 20 mA 4 to 20 mA | ±0.2 % ±0.2 % ±0.2 % |

| Temperature error (with reference to the input range) | ±0.004%/K | |

| Linearity error (with reference to the input range) | ±0.03 % | |

| Repeat accuracy (steady state at 25 _C, with reference to the input range) | ±0.1 % | |

Status, Interrupts, Diagnostics

| Interrupts | |

|

|

| Diagnostic functions | |

|

|

Data for Selecting a Sensor

| Input range (rated values)/Input resistance | |

| ±1 V /10 MΩ ±5 V /100 kΩ ±10 V /100 kΩ 1 to 5 V; /100 kΩ |

| ±20 mA /50 Ω 0 to 20 mA; /50 Ω 4 to 20 mA: /50 Ω |

| Maximum input voltage for voltage input (destruction limit) | max. 20 V continuous; 75 VDC for no more than 1 s (pulse duty factor 1: 20) |

| Maximum input current for current input (destruction limit) | 40 mA |

| Connection of the sensor | |

| Possible |

| As two-wire transmitter | Possible |

| As four-wire transmitter | Possible |

| max. 820 Ω |

| Characteristic linearization | None |

Clock synchronization

Characteristics

Reproducible response times (i.e. times of the same length) are achieved in SIMATIC by means of an equidistant DP bus cycle and the synchronization of the following free-running individual cycles:

- Free-running cycle of the user program. On account of cyclic program branches the length of the cycle time may vary.

- Free-running, variable DP cycle on the PROFIBUS subnet.

- Free-running cycle on the DP slave backplane bus.

- Free-running cycle at signal conditioning and conversion in the electronic modules of the DP slaves.

With equidistance the DP cycle runs with the same clock pulse and for the same length. The priority classes of a CPU (OB 61 to OB 64) and the clocked I/Os are synchronized with this clock pulse. The I/O data are thus transferred at defined, fixed intervals (clock synchronization).

Prerequisites

The DP master and DP slave must support clock synchronization. STEP 7 as of Version 5.2 is required.

Mode: clock synchronization

The following conditions apply to clocked mode:

| Filter and processing time TWE between the actual values being read in and made available in the transfer buffer (the specified value for T WE applies regardless of the activation of the hardware interrupt or diagnosis) | 516 to 606 s |

| Includes an input delay of | 80 s |

| TDPmin | 3.5 ms |

| Diagnostic interrupt | max. 4 x TDP |

In clocked mode, the integration time for the module is always set to "none" or "interference frequency", regardless of the parameter assignment in STEP 7.

Hardware interrupt functionality is not possible in clocked mode.

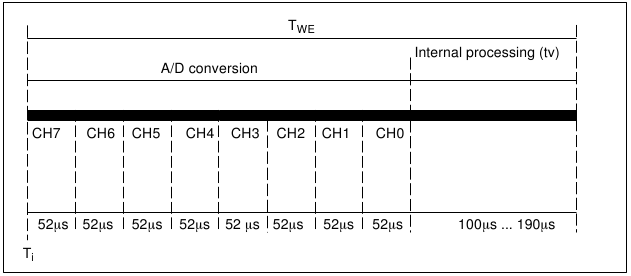

Calculation of the filter and processing time

The same time conditions apply regardless of the number of channels parameterized. The point of time in relation to the clock signal at which a specific channel is read in is calculated on the basis of the following formula:

TWE_CH = (channel number +1) x 52 μs + tv; tv = 100 to 190 s

Figure 6; Figure 7 Calculation of the filter and processing time

Explanation of functioning in clocked mode

At Ti starts AD conversion for channel 7 and saves its result internally. Channels 6 to 0 are then converted sequentially in the same way at intervals of 52 s. After an additional internal processing time, the results of all the converted channels are made available on the backplane bus to be picked up by the CPU.

Further information

You will find further information on clock synchronization in the online help system of STEP 7, in the manual ET 200M Distributed I/O System and in the manual Clock Synchronization.

Commissioning the SM 331; AI 8 14 Bit High Speed

You specify how the SM 331; AI 8 14 Bit High Speed is to work by means of measurement range modules on the module and STEP 7.

Measuring range modules

If necessary, the measuring range modules must be replugged to change the measuring method and the measuring range. You then have to switch the 24 V supply off and on again at the front connector. Section of the reference manual provides a detailed description of how to do this.

Section of the reference manual contains a table indicating the settings to be selected for different measurement methods and ranges. The required settings are also printed on the module.

Default settings for measuring range module

The measuring range modules are preset to "B" (voltage; 10 V) when the module is supplied.

To use the following preset measuring methods and measuring ranges, you only have to change the measuring range module to the corresponding setting. Parameter assignment in STEP 7 is not necessary.

Table 7: Defaults of the SM 331; AI 8 14 Bit High Speed via measuring range modules

| Measuring Range Module Setting | Measuring Method | Measuring Range |

| A | Voltage | 1 V* |

| B | Voltage | 10 V |

| C | Current, Four-wire transmitter | 4 to 20 mA |

| D | Current, Two-wire transmitter | 4 to 20 mA |

* You must short-circuit unused channels and connect them to MANA.

Parameters

Section of the reference manual describes how analog modules are generally parameterized.

An overview of the parameters that you can set and their default settings are shown in the table below.

Table 8: Parameters of the SM 331; AI 8 14 Bit High Speed

| Parameter | Value Range | Default Settings | Parameter Type | Scope |

| Enable | ||||

|

|

| Dynamic | Module |

| Trigger for hardware interrupt | Constraint possible due to measuring range. | |||

|

| – | Dynamic | Channel |

| Diagnostics | ||||

| Yes/no | No | Static | Channel group |

| Measurement | ||||

| Deactivated U Voltage 4DMU Current (4-wire transmitter) 2DMU Current (2-wire transmitter) | U | Dynamic | Channel or Channel group |

| For the settable measuring ranges of the input channels, please refer to section of the reference manual. | ±10 V | ||

| None; 400 Hz; 60 Hz; 50 Hz | 50 Hz | ||

Channel groups

The channels of the SM 331; AI 8 14 Bit High Speed are arranged in four groups of two. You can only ever assign parameters to one channel group.

The SM 331; AI 8 14 Bit High Speed has a measuring range module for each channel group.

The table below shows which channels are parameterized as a channel group in each case. You will need the channel group number to set the parameters in the user program with an SFC.

Table 9: Assignment of the channels of the SM 331; AI 8 14 Bit High Speed to channel groups

| Channels... | ... form one Channel Group each |

| Channel 0 | Channel group 0 |

| Channel 1 | |

| Channel 2 | Channel group 1 |

| Channel 3 | |

| Channel 4 | Channel group 2 |

| Channel 5 | |

| Channel 6 | Channel group 3 |

| Channel 7 |

Special characteristic of channel groups for hardware interrupts

You can set hardware interrupts in STEP 7 for the channel groups 0 and 1. Note, however, that a hardware interrupt is set only for the first channel in the channel group in each case – in other words, for channel 0 or channel 2.

Diagnostics

You will find the diagnostic messages that are grouped under the "group diagnosis" parameter in Table 4-47 of the reference manual.

Measuring methods and measuring ranges of the SM 331; AI 8 14 Bit High Speed

Measuring Methods

You can set the following measuring methods for the input channels:

Voltage measurement Current measurement

You perform the setting by means of the measuring range modules on the module and with the "measuring method" parameter in STEP 7.

Unused Channels

You must short-circuit unused channels and connect them to MANA. In this way, you obtain an optimum interference immunity for the analog input module. Set the "measuring method" parameter for unused channels to "disabled".

Special characteristics of unused channels for some measuring ranges

Since configured inputs can remain unused because of the channel group generation, you must take note of the following special characteristics of these inputs to enable the diagnostic functions on the used channels.

- Measuring range 1 to 5 V: parallel connection of the unused input with the used input of the same channel group.

- Current measurement, 2-wire transmitter: two channel wiring options.

- Leave the unused input open and do not enable diagnostics for this channel group. Otherwise, if diagnostics are enabled, the analog module triggers a single diagnostic interrupt and the SF LED of the analog module comes on.

- Connect the unused input with a resistance of 1.5 to 3.3 k. You may then enable diagnostics for this channel group.

- Current measurement 4 to 20 mA, 4-wire transmitter: series connection of the unused input with the input of the same channel group.

Measuring ranges

You perform the setting of the measuring ranges by means of the measuring range modules on the module and with the "measuring method" parameter in STEP 7.

Table 10: Measuring ranges of the SM 331; AI 8 x 14 Bit High Speed

| Method Selected | Measuring Range (Type of Sensor) | Measuring Range Module Setting | Description |

| U: voltage | 1 V | A | You will find the digitized analog values in Section of the reference manual in the part that deals with the voltage measuring range. |

| 5 V 1 to 5 V 10 V | B | ||

| 4DMU: Current (4-wire transmitter) | 0 to 20 mA 4 to 20 mA 20 mA | C | You will find the digitized analog values in Section of the reference manual in the part that deals with the current measuring range. |

| 2DMU: Current (2-wire transmitter) | 4 to 20 mA | D |

Default Settings

The default settings of the module in STEP 7 are the "voltage" measuring method and the " 10 V" measuring range. You can use this measuring method with this measuring range without parameterizing the SM 331; AI 8 14 Bit High Speed using STEP 7.

Special characteristics of the wire-break check for the 4 to 20 mA measuring range

With a parameterized measuring range of 4 to 20 mA and enabled wire-break check, the analog input module enters wire-break in the diagnosis when a current falls below 3.6 mA.

If you have enabled diagnostics interrupt during configuration, the module additionally triggers a diagnostic interrupt.

If no diagnostic interrupt has been enabled, the illuminated SF LED is the only indication of the wire-break and you must evaluate the diagnostic bytes in the user program.

With a parameterized measuring range of 4 to 20 mA and disabled wire-break check and enabled diagnostic interrupt, the module triggers a diagnostic interrupt when the underflow is reached.

Analog Output Module SM 332

AO 4 16 Bit; clocked; (6ES7 332-7ND01-0AB0)

Order number

6ES7 332-7ND01-0AB0

Characteristic

The Analog Output Module SM 332; AO 4 × 16 Bit has the following characteristic features:

- 4 outputs in 4 channel groups

- Individual output channels can be programmed as

- voltage outputs

- current outputs

- Resolution of 16 bits

- Supports clocked operation

- Supports the function "Reparameterization in RUN mode"

- Programmable diagnostics

- Programmable diagnostic interrupt Programmable substitute value output

- Galvanic Isolation between:

- backplane bus interface and analog output channels

- the different analog output channels

- analog output and L+, M

- backplane bus interface and L+, M

Terminal connection diagram and block diagram of the SM 332; AO 4 × 16 Bit

Figure 8 Module view and block diagram of the SM 332; AO 4 x 16 Bit

Switching the rated load voltage (L+) on and off, can cause wrong intermediate values at the output for approximately 10 ms.

Technical specifications of the SM 332; AO 4 16 bits

Dimensions and Weight

| Dimensions W H D (in millimeters) | 40 125 117 |

| Weight | Approx. 220 g |

Data for Specific Module

| Supports clocked operation | Yes |

| Reparameterization in RUN mode possible | Yes |

| Output the last valid output value before parameterization |

| Number of outputs | 4 |

| Length of cable | |

| max. 200 m |

Voltages, Currents, and Potentials

| Rated load voltage L+ | 24 VDC |

| Yes |

| Isolation | |

|

|

| Permitted potential difference | |

|

|

| Insulation tested with | 500 VDC |

| Current consumption | |

|

|

| Power dissipation of the module | |

Analog Value Generation

| Resolution (including overrange) | |

|

|

| Conversion time (per channel) | |

|

|

| Basic response time of module (all channels enabled) | |

|

|

| Settling time | |

|

|

Suppression of interference, Limits of Error

| Crosstalk between outputs | > 100 dB |

| Operational limit (in the entire temperature range, with reference to the output range) | |

|

|

| Basic error (operational limit at 25°C, referred to output range) | |

| |

| ±10 V 0 to 10 V 1 to 5 V | ±0.02% ±0.02% ±0.04% |

| |

| ±20 m 0 to 20 mA 4 to 20 mA | ±0.02% ±0.02% ±0.04% |

| Temperature error (with reference to the output range) | |

|

|

| Linearity error (with reference to the output range) | ±0.004% |

| Repeat accuracy (in the steady state at 25°C, referred to the output range) | ±0.002 % |

| Output ripple; band width 0 to 50 kHz (with reference to the output range) | ±0.05 % |

Status, Interrupts, Diagnostics

| Interrupts | |

| Programmable |

| Diagnostic functions | Programmable |

|

|

| Substitute value can be applied | Yes, programmable |

Data for Selecting an Actuator

| Output ranges (rated values) | |

| ±10 V 0 to 10 V 1 to 5 V |

| ±20 mA 0 to 20 mA 4to 20 mA |

| Load resistance (in the nominal range of the output) | |

|

|

|

|

| Voltage outputs | |

|

|

| Current outputs | |

| max. 18 V |

| Destruction limit against voltages/currents applied from outside | |

| max. 15 V continuous 75 VDC for max. 0.1 s (pulse duty factor 1:20) |

| max. 50 mA DC |

| Connection of actuators | |

| |

| Possible |

| |

| Possible |

Clock synchronization

Characteristics

Reproducible response times (i.e. times of the same length) are achieved in SIMATIC by means of an equidistant DP bus cycle and the synchronization of the following free-running individual cycles:

- Free-running cycle of the user program. On account of cyclic program branches the length of the cycle time may vary.

- Free-running, variable DP cycle on the PROFIBUS subnet.

- Free-running cycle on the DP slave backplane bus.

- Free-running cycle at signal conditioning and conversion in the electronic modules of the DP slaves.

With equidistance the DP cycle runs with the same clock pulse and for the same length. The priority classes of a CPU (OB 61 to OB 64) and the clocked I/Os are synchronized with this clock pulse. The I/O data are thus transferred at defined, fixed intervals (clock synchronization).

Prerequisites

The DP master and DP slave must support clock synchronization. STEP 7 as of Version 5.2 is required.

Mode: Clock synchronization

The following conditions are applicable for synchronous operation:

| Processing and activation time TWA between read in of output value in the transfer buffer and loading in the output DAC | 1.6 ms |

| TDPmin | 2.4 ms |

| Diagnostic interrupt | 4 x TDP, max |

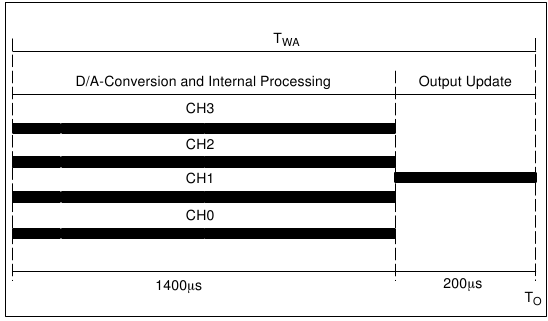

Processing and Output Update Time

The same time conditions are always applicable, irrespective of the number of channels programmed.

Figure 9 Calculation of the Processing Time and Output Update Time

Description of the Method of Functioning in Synchronous Operation

At time TO – TWA, the module reads in the output data and saves the data internally. Following internal processing time for each channel, the results are written to each D/A converter.

Additional Information

You will find additional information about synchronous operation in the STEP 7 online Help, the ET 200M Distributed I/O System manual and

in the Manual Clock Synchronization.

Commissioning the SM 332; AO 4 16 bits

Parameter

You will find a description of the general procedure for assigning parameters to analog modules in the reference manual.

You will find an overview of the programmable parameters and their default values in Table 4-42 of the reference manual.

Assigning parameters to channels

You can configure each output channel of the SM 332; AO 4 16 bits individually.

You can thus assign separate parameters for each output channel.

When you set the parameters with SFCs in the user program, the parameters are assigned to channel groups. Every output channel of the SM 332; AO 4 16 bits is assigned to a channel group in this instance – in other words, for example output channel 0 = channel group0.

If you modify output ranges when the analog output module SM 332; AO 4 16 bits is in operation, incorrect intermediate values may arise across the output.

Diagnostics

You will find the diagnostic messages that are grouped under the "group diagnosis" parameter in Table 4-47 of the reference manual.

Output Ranges of the Analog Output Module SM 332; AO 416 bits

Connecting the analog outputs

You can connect the outputs as voltage or current outputs, or disable them. You perform connection of the outputs with the "output type" parameter in STEP 7.

Unused channels

So that unused output channels of the SM 332; AO 4 16 bits remain de-energized, you must set the "output type" parameter to "disabled" and leave the terminal open.

Output ranges

You program the output ranges for voltage and current outputs in STEP 7.

Table 11: Output Ranges of the Analog Output Module SM 332; AO 416 bits

| Selected Type of Output | Output Range | Description |

| Voltage | 1 to 5 V 0 to 10 V 10 V | You will find the digital analog values in Section(of the reference manual) in the voltage and current output ranges |

| Current | 0 to 20 mA 4 to 20 mA 20 mA |

Default settings

The default settings of the module are "Voltage" for the output type and " 10 V" for the output range. You can use this combination of output type and output range without parameterizing the SM 332; AO 4 16 bits in STEP 7.

Substitute values

You can configure the SM 332; AO 4 16 bits for the CPU operating mode STOP as follows: Outputs De-energized, Hold Last Value or Inject Substitute Values. If you inject substitute values, they must be within the output range.

Documents / ResourcesDownload manual

Here you can download full pdf version of manual, it may contain additional safety instructions, warranty information, FCC rules, etc.

Advertisement

Need help?

Do you have a question about the S7-300 and is the answer not in the manual?

Questions and answers