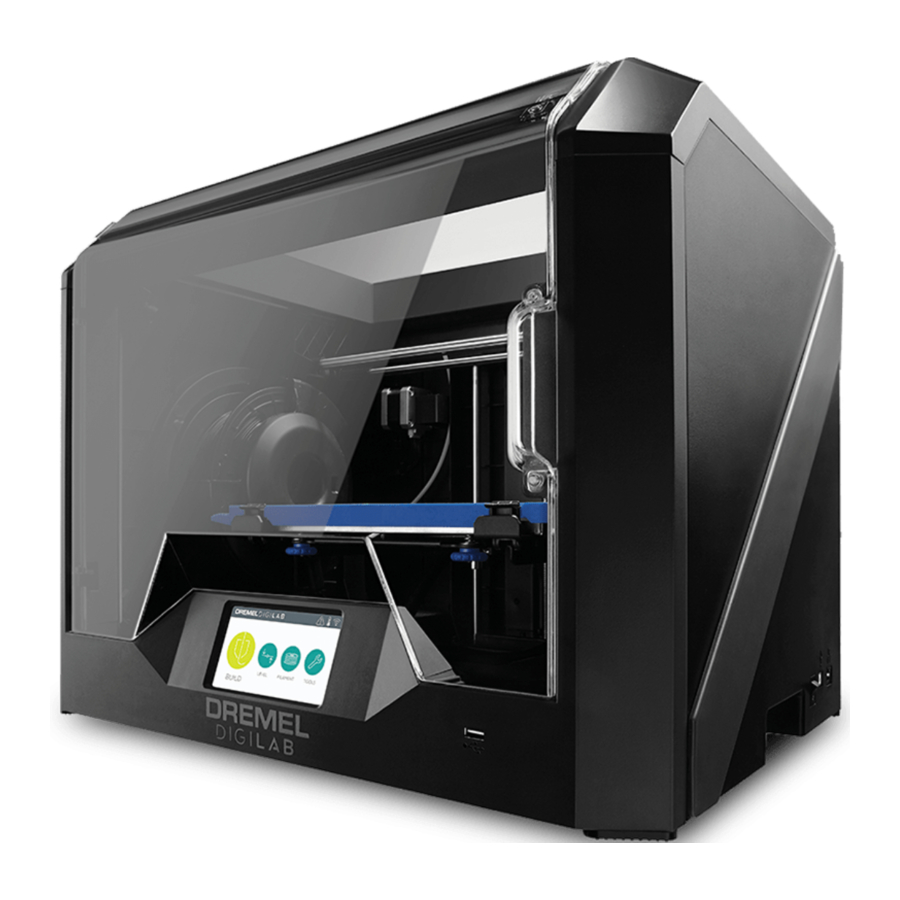

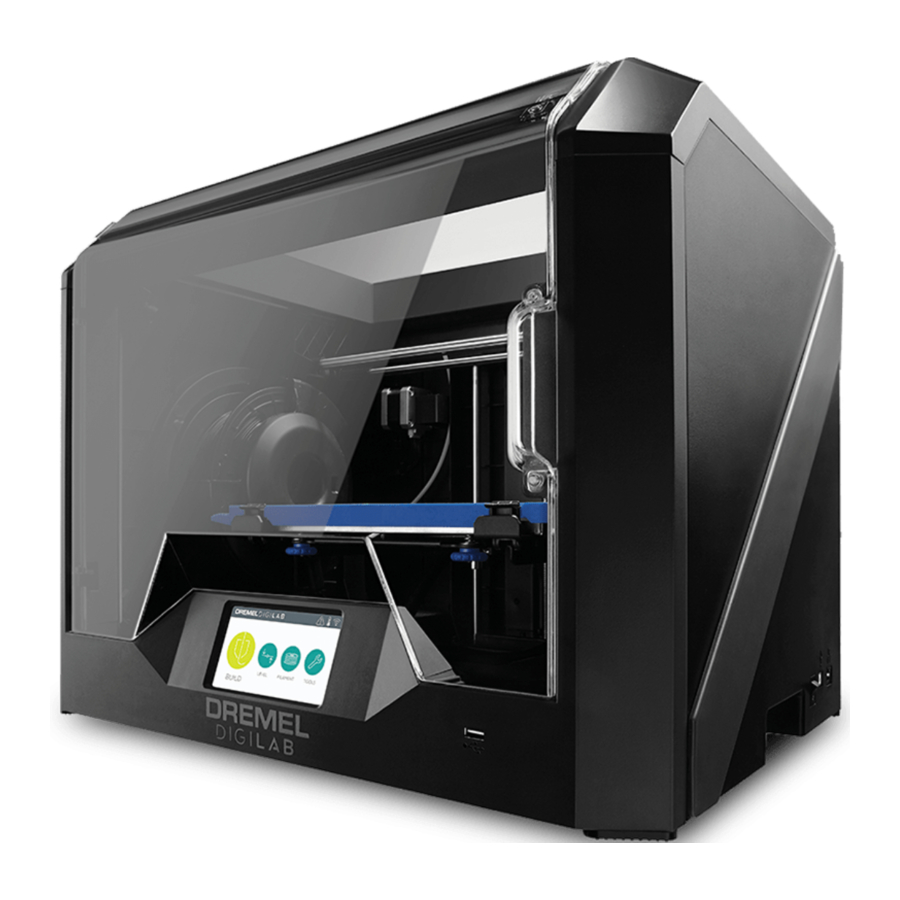

Dremel 3D45 Manual

- Original instructions manual (396 pages) ,

- Operating and safety instructions manual (112 pages) ,

- Operating/safety instructions manual (37 pages)

Advertisement

- 1 Symbols

- 2 Dremel Remote Services

- 3 Specifications

- 4 Resources

- 5 Glossary of Terms

- 6 Introduction

- 7 Kit Contents

- 8 Unpacking

- 9 Getting To Know your Product

- 10 Touch Screen

- 11 Touch Screen Icons

- 12 Initial Setup

- 13 Dremel Cloud Platform

- 14 Getting Ready to Build

- 15 Building

- 16 Removing your Object

- 17 Using the Camera

- 18 Best Practices

- 19 Maintenance

- 20 Troubleshooting

- 21 Firmware & Open Source Software

- 22 Safety Symbols

- 23 General Safety Warnings

- 24 Dremel Limited Warranty

- 25 Documents / Resources

Symbols

Some of the following symbols may be used on your 3D45. Please study them and learn their meaning. Proper interpretation of these symbols will allow you to operate the tool better and safer.

| Symbol | Designation / Explanation |

| V | Volts (voltage) |

| A | Amperes (current) |

| Hz | Hertz (frequency, cycles per second) |

| ø | Diameter |

| 0 | Off position |

| ~ | Alternating current (type or a characteristic of current) |

| Hot surface hazard symbol. Contact may cause burn. Allow to cool before servicing. |

Dremel Remote Services

Dremel remote services provide you with information and services regarding your Dremel 3D products. The type of information provided by Dremel remote services may change from time to time. All product information and services are provided for your convenience, "As is" and "As Available".

Dremel does not guarantee that the information or services will be available, accurate, or reliable, or that product information or services will provide safety in your home. You use all product information, services, and products at your discretion and risk. The product information and services are not intended as a substitute for direct means of obtaining information.

Network connectivity requires an access point and high speed internet connection. Internet service provider charges may apply.

Remote printing requires a compatible mobile device and data plan. Carrier charges may apply.

Specifications

BUILDING

Extruder: single extrusion

Extruder Temperature: Up to 280 C, 536 F

Build Platform Temperature: Up to 100 C, 212 F

Operating Interface: 4.5" full color IPS touch screen

Maximum Build Volume: 10" x 6" x 6.7" (255mm x 155mm x 170mm)

Layer Thickness: 50 microns (0.05 mm)

Filament Types and Colors: See www.digilab.dremel.com for color choices

Internal Storage: 8GB

External Storage: USB flash Drive

WEIGHT & DIMENSIONS

Weight (without spool): 19.4 kg (42.8 lb)

Dimensions: 20.25" x 16" x 15.9" (515mm x 406mm x 394mm)

FILAMENT

ONLY works with Dremel 1.75mm filament

FILAMENT STORAGE

All polymers degrade with time. Do not unpack until filament is needed. Filament should be stored at room temperature: 16-29°C (60-85°F) and in dry conditions.

SOFTWARE

Dremel 3D45 comes with complimentary file slicing software for Windows and Mac OSX. This application converts your 3D digital files into buildable files.

SUPPORTED OPERATING SySTEMS

- Apple Mac OS X v10.9 or later (Mavericks)

- Microsoft Windows 7 SP1

- Microsoft Windows Window 8, 8.1

- Microsoft Windows Window 10

MINIMUM SYSTEM SPECIFICATIONS FOR PRINT STUDIO

- CPU: 64-bit processor (32-bit not supported)

- Memory: 3 GB RAM (4 GB or more recommended)

- Disk space: ~2 GB free disk space for installation

- Display card: 1,024 MB GDDR RAM or more. Microsoft Direct3D 11 capable graphics card or higher

- Pointing Device: three-button mouse

ELECTRICAL REQUIREMENTS

3D45 input rating: 100-240V, 47-60Hz, 0.85-2.3Amps

OPERATING ENVIRONMENT

Room Temperature: 16-29°C (60 - 85°F)

Level workspace

Dry workspace environment

Resources

| Resource | Description | Location |

| Quick Start Guide | Provides illustrated walkthrough of how to un-box your 3D45 and start building out of the box. | Printed version of the Quick Start Guide is located in the carton with the printer. |

| Dremel Website | Provides the latest 3D45 software, product information, customer support, and 3D model and project downloads. | www.digilab.dremel.com |

| Dremel 3D Customer Support | Contact Dremel for product support, maintenance, and service. | 1-844-4DRML3D (1-844-437-6533) www.digilab.dremel.com |

| File Slicing Software | Allows you to upload, edit, and build 3D files. | Install from www.digilab.dremel.com or from USB flash drive provided with the Dremel 3D45. |

Glossary of Terms

| Build Platform | The flat surface used by your Dremel 3D45 to build objects. The build platform is comprised of a tempered glass plate with a plastic holder. |

| Build Platform Clips | Clips located at the front of the build platform base that are used to secure the build platform in place. |

| Build Volume | The three dimensional (3D) amount of space that an object will use once it is completed. Your Dremel 3D45 has a maximum build volume which means that objects with a larger build volume cannot be built unless they are resized or broken into sub-objects. |

| Door | Your Dremel 3D45 has a door located on the front panel. This allows for easy access to the build platform, extruder, filament, and your objects. This door is made with a transparent material so you can monitor the progress of your objects while keeping the build environment stable. |

| ECO-ABS | Natural thermoplastic that provides users with durable and impact resistant parts. |

| Ethernet Port | A local area wired networking technology that allow electronic devices to communicate. |

| Extruder | An assembly that uses gears to pull filament through the extruder intake, heat the filament to the build temperature, and push the heated filament out of the extruder tip. |

| Extruder Fans | Fans used to cool the outer assembly of the extruder and gear motor. |

| Extruder Fan Baffle | A plastic piece that directs air from the extruder fan onto the build platform to assist in cooling the active build. |

| Extruder Intake | An opening located at the top of the extruder where filament is inserted for building. |

| Extruder Lever | A lever located on the side of the extruder that is used to loosen the grip of the extruder gear motor. |

| Extruder Tip | A nozzle located at the bottom of the extruder where heated filament is forced out for building. |

| Filament | A threadlike strand of plastic material. |

| Filament Guide Tube | A plastic tube that guides the filament from the spool holder to the extruder of the printer, preventing any snags. |

| Filament Runout Sensor | A sensor in the extruder intake that pauses your printer if it runs out of filament during a build. |

| Filament Spool | A cylindrical piece on which a long strand of filament is wound for storage and continuous use. |

| .g, .gcode and.g3drem | Buildable file formats compatible with your Dremel 3D45. |

| Glue Stick | Non-toxic and acid-free stick of glue that is applied to the build platform to help prints stick. |

| Leveling Knobs | Knobs located under the base of the build platform that allow users to easily level the build platform before each print. |

| Leveling Sensor | A sensor that detects the height of the build platform and assists in proper leveling. |

| Lid | Your Dremel 3D45 has a pivoting lid on the top. This allows for more access to the build platform, extruder, filament, and objects when necessary. |

| Needle Nose Pliers | Common tool used to hold small objects and to grab excess material that may be too hot to touch directly. |

| Nylon | Synthetic polymer that provides strong and flexible prints with heavy wear resistance. |

| OBJ File | A common digital file format used in a wide range of 3D model software. This file is created in 3rd party 3D software or downloaded from www.digilab.dremel.com. |

| Object Removal Tool | A tool used to separate your object platform. |

| PETG | A thermoplastic filament that combines flexibility, strength and durability similar to Nylon but is easier to print, similar to PLA. |

| PLA | A bioplastic derived from renewable resources such as corn starch. |

| Spool Holder | A plastic piece located to the left of the build platform inside your Dremel 3D45 build area that is designed to hold a filament spool. |

| Spool Door | A removable door which locks the filament spool to the spool holder. |

| Stepper Motor | A brushless DC electric motor used to drive the guide rails and extruder gears. |

| .STL File | A common digital file format used in a wide range of 3D model software. This file is created in 3rd party 3D software or downloaded from www.digilab.dremel.com. |

| Touch Screen | Full color display that is touch activated. It allows you to monitor your Dremel 3D45 and objects while also providing commands directly to your Dremel 3D45 without the use of a computer. |

| USB Flash Drive | A portable memory card used on a wide array of devices. |

| WIFI | A local area wireless networking technology that allow electronic devices to communicate. |

| X-Axis Guide Rails | A set of rails on either side of the extruder that allow a stepper motor to move the extruder to the left or right side of the build area. |

| Y-Axis Guide Rails | A set of rails on either side of the build area that allow a stepper motor to move the extruder to the front or back of the build area. |

| Z-Axis Guide Rails | A set of rails located at the back of the build area that allow a stepper motor to move the build platform up or down. |

Introduction

To get started with 3D45 follow the initial setup routine on the touch screen to connect and register the printer.

You can create a user profile by going to www.digilab.dremel.com. Your profile gives you access to high-quality models, support and software downloads, and remote printing services powered by 3DPrinterOS. Once setup and registration is complete you are ready to start building.

Kit Contents

*Quantities may vary depending on kit.

**Do not store in moist or hot environment.

Unpacking

- Place box on table, cut tape, and open.

- Remove top insert.

![Dremel - 3D45 - Unpacking - Step 1 - Remove top insert Unpacking - Step 1 - Remove top insert]()

- Remove 3D45 and place on table.

- Open lid and remove top insert.

![Dremel - 3D45 - Unpacking - Step 2 - Open lid & remove top insert Unpacking - Step 2 - Open lid & remove top insert]()

- Raise build platform by lifting from both sides.

![Dremel - 3D45 - Unpacking - Step 3 - Raise build platform Unpacking - Step 3 - Raise build platform]()

- Open door and remove middle insert.

![Dremel - 3D45 - Unpacking - Step 4 - Remove middle insert Unpacking - Step 4 - Remove middle insert]()

- Remove bottom insert.

![Dremel - 3D45 - Unpacking - Step 5 - Remove bottom insert Unpacking - Step 5 - Remove bottom insert]()

Tip: Keep packaging for future transportation and storage.

Getting To Know your Product

- Lid

- Extruder

- Z-Axis Guide rail

- Door

- Build Platform Tabs

- Gripping Handles

- USB A Port

- Leveling Knobs

- Build Platform

- Touch Screen

- Build Platform Clips

- Filament Spool Holder

- RFID Reader

- Filament Spool

- Camera

- Y-Axis Guide Rail

- Stepper motor

- Filament Guide Tube

- Extruder Lever

- Filament Guide Clip

- Extruder Intake

- Chamber Fan

(With optional filtration hook-up) - Ribbon Cable

- X-Axis Guide Rail

- Leveling Sensor

- Extruder Tip

- Power Switch

- USB B Port

- Ethernet Port

- Nameplate

- Power Input

Touch Screen

Using your Dremel 3D45 without a computer is easy with the onboard software and full color touch screen.

Before building your model we want to familiarize you with the touch screen menu structure and options.

Observe all provided warnings and safety instructions when using the Dremel 3D45. Failure to do so may result in fire, equipment damage, property damage or personal injury.

| BUILD Tap to select a 3D model and begin build process. (see "Building" for detailed build instructions) |

| BUILD MENU Tap Printer, USB Flash Drive, or Print Queue to choose the destination of your desired file. |

| MODEL MENU Tap to select the desired model or use arrows to scroll through pages to find your model. |

| FILE DETAILS Nozzle and platform temperatures settings referenced for the current build. BUILD – Tap to begin build process. DELETE – Tap to remove model file from on-printer storage or USB flash drive. COPY TO PRINTER – From USB flash drive, tap to copy model file to on-printer storage. |

| BUILD STATUS PAUSE/PLAY – Tap to pause or resume the current build process. Pause will allow you to access the filament button. STOP – Tap to cancel the current build process. |

| PRINT QUEUE MENU YES – Tap to proceed to print file. NO – Tap to cancel printing of file. |

| LEVEL Tap to begin build platform leveling process. (see "LEVELING BUILD PLATFORM" for instructions on leveling the build platform) |

| |

| FILAMENT Tap to begin heating and start filament load/change process. (See "LOADING/CHANGING FILAMENT" for instructions on filament load/change process) |

| |

| TOOLS Tap to access the following individual printer functions and settings. |

| NETWORK Tap to enter Network menu to connect or disconnect WiFi and Set Proxy. CONNECT WIFI – Tap to connect to WiFi. SET PROXY – Tap to set manual proxy. SET STATIC IP – Tap to setup static IP. |

| PREHEAT Tap "Nozzle Temp" to automatically begin preheating the extruder for building or removing excess debris. Once your optimal temperature is achieved, tap "Plate Temp" to begin preheating the build platform. PURGE – Once extruder is hot, tap to manually extrude filament. |

| |

| CALIBRATE Tap to move extruder and build platform to zero position. |

| |

| JOG MODE Tap to display options to move extruder and build platform along the X, Y, and Z-axis. |

| |

| HELP Tap to enter service menu to see customer service contact information. |

| |

| SETTINGS LANGUAGE – Tap to pick alternate menu language. DISPLAY – Tap to customize cabinet LEDs or main menu hotkeys. SOUNDS – Tap to turn 3D45 sounds On/Off. TOKEN – Tap to release current token and get a new token when connected to Wifi or Ethernet. ADVANCED MODE – Tap to manually prioritize G-Code settings. FACTORY RESET – Tap to remove all information stored on 3D45 and return it to factory defaults. |

| |

| ABOUT Tap to see 3D45 information such as firmware version, usage counter, printer status, MAC address, and token. |

|

Touch Screen Icons

| Indicates that there is an error such as filament empty or door open. |

| Indicates that Ethernet is connected. |

| Indicates WiFi signal strength and connected status. |

| Indicates that the extruder and build platform is cool. |

| Indicates that the extruder and build platform is warm. |

| Indicates that the extruder and build platform is hot. |

| Indicates that the printer is connected to 3DPrinterOS printing services and that it can receive remote commands. |

Initial Setup

The first time you power on your Dremel 3D45 you will be prompted to perform an initial setup of network. Completing this process will give you access to features such as printing wirelessly from your PC or Dremel3D cloud based program, printer sharing amongst your friends and family, notifications of firmware updates, and printer status monitoring. You will then be walked through how to loading your first roll of filament and how to properly level the build plate.

NOTE: Dremel3D cloud based software can be accessed on www.digilab.dremel.com.

- To complete initial setup, tap "Start" when prompted on the initial setup screen. If you decline this setup you can always setup network later.

![Dremel - 3D45 - Initial Setup - Step 1 Initial Setup - Step 1]()

- If you choose "Start", 3D45 will automatically connect to your ethernet (if plugged into router skip to step 5) or search for available wireless networks.

![Dremel - 3D45 - Initial Setup - Step 2 Initial Setup - Step 2]()

- Choose your wireless network using the touch screen. Use the arrows to scroll through the list of available wireless networks. Tap on your network name to accept it.

![Dremel - 3D45 - Initial Setup - Step 3 Initial Setup - Step 3]()

- Enter your wireless network password and tap "Done".

![Dremel - 3D45 - Initial Setup - Step 4 Initial Setup - Step 4]()

- Write down the token displayed at the bottom of the touch screen. This token will be used to link your printer to your Dremel account.

![Dremel - 3D45 - Initial Setup - Step 5 Initial Setup - Step 5]()

- Visit www.digilab.dremel.com and follow the prompts to complete your user profile creation and printer registration.

Dremel Cloud Platform

Dremel's cloud-based platform allows you to connect to your 3D45 from any web browser. In the platform, you can view models and projects in the Dremel 3D library, send, pause and cancel builds, monitor build status, receive push notification updates, and more. Create a user profile on www.digilab.dremel.com and follow the setup steps below to get started.

Note: This feature is currently only available in the United States.

- After launching the Dremel cloud platform in your web browser, you will need to Log In with your existing Dremel user information or Social Log In or Sign Up to create a new account.

![]()

- Click on the "Go To Print Cloud" button to launch the new cloud platform.

![]()

- When you enter the cloud platform, click on printers on the top toolbar to register your 3D45. Register your 3D45 by entering the token number where it says "Registration code" and clicking "OK".

![]()

- Your mobile device is now connected to your 3D45.

![]()

Getting Ready to Build

Observe all provided warnings and safety instructions when using the Dremel 3D45. Failure to do so may result in fire, equipment damage, property damage or personal injury.

Do not touch the extruder tip or heated build platform during Dremel 3D45 operation or until it has cooled down to at least 60°C (140°F). Contact with the extruder tip or build platform during or after operation before tip and build plate has cooled may result in personal injury.

Use only DREMEL filament. Use of filament not authorized by Dremel may result in equipment, property damage, or personal injury.

Do not adjust extruder setting to exceed the maximum rated temperature of the filament type being used. Heating filament above recommended range can cause emissions that may result in personal injury.

Do not pull the filament out. Doing so may damage the extruder.

LOADING/CHANGING FILAMENT

- Start filament load/change process by tapping "Filament" button on touch screen. Extruder will move to front right corner of print area and extruder tip will begin to heat.

![Dremel - 3D45 - LOADING/CHANGING FILAMENT - Step 1 LOADING/CHANGING FILAMENT - Step 1]()

- After extruder stops moving, open the 3D45 Lid for better access to extruder.

- If existing filament is loaded, cut existing filament near extruder intake and tap the arrow button on touch screen.

![Dremel - 3D45 - LOADING/CHANGING FILAMENT - Step 2 LOADING/CHANGING FILAMENT - Step 2]()

- Remove Spool door by rotating it counter clockwise, see figure 1. Remove existing spool if one is present.

![Dremel - 3D45 - LOADING/CHANGING FILAMENT - Step 3 LOADING/CHANGING FILAMENT - Step 3]()

- Thread tip of new filament through guide tube, place spool on spool holder, replace spool door by aligning locking tabs and rotating clockwise, see figure 1.

- When you place a roll of Dremel filament into the spool holder, the printer will autorecognize the filament type and adjust the printer settings to be optimized for the filament you are using (This will bypass any print settings loaded in your sliced file).

NOTE: You have the option to enter advanced printer mode to manually alter print settings after you change filament. Please check all settings (if manually entered) as improper settings may cause prints to fail or damage the equipment, see "Filament Type and Settings" or on digilab.dremel.com for the latest chart.

![Dremel - 3D45 - LOADING/CHANGING FILAMENT - Step 4 LOADING/CHANGING FILAMENT - Step 4]()

NOTE: You also have the option to pull print settings from the saved sliced file. This will prevent the printer from altering its print settings. Please check all settings prior to printing as improper settings may cause prints to fail, property damage, or personal injury.

- If changing existing filament, 3D45 will automatically purge existing filament.

- When Feed Filament screen appears, tap the arrow on touch screen and thread filament coming from guide tube into extruder intake until filament feeds through on its own, see figure 2.

NOTE: Ensure the gears inside of the extruder have properly grabbed the filament before you finish the filament change. You will feel a tug and see the filament start to feed itself into the extruder when this occurs.

![Dremel - 3D45 - LOADING/CHANGING FILAMENT - Step 5 LOADING/CHANGING FILAMENT - Step 5]()

![Dremel - 3D45 - LOADING/CHANGING FILAMENT - Step 6 LOADING/CHANGING FILAMENT - Step 6]()

- Filament will be drawn into the extruder and begin to exit from the hot extruder tip.

NOTE: Your Dremel 3D45 was tested by building objects before leaving the factory. These test objects may have been made with a different filament color than you are using. Therefore, a small amount of filament may be remaining in the extruder. - When new filament appears from extruder tip, tap "done" on touch screen to complete filament load process, return to main menu, and calibrate extruder. Carefully remove excess filament without touching hot extruder tip. If necessary, carefully remove debris from extruder tip with needle nose pliers.

![Dremel - 3D45 - LOADING/CHANGING FILAMENT - Step 7 LOADING/CHANGING FILAMENT - Step 7]()

Use extra care not to when clearing debris. Dremel 3D45 will not damage the extruder tip work properly with a damaged extruder tip and will require replacement.

- Close 3D45 lid and door.

| FILAMENT TYPE AND SETTINGS | ||||

| Filament Type | PLA | ECO-ABS | Nylon | PETG |

| Nozzle Temperature Range | 190 -240 C | 190 -240 C | 220 – 280 C | 230-260 C |

| Optimal Nozzle Temperature | 220 C | 220 C | 255 C | 250 C |

| Build Platform Temperature Range | 0 – 60 C | 0 – 70 C | 0 – 100 C | 0 – 80 C |

| Optimal Build Platform Temperature | 35 C | 45 C | 80 C | 70 C |

| Print Speed Multiplier | 0 – 100% | 0 – 100% | 0 – 100% | 0 – 100% |

| Recommended Speed Multiplier | 100% | 100% | 90% | 100% |

| Fan Range | 0 – 100% | 0 – 100% | 0 – 100% | 0 – 100% |

| Object cooling fan setting | 100% | 100% | 50% | 100% |

NOTE: Please check website digilab.dremel.com for latest filament settings.

PREPARING BUILD PLATFORM

Do not touch the extruder tip or heated build platform during Dremel 3D45 operation or until it has cooled down to at least 60°C (140°F). Contact with the extruder tip or build platform during or after operation before tip and build plate has cooled may result in personal injury.

Do not drop the build platform. Tempered glass plate may break and result in personal injury.

Do not remove tempered glass plate from plastic holder. Contacting with tempered glass plate edge may result in personal injury.

Before every build make sure that the build platform is covered with glue from the supplied glue stick. If glue is not used, it may cause poor object build quality.

- Remove build platform by first pressing down and releasing the two clips located at the front of the build platform, then lift the build platform off the base using the build platform tabs (figure 3).

![Dremel - 3D45 - PREPARING BUILD PLATFORM - Step 1 PREPARING BUILD PLATFORM - Step 1]()

- Apply the glue in two overlapping layers to ensure that the entire build surface is properly covered. You can apply glue to the perimeter of the build plate first, and then zigzag up and down while overlapping the entire area. Wait for 10 seconds and then apply another layer zigzagging left to right. This ensures a uniform layer over the entire build area (figure 4).

NOTE: To clean the build platform, rinse the platform with warm water and dry with a towel.

![Dremel - 3D45 - PREPARING BUILD PLATFORM - Step 2 PREPARING BUILD PLATFORM - Step 2]()

- Install the build platform by first inserting the rear of the platform onto the rear clips, then press down on the front of the platform until it snaps in place.

LEVELING BUILD PLATFORM

Do not touch the extruder tip or heated build platform during Dremel 3D45 operation or until it has cooled down to at least 60°C (140°F). Contact with the extruder tip or build platform during or after operation before tip and build plate has cooled may result in personal injury.

It is important you level the build platform every time you reinstall the build platform to ensure that the build platform is evenly spaced from the extruder head. Not leveling the build platform may cause objects to not build properly.

- Tap "Level" on 3D45's touch screen.

![Dremel - 3D45 - LEVELING BUILD PLATFORM - Step 1 LEVELING BUILD PLATFORM - Step 1]()

- The extruder and build platform will move into position to level the build platform. 3D45 will first check level at the back center of the build platform. The two knobs under the build platform are used to raise and lower the build platform on the left and right. The extruder contains a sensor that detects if the bed is level, no additional tools are necessary.

- The touch screen will indicate if your build platform is too high or too low. If the build platform is too high, adjust the appropriate knob by rotating right until you hear a "beep" and the touch screen indicates that it is ready to verify that the bed is level.

![Dremel - 3D45 - LEVELING BUILD PLATFORM - Step 2 LEVELING BUILD PLATFORM - Step 2]()

- If the build platform is too low, adjust the knob by rotating left until you hear a "beep" and the touch screen indicates that it is ready to verify that the bed is level.

![Dremel - 3D45 - LEVELING BUILD PLATFORM - Step 3 LEVELING BUILD PLATFORM - Step 3]()

- Tap "Verify" to check the bed level. If further adjustment is needed the touch screen will indicate the direction, if the level is correct, the extruder will move to the next point and the level process can be repeated.

![Dremel - 3D45 - LEVELING BUILD PLATFORM - Step 4 LEVELING BUILD PLATFORM - Step 4]()

- Repeat steps 3-5 for the second position, when you bed is fully level the extruder will automatically move to the calibration position and complete the leveling process.

![Dremel - 3D45 - LEVELING BUILD PLATFORM - Step 5 LEVELING BUILD PLATFORM - Step 5]()

CONNECTING USB CABLE

- Ensure 3D45 power switch is in the off position.

- Connect the included USB cable to your 3D45 and computer, figure 5.

![Dremel - 3D45 - CONNECTING USB CABLE CONNECTING USB CABLE]()

- Open software.

- Turn your Dremel 3D45 on using the power switch to sync your computer to your Dremel 3D45.

CONNECTING ETHERNET

- Ensure 3D45 power switch is in the off position.

- Plug ethernet cable into your 3D45, figure 6.

![Dremel - 3D45 - CONNECTING ETHERNET CONNECTING ETHERNET]()

- Turn your Dremel 3D45 on using the power switch. Ethernet connection should be detected automatically. Tap "Accept" to confirm connection.

Building

Observe all provided warnings and safety instructions when using the Dremel 3D45. Failure to do so may result in fire, equipment damage, property damage or personal injury.

Do not reach inside the Dremel 3D45 while it is in operation. Contact with Dremel 3D45 moving parts during operation may result in poor build quality, equipment damage or personal injury.

NOTE: Your Dremel 3D45 will build test objects before leaving the factory. These test objects may have been made with a different filament color than you are using. Therefore, a small amount of filament may be remaining in the extruder. The start of your first object may have some of this filament color until it transitions over to your filament color.

You have several options when building on your 3D45:

- On-Printer Storage

- USB Flash Drive

- Online Print Queue

- Computer

BEFORE YOU BUILD

- Ensure an adequate amount of filament is loaded (see "LOADING/CHANGING FILAMENT"). If 3D45 runs out of filament during a build, it will pause until more filament is added.

- Ensure glue is applied, build platform is level and clear of objects.

- Ensure the extruder and build platform temperature is set according to the filament type used, see "LOADING/CHANGING FILAMENT" for details.

BUILDING FROM ON-UNIT STORAGE

- On the main menu tap "Build".

![]()

- On the build menu tap the printer icon.

![]()

- Tap the model file you would like to build. (Use arrows to scroll through pages)

![]()

- In the model detail page tap "Build" to begin building process.

![]()

- Your 3D45 will first align the extruder and build platform to their zero positions then the level sensor will lightly touch the build platform to complete alignment. Your extruder tip and build plate will begin to heat which may take a few minutes. Once the proper temperature is reached your model will begin to build.

- Once your object is finished your 3D45 will automatically align the extruder and build platform to their calibration positions and cool the extruder tip and build platform.

- Wait until the touch screen indicates that the extruder and build platform is "cool" to remove your object. See section "Removing Object from Build Platform" for object removal instructions.

BUILDING FROM USB FLASH DRIVE

Plug in the USB flash drive (figure 7)

- On main menu tap "Build".

![]()

- Tap USB icon to access contents of USB flash drive.

![]()

- Follow steps 3-7 from Build from On-Unit storage to complete build from USB flash drive.

BUILDING FROM PRINT QUEUE

If your 3D45 is registered and added to your Dremel3D profile, you can send Builds from your web browser at www.digilab.dremel.com or by using the Dremel3D cloud slicer (see "Dremel Cloud Platform").

- If your 3D45 is displaying the Print Queue notification tap "YES" in the notification window to access the Print Queue. If you choose "NO" you can later access your Print Queue by tapping "Build" then "Print Queue".

![]()

- In the Print Queue menu you can choose to "Build" the next model in the queue or "Delete" it and advance to the next model.

![]()

- In Model Details tap "Build" to begin building process or "Delete" to remove the file.

![]()

BUILD FROM COMPUTER

Dremel 3D45 is compatible with Print Studio from Autodesk, Dremel's cloud-based platform, and will included plug-ins for Cura and Simplified 3D. Follow the instructions that came with this software to complete a Build from your computer.

CANCELING YOUR BUILD ON THE UNIT

To cancel your object during preheating or building, tap "Stop" on the touch screen. If you confirm "Yes" the extruder and build platform will move to their calibration positions.

Removing your Object

REMOVING YOUR OBJECT FROM THE BUILD PLATFORM

Do not touch the extruder tip or heated build platform during Dremel 3D45 operation or until it has cooled down to at least 60°C (140°F). Contact with the extruder tip or build platform during or after operation before tip and build plate has cooled may result in personal injury.

Use personal protective equipment. The use of protective equipment such as heat resistant gloves and safety glasses will reduce personal injuries.

Be aware of your body position when using hand tools to remove objects from the build platform. Sudden tool slip and improper body position during object removal from the build platform may result in personal injury.

Do not drop the build platform. Tempered glass plate may break and result in personal injury.

Do not twist or bend the removing objects. Tempered glass plate build platform while may separate from plastic holder and result in personal injury.

Avoid scratching the build objects. Scratches in the build platform will platform when removing result in improper object creation.

- Wait for the extruder or build platform to cool before removing your object.

- With the object still attached, remove build platform from the build area.

- Peel your object from the build platform. If needed, gently use the object removal tool to remove object from build platform (figure 8).

![Dremel - 3D45 - REMOVING YOUR OBJECT FROM THE BUILD PLATFORM REMOVING YOUR OBJECT FROM THE BUILD PLATFORM]()

REMOVING SUPPORTS

(IF REQUIRED)

Use needle nose pliers to remove supports that are inside your object or hard to reach.

Using the Camera

Your 3D45 is equipped with a camera that can be used to remotely monitor prints as long as your printer is connected to a network. There are two ways to access the camera: through the Dremel Cloud Platform or directly via a web browser.

Dremel Cloud Platform

- Create a Dremel Cloud account and register your 3D45. See "Dremel Cloud Platform" for detailed instructions.

- Log in to your Dremel Cloud account.

- Click on your registered printer, or click on Add a Printer if you need to register your printer.

![Dremel - 3D45 - Using Camera via Dremel Cloud Platform - Step 1 Using Camera via Dremel Cloud Platform - Step 1]()

- You will be directed to the Printers page of the Dremel Print Cloud. Here, you can click on Live View to see the camera view of any camera currently online.

![Dremel - 3D45 - Using Camera via Dremel Cloud Platform - Step 2 Using Camera via Dremel Cloud Platform - Step 2]()

Direct through Web Browser

- Make sure the device you want to view the camera on is connected to the same network as the 3D printer. This could be via Wi-Fi or via Ethernet.

- On the main menu of your 3D45 tap "Tools"

![]()

- In the tools menu tap "About"

![Dremel - 3D45 - Using the Camera via a Web Browser - Step 1 Using the Camera via a Web Browser - Step 1]()

- Locate the IP address of your printer. If your printer is connected to the network via Ethernet, this is the address next to "Ethernet IP". If it is connected via Wi-Fi this is the address next to "WiFi IP". It will be a sequence of three or four numbers separated by dots.

![Dremel - 3D45 - Using the Camera via a Web Browser - Step 2 Using the Camera via a Web Browser - Step 2]()

- Open any web browser on the device you want to view the camera on.

- In the address bar, enter the string:

http://IPADDRESS:10123/stream_simple.html

For example:

http://000.000.000.000:10123/stream_simple.html - Press enter and you will see a screen with a view of the camera as below.

![Dremel - 3D45 - Using the Camera via a Web Browser - Step 3 Using the Camera via a Web Browser - Step 3]()

Best Practices

- ALWAYS USE PROVIDED GLUE STICK.

- Ensure your build platform is level before every print.

- For proper adhesion of filament to the build platform, regularly wash the glue from the build platform with warm water, dry the build platform, re-apply a fresh layer of glue and re-level.

- Ensure spool is installed properly and can rotate freely.

- When using your Dremel 3D45 for the first time or after changing filament, allow Dremel 3D45 to extrude until material is consistent with the installed filament color.

- It is important to watch your Dremel 3D45 begin building objects. Your object is most likely to experience difficulty in the beginning. Thankfully, this is also the most convenient time to cancel the object, clean the build platform, and start your object again. Remain near the Dremel 3D45 during the building process.

- It is important to save your Dremel 3D45 packaging as it will make re-boxing and transporting your Dremel 3D45 easier.

- Ensure that you store filament spools in an environment that is not moist or too hot. It is recommended that you do not remove the filament spool from its airtight packaging until use.

- Use object removal tool gently to avoid damaging the build platform or object.

- Whenever possible, it is best to locate your object in the center of the build platform. Using the best orientation for your object is critical. Ensure that your object is located on the build platform and that you are using the best orientation for building.

- For steep overhangs (Less than 45 degree angle) it is recommended to build with support.

- Always remove the build platform before removing the object.

Maintenance

UNCLOGGING THE EXTRUDER

Use the unclogging tool to clean the extruder and unclog built up filament, fig 9.

- Click on the filament change button on the screen and wait for extruder to heat up. As filament starts to purge, insert the unclog tool into the extruder intake (top).

- Clogged debris will be pushed down and will extrude from the extruder tip. You should push the unclog tool all the way down to ensure all filament is purged. You do not need to push with excessive force, as this may damage the extruder.

UPDATING FIRMWARE VIA NETWORK

If your 3D45 is registered and connected to WiFi, it should check for firmware updates each time it boots up. You can also update its firmware directly from the touch screen. To update firmware:

- Tap "Tools", then tab "Updates".

![Dremel - 3D45 - UPDATING FIRMWARE VIA NETWORK - Step 1 UPDATING FIRMWARE VIA NETWORK - Step 1]()

- Your 3D45 will check to see if it has the latest firmware installed and ask if you would like to update if one is needed.

- Choose accept to download and install the latest firmware.

![Dremel - 3D45 - UPDATING FIRMWARE VIA NETWORK - Step 2 UPDATING FIRMWARE VIA NETWORK - Step 2]()

- When the 3D45 starts up and returns to the Home Screen, firmware update is complete.

UPDATING FIRMWARE MANUALLY

If your 3D45 is not connected to a network, you can update firmware directly from a USB flash drive.

- On your web browser go to www.digilab.dremel.com and download the latest 3D45 firmware file.

- Add the 3D45 firmware file to an empty, FAT32 formatted, USB flash drive.

- Turn off your 3D45 using the ON/OFF switch.

- Insert the USB flash drive into the USB-A port.

- Turn on your 3D45 and it should automatically detect and install the new firmware.

- Turn your 3D45 OFF, remove the USB flash drive, and turn ON again to complete the update.

CLEANING THE EXTERIOR

Clean the 3D45's exterior with a lint free cloth. Clear the outer surfaces of any debris that is visible.

To avoid damaging your Dremel 3D45 do not use water, chemicals or other cleaners on the 3D45.

CLEANING THE EXTRUDER TIP

Use extra care not to damage the extruder tip damage the extruder tip when clearing debris. Dremel 3D45 will not work properly with damaged extruder tip and will require replacement.

Do not touch the extruder tip or heated build platform during Dremel 3D45 operation or until it has cooled down to at least 60°C (140°F). Contact with the extruder tip or build platform during or after operation before tip and build plate has cooled may result in personal injury.

Using small needle nose pliers, pull away any plastic debris from the extruder tip.

If the debris is stubborn, the extruder may need to be heated.

CLEANING THE TOUCH SCREEN

Wipe the touch screen with the soft, lint-free cloth. Do not spray cleaners on the touch screen.

Troubleshooting

| PROBLEM | CAUSE | CORRECTIVE ACTION |

| Filament is not extruding or sticking to the build plate properly | This can be caused by the build platform not being leveled with the extruder head. | Leveling the build platform will align the extruder head and ensure a better object quality. Cancel your object, clear build platform, level the build platform, and restart the object. |

| Dremel 3D45 froze before my object started | Dremel 3D45 may have received conflicting commands. | Turn power switch off, wait 30 seconds, and turn power switch on. |

| Support material does not break away during cleaning and results in decreased quality of the final object. | Orientation of the part is not optimized. | Reorient the position of the 3D file in Print Studio to minimize the support material or place the support material on a non-critical surface. |

| Spaghetti mess at end of build. | A layer of your object did not stick properly, model was saved with minimal surface area contacting the build platform, or object was built floating above the build platform with no support selected. | Use the preview feature in Print Studio to see the first layer height and position. Build with supports when necessary. |

| Z-Gap offset may not be correct and the extruder tip is not properly spaced with the build plate. | Contact customer service on how to calibrate the Z-Gap Offset. | |

| Part only built halfway. | Filament ran out. Filament clogged during build. | Replace filament and resume build. See "No filament coming out". |

| No filament coming out. | Clogged extruder. | Contact customer service. |

| Filament not properly loaded. | Try running a filament change again to ensure the extruder gears have properly caught the filament. | |

| Extruder will not home. | Contact customer service. | |

| Stringy or fraying plastic layers on steep overhangs. | Object overhangs are too far apart or too steep (<45 degree angle). | Build with supports. |

| 3D45 will not find my Wi-Fi network. | Printer too far from wireless router. | Reposition 3D45 to be closer to your router. Connect to network with Ethernet |

| 3D45 will not connect to my network. | Printer too far from wireless router. | Reposition 3D45 to be closer to your router. |

| Network password or SSID incorrect | Re-enter your password/SSID or verify your password with your network owner. | |

| 3D45 will not retrieve a token. | Network password incorrect. | Re-enter your password or verify your password with your network owner. |

| Network has a firewall. | Enter network proxy information. | |

| Cloud slicer will not connect to 3D45 or shows "printer offline". | 3D45 not connected to network. | Check 3D45 network settings and retry connection. |

| Token invalid. | Verify the current 3D45 token using "Tools/About" and retry. | Use "Get new token" to generate a new token and retry connection. Note this will remove any users that are sharing your printer. |

| Build did not start when sent over network. | Filament ran out. | Load additional filament and resume build. |

| Doors open. | Doors must be closed to start builds over your network, start build from print queue. | |

| Model was already building | The build plate must be clear to start a build over your network, clear the build plate and start build from print queue. |

Firmware & Open Source Software

Firmware Updates

Dremel recommends that firmware be updated whenever

Dremel provides an update. Dremel will provide firmware updating to improve performance and add additional features for the 3D45 throughout the life of the product. There are two ways of updating the 3D45:

- Download update from www.digilab.dremel.com and install using USB memory drive.

- Connect the 3D45 to the internet and update from the 3D45 touch screen.

Open Source Software used in this product

This product contains software components that are licensed by the holder of the rights under any version of the GNU General Public License (GPL), GNU Lesser General Public License (LGPL) or any other open source software license which requires that source code be made available. You can receive a complete machine-readable copy of the corresponding source code by sending a written request to:

Dremel

Attn: Open Source Software Officer

P.O Box 081126

Racine, WI USA 53408-1126 Your request should include:

- the name of the Dremel product,

- the serial number (if applicable),

- the software version (if applicable),

- your name,

- your company name (if applicable) and

- your return mailing and email address (if available).

We may charge you a nominal fee to cover the cost of the physical media and distribution.

You may send your request

- within three (3) years of the date you received the product that included the software which is subject of your request or

- in the case of code licensed under the GPL version 3 for as long as Dremel offers spare parts or customer support for that product.

Safety Symbols

The definitions below describe the level of severity for each signal word. Please read the manual and pay attention to these symbols.

| This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death. |

| DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury. |

| WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury. |

| CAUTION, used with the safety alert symbol, indicates a hazardous situation which, if not avoided, will result in minor or moderate injury. |

General Safety Warnings

Read all instructions in this manual and familiarize yourself with the Dremel 3D45 before setup and use. Failure to comply with the warnings and instructions may result in fire, equipment damage, property damage, or personal injury.

READ ALL INSTRUCTIONS

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

Work Area Safety

Keep work area clean and well lit. Cluttered or dark areas invite accidents.

Do not operate Dremel 3D45 in the presence of flammable liquids, gases or dust. Dremel 3D45 creates high temperatures which may ignite the dust or fumes.

Store idle 3D45 out of reach of children and other untrained persons. Injury can occur in hands of untrained users.

Electrical Safety

Avoid using this product during an electric storm. There may be a remote risk of a power surge from lightning that may result in electric shock hazard.

In case of emergency unplug Dremel 3D45 from outlet.

Personal Safety

Stay alert, watch what you are doing and use common sense when operating a Dremel 3D45. Do not use Dremel 3D45 while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating Dremel 3D45 may result in personal injury.

Use personal protective equipment. The use of protective equipment such as heat resistant gloves and safety glasses will reduce the risk of personal injuries.

Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in moving parts.

Dremel 3D45 Use and Care

Before every use check Dremel 3D45 for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the Dremel 3D45's operation. If damage is suspected have the Dremel 3D45 repaired by authorized Dremel service center before use. Use of Dremel 3D45 when damaged may result in poor quality of object creation, further equipment damage, property damage or personal injury.

Do not touch the extruder tip or heated build platform during Dremel 3D45 operation or until it has cooled down to at least 60°C (140°F). Contact with the extruder tip or build platform during or after operation before tip and build plate has cooled may result in personal injury.

Set up the Dremel 3D45 in a well-ventilated area. Place Dremel 3D45 printer on flat nonflammable surface and away from flammable materal. Provide at least 8 inches of unobstructed spacing around Dremel 3D45. Dremel 3D45 melts plastic during building. Plastic odors emitted during Dremel 3D45 operation may irritate eyes and airways. Locating Dremel 3D45 close to surrounding objects prevents proper ventilation.

Do not reach inside the Dremel 3D45 while it is in operation. Contact with Dremel 3D45 moving parts during operation may result in poor build quality, equipment damage or personal injury.

Always monitor the Dremel 3D45 during operation. Use of Dremel 3D45 by persons unfamiliar with these warnings and instructions may result in equipment or property damage and personal injury.

Use only DREMEL filament. Use of filament not authorized by Dremel may result in equipment, property damage, or personal injury.

Do not adjust extruder/nozzle setting to exceed the maximum rated temperature of the filament type being used. Heating filament above recommended range can cause emissions that may result in personal injury.

Ensure small objects created by Dremel 3D45 are not accessible to young children. Small objects are potential choking hazards for young children.

Do not create illegal or inappropriate objects using Dremel 3D45.

Do not use Dremel 3D45 to create objects intended for food or drink applications such as preparation, decoration, storage, or consumption. Such use of objects created by Dremel 3D45 may result in illness or personal injury.

Do not use Dremel 3D45 to create objects intended with use with components or housings of electrical components. Dremel filament is not suitable for electrical applications. Such use of objects created by Dremel 3D45 may result in property damage and personal injury.

Do not put plastic objects in or around your mouth. Dremel filament is not suitable for food or drink preparation and food utensils. Such use of objects created by Dremel 3D45 may result in illness or personal injury.

Do not use Dremel 3D45 to create objects intended for chemical storage. Dremel filament is not suitable for chemical storage. Such use of objects created by Dremel 3D45 may result in property damage and personal injury.

Do not modify Dremel 3D45 or alter factory settings. Modifications may result in equipment and property damage, and personal injury.

Do not expose Dremel 3D45 to temperatures exceeding 70°C (158°F). Dremel 3D45 may become damaged. Dremel 3D45 is intended to operate in temperature between 16-29°C (60 - 85°F).

Do not move or bump Dremel 3D45 or the extruder during operation. The object may build incorrectly.

Do not change filament spool unless the building process is completed, stopped, or paused. Changing the filament during building will cancel the object and may damage the extruder.

Do not pull the filament out. Doing so may damage the extruder.

Use extra care not to damage the extruder tip when clearing debris. Dremel 3D45 will not work properly with damaged extruder tip and will require replacement.

Before every build make sure that the build platform is covered with Dremel specified glue. Use of improper glue may result in equipment damage and poor object build quality.

Be aware of your body position when using hand tools to remove objects from the build platform. Sudden tool slip and improper body position during object removal from the build platform may result in personal injury.

Avoid scratching the build platform when removing objects. Scratches in the build platform will result in improper object creation.

Do not drop the build platform. Tempered glass plate may break and result in personal injury.

Do not remove tempered glass plate from plastic holder. Contact with tempered glass plate edge may result in personal injury.

Do not twist or bend the build platform while removing objects. Tempered glass plate may separate from plastic holder and result in personal injury.

Dremel is not responsible for structural integrity or utility of objects created using Dremel 3D45. Structural models created by inexperienced designers may result in property damage and personal injury.

Service

Always unplug Dremel 3D45 from its power before performing any service procedures. Failure to do so may result in personal injury and equipment damage.

Have your Dremel 3D45 serviced only by an authorized Dremel service center using only Dremel replacement parts. This will ensure that proper operation and safety of Dremel 3D45 is maintained.

Use only Dremel approved components. Use of components other than genuine Dremel components may void warranty.

Use only Dremel approved filament. Damage to the product resulting from use of filament other than Dremel approved filament is not covered under warranty.

Dremel Limited Warranty

| CONTINENTAL UNITED STATES | CANADA | |

| Dremel Service Center 4915 21st Street Racine, WI 53406 Phone: 1 (800) 437-3635 | Giles Tool Agency 47 Granger Av. Scarborough, ON M1K 3K9 Phone: 1-416-287-3000 | West Coast Tool 4008 Myrtle Street Burnaby, B.C. V5C 4G2 Phone: 1-604-873-5394 |

| OUTSIDE CONTINENTAL UNITED STATES See your local distributor or write to Dremel, 4915 21st Street Racine, WI 53406. | ||

Imported for Dremel in the U.S. by:

Robert Bosch Tool Corporation

1800 West Central Road

Mount Prospect, Illinois 60056

Call Toll Free for Consumer Information & Service Locations

1-844-4DRML3D (1-844-437-6533) www.digilab.dremel.com

Documents / Resources

References

![www.digilab.dremel.com]() Dremel Tools - Rotary, Saws, Oscillating and more | Dremel

Dremel Tools - Rotary, Saws, Oscillating and more | Dremel![digilab.dremel.com]() Dremel Tools - Rotary, Saws, Oscillating and more | Dremel

Dremel Tools - Rotary, Saws, Oscillating and more | Dremel

Download manual

Here you can download full pdf version of manual, it may contain additional safety instructions, warranty information, FCC rules, etc.

Advertisement

Need help?

Do you have a question about the 3D45 and is the answer not in the manual?

Questions and answers