Subscribe to Our Youtube Channel

Summary of Contents for Dynapac REDLINE DRA30

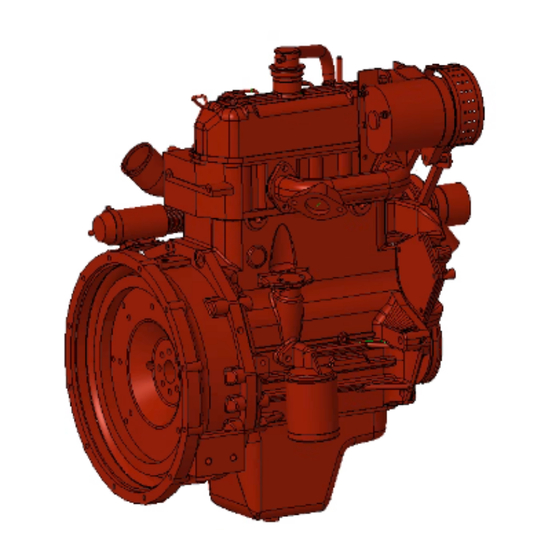

- Page 1 ENGINE OPERATION MANUAL DRA30 SERIAL NUMBER: 10300619HME011517 ENGINE: Dynapac- 275 DI TU PART NUMBER: 4812333214_A-EN...

- Page 2 Manual Revisions Table 1: Revision History Sr no Date Revision Dec’ 2021 New Released...

- Page 3 FOREWORD Dear Customer, We are happy to provide you with latest revision of Dynapac Engine 275 DI-TU O & M manual. The Dynapac 275 DI-TU series Engine liquid cooled are developed and supplied for wide range of application meeting your requirements.

- Page 4 Important note: The information contained within this publication is given with our best intensions and are believed to be correct at the time of going to the press. Our policy is one of continued development and we reserve the right to amend any technical information with or without prior notice.

- Page 5 TABLE OF CONTENTS WARRANTY POLICY……………………………………………………………………………………………….1 TECHNICAL SPECIFICATIONS………………………………………………………………………………….3 Engine Technical Specification…………………………………………………………………..3 Torque Chart Component………………………………………………………………………….4 PREPARING ENGINE FOR WORK……………………………………………………………………………5 Inspection before Starting Engine……………………………………………………………..5 OPERATING INSTRUCTIONS………………………………………………………………………………….7 New Engine……………………………………………………………………………………………….7 Pre-starting Instruction……………………………………………………………………………..7 Normal Starting Procedure………………………………………………………………………..8 Warm up……………………………………………………………………………………………………8 Engine Speed……………………………………………………………………………………………..8 Oil Pressure……………………………………………………………………………………………….8 Water Temperature…………………………………………………………………………………..8 Engine Exhaust…………………………………………………………………………………………..8 Engine Shut Down…………………………………………………………………………………….9 Trial Run……………………………………………………………………………………………………9 PREVENTIVE MAINTENANCE…………………………………………………………………………………10...

- Page 6 This warranty applies to the Dynapac 275 DI-TU Series Engine for off Highway application. Duration of Warranty Off Highway Engines - Within 18 Calendar Months from Date of Dispatch from Dynapac India 12Months of hours date of installation or 1500 Hrs of operation whichever occurs first if customer source the filters, Engine oil, coolant and avail the services from Dynapac Authorised Service dealer for off Highway application.

- Page 7 *Dynapac recommends use of Engine oil, Coolant & Dynapac genuine filters to be used in engine. *Dynapac will provide for 5 free service checks (Namely C1, M1, M2, M3 & M4) for off highway application. For availing free service checks contact nearest Dynapac authorised service dealer...

- Page 8 Owner’s Manual TECHNICAL SPECIFICATIONS Engine Technical Specification MDI – BS III Model 275 DI TU Type 4Storke, DI Water cooled Aspiration No. Of Cylinder Bore (mm) 68.9 Stroke (mm) 101.6 Volume (cc) 1892 RATED POWER RATED SPEED(RPM) 2600 FLY UP RPM 2850 +/- 50 IDLING RPM 800 +/-50...

- Page 9 Owner’s Manual Torque Chart Component...

- Page 10 Cooling System ▪ Check coolant level in radiator as well as recovery bottle. ▪ Ensure ‘Dynapac recomended Coolant' is filled. ▪ Recovery bottle to be topped up only up-to max mark. ▪ Cap of recovery bottle should be securely fixed.

- Page 11 Priming the Lubrication System Fill the Dynapac recommended oil in the oil sump. Crank the engine at least for 15 second s with fuel shut off conditions. Check that oil has reached up to all points in tappets. (Remove tappet cover).

- Page 12 Dynapac Diesel Engine. New Engine Dynapac engines are tested on dynamometers before being shipped from the factory and are ready to be put to work. But the operator has an opportunity to establish conditions for optimum service life during initial 100 hours of operation by: 1.

- Page 13 CAUTION: If the pressure at any time, drops below 2 kg/cm at minimum operating speed of 1500 rpm, under loaded condition, then replace the lube oil filter element / cartridge and check the pressure. If the pressure is still low, then contact our Dynapac Dealer for the services of their technicians. Water Temperature A water temperature of 82°Cto 95°Cis the best assurance that working parts of engine have expanded to most...

- Page 14 Owner’s Manual Engine Shut Down ▪ Run the engine in idle condition for a few minutes before shut down. It is important to idle an engine 3 to 5 minutes before shutting it down to allow lubricating oil & water to carry heat away from the combustion chamber, bearings, shaft etc.

- Page 15 Owner’s Manual PREVENTIVE MAINTENANCE Maintenance is the key to lower operating costs. A diesel engine requires regularly scheduled maintenance to keep it running efficiently. Maintenance Schedule Preventive maintenance is the easiest and least expensive type of maintenance. It permits the Maintenance Department to do the work at a convenient time.

- Page 16 Owner’s Manual Paper element filter This screens the fine impurities. This has to be cleaned by compressed air during every service or earlier if required. The filter should be replaced after every 1000 hours or earlier if required. Safety Cartridge Safety Cartridge fits inside the paper element filter.

- Page 17 To prevent rust formation in sleeve cylinder, water pump, cylinder block, Radiator tube & other parts of cooling system, “Dynapac coolant” is recommended. Continuous usage of the solution will ensure increased efficiency & increase life of the cooling system. During repair if for any reason coolant is to be removed, collect the solution in clean vessel &...

- Page 18 Owner’s Manual Hose Connections • Inspect the hoses for cracks &damages. Replace if necessary. • Check clips are tight &no leakage. • Replace Coolant. Flush the cooling system at 1000 hrs. or one year, whichever is earlier. Flushing of Cooling System Draining the System There are two drain taps which must be opened, one is to the left hand said of the crankcase and one on the bottom tank of the radiator.

- Page 19 Owner’s Manual Lubrication System To prevent excessive friction and heat generation between any two surfaces in relative motion with respect to each other, an oil or lubricant film is required in between the two. Lubricant oils mainly have the following additives: ▪...

- Page 20 Owner’s Manual Fuel System Providing clean and adequate supply of fuel to the engine is the prime function of the fuel system. Service Instructions: ▪ Drain the sediment from fuel filter from the drain plugs. ▪ Do not permit dirt to get into fuel tank.

- Page 21 Owner’s Manual Exhaust System The Exhaust System is designed to remove the exhaust gases from the Engine into the atmosphere. CAUTION: Do not run the engine with disconnecting the silencer. Service Instruction Silencer is required to be cleaned if the back pressure exceeds to 70 mm of Hg. Electrical System Maintaining the electrical system in good working order will enable the alternator to provide the battery with the flow of current needed to keep it fully charged thus ensuring maximum efficiency of...

- Page 22 Owner’s Manual Checking Specific Gravity of Electrolyte: Check the specific gravity of Electrolyte with a hydrometer five min. after adding distilled water. SPECIFIC GRAVITY (Kg/Ltr) STATE OF CHARGE NORMAL TROPICS 1.280 1.230 Fully charged. 1.200 1.112 Half charged / recharging. 1.120 1.080 Discharge / Charge up immediately.

- Page 23 Owner’s Manual Preventive Maintenance Schedule -18-...

- Page 24 Owner’s Manual CHECKING OF SENSORS Checking of HWT ▪ Remove the wiring connector of the HWT ▪ Connect with Body to check if the wiring connection of HWT is To separately check the HWT sensor, its resistance value MULTIMETER should be checked by a multimeter. sensor With temperature increase then the resistance decreases.

- Page 25 In extremely arduous conditions, however, it may be necessary to reduce these periods and this point should be discussed with Dynapac or with authorised service dealers Recommended Lubricating Oil Dynapac recommends the use of Dynapac Engine Oil .

- Page 26 Owner’s Manual SAFETY PRECAUTIONS AND DO’S / DONT’S The following precautions are suggested to help prevent accidents. A careful operator is the best operator. Most accidents can be avoided by observing certain precautions. Read and take the following precautions before operating the Engine to prevent accidents. Engine should be operated only by those who are responsible and instructed to do so.

- Page 27 Keep all fuel in clean storage and use a filter when filling the tank. ▪ Attend to minor adjustments and repairs as soon as necessity is apparent. When in doubt, consult Dynapac service dealer ▪ Allow the Engine to cool before removing the radiator filler cap and adding water. Remove the radiator cap slowly.

- Page 28 Owner’s Manual FAULT TRACING If any trouble is experienced, make sure of the cause before attempting to make any adjustments. When making adjustments keep in mind the previous setting, in case, the adjustment brings no remedy. PROBABLECAUSE POSSIBLE REMEDY ENGINE FAILS TO START Faulty Starter Switch Replace Battery too low to run engine...

- Page 29 Owner’s Manual PROBABLECAUSE POSSIBLE REMEDY LUBRICATING OIL PRESSURE TOO HIGH OR TOO LOW Defective oil pressure indicator Replace Wrong viscosity, diluted or insufficient oil Refer to LUBRICANT SPECIFICATIONS. Select correct grade of oil. Broken, loose or plugged oil lines Replace, clean and tighten. * Low oil level in the crankcase Add all an check for oil leakage Defective or dirty oil pressure regulating valve...

- Page 30 Owner’s Manual -25-...

- Page 31 Dynapac road construction India Pvt ltd. Pune, India.

Need help?

Do you have a question about the REDLINE DRA30 and is the answer not in the manual?

Questions and answers