Advertisement

Quick Links

Advertisement

Summary of Contents for IBEA IB 621

- Page 1 Safety and operation instruction IB 621...

- Page 2 - 2 -...

- Page 3 - FLAIL MOWER MANUAL - CONTENTS USE OF THE MANUAL..............page 4 NOTICE ON THE MACHINE...............page 5 TECHNICAL DATA................page 8 LIFTING AND TRANSPORTATION.............page 9 MAIN PARTS OF THE MACHINE............page 10 CONTROLS AND ADJUSTMENTS.............page 12 ASSEMBLY INSTRUCTIONS FOR THE HANDLEBARS AND FRONT SUPPORT WITH WHEELS............page 14 SAFETY INFORMATION A) GENERAL INSTRUCITONS............page 15...

- Page 4 Operating and Safety Instruction FLAIL MOWER MOD. IB 621 FOREWORD This machine may only be utilized for the purpose for which it was designed, i.e. agricultural use, for the cutting of shoots, grass and brushwood. Any other use other than that stated, not covered or deducible from this Manual and the enclosed Engine Manual is "PROHIBITED".

- Page 5 NOTICE ON THE MACHINE The symbols affixed to the machine serving to warn of danger during its use and maintenance are as follows: THE USER MUST READ THE INSTRUCTION MANUAL PROVIDED DANGER OF FOREIGN OBJECTS BEING THROWN OUTWARDS. KEEP A SAFE DISTANCE ALWAYS DISCONNECT THE CABLE FROM THE ENGINE SPARK PLUG.

- Page 6 DANGER OF CRUSHING. KEEP A SAFE DISTANCE DANGER OF INJURY TO BOTH UPPER AND LOWER LIMBS. DO NOT PUT HANDS OR FEET INSIDE THE CUTTING ELEMENT WHILE IN MOTION DANGER OF GETTING CAUGHT UP IN ROTATING PARTS. DO NOT PUT HANDS IN THE ROTATING PARTS DANGER OF FOREIGN OBJECTS BEING THROWN OUTWARDS.

- Page 7 EAR MUFFS MUST BE WORN. DO NOT ALLOW CHILDREN NEAR THE MACHINE WHEN IN OPERATION. CAUTION: HOT PARTS. DANGER OF BURNS. FIRE HAZARD The symbols affixed to the machine serve to warn of danger during its use and maintenance. It is vitally important to understand the meaning of the danger notices and all messages should be kept in legible condition.

- Page 8 1 3 8...

- Page 9 LTITUDE The altitude of the place in which the machine is to be used must not exceed 1500 m above sea level. EMPERATURE Minimum ambient temperature: -5°C Maximum ambient temperature: +50°C TMOSPHERIC ONDITIONS The electrical equipment will function correctly in atmospheric conditions with a relative humidity up to 50% at a temperature of 40°C and at 90% with a temperature up to 20°C (without condensate).

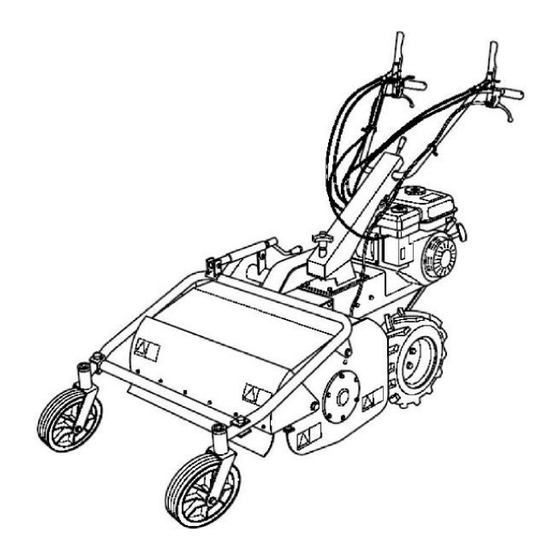

- Page 10 5. MAIN PARTS OF THE MACHINE The machine consists of the following main parts: FORWARD CLUTCH CONTROL LEVER ACCELERATOR CONTROL LEVER PINS TO BLOCK/RELEASE THE FRONT WHEELS FLAIL ROTOR CLUTCH CONTROL LEVER RIGHT WHEEL RELEASE LEVER E1 - LEFT WHEEL RELEASE LEVER ENGINE FRONT WHEELS FRONT GUARD...

- Page 11 Figure 1 Figure 2 - 11 -...

- Page 12 6. CONTROLS AND ADJUSTMENTS A) FORWARD CLUTCH CONTROL LEVER This lever only has two positions: engage and disengage. Lowering the lever engages the clutch and releasing it disengages the clutch. The service brake is connected to this lever. The brake operates automatically when the clutch is disengaged. B) ACCELERATOR CONTROL LEVER This is used to adjust the number of engine revolutions according to the operations to be carried out.

- Page 13 H) FRONT GUARD The front guard (Fig. 1 Ref. H) opens or closes automatically according to the amount of grass to be cut. Use of the machine with the guard left open is strictly prohibited. This may cause the outward projection of objects. The guard may only be set in the open position during flail replacement operations with the machine switched off.

- Page 14 7. ASSEMBLY INSTRUCTIONS FOR THE FRONT SUPPORT WITH WHEELS The flail mower is delivered with the front support with wheels disassembled. Remove the cardboard packaging or crate (to be disposed of in an appropriate manner, in accordance with current regulations in force). To assemble, proceed as follows : ...

- Page 15 8. SAFETY INFORMATION Before using the flail mower it is essential that the operator has understood the warnings, do’s and don’ts and precautionary measures given in this manual and in the engine manual: the prevention of injury to the operator, third parties, animals or objects directly depends on observance of these instructions.

- Page 16 Do not switch on and operate the flail mower in enclosed areas since the engine gives off carbon monoxide fumes which are colourless, odourless, tasteless and extremely dangerous. Take care when handling fuel. Fuel is highly flammable and its vapours explosive : - Only use an approved container.

- Page 17 When working in a stony or obstacle-riddled area try to remove as many objects as possible before commencing cutting. Then work at a greater cutting height than usual. WARNING Stones and other objects may be thrown outwards in direction of the operator or of other persons in the vicinity.

- Page 18 9. TRANSPORTATION OF THE MACHINE LOADING AND UNLOADING FROM A VEHICLE For transportation it is pReferable to use a vehicle with an open bed. Choose firm, flat ground. Switch off the vehicle’s ignition, put into reverse gear, pull on the hand brake and block the tyres with chocks to prevent accidental movement of the vehicle.

- Page 19 10. SAFETY AND GUARD SYSTEMS WARNING The safety devices must never be tampered with. It is necessary to understand how they work and safeguard their efficiency and correct operation. In the instance of doubt, prob- lems or malfunction contact your dealer. FORWARD CONTROL AND FLAIL MOVEMENT LEVERS When released both of these levers instantly disengage the transmission connected to them, thus automatically engaging their respective brakes, hence the machine service brake in the...

- Page 20 12. STARTING AND DRIVING THE FLAIL MOWER The machine can be switched on once all the aforementioned preliminary operations have been carried out. Place the feed cock in the OPEN position (direction shown by the arrow, Fig. 4). Bring the choke to the CLOSED position for a cold start (direction shown by the arrow, Fig.

- Page 21 DRIVING THE MACHINE WARNING When using the machine for the first time it is advisable to get the feel of it by executing manoeuvres on flat ground free of foreign objects. Cut in a straight line at low speed, slightly overlapping the section cut previously. After switching on the engine following the instructions given in the previous paragraph: 1.

- Page 22 13. CUTTING TIPS 1. Before commencing cutting operations, read the safety instructions given in the previous sections. 2. Before engaging flail movement using the relative lever ( Figure 1 Ref. D) the guard (Fig. 1 Ref. H) must be fully lowered to prevent the outward projection of objects. 3.

- Page 23 14. CHECKS Adjust the belt and cable control tension after the first few working hours to compensate initial loosening. Briefly operate all the machine's components to detect any abnormal noises or overheating. During the initial running in period avoid heavy-duty usage to encourage proper settling of the mechanical parts.

- Page 24 B) CABLE CONTROL ADJUSTMENT To adjust the cables place the machine on flat ground, switch off the engine and disconnect the wire from the spark plug. B1) RIGHT AND LEFT WHEEL RELEASE CABLES Reset the setting screws on the release lever cables to zero, so they are screwed down completely (Fig 5 Ref G).

- Page 25 Figure 5 Forward lever Forward cable Forward brake cable Rotor engagement lever Rotor brake cable Rotor engagement cable Wheel release cable Wheel release lever Adjustment screw for release cable - 25 -...

- Page 26 C) BRAKE ADJUSTMENT To adjust the brake cables place the machine on a flat surface, switch off the engine and disconnect the spark plug wire. C1) ROTOR BRAKE Loosen and remove the screw (Fig. 7 Ref. B). Remove the brake adjustment device (Fig. 7 Ref. A ). Shorten or lengthen the threaded pin as necessary (Fig.

- Page 27 D) BELT REPLACEMENT AND ADJUSTMENT If a belt breaks or becomes worn it is advisable to change both belts connected to the engine at the same time. The replacement of just one belt alone may give rise to adjustment problems. Conversely, the blade rotor control belt is completely independent of the others, so for its replacement or adjustment carry out the following: D1) BLADE ROTOR DRIVE BELT...

- Page 28 D2) FORWARD BELT Remove the brake adjustment device (Fig.7 Ref. A) by unscrewing the screw (Fig. 7 Ref. B), slip off the rotor engagement belt (Fig.12 Ref. A) by turning the engine pulley anticlockwise. Slip off the “FORWARD” belt (Fig. 11 Ref. A) from the large pulley side (Fig. 11 Ref. B) , by turning the engine pulley anticlockwise (Fig.

- Page 29 D3) ROTOR ENGAGEMENT BELT The rotor engagement belt should only be replaced and adjusted after having first replaced the forward belt( point D2) Remove the belt (Fig. 12 Ref. A) turning the engine pulley (Fig. 12 Ref. C) anticlockwise. Fit the new belt by slipping it onto the large pulley (Fig.

- Page 30 E) CHECKING AND REPLACING THE FLAILS Always check the state of the flails before commencing work. Do not forget to switch the engine off! Checking and replacement of the flails requires the assistance of another person to hold the handlebars down to tilt up the front part of the machine. The flails will be presented as shown in Figure 15.

- Page 31 To remove the flails proceed as follows: 1. Switch off the engine and disconnect the spark plug wire 2. Adjust the cutting height to maximum 3. Open the front housing. 4. Check the state of the flails. 5. Check that the flails are not cracked, bent, excessively worn or broken. If they are, either reverse them (turning them 180°) or replace them.

- Page 32 G) CHECKING AND REPLACING THE TRANSMISSION OIL Check the transmission oil level using the relative level cap (Fig. 16 Ref. A). If oil leaks out upon removal of this cap then there is enough of it in the transmission. If not, remove the filling cap shown in Fig.

- Page 33 15. MAINTENANCE AND STORAGE All operations on the machine must be carried out exclusively by authorized personnel. Always switch off the engine when checking, adjusting or servicing the machine. Allow the machine to cool down before inspection. ...

- Page 34 16. CLEANING THE MACHINE Proceed in the following order: Switch off the engine and disconnect the spark plug wire; Clean the engine and the outside of the machine with a cloth soaked in a little oil. Clean all parts of the machine, particularly the starting unit, air filter, exhaust and carburetor.

- Page 35 18. DECOMMISSIONING AND SCRAPPING After the working life of the flail mower the user must have it dismantled and its components removed as per EEC directives or in accordance with current legislation in force in his country, taking particular care over the dismantling of the following materials of environmental impact: plastic parts rubber parts...

- Page 36 21. CE MARKING The plate bearing the CE mark gives the main characteristics and information for the identification of the flail mower. Manufacturer’s details Machine model Serial number Year of construction Capacity in kW Weight in kg The above information must not be altered or modified in any way. It is up to the user to keep the plate clean, legible and in good condition.

- Page 37 22. TROUBLESHOOTING The following table illustrates some problems which may arise during operation. FAULT CAUSE MEASURES TO BE TAKEN Grass ejection insufficient 1. Grass wet Wait until the grass has dried 2. Grass too long Go over the grass twice, changing the cutting height 3.

- Page 38 ENGINE FAULT CAUSE MEASURES TO BE TAKEN Engine sluggish at switch on accelerator not in start-up 1. move the accelerator to the position intermediate position Choke not closed 2. Close the choke when cold. Petrol does not arrive 3. Check the fuel tank and remove water sediment.

- Page 39 NOTES _________________________________________________________________ _________________________________________________________________ _________________________________________________________________ _________________________________________________________________ _________________________________________________________________ _________________________________________________________________ _________________________________________________________________ _________________________________________________________________ _________________________________________________________________ _________________________________________________________________ _________________________________________________________________ _________________________________________________________________ _________________________________________________________________ _________________________________________________________________ _________________________________________________________________ _________________________________________________________________ _________________________________________________________________ _________________________________________________________________ _________________________________________________________________ _________________________________________________________________ _________________________________________________________________ _________________________________________________________________ _________________________________________________________________ _________________________________________________________________ _________________________________________________________________ _________________________________________________________________ _________________________________________________________________ - 39 -...

- Page 40 The undersigned manufacturer and depositary of the documentation : IBEA SRL VIA MILANO, 15/17 21049 TRADATE (VA) ITALY Hereby declares under its own responsibility that the new machine type : FLAIL MOWER model : IB 621 serial number starting 160001 from: year of 2016 manufacture : 4,1kW...

- Page 41 - 41 -...

- Page 42 - 42 -...

- Page 43 - 43 -...

- Page 44 IBEA s.r.l. Via Milano, 15/17 - 21049 Tradate (VA) Tel. 0331-1586940 - Fax 0331-1582268 email ITALY : ibea@ibea.it email EXPORT : export@ibea.it www.ibea.it...

Need help?

Do you have a question about the IB 621 and is the answer not in the manual?

Questions and answers