Summary of Contents for Welch MPC 303 Z

- Page 1 Operation Manual (EN) Translation of the german original manual Diaphragm pumps 2 - headed Models: ► MPC 303 Z 415722-40 2022-08-27...

- Page 2 F +49 3677 604 131 without the prior written permission of Co. Gardner Denver Thomas GmbH. welch.emea@gardnerdenver.com www.welchvacuum.com All rights under the copyright laws are expressly reserved by Co. Gardner Customer Support +49 3677 604 0 Denver Thomas GmbH.

-

Page 3: Table Of Contents

Contents Contents Important Information ................. 5 General Information ..................5 Target Groups ....................5 Intended Use ....................5 Use for an Unauthorized Purpose ..............6 Safety Devices ....................6 Meaning of the Warning notes ............... 6 Basic Safety Instructions ................7 General Information .................. - Page 4 Spare parts view MPC 303 Z ..............22 8.2.1 Spare parts list diaphragm pumps MPC 303 Z ..........23 - Instructions for certification - Diaphragm Pumps MPC - for use in Zone 2 in accordance with device category 3 per ATEX Directive...

-

Page 5: Important Information

Important Information Important Information General Information The Diaphragm Pumps conform to the following directives: 2006 / 42 / EC Machinery Directive 2014 / 30 / EU Electromagnetic Compatibility Directive ATEX Guideline for use in potentially explosive atmospheres, 2014 / 34 / EU Appendix III The CE sign is located on the rating plate. -

Page 6: Use For An Unauthorized Purpose

Important Information Use for an Unauthorized Purpose It is forbidden to use the pump for applications deviating from the technical data stated on the type plate or the conditions stated in the supply contract, or to operate it with missing or defective protective devices. -

Page 7: Basic Safety Instructions

Basic Safety Instructions Basic Safety Instructions General Information Warning notices must be observed. Disregarding them may lead to damage to health and property. The diaphragm pumps must be operated by personnel who can detect impending dangers and take action to prevent them from materialising. The manufacturer or authorized workshops will only service or maintain the diaphragm pump if it is accompanied by a fully completed damage report. -

Page 8: Hazardous Substances

Basic Safety Instructions CAUTION ! Solid particles in the pumping medium impair the pumping action and can lead to damage. Prevent solid particles penetrating into the pump. Hazardous Substances The operating company bears the responsibility for the use of the diaphragm pump. Hazardous substances in the gases to be pumped can cause personal injuries and property damage. -

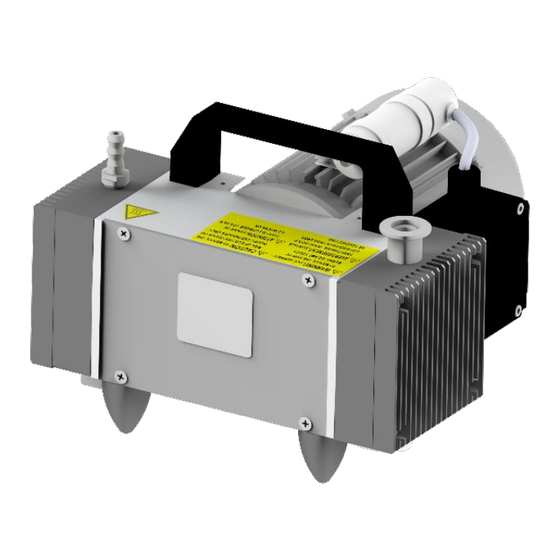

Page 9: Description

1 to 2 stage pumps are supplied, depending upon the circuitry of the pump heads. Fig. 1 Diaphragm pump MPC 303 Z Principle of Operation Motor, eccentric shaft and connecting rod set the form diaphragms in stroke movement. This changes the size of the space between the form diaphragms and pump head (pump cham- ber). -

Page 10: Pump Head Circuitry

Two-stage (Z): Both pump heads are connected in series. Ultimate pressure: < 5 mbar Model: MPC 303 Z Special designs: • Special diaphragm pumps can be supplied after consultation with the manufacturer or for a corresponding supply contract. Explosion protection motors. -

Page 11: Technical Data

Small flange DN 16 KF (hose nozzle(s) DN 8 for fitting, enclosed) Exhaust port Hose nozzle DN 8 Fig. 3 Dimensions (MPC 303 Z) Intake Pressure / Pumping Speed – Diagram Fig. 4 Intake Pressure / Pumping Speed - Diagram... -

Page 12: Device Data

Technical Data Device Data Diaphragm pump models Parameter Unit MPC 303 Z (two-stage) Pumping speed 50/60 Hz 2.0 / 2.2 DIN 28432 l / min 33.3 / 36.6 at speed of 1500 rpm Ultimate pressure < 5 at speed of 1500 rpm... -

Page 13: Installation And Operation

Installation and Operation Installation and Operation Unpacking Carefully unpack the diaphragm pump. Check the pump for: Transport damage, • Conformity with the specifications of the supply contract (model, electrical supply • data), • Completeness of the delivery. Please inform us without delay if there are discrepancies between the delivery and the con- tractually agreed scope of delivery, or if damage is detected. -

Page 15: Maintenance And Servicing

Maintenance and Servicing Maintenance and Servicing General Requirements Check the diaphragm pump daily for unusual running noises and heat building up on • the surface of the pump. • We recommend the changing the diaphragm annually, with 8 hours of operation per workday. -

Page 16: Disassembly

6. Clean the valves (7), the pump head (5) and the form diaphragm (9) with a soft cloth and acetone. 7. Check that the drive is in good working order. Fig. 5 Disassembly, assembly (MPC 303 Z) WARNING ! Renew defective parts, if necessary! Wear protective gloves! -

Page 17: Test

Maintenance and Servicing 6.2.3 Test Connect a vacuum measuring device to the suction connector and measure the • ultimate pressure. If the device is working properly, then the figure stated in the technical data must be attained within a maximum of one minute. •... -

Page 19: Troubleshooting

Troubleshooting Troubleshooting During the warranty period, intervention in the diaphragm pumps and accessory components may only be made by manufacturing firm. Remedy Trouble Cause with: Qualified No power supply Check electrical installation electrician Vacuum pump does not start Motor defective Exchange Service workshop... -

Page 21: Spare Parts Overview

Spare Parts Overview Spare Parts Overview The spare parts lists contain all the spare parts and all the information necessary for order- ing. When ordering, please quote the description, quantity, serial number and order number! CAUTION ! We are not liable for any damage caused by the installation of any parts not sup- plied by the manufacturer. -

Page 22: Spare Parts View Mpc 303 Z

Spare Parts Overview Spare parts view MPC 303 Z Fig. 6 Exploded view MPC 303 Z Operation Manual... -

Page 23: Spare Parts List Diaphragm Pumps Mpc 303 Z

Spare Parts Overview 8.2.1 Spare parts list diaphragm pumps MPC 303 Z MPC 303 Z Item 230 V Designation Piece Order no. 415722-40 Order no. - Basic pump complete - *) 410407 (consisting of position: 1 – 9) - Pump casing... - Page 24 Spare Parts Overview Operation Manual...

Need help?

Do you have a question about the MPC 303 Z and is the answer not in the manual?

Questions and answers