Summary of Contents for Jefferson JEFBAN200-08

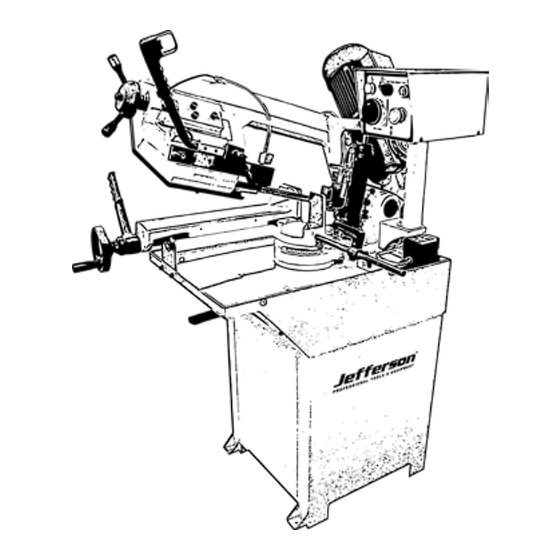

- Page 1 8" SWIVEL HEAD BANDSAW Gearbox-driven • Horizontal • Metal-Cutting 1100W • Single-Phase 230V~50Hz JEFBAN200-08 User Manual v.1.1...

-

Page 3: About This Document

ABOUT THIS DOCUMENT This manual has been compiled by Jefferson Tools and is an integrated part of the product with which it's enclosed and should be kept with it for future reference. Please read all of the information supplied in this User Manual before operating this product. -

Page 4: Equipment Identification

• Fit any additional components supplied (eg. bar-stop rod, roll- supporting arm etc.) contact Jefferson Tools for any advice required. • Position the machine on a firm cement floor, maintaining, at the rear, a minimum distance of 800mm from the wall;... -

Page 5: Safety Guidelines

• Only use Jefferson approved replacement parts. Non-approved parts will void your warranty and can lead to malfunction and resulting injuries. Genuine parts are available from Jefferson or your local dealer. •... -

Page 6: Control Panel

USER MANUAL v1.1 JEFBAN200-08 1100W 8" SWIVEL BANDSAW 230V~50Hz OPERATION GUIDE Control Panel The control panel consists of a series of switches and indication lights to allow you to operate the bandsaw. (as shown in Fig.4): A: Main power switch... -

Page 7: Cutting Capacity

USER MANUAL v1.1 JEFBAN200-08 1100W 8" SWIVEL BANDSAW 230V~50Hz Cutting Capacity The machine has been designed to cut metal building materials, with different shapes and profiles, used in workshops, and general mechanical structural work. Only one operator is needed to use the machine. -

Page 8: Changing The Blade

USER MANUAL v1.1 JEFBAN200-08 1100W 8" SWIVEL BANDSAW 230V~50Hz Checking The Blade Adjustment 1. Use a strip of scrap paper and slide it between the blade and the flywheel while it is running (Fig.14). 2. If the paper is cut then the blade is riding too close to the flange, then readjust. -

Page 9: Daily Maintenance

USER MANUAL v1.1 JEFBAN200-08 1100W 8" SWIVEL BANDSAW 230V~50Hz MAINTENANCE • You can keep the bandsaw well-maintained by carrying out the maintenance tasks outlined below. • Keeping the bandsaw in good condition will help to ensure safe and reliable performance and will increase the lifespan of the saw. -

Page 10: Troubleshooting

3. Wrong tooth pitch. 3. Ensure you are using the correct blade for this saw. Contact Jefferson Tools for advice if required. 4. Chips sticking onto teeth and in the guides or 4. Check for clogging of coolant drain holes on the material that forms a gum. - Page 11 USER MANUAL v1.1 JEFBAN200-08 1100W 8" SWIVEL BANDSAW 230V~50Hz TROUBLESHOOTING FAULT CAUSE REMEDY PREMATURE BLADE WEAR 1. Teeth positioned in the direction oppo site the 1. Turn teeth in correct direction. cutting direction 2. Poor quality blade 2. Use a superior quality blade.

- Page 12 USER MANUAL v1.1 JEFBAN200-08 1100W 8" SWIVEL BANDSAW 230V~50Hz TROUBLESHOOTING FAULT CAUSE REMEDY BLADE BREAKING 1. Blade guide pads not regulated or dirty because 1. Check distance between pads in the blade guide of lack of maintenance. blocks: extremely tight guiding may create tension an result in cracks and tooth damage.

- Page 13 3. The teeth on the blade may be too large for the material. Select a more suitable blade (contact Jefferson Tools for advice.) 4. The blade guide block too far from material to be 4. Approach it as near as possible to material to be cut .

- Page 14 USER MANUAL v1.1 JEFBAN200-08 1100W 8" SWIVEL BANDSAW 230V~50Hz TROUBLESHOOTING FAULT CAUSE REMEDY FAULTY MOTOR 1. "SA1 "speed switch. 1. It must be turned towards position 1 or 2. 2. Band motor temperature relay. 2. Check for current continuity on both wires of the probe after a motor cool ing time of 10-15minutes.

-

Page 15: Wiring Diagram

USER MANUAL v1.1 JEFBAN200-08 1100W 8" SWIVEL BANDSAW 230V~50Hz WIRING DIAGRAM www.jeffersontools.com... -

Page 16: Parts Lists And Diagrams

USER MANUAL v1.1 JEFBAN200-08 1100W 8" SWIVEL BANDSAW 230V~50Hz PARTS LISTS & DIAGRAMS Description Description Base (right part) Shaft Base (left part) Oil seal Hex. cap bolt Set screw Disk Base cover plate Spring washer Hex. cap bolt Hex. socket cap screw... - Page 17 USER MANUAL v1.1 JEFBAN200-08 1100W 8" SWIVEL BANDSAW 230V~50Hz Description Description 90-2 AC connector Blade 90-3 Breaker Knob bolt 90-4 Thermal relay Blade cover 90-5 Terminal block Round head screw 90-6 Ground copper bar Spring washer 90-7 Breaker 138-1 Hex. socket cap screw Hex.

- Page 18 USER MANUAL v1.1 JEFBAN200-08 1100W 8" SWIVEL BANDSAW 230V~50Hz www.jeffersontools.com...

- Page 19 USER MANUAL v1.1 JEFBAN200-08 1100W 8" SWIVEL BANDSAW 230V~50Hz www.jeffersontools.com...

- Page 20 USER MANUAL v1.1 JEFBAN200-08 1100W 8" SWIVEL BANDSAW 230V~50Hz www.jeffersontools.com...

- Page 21 USER MANUAL v1.1 JEFBAN200-08 1100W 8" SWIVEL BANDSAW 230V~50Hz www.jeffersontools.com...

- Page 22 USER MANUAL v1.1 JEFBAN200-08 1100W 8" SWIVEL BANDSAW 230V~50Hz www.jeffersontools.com...

-

Page 23: Environmental Protection

USER MANUAL v1.1 JEFBAN200-08 1100W 8" SWIVEL BANDSAW 230V~50Hz ENVIRONMENTAL PROTECTION Recycle any packaging and unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be sorted, taken to a recycling centre and disposed of in a manner which is compatible with the environment. - Page 24 1100W 8" SWIVEL BANDSAW 230V~50Hz EU / UK DECLARATION OF CONFORMITY We, Jefferson Professional Tools & Equipment, as the authorised European Community representative of the manu- facturer, declare that the following equipment conforms to the requirements of the following: Directive:...

-

Page 25: Limited Warranty Statement

Jefferson will assume both the parts and labour expense of correcting defects during the stated warranty periods below. All warranty periods start from the date of purchase from an authorised Jefferson dealer. If proof of purchase is unavailable from the end user, then the date of purchase will be deemed to be 3 months after the initial sale to the distributor. - Page 26 • A Warranty Returns form will be sent to you for completion and return by post or fax, together with details of your nearest authorised Jefferson repair centre. On receipt of this form Jefferson will arrange to collect the equipment from you at the earliest convenience.

- Page 28 Jefferson Professional Tools & Equipment 24 Lisgorgan Lane, Upperlands BT46 5TE T +44 (0)1244 646 048 (UK) / +353 (0)1473 0300 (ROI): +44 (0)1244 646 048 E info@jeffersontools.com...

Need help?

Do you have a question about the JEFBAN200-08 and is the answer not in the manual?

Questions and answers