Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Rema Tip Top 517 5150

- Page 1 T2 COMPOUND EXTRUDER GUN Operating instructions...

-

Page 2: Table Of Contents

2.5 Risks arising from the use of the extruder • All the information given in this manual refers only to 3. Th e REMA TIP TOP T2-Compound repair system the use of original TIP TOP materials. 3.1 Th e REMA TIP TOP T2-Compound repair system •... -

Page 3: Fields Of Application Of The T2 Compound Extruder Gun

For this purpose, Indications/prohibitions for prevention of only products from the REMA TIP TOP T2-Compound Caution! personal injuries and or severe material damage. Repair System should be used. As to injury preparation,... -

Page 4: Repair/Maintenance

2. Safety instructions / prevention of accidents 3. Th e REMA TIP TOP T2-Compound repair system 2.4 Repair/maintenance 3.1 Th e REMA TIP TOP T2-Compound repair system • Parts and/or accessories have to be replaced only by Advantages: specialists. • Quick and cost-saving repair system. -

Page 5: Description Of The Extruder

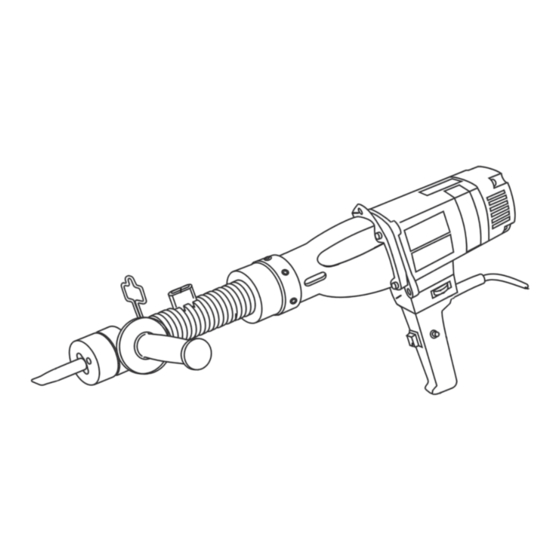

4. Description of the extruder 4.1 Parts and operating elements Fig. 1 Fig. 2 Handle with trigger Handle Locking button for trigger Speed control wheel (SPEED) Torque control wheel (POWER) Main body Feeding hopper Nozzle Fasteners for shoulder strap Mains cable with earthed plug (for 115 V: without plug) Motor and gear box (fi... -

Page 6: Standard Accessories Included

4. Description of the extruder 5. Technical data 4.2 Standard accessories included: 5.1 Technical data • Shoulder strap Mains supply: 230 V (115 V) • Transport box Nominal power input: 1600 W • Set of tools Operating temperature: approx. 176°F •... -

Page 7: Handling

8. Handling 8.1 Handling Caution! When using the extruder, observe the valid regulations for prevention of accidents as well as all the instructions given in the section 2 "Safety instructions/prevention of accidents". 8.2 Operating elements/handling Th e T2 Compound Extruder Gun has the following operating elements: Handle with trigger Handle... -

Page 8: Cleaning/Warming Up The Extruder

8. Handling 8.3 Cleaning/warming up the extruder Attention! Do not leave any T2 Compound in the extruder, as it may vulcanize in the mixing unit, thus damaging the extruder. Th erefore the extruder always has to be cleaned with cleaning rubber before and after use and in the case of downtime exceeding 3 minutes. -

Page 9: Maintenance

9. Maintenance 9.1 Maintenance rates Before every use: ³ Unplug the extruder from the mains. ³ Check the tool for visible damage (electric cables, plug, housing). ³ Replace damaged parts. Spare parts: See spare parts lists (pages 12 & 14). Every 100 operating hours: ³... -

Page 10: Demounting The Feeder Worm

9. Maintenance 9.3 Demounting the feeder worm Disassemble the front part as described under 9.2. In addition: • Unscrew the six headless allen screws M8 x 10 with the allen key SW 4 mm. • Remove the aluminium main body by pulling it forwards. -

Page 11: Troubleshooting

10. Troubleshooting 10. Troubleshooting In case of malfunction, disconnect the extruder from the mains at once. Th en have the Troubleshooting carried out with the help of a specialist. When carrying out repairs to the extruder, observe the safety instructions given in this manual. Th e following explanations do not cover all troubles which are theoretically possible. -

Page 12: Spare Parts List A

Spare Parts List A Spare Parts List A Applies to Ref. No. 517 5150 and 517 5160 from model I.04 and serial number 50-0001-230 and 50-0001-115 Extruder Ref.no. Description 517 5150 T2 Compound Extruder Gun 230 V - 1600 W... - Page 13 Spare Parts List A Spare Parts List A Applies to Ref. No. 517 5150 and 517 5160 from model I.04 and serial number 50-0001-230 and 50-0001-115 T2 COMPOUND EXTRUDER GUN Operating instructions...

-

Page 14: Spare Parts List B

Spare Parts List B Spare Parts List B Applies to Ref. No. 517 5150 and 517 5160 from model I.04 and serial number 50-0001-230 and 50-0001-115 Pos. Ref.no. Description Pos. Ref.no. Description 558 3880 Sheet metal screw 4.8 x 45 558 4160 Snap ring 20/1.2... - Page 15 Spare Parts List B Spare Parts List B Applies to Ref. No. 517 5150 and 517 5160 from model I.04 and serial number 50-0001-230 and 50-0001-115. T2 COMPOUND EXTRUDER GUN Operating instructions...

- Page 16 REMA TIP TOP Product & Solutions CONVEYING SOLUTIONS Pulley Lagging Skirting Other • PERFORMANCE GRIP 70 • REMASKIRT • Conveyor Belting • REMAGRIP • Combi-Skirt • REMACLEAT • REMAGRIP Ceramic Lagging • T-REX • Edge Wall • UNIGRIP • UNISKIRT •...

Need help?

Do you have a question about the 517 5150 and is the answer not in the manual?

Questions and answers