Summary of Contents for BOCI BLT421S

- Page 1 BLT421S Product Manual Laser Cutting Head BLT 421S- QBH/EOC Brilliant Optical Cutting Instrument...

-

Page 2: Document History

BOCI is constantly updating/upgrading products, so our company reserves the right to modify the product models and descriptions in this manual without prior declaration. -

Page 3: Table Of Contents

A.1 Schematic diagram of product structure ............... 16 A.2 Replace the upper protective window ......................... 17 A.3 Replace the lower protective window ......................... 18 Appendix B - Mechanical Dimensions ................ 19 B.1 Cutting head installation size ..........................19 B.2 BLT421S Laser Fiber Types ..........................23... -

Page 4: Product Description

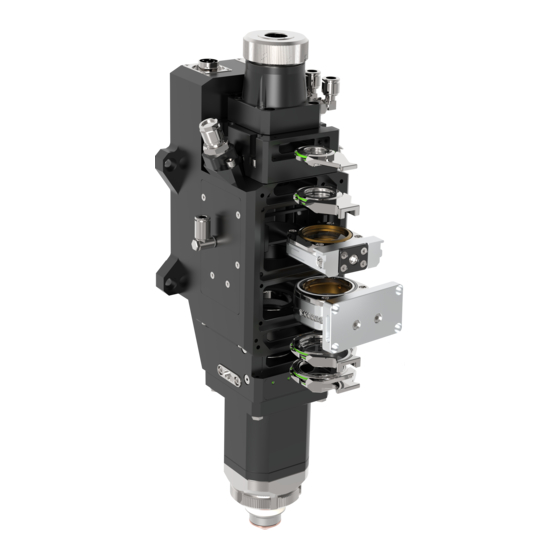

BLT421S Product Manual 1.Product Description 1.1 Product View Product View (Structure and Interface Description) 1. Optical fiber interface; 9. Cooling water outlet; 2. 1 Upper protective window; 10. Cutting gas interface; 3. 2 Upper protective window; 11. Nozzle cooling gas inlet;... -

Page 5: Technical Parameters

BLT421S Product Manual 1.2 Technical Parameters Cutting Head BLT421S Laser Wavelength: 1030-1090nm Laser Power: ≤8kW Fiber Interface: QBH, EOC Spot Magnification: M=1.5/2.0 (100:150/100:200) Max Focus Adjustment Range: ±50mm Max.0.13 at Fc100 Centering Adjustment Range: ±1.5mm Focus Acceleration: 7.5m/s² Cutting Gas Interface: ø10, maximum 25bar (2.5Mpa) -

Page 6: Meaning Of Led Indicator

BLT421S Product Manual 1.3 Meaning of LED indicator Icon State Meaning green Power is normal. Under-voltage alarm: insufficient electrical power. No power supply: There is no power supply, the connection cable is broken, and the bright interface is loose. Icon... -

Page 7: Gas Interface

BLT421S Product Manual 2.Gas interface Cutting Gas Interface Nozzle Cooling Gas Connection Installation Connection: Cutting gas 1, Nozzle cooling gas 2 Notice: The maximum pressure of cutting gas is 25bar (2.5Mpa). The cutting gas quality shall meet the requirements of gas quality in accordance with ISO ... -

Page 8: Water Cooling Interface

BLT421S Product Manual 3.Water Cooling Interface Water cooling water outlet Water cooling water inlet Caution: Installation connection: water-cooled inlet port 2A, water-cooled outlet port 1A Pure water or drinking water shall be used for coolant. In order to prevent the water in the cooler from growing molds which can cause blockage of the pipeline, it is ... -

Page 9: Electrical Interface

BLT421S Product Manual Dew point temperature at different temperature and humidity 4.Electrical Interface PWE and aviation plug interface waterproof precautions: PWE interface and air plug interface are equipped with dust plugs from the factory. If the dust plug does not fall off, the protection level of IP64 can be achieved; at the same time, when the PWE cable and the air plug cable are well connected, IP64 can also be achieved;... -

Page 10: Bus System

BLT421S Product Manual 4.1 Bus system BCS210E Power supply 220V AC BLT421S cutting head installation wiring diagram Slave Station Hypcut HyPanel master station Notice: The above wiring operations should only be performed by trained and professional personnel. When the cutting head is connected to the BCS210E, the BCS210E must ... -

Page 11: Non-Bus Systems

BLT421S Product Manual 4.2 Non-bus systems BCL4500A BLT421S Cutting Head Installation Power Wiring Diagram 24VDC Cypcut Slaves Station master station Notice: The above wiring operations should only be performed by trained and professional personnel. When the cutting head is connected to the BCL4500A, the BCL4500A must be powered off. -

Page 12: Cutting Head Installation

BLT421S Product Manual 5.Cutting head installation During the installation of the cutting head, dust or dirt may accidentally enter the cutting head, contaminate the optical window, and affect its normal functions. To prevent dust or dirt from entering the cutting head, please refer to the following methods for the installation of the cutting head: 5.1 Preparation before operation... -

Page 13: Specific Operation Process

BLT421S Product Manual 5.2 Specific operation process 5.2.1 Preparation of clean bench Prepare the clean bench, start it up and ensure its functionality: Clean table type: vertical purification; cleanliness class: ISO 5, 100; average wind speed ≥ 0.4m/s Check that the equipment is clean and qualified (checks the cleanliness of the dust particle counter ), and confirm that the FFU purification unit is within the validity period (measure the average wind speed in the working area, when the wind speed cannot reach 0.3m/s, the FFU purification unit must be replaced);... -

Page 14: Clean And Wipe The Fiber Interface Of The Cutting Head

BLT421S Product Manual 5.2.3 Clean and wipe the fiber interface of the cutting head Wipe the fiber interface of the cutting head with a clean cloth and anhydrous ethanol. 5.2.4 Check the laser fiber end face Remove the protective cap of the laser fiber, and irradiate the end face of the fiber with a strong flashlight to observe whether there is any pollution;... -

Page 15: Insert The Laser Fiber Interface Into The Cutting Head

BLT421S Product Manual 5.2.6 Insert the laser fiber interface into the cutting head Align the fiber optic plug with the red dot, insert it into the unlocked fiber optic port, and ensure that it is inserted as far as it will go. Rotate the lock cap until it tightly locked. - Page 16 BLT421S Product Manual Tape wrap seal Notice: To achieve affective sealing, it is recommended to wrap the tape at least three times for sealing.

-

Page 17: Mount The Cutting Head On The Backplane

BLT421S Product Manual 5.2.8 Mount the cutting head on the backplane The cutting head can be installed on the Z-axis backplane of the machine tool through four screws A, B, C, and D. When fixing the cutting head on the machine, it must be ensured that the cutting head is locked and there is no obvious movement. -

Page 18: Beam Centering

BLT421S Product Manual 5.2.10 Beam centering Adjust the XY centering knob to make the focal point in the center of the nozzle by low-power dotting. The conditioned laser beam must be in the center of the adjustment nozzle. screw Relative position of laser beam... -

Page 19: Appendix A - Care/Maintenance

BLT421S Product Manual Appendix A - Care/Maintenance A.1 Schematic diagram of product structure Laser Fiber Upper Protective Window Cartridge Upper Protective Window D25.4T4-2 2nd-Upper Protective Window Cartridge 2nd-Upper Protective Window D25.4T4-2 Collimating Cartridge Unit Focusing Cartridge Focal length Collimation Focusing Length... -

Page 20: Replace The Upper Protective Window

BLT421S Product Manual A.2 Replace the upper protective window 1st Upper protective window base 1st Upper Protective window Drawer Door Loosen the screws; Pull out the upper protective mirror drawer; Use mask tape to prevent dust from entering; Remove the pressure ring on the protective window;... -

Page 21: Replace The Lower Protective Window

BLT421S Product Manual A.3 Replace the lower protective window Loosen the screws of the drawer door; Pull out the lower protective mirror drawer; Close the protective door of the lower protective mirror drawer to prevent dust from entering; Remove the pressure ring on the protective window;... -

Page 22: Appendix B - Mechanical Dimensions

BLT421S Product Manual Appendix B - Mechanical Dimensions B.1 Cutting head installation size BLT421S-QBH-200... - Page 23 BLT421S Product Manual BLT421S-QBH-150...

- Page 24 BLT421S Product Manual BLT421S-EOC-200...

- Page 25 BLT421S Product Manual BLT421S-EOC-150...

-

Page 26: Blt421S Laser Fiber Types

BLT421S Product Manual B.2 BLT421S Laser Fiber Types Picture Others Laser Fiber Types Trumpf LLK-Q IPG HLC-8/LC-8 MAX G5...

Need help?

Do you have a question about the BLT421S and is the answer not in the manual?

Questions and answers