Summary of Contents for Endress+Hauser TM501

- Page 1 Operating instructions TM501 RTD thermometer in thermowell < RTD Thermometer (from page 15) BA291R/09/b2/04.10 71110480...

- Page 3 TM501 ……………………………………………………………………………………………………….4 ……………………………………………………………………………………………………………4 …………………………………………………………………………………..………4 ………………………………………………………………………………………………………4 ………………………………………………………………………………....…………5 …………………………………………………………………………………………………………….5 ………………………………………………………………………………………………………5 ………………………………………………………………………………………………………6 …………………………………………………………………………………………………………….6 ………………………………………………………………………………………6 ………………………………………………………………………………………………………7 ………………………………………………………………………………………………………8 …………………………………………………………………………………………………………...10 …………………………………………………………………………………………………..……...11 …………………………………………………………………………………………………………...11 ……………………………………………………………………………………………………...11 ……………………………………………………………………………..…………………………..11 …………………………………………………………………………………………………………..12 …………………………………………………………………………………………………………..12 ……………………………………………………………………………………………………...12 …………………………………………………………………………………………………………..12 …………………………………………………………………………………………………………..12 ……………………………………………………………………………………………………..13 ……………………………………………………………………………………………………..14 ……………………………………………………………………………………………………..14 Endress+Hauser...

- Page 4 TM501 • -50 °C +500 °C(-58 °F +932 °F) 4….20mA HART • • • • • • • IEC 61010-1 "SELV " • Endress+Hauser...

- Page 5 TM501 1: RTD Endress+Hauser...

- Page 6 TM501 • • 3.1.1 • • 3.1.2 • • +85 °C (-40 185 °F) Endress+Hauser...

- Page 7 TM501 3.2.1 3,2 µm (126 µinch) (3.15 (2.95 (0.47 M20x1.5 (5.9 (3.94 (0.63 ½” NPT (7.9 (5.9 (= A ) (7.9 (9.84 50...740 (1.97...29.1 Endress+Hauser...

- Page 8 TM501 M27x2 16 (0.63) M33x2 18 (0.71) M20x1.5 15 (0.6) a0013608 3.2.2 • °C (°F) -40 130 °C (-40 266 °F) -40 85 °C (-40 185 °F) • -50 +500 °C (-58 +932 °F) • 75 bar (1088 psi) •...

- Page 9 TM501 B - C: • • 12mm 0.47in 96 12x8 (3.8 DIN43772 4.72 • Endress+Hauser...

- Page 10 TM501 TMT18x ( 1.75 mm² 1.5 mm² 2.5 mm² Endress+Hauser...

- Page 11 TM501 TPR100 RTD TPR100-. IL = U + 29 (1.14) + 11 (0.43) IL = E + U + 11 (0.43) Endress+Hauser...

- Page 12 TM501 Endress+Hauser • “ ” www.endress.com/decontamination_form • Pt100 IEC 60751 +500 °C (-58 +932 °F) • Pt100, A • 4-20 mA 20-4 mA HART®- Endress+Hauser...

- Page 13 TM501 Pt100 C (32 F) ( C (77 IEC 60751 (TF) C, A (0.15 + 0.002 |t|) +250 (WW) (0.15 + 0.002 |t|) +450 1) |t| = 0.1 K (0.18 0.05%/ Pt100 (15 ppm/K * ( + 200) + 50 ppm/K * 0.02%/100...

- Page 14 TM501 3.2.1 U = 300 (11.8 E = 150 (5.9 (21.2 oz) ADC12 SS 316L 1Cr18Ni9Ti. 3.2.2 IP 65 IEC 60068-2-6 4g / 2-150 Hz www.endress.com/temperature Endress+Hauser...

-

Page 15: Table Of Contents

TM501 Table of contents Safety instructions ......... . 16 Designated use . -

Page 16: Safety Instructions

Safe and secure operation of the temperature sensor can only be guaranteed if the operating instructions of the used transmitters and all included safety notes are read, understood and followed. For applied Endress+Hauser temperature transmitters see enclosed Operating Instructions. Safety instructions Designated use •... -

Page 17: Notes On Safety Conventions And Icons

TM501 Identification • Due to its design, the device is not repairable. When later disposing of the device, please observe the local regulations. Notes on safety conventions and icons Always refer to the safety instructions in these Operating Instructions labeled with the following symbols: "... -

Page 18: Scope Of Delivery

Installation TM501 Scope of delivery The scope of delivery of the device comprises: • RTD thermometer on order The accessories for pipe connections are not supplied with the thermometer. These are the customer’s responsibility. The appropriate gaskets for the process connection are supplied with the device. -

Page 19: Installation Conditions

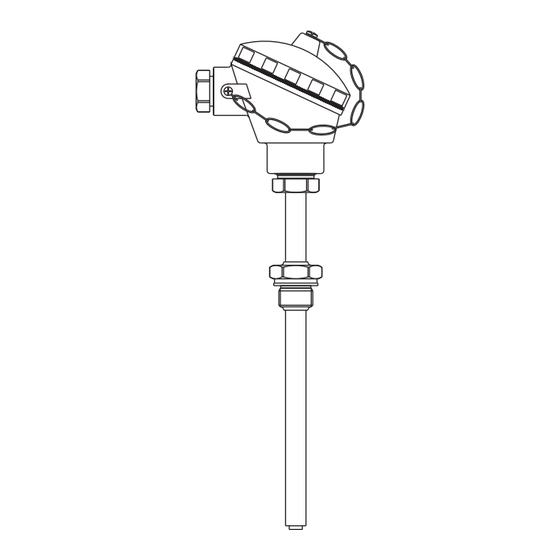

TM501 Installation Installation conditions 3.2.1 Dimensions a0013607 Fig. 2: All dimensions of the thermometer in mm (in). Surface roughness Ra 3,2 μm (126 μinch) Model without extension neck Replaceable insert with terminal block mounted Model with extension neck Replaceable insert with head transmitter mounted... -

Page 20: Installation Instructions

Installation TM501 Threaded process connection Version Thread length TL in mm (in) Width across flats AF Cylindrical M27x2 16 (0.63) M33x2 18 (0.71) M20x1.5 15 (0.6) a0013608 Fig. 3: Process connection 3.2.2 General information • Permitted ambient temperature range: Terminal head Temperature in °C (°F) - Page 21 TM501 Installation a0013609 Fig. 4: Installation examples A: In pipes with a small cross section the sensor tip should reach or extend slightly past the center line of the pipe (= U). B - C: Tilted installation. The immersion length of the thermometer influences the accuracy. If the immersion length is too small then errors in the measurement are caused by heat loss via the process connection and the container wall.

-

Page 22: Wiring

Wiring TM501 Wiring " Caution! Switch off power supply before installing or connecting the device. Failure to observe this may result in destruction of the device. For wiring a head mounted transmitter or a terminal block, proceed as follows: Open the cable gland and the housing cover on the terminal head. -

Page 23: Commissioning

TM501 Commissioning Commissioning After installation of the device, always perform the following final checks: Device condition and specifications Notes Are the device and the cables free of damage (visual check)? ä 19 Has the device been mounted in accordance with specifications? -

Page 24: Return

Technical data TM501 Return The following procedures must be carried out before a device is returned to Endress+Hauser: • Always enclose a fully completed “Declaration of Decontamination” form with the device. This declaration form can be downloaded from the internet at www.endress.com/decontamination_form. -

Page 25: Performance Characteristics

TM501 Technical data Performance characteristics Reference operating conditions • Calibration temperature (ice bath) 0 °C (32 °F) for Pt100 sensor • Ambient temperature 25 °C ± 5 °C (77 °F ± 9 °F) for head transmitter Maximum measured error RTD corresponding to IEC 60751 •... -

Page 26: Mechanical Construction

Technical data TM501 Mechanical construction Design, dimensions ä 19 Weight Version with U = 300 mm (11.8 in) and E = 150 mm (5.9 in) as example 0.6 kg (21.2 oz) Material • Terminal head: Aluminum alloy ADC12 • Parts in contact with process and process connection: SS 316L or 1Cr18Ni9Ti. - Page 27 TM501 Technical data Endress+Hauser...

- Page 28 www.endress.com/worldwide BA291R/09/b2/04.10 71110480 FM+SGML6.0...

Need help?

Do you have a question about the TM501 and is the answer not in the manual?

Questions and answers