Table of Contents

Advertisement

Quick Links

g

GEK 116862

April 2011

GE Energy

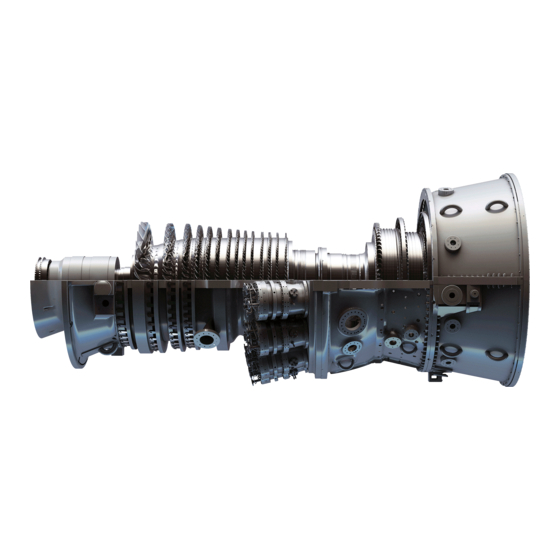

Inspection and Maintenance Instructions for

7FA.05 Gas Only and Dual Fuel Gas

Turbines

Auxiliaries and Controls

These instructions do not purport to cover all details or variations in equipment nor to provide for every possible contingency to

be met in connection with installation, operation or maintenance. Should further information be desired or should particular

problems arise which are not covered sufficiently for the purchaser's purposes the matter should be referred to the GE Company.

© General Electric Company, 2011. GE Proprietary Information. All Rights Reserved.

Advertisement

Table of Contents

Summary of Contents for GE 7FA.05

- Page 1 Should further information be desired or should particular problems arise which are not covered sufficiently for the purchaser's purposes the matter should be referred to the GE Company. © General Electric Company, 2011. GE Proprietary Information. All Rights Reserved.

- Page 2 GEK 116862 Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas Turbines ATTENTION NOTES, CAUTIONS AND WARNINGS Notes, Cautions and Warnings will be found throughout this Maintenance Publication. It is important that the significance of each is thoroughly understood by personnel using these Maintenance Procedures.

-

Page 3: Table Of Contents

Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas TurbinesGEK 116862 TABLE OF CONTENTS I. AUXILIARY AND CONTROLS SYSTEMS MAINTENANCE - GENERAL ......6 II. STANDARD MAINTENANCE ITEMS ..................17 A. Pressure Switches and Gauges ...................... 17 ... - Page 4 GEK 116862 Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas Turbines XI. FUEL GAS SYSTEM ........................26 A. General Notes ..........................26 B. Fuel Gas Stop Ratio and Control Valves ..................26 XII. LIQUID FUEL FORWARDING SYSTEM (DUAL FUEL UNITS ONLY)........ 26 ...

- Page 5 Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas TurbinesGEK 116862 XXI. TEMPERATURE CONTROL ......................35 A. Exhaust Thermocouples (Control and Over temperature) ............35 B. Wheelspace Thermocouple Temperature Limits ................35 XXII. FLAME DETECTION AND PROTECTION SYSTEM ............... 36 ...

-

Page 6: Auxiliary And Controls Systems Maintenance - General

GEK 116862 Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas Turbines I. AUXILIARY AND CONTROLS SYSTEMS MAINTENANCE - GENERAL The maintenance procedures recommended in this section apply to a typical power plant installation. This manual is subdivided into two subsections: the Periodic Inspection Schedule followed by Inspection and Maintenance Procedures. -

Page 7: Table 1. Periodic Inspection Schedule

Operation and Maintenance Manual. It is our intent that these instructions, with the help of a GE Field Service Representative, be used as an aid in the preparation of an individual maintenance program for each purchaser. - Page 8 GEK 116862 Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas Turbines Inspection Document Frequency and or Section Inspection What to Inspect for Turbine Status Reference Zero Reading M — S Calibration A — S Pressure/Temperature XXX. A.

- Page 9 Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas TurbinesGEK 116862 Inspection Document Frequency and or Section Inspection What to Inspect for Turbine Status Reference HEATING COOLING AND VENTILATION Air Conditioners V. A. Dirty Filter W — O/S Improper Thermostat Setting W —...

- Page 10 GEK 116862 Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas Turbines Inspection Document Frequency and or Section Inspection What to Inspect for Turbine Status Reference Hangers and Clamps Loose Hardware at Pump Intakes Maj — S...

- Page 11 Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas TurbinesGEK 116862 Inspection Document Frequency and or Section Inspection What to Inspect for Turbine Status Reference Cooling Water Radiator Fan Dirty Wheel Housing, Ducts and X. E. Module Screens A —...

- Page 12 GEK 116862 Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas Turbines Inspection Document Frequency and or Section Inspection What to Inspect for Turbine Status Reference Bound or Rubbing Shaft M – O Excessive Vibration, Loose Shaft Fit M –...

- Page 13 Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas TurbinesGEK 116862 Inspection Document Frequency and or Section Inspection What to Inspect for Turbine Status Reference Compressor Air Filter Dirty Filter M – O Signs of Moisture Atomizing Air Pre–cooler XIV.

- Page 14 GEK 116862 Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas Turbines Inspection Document Frequency and or Section Inspection What to Inspect for Turbine Status Reference Orifice Plates A — S Orifice Unions A — S Leakage D —...

- Page 15 Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas TurbinesGEK 116862 Inspection Document Frequency and or Section Inspection What to Inspect for Turbine Status Reference SPEEDTRONIC CONTROL SYSTEMS (Refer to Control Systems Section in the Operators Manual)

- Page 16 GEK 116862 Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas Turbines Inspection Document Frequency and or Section Inspection What to Inspect for Turbine Status Reference Cylinder rod seal leakage M—O Rough operation SA—S Improper operation of trip relay SA—S...

-

Page 17: Standard Maintenance Items

Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas TurbinesGEK 116862 II. STANDARD MAINTENANCE ITEMS A. Pressure Switches and Gauges The setting of pressure switches and calibration of the gauges can be checked with a dead weight tester, a regulated source of clean, dry, compressed air or a nitrogen cylinder and a calibrated pressure gauge. -

Page 18: Panel Meters

GEK 116862 Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas Turbines F. Panel Meters Unless a competent instrument mechanic is available, it is recommended that the instrument be returned to the manufacturer, or a laboratory, for calibration and for repairs. -

Page 19: Temperature Control Valves (Vtrs)

Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas TurbinesGEK 116862 Refer to MLI 0414 Device Summary for the proper setting of the valve. It is recommended that valve diaphragms and stem packings be replaced every five years, unless operating experience indicates that more frequent replacement is necessary. -

Page 20: Check Valves, Orifices And Orifice Check Valves

GEK 116862 Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas Turbines D. Check Valves, Orifices and Orifice Check Valves During a shutdown period, the system has to be drained and the valves and orifices have to be removed to check for evidence of erosion, corrosion, or component deterioration. -

Page 21: Heating, Cooling And Ventilation

Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas TurbinesGEK 116862 V. HEATING, COOLING AND VENTILATION A. Air Conditioners (where applicable) Clean dust and dirt from the condenser and evaporative coils. Clean condensate drip pan and verify proper condensate drain function. -

Page 22: Ac Motors

GEK 116862 Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas Turbines Check operation and timing of the staged resistance starting system. A high speed chart recorder and DC current probe (or equivalent equipment) are required to perform these checks. Motor current should not exceed 5 times nameplate current or 66% of circuit breaker trip settings. -

Page 23: Lube Oil System Maintenance

Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas TurbinesGEK 116862 IX. LUBE OIL SYSTEM MAINTENANCE A. Lube System Oil Pumps Check the lube oil pumps for excessive vibration. Check the thrust bearings and bearing seal for wear. -

Page 24: Pipe Couplings

GEK 116862 Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas Turbines H. Pipe Couplings Check the couplings for oil leakage due to aging and heat. Replace seals as needed. Lubricate seals prior to each assembly of seals. -

Page 25: Water Expansion Tank (If Applicable)

Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas TurbinesGEK 116862 where the symbols are as follows: orifice pipe Δ (orifice AREA ORIFICE ( IN ρ WATER DENSITY ( / FT ORIFICE DISCHARGE COEFFICIEN The flow coefficient K for flange taps is determined experimentally; therefore, it may be extracted from tables available in several references. -

Page 26: Fuel Gas System

GEK 116862 Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas Turbines rings should be replaced and reworked to restore the manufacturer’s recommended clearance values. This will restore pump efficiency insofar as this clearance is concerned. Whenever the pump is disassembled, all parts of the pump, especially the impeller, shaft sleeve, and wearing parts of the mechanical seal should be checked and replaced, if worn. -

Page 27: Fuel Oil System (Dual Fuel Units Only)

Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas TurbinesGEK 116862 XIII. FUEL OIL SYSTEM (DUAL FUEL UNITS ONLY) A. General Notes In addition to these general guidelines, reference any detailed maintenance instructions provided by the Liquid Fuel/Atomizing Air Module (MLI A162) vendor, including maintenance manuals for the individual components in the system (pumps, valves, etc.). -

Page 28: Atomizing Air System (Dual Fuel Units Only)

GEK 116862 Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas Turbines XIV. ATOMIZING AIR SYSTEM (DUAL FUEL UNITS ONLY) A. General Notes In addition to these general guidelines, reference any detailed maintenance instructions provided by the Liquid Fuel/Atomizing Air Module (MLI A162) vendor, including maintenance manuals for the individual components in the system (compressor, valves, etc.) -

Page 29: Air Separators

Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas TurbinesGEK 116862 in a given pre-cooler and still have the pre-cooler perform satisfactorily in gas turbine service. The tapered plug material which is selected should be compatible with the pre-cooler bundle material. -

Page 30: Hydraulic And Lift Oil Supply Manifold

GEK 116862 Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas Turbines If the pump does not operate properly, or if there is evidence of damage, it should be overhauled in accordance with the instructions in the Operation and Maintenance Manual under the Hydraulic Supply System. -

Page 31: Compressor Bleed Valves

Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas TurbinesGEK 116862 C. Compressor Bleed Valves These valves should operate freely with no evidence of sticking. Where sticking is evident, contact the vendor and GE engineering. WARNING DO NOT ATTEMPT TO PERFORM ANY IN-FIELD SERVICING OF THE BLEED VALVES WITHOUT PROPER AUTHORIZATION AND INSTRUCTION FROM THE VENDOR AND GE ENGINEERING. -

Page 32: Fire Protection System

GEK 116862 Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas Turbines XIX. FIRE PROTECTION SYSTEM WARNING (CO FIRE PROTECTION ONLY) FIRE SUPPRESSANT, IN A CONCENTRATION SUFFICIENT TO EXTINGUISH FIRE, CREATES AN ATMOSPHERE THAT WILL NOT SUPPORT LIFE. IT IS EXTREMELY HAZARDOUS TO ENTER THE COMPARTMENT AFTER THE CO SYSTEM HAS DISCHARGED. -

Page 33: Co High Pressure System Tests (Clean Agent Systems)

Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas TurbinesGEK 116862 The empty and full weights of all cylinders are permanently stamped on the cylinder valve bodies. Each time the cylinders are weighed, the date and net weight should be recorded on the attached tag. -

Page 34: Fire Detectors

GEK 116862 Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas Turbines When the system starts to discharge, relay 45FTX should pick up to trip the turbine. The fire alarm bell in the accessory compartment should also ring, and the fire flag on the annunciator should drop. -

Page 35: Hazardous Gas Detection

Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas TurbinesGEK 116862 XX. HAZARDOUS GAS DETECTION A. Infrared (IR) Detectors The IR detectors have a manual self-test feature to verify proper operation. For additional information on the IR detectors, refer to the Operation and Maintenance Manual under the Hazardous Gas Detection System. -

Page 36: Flame Detection And Protection System

GEK 116862 Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas Turbines 7. Excessive distortion of exhaust inner diffuser 8. Improper positioning of cooling and sealing air valves 9. For 3rd stage aft wheelspace, malfunctioning exhaust frame blowers. -

Page 37: Scanner Lens

Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas TurbinesGEK 116862 B. Scanner Lens The scanner lens should be cleaned with a dry cloth as often as necessary on a regular schedule. No repair of any sort should be attempted on the scanner, or switch assembly. If damaged, or defective, it should be replaced and returned to the factory. -

Page 38: Inlet Bleed Heat Systems

GEK 116862 Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas Turbines XXVI. INLET BLEED HEAT SYSTEMS A. Piping Insulation The insulation installed on the inlet bleed heat piping between the turbine base and the inlet duct is for personnel protection and heat retention. -

Page 39: Blade Health Monitoring

The probes used in the system will experience sensitivity drifts and signal degradation over time. As a result, GE recommends that each probe be calibrated or replaced at least every two years or at each C.I. (Combustion Inspection Outage). -

Page 40: Required Actions During Interface Maintenance

GEK 116862 Inspection and Maintenance Instructions for 7FA.05 Gas Only and Dual Fuel Gas Turbines B. Required Actions During Interface Maintenance During major outage, remove sensors and perform a visual inspection of the probes. A continuity check should also be completed.

Need help?

Do you have a question about the 7FA.05 and is the answer not in the manual?

Questions and answers