Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for HELI D48V-200A-Li-EN

- Page 1 User Manual of Lithium Electric Forklift Intelligent Charger ANHUI HELI CO., LTD.

-

Page 2: Security Considerations

When operating the products and equipment of our company, you must comply with the safety standards of the related industries and strictly observe the attention of related equipment and special safety instructions provided by Anhui Heli Co., LTD. Electrical safety ( electric hazards) High Voltage When the power system is running, some parts are with high voltage. -

Page 3: Static Electricity

Tools When carrying out various operations of high voltage and alternating current, you WARNING must use special tools rather than ordinary tools. Thunderstorm It is forbidden to carry out operation with high voltage, alternating current, iron tower DANGER and mast in thunderstorm. In thunderstorm, strong electromagnetic fields will appear in the atmosphere. -

Page 4: Safety And Regulatory Requirements

Take off watches, bracelets, bangles, rings and other conductive objects on the hand. Use special insulation tools. Use eye protection device and make preventive measures. Put on rubber gloves and wear apron to prevent electrolyte from overflowing. The battery should always keep the electrode upwards in the process of transportation. -

Page 5: Table Of Contents

CATALOGUE 1 Product Summarization ........................1 2 Model Description.......................... 1 3 Introduction of Operational Principle .................... 1 4 Whole Machine Parameter ......................2 5 Installation Instructions ........................3 6 Instruction of the Panel and LCD Screen ..................4 7 Method of Use ..........................5 8 Protection And Fault List ....................... -

Page 6: Product Summarization

1 Product Summarization This series of charger uses the world's leading LLC resonant mode and active PFC, which is specially designed for lithium battery charging power conversion equipment. The charger has the characteristics of active power factor correction, high efficiency, high power density, high reliability, intelligent control and attractive appearance. -

Page 7: Whole Machine Parameter

So that the charger can always work in efficient and reliable charging state, improve the charging efficiency and save the electric energy. 4 Whole Machine Parameter Item Parameter Index Type D48V-200A-Li-EN D80V-200A-Li-EN DC Output Maximum Output 13kW 20kW... -

Page 8: Installation Instructions

Working Conditions Working -30℃~55℃work normally, 57℃~75℃ reduce output, over 75℃ Environment Shutdown Temperature Storage -40℃~75℃ Temperature Relative Humidity 0~95% ≤2000m full load output, 2000~3000m according to the 5.11.2 rules in Altitude GB/T3859.2-1993, derating output Safety and Reliability IN-OUT:3000VAC/10Ma/1Min, IN-SHELL:2500VAC/10Ma/1Min, Insulation OUT-SHELL:2500VAC/10Ma/1Min. -

Page 9: Instruction Of The Panel And Lcd Screen

Circuit breaker specification ≥40A Example: D48V-100A-Li, D48V-200A-Li, D80V-100A-Li Circuit breaker specification ≥63A D80V-200A-Li 3. There is not zero line in this series of charger. So it is forbidden to connect earth line to zero line. 5.3 Check Before Starting Machine: When the charger has been connected, please check it carefully before starting the charger. -

Page 10: Operation Method

7 Operation Method 7.1 Operation steps: 7.1.1 Forklift parked, turn off the power, open the charging door and the protecting cap. 7.1.2 Turn on the power input switch of the charger, charging prepared. 7.1.3 Take down the charging gun, straighten the cable, connect with the forklift correctly, then charging begin automatically. -

Page 11: Protection And Fault List

the electromagnetic lock rod is drawn back. Note: Don't use emergency unlocking in normal condition. 8 Protection And Fault List 8.1 Input Protection: Overvoltage protection, under-voltage protection, overcurrent protection and lack of phase protection 8.2 Output Protection: Short circuit protection, overcurrent protection, overvoltage protection and reverse protection 8.3 Others:... -

Page 12: Maintenance

Module Timeout module timeout Fan fault Fan fault BAT overcharge Battery overcharge protect Over-temperature protect BAT overtemp Interlock protect interlock Lower temperature protect Lower-temp Cell voltage lower cell-volt lower Charging overcurrent overcurrent Please check Battery Fault the battery. BMS Fault BMS Fault connector over-temp protect CONN overtemp... -

Page 13: Packaging, Transportation And Storage

when the terminals connect well, the machine can charge normally. 10 Packaging, Transportation and Storage 10.1 Packaging This product is packed in wooden cases. The packing case contains installation instructions. Each charger has a factory certificate. 10.2 Transportation The transportation of this product should be carried out with good packing. The product can’t be shocked and collided severely during transportation. -

Page 14: Appendix A: Wiring Principle Diagram Of Charger

Appendix A: Wiring Principle Diagram of Charger... -

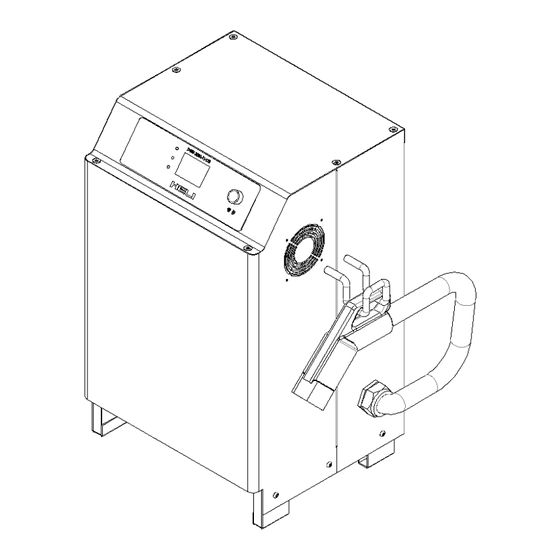

Page 15: Appendix B: Component Details Of Charger

Appendix B: Component Details of Charger... -

Page 16: Appendix C: Common Faults And Solutions

Appendix C: Common Faults and Solutions Fault Information in LCD Number Fault Investigations Phenomenon screen 1. Whether the three-phase switch on the side of the charger is in the ON position. 2. Check whether the input three-phase power is connected or LCD screen and not and whether lack of phase. - Page 17 2.2 If voltage can be measured, then measure the voltage between OUT+ and OUT- terminals. If voltage still can be measured, then the control panel is broken. Otherwise, check further whether 300A fuse, pre-charge resistors and diodes between the two ends of the output contactor are broken or not.

Need help?

Do you have a question about the D48V-200A-Li-EN and is the answer not in the manual?

Questions and answers