Subscribe to Our Youtube Channel

Summary of Contents for Samson 4744

- Page 1 EB 8367 EN Translation of original instructions Type 4744 Electric Limit Switch For hazardous areas Edition June 2015...

- Page 2 Î For the safe and proper use of these instructions, read them carefully and keep them for later reference. Î If you have any questions about these instructions, contact SAMSON‘s After-sales Service Department (aftersalesservice@samson.de). The mounting and operating instructions for the devices are included in the scope of delivery.

-

Page 3: Table Of Contents

Design and principle of operation ..............6 Versions ......................6 Principle of operation ..................6 Technical data ....................8 Summary of explosion protection approvals .............9 Attachment according to IEC 60534-6 (NAMUR) ...........10 4.1 Attachment of Type 4744-1 ................10 4.2 Attachment of Type 4744-2 ................10 Electrical connections ...................13 5.1 Connection with type of protection Ex d according to EN 60079-1 ....13 5.2 Connection with type of protection Ex e according to EN 60079-7....14... -

Page 4: General Safety Instructions

General safety instructions 1 General safety instructions For your own safety, follow these instructions concerning the mounting, start-up and opera- tion of the device: − The device is to be mounted, started up or operated only by trained and experienced personnel familiar with the product. -

Page 5: Markings On The Device

Protection 2 Configuration ID Max. Travel 3 Degree of protection 4 Rated travel Temperature °C 5 Permissible ambient temperature SAMSON AG D-60314 Frankfurt Made in Germany 6 Serial number 2.2 Article code Electric limit switch Type 4744- x Attachment To NAMUR rib To rods for Type 3372 Actuator... -

Page 6: Design And Principle Of Operation

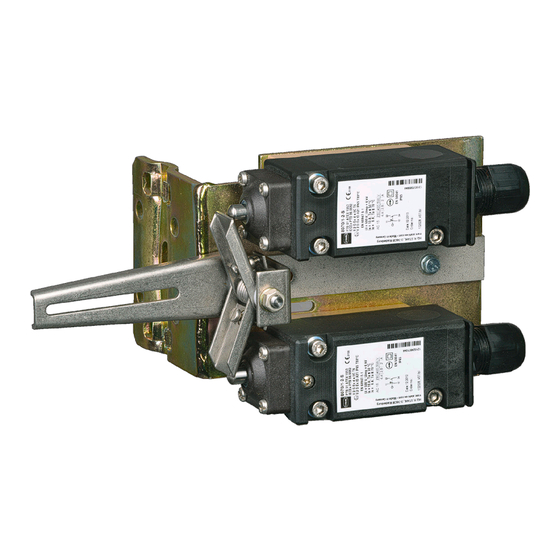

(SPDT). Type 4744-2 − Type of protection: flameproof enclosure. Fig. 1: Type 4744 with protective cover See section 3.4 on page 9. Limit switch with one limit contact for mount- Type 4744-2 ing to the rod-type yoke of Series V2001 The valve travel is transferred over the stem valves. - Page 7 Design and principle of operation Type 4744 with two limit contacts Type 4744-2 Lever Limit contact Adjusting lever Adjustment screw Fig. 2: Functional depiction of Type 4744 and Type 4744-2 EB 8367 EN...

-

Page 8: Technical Data

Design and principle of operation 3.3 Technical data Limit switch Type 4744 4744-2 Limit contact 1 or 2 Type of protection Flameproof enclosure, Flameproof enclosure terminal space in increased safety Load capacity 500 V/10 A 250 V/5 A (contact rating) Utilization category AC-15 125 V/10 A 250 V/0.4 A... -

Page 9: Summary Of Explosion Protection Approvals

DMT 01 ATEX E 178 II 2G Ex de IIC T6 Gb examination II 2D Ex tb IIIC IP65 T80°C Date 2015-06-12 certificate 4744 Number RU C-DE.HA65.B.00615/20 II 2G Ex de IIC T6/T5 Gb Date 2020-06-08 II 2D Ex tb IIIC T80°C/T95°C Db Valid until... -

Page 10: Attachment According To Iec 60534-6 (Namur)

Attachment according to IEC 60534-6 (NAMUR) 4 Attachment according to 4.2 Attachment of Type 4744-2 IEC 60534-6 (NAMUR) Î Refer to Fig. 4 1. Undo the clamps of the stem connector 4.1 Attachment of Type 4744-1 on the valve. Replace the front clamp with the stem connector clamp including Î... - Page 11 Attachment according to IEC 60534-6 (NAMUR) Valve with cast yoke 8 10 Valve with rod-type yoke 8 10 Lever Plate Screws Nuts Screw Washer U-bolt Washer Fig. 3: Attachment of Type 4744 EB 8367 EN...

- Page 12 Stem connector clamp with U-bolt Actuator stem extends: Actuator stem retracts: The switch of the limit switch is actuated when The switch of the limit switch is actuated when the valve is closed the valve is open Fig. 4: Attachment of Type 4744-2 EB 8367 EN...

-

Page 13: Electrical Connections

Ex d according DANGER to EN 60079-1 Risk of fatal injury due to the formation of an explosive atmosphere. Î Connect the Type 4744 Limit Switch us- For installation in hazardous areas, observe ing suitable cable entries or conduit sys- the relevant standards that apply in the coun- tems that comply with EN 60079-1, try of use. -

Page 14: Connection With Type Of Protection Ex E According To En 60079-7

Î The degree of protection (IP grade) of the cable entries and the blanking plug must be the same as that of the limit switch. Type 4744: Î Seal cable entries left unused with plugs. 1. Unthread the fastening screws of the housing cover. -

Page 15: Operation

Operation 6 Operation Type 4744 6.1 Adjusting the switching point Type 4744 The limit switch unit mounted to the control valve is adjusted by the manufacturer to pro- duce a signal when the valve travel reaches one of its end positions. -

Page 16: Servicing Explosion-Protected Devices

Servicing explosion-protected devices 7 Servicing explosion-protected devices If a part of the device on which the explosion protection is based needs to be serviced, the device must not be put back into operation until a qualified inspector has assessed it accord- ing to explosion protection requirements, has issued an inspection certificate, or given the device a mark of conformity. Inspection by a qualified inspector is not required if the manu- facturer performs a routine test on the device before putting it back into operation. Document the passing of the routine test by attaching a mark of conformity to the device. -

Page 17: Disposal

Disposal 8 Disposal SAMSON is a producer registered at the following European institution u https:// www.ewrn.org/national- registers/national-registers. WEEE reg. no.: DE 62194439/FR 025665 Î Observe local, national and international refuse regulations. Î Do not dispose of components, lubricants and hazardous substances together with your other household waste. - Page 18 EB 8367 EN...

- Page 19 EB 8367 EN...

- Page 20 EB 8367 EN...

- Page 21 EB 8367 EN...

- Page 22 EB 8367 EN...

- Page 23 EB 8367 EN...

- Page 24 EB 8367 EN SAMSON AKTIENGESELLSCHAFT Weismüllerstraße 3 · 60314 Frankfurt am Main, Germany Phone: +49 69 4009-0 · Fax: +49 69 4009-1507 samson@samson.de · www.samson.de...

Need help?

Do you have a question about the 4744 and is the answer not in the manual?

Questions and answers