Summary of Contents for Gradall XL2200

- Page 1 OPERATOR’S MANUAL XL2200 2460-4143 July 2002 Starting S/N 0221400 Form #29629 Original Issue 5-97 GRADALL 406 Mill Avenue S.W. New Philadelphia, OH, 44663, USA Telephone: (330) 339-2211 Fax: (330) 339-3579...

-

Page 4: Important Safety Notices

Strict attention to, and compliance with, instructions provided in this manual as well as the EMI & Gradall Hydraulic Excavator Safety Manuals and all instructional decals and plates affixed to the machine, will help you avoid personal injury and damage to the equipment. -

Page 5: List Of Effective Pages

LIST OF EFFECTIVE PAGES This page is provided to enable reader to determine that PAGE DATE DESCRIPTION this manual is complete and current with respect to the latest revision issued. Revised material will be indicated by a vertical bar to the left of added, changed or deleted material. - Page 7 When used to indicate direction or location, the terms and with safe operating procedures for the Gradall front, rear, left and right relate to the orientation of a Hydraulic Excavator. person sitting in the operator’s seat.

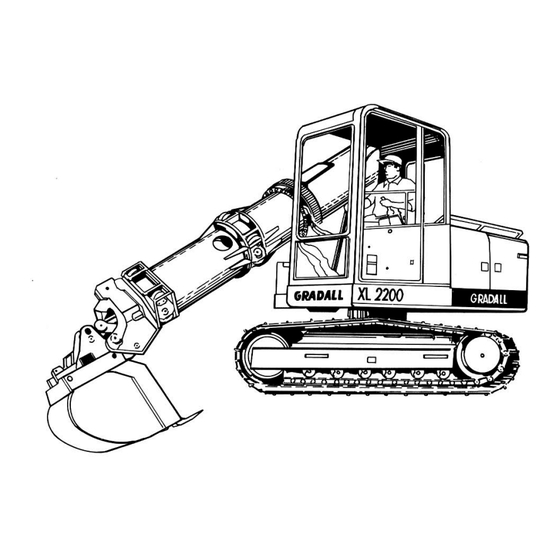

- Page 8 Nomenclature...

- Page 9 TOOL KITS TOOL KIT (Kit can be ordered under part number 8021-5004)

- Page 10 SAFETY HIGHLIGHTS Read and understand this manual, the Gradall Hydraulic Excavator Safety Manual, the EMI Hydraulic Excavator Safety Manual and all instructional decals and plates before starting, operating or performing maintenance procedures on this machine. Keep these manuals in cab.

- Page 11 SAFETY HIGHLIGHTS Learn to recognize ‘PINCH POINTS’ Stay clear of pinch points. Getting caught in a pinch point can cause serious injury or death. Boom Holes Access Covers Boom Cradle Bucket and Linkage Boom Counterweight and another object Upperstructure and Carrier...

- Page 12 If it differs, or if you aren’t sure machine. Such items can cause other workers to contact your Gradall distributor before you run approach the machine without your knowledge and your unit. result in serious injury or death.

- Page 13 SAFETY HIGHLIGHTS Be particularly careful if this is not the machine Learn and follow your employer’s safety rules. you usually operate. Read the manuals listed on page 3 and then operate the unit in a safe, open area to become familiar with the.controls. swinging.

- Page 14 Check operation of all flashing swing warning lights. Lights flash when swinging. Always install shipping pin and secure with GRADALL LIFTING CAPACITIES hitch pins when preparing machine for transport. RATED LIFT CAPACITY Shipping pin is stored in valve compartment.

- Page 15 SAFETY HIGHLIGHTS Avoid injury! Always relieve pressure trap- ped in circuits before disconnecting, re- moving or installing hydraulic components. Pressure can be maintained in hydraulic circuits Do not operate with bystanders or other long after the engine has been shut down. This workers near machine.

-

Page 16: Decals Inside Cab

Decals Inside Cab USE TWO FOR SAFE OPERATION OF MACHINE AND TO MINIMIZE HANDS WHEN RISK OF SERIOUS INJURY: BEFORE OPERATING, READ OPERATOR CLIMBING ON AND SAFETY MANUALS, UNDERSTAND ALL CONTROLS IN CAB AND CLEAR LOOSE OBJECTS OFF MACHINE, SOUND MACHINE. - Page 17 Decals Inside Cab Located on right cab wall Part No. 8026-3021 (for Gradall control configuration) Located on right cab wall Part No. 8026-3022 (for S.A.E. control configuration) Located on right cab wall Part No. 8026-3023 (for J. D. control configuration) Located on fuse cover Part No.

-

Page 18: Decals Outside Cab

Decals Outside Cab Located at front center of upperstructure Located on track adjustment plate Part No. 7733-3047 Part No. 8021-3032 Located both sides of cradle & rear bottom frame plate Part No. 8021-3051 Located both sights gages Part No. 8697-1197 IMPORTANT To prevent damage to the electrical system when using booster battery or charger, always connect... -

Page 19: Diesel Fuel

Decals Outside Cab TO PREVENT INJURY, STAY CLEAR OF MOVING PARTS. FASTEN COVERS OR INJURY MAY RESULT FROM DEATH BEFORE STARTING CONTACTING ELECTRICAL LINES. ENGINE. READ SERVICE TO PLACE ANY PARTS OF THIS MANUAL BEFORE MACHINE OR LOAD WITHIN 10 UNLAWFUL ADJUSTING OR FEET OF HIGH VOLTAGE LINES... - Page 20 Decals Outside Cab Located inside valve compartment door Part No. 9108-3492 Located on hyd. reservoir & valve compartment Part No. 8021-3037 Located outside right cab wall Part No. 8021-3049 APPROXIMATE MACHINE WEIGHT: 27,000# (12,250 KG) WITH 700# (320KG) ATTACHMENT Located beside pressure fill port Located at front center of upperstructure Part No.

- Page 21 SERIAL NO. PLATES See page 4 for help in finding locations. Machine P.I.N. Plate Located on Front Upperstructure Frame Engine Main Hydraulic Pump Located in Engine Compartment Located in Pump Compartment Swing Transmission Implement Pump Located Beneath Boom Cradle Located in Pump Compartment Swing Motor Track Drive Motors Located on Swing Transmission...

-

Page 22: Operator's Cab

OPERATOR’S CAB Seat Adjustment Perform all seat adjustments with engine stopped. Accidental actuation of controls can cause serious accidents. It may become necessary to revise some adjustments to find the most comfortable operating position. Be sure to stop engine first. NOTE: Raise control to unlock control pod and armrest assembly. - Page 23 Heater Ventilation The cab is equipped with a heater located beneath operator’s seat. Engine coolant supplied to heater is controlled by a valve at rear of engine cylinder head Always be certain to position boom or and a push/pull knob located on right arm rest. Raise attachment on ground and stop engine knob fully for maximum heat or depress knob fully before opening or closing door or front...

- Page 24 CONTROL AND INSTRUMENT IDENTIFICATION (Common to all units unless noted) Test your controls before operating. The control pattern illustrated is the standard Gradall control pattern. If your machine controls have been modified to any other pattern, be certain you are...

-

Page 25: Electronic Monitor

Electronic Monitor An electronic monitor caution signal indi- cates a condition which could cause serious damage to your unit. Correct cause of signal before continuing operation. CAUTION SYMBOLS & ALARM Battery Charge: Symbol glows (red) in response to low battery charge (below 11.6 VDC). Engine Coolant Level: Symbol glows (red) and alarm sounds if coolant level falls below acceptable operating level. - Page 26 CHECKS & SERVICES BEFORE STARTING ENGINE (To be performed at beginning of each work shift.) Complete all required maintenance before operating unit. enter these ports, it can shorten the life of o-rings, seals, packing and bearings. When adding fluids or lubricants, refer to lubrication Use extreme caution when checking section of this manual to determine proper type, items beyond your normal reach.

- Page 27 Always stop engine when refueling. Be sure area is free of open flame, sparks or any condition which could cause fuel or fuel vapor to ignite. Check for the presence of a fully charged fire Check fuel level symbol on electronic monitor extinguisher on wall behind operator’s seat.

-

Page 28: Engine Operation

ENGINE OPERATION NOTE: If engine is being started at beginning of work shift be sure to perform all “CHECKS AND SERVICES BEFORE STARTING ENGINE’’ (pages 19 and 20). Turning ignition switch to START position while engine flywheel is rotating can cause serious damage to engine and/or starting motor. Starting Cummins Engine After engine starts, reduce speed to low idle and Insert ignition key and turn clockwise to RUN... -

Page 29: Normal Engine Operation

Normal Engine Operation Be alert for unusual noises or vibration. When an unusual condition is noticed, stop machine in a safe position and shut off engine. Determine cause and correct problem before continuing. Always operate with engine at full throttle to prevent possibility of stalling under heavy Avoid prolonged idling. - Page 30 WARM UP & OPERATIONAL CHECKS (To be performed at beginning of each work shift) Complete all required maintenance before operating unit. The safety, efficiency and service life of your excavator Observe hydraulic oil return filter caution will increased performing following symbol.

- Page 31 ADAPTER ATTACHMENT INSTALLATION Keep boom in fully extended position while installing bucket. Stay clear until bucket adapter has been fitted to bucket as shown in step 2. Digging with a loose or improperly fitted bucket can cause excessive wear, shear adapter bolts or cause loss of bucket.

- Page 32 USE YOUR CRAWLER PROPERLY Travel in forward direction whenever possible Never park crawler units on a steep incline or on (with track drive motors at rear). Traveling in the side of a hill. This can distort roller seals and reverse increases wear on sprockets and rollers. cause a loss of lubricant which could ruin the rollers.

- Page 33 HOW TO OPERATE THE CRAWLER Practice with travel controls in a safe, open area. Avoid confusion! Before actuating track drive pedals, think about the direction you are facing with respect to the direction the crawler is facing. (Drive sprockets are at rear of crawler). Confusion could cause you to travel in the direction opposite that expected.

- Page 34 When excavator/crawler functions are control pattern shown is the standard not being used, reduce engine speed to Gradall pattern. If controls have been low idle. When excavator functions are modified to another pattern, be sure you idle, there is little cooling flow thru main...

- Page 35 A TYPICAL GRADALL DIGGING CYCLE Pull back on left joystick (A) to raise boom far enough to clear all obstructions. Move right joystick to left (G) to swing left or to right (H) to swing right to digging site. While pushing right joystick forward (F) to extend...

- Page 36 A TYPICAL GRADALL DIGGING CYCLE If required, press left side of tilt switch (I) to tilt While pushing forward on left joystick (B) to counterclockwise or right side of switch (J) to tilt lower boom and force bucket into ground, pull back clockwise.

- Page 37 A TYPICAL GRADALL DIGGING CYCLE Move right joystick to right (H) to swing right or Move left joystick to left (C) to open bucket and to left (G) to swing left to dump site. If necessary, dump load. extend boom by pushing right joystick forward (F).

- Page 38 LIFTING AND POSITIONING A LOAD Precautions Do not travel with a suspended load. Excavators Do not depend on machine tipping as a warning are not designed for pick and carry lifts. of overload. Some load ratings are based on hydraulic lift capacity, not stability. Sudden swing braking can cause unexpected movement of the load and tip the machine.

- Page 39 Perform an unloaded trial run of lift to determine Measure boom height/depth from hole in adapter to maximum boom height/depth and load radius ground level (same level as bottom of tracks). Be required to complete lift. sure to allow or length of chain and height of load. Measure load radius from inner corner of frame at front of cab to vertical load line and add distance to center of rotation (69 inches).

- Page 40 LUBRICATION & MAINTENANCE DIAGRAM SYMBOLS • = Lube Fitting = Other Service = Service Both Sides Lubricant Symbols AF - ANTI-FREEZE (permanent) CG - GREASE (extreme pressure) DF - DIESEL FUEL EO - ENGINE OIL GO - MULTI-PURPOSE LUBE HF - HYDRAULIC FLUID MC - MOLYCOTE (open gear lube) LUBRICATION NOTES •...

- Page 41 Always check hourmeter and date at beginning of shift to be certain services are performed at proper interval. Perform service at whichever interval occurs first. FAILURE TO USE GRADALL HYDRAULIC FILTER ELEMENTS COULD VOID WARRANTY.

- Page 42 Recommended Lubricants & Capacities *Capacities are approximate; check level to be sure. **May vary; check vendor literature in service manual for ambient temperature limits. ***Hydraulic Fluid Specifications: Pour Point -46° F.; SSU @ 100° F. 275; Flash point 442° F. Approved Supplier &...

- Page 43 SECURING BOOM Always install shipping pin and secure with hitch pins when preparing machine for transport. Shipping pin is stored in valve compartment. TOWING REFER TO SERVICE MANUAL FOR INSTRUCTIONS FOR TOWING CRAWLER. IF YOU GET STUCK If unit becomes stuck in soft ground you can use the While actuating travel pedals/levers in appropriate boom to help free it.

- Page 44 LOADING & SECURING FOR TRANSPORT Weight with 60 inch ditching bucket is 27,000 pounds. Pad chains as necessary to prevent damage to Retract horizontal boom fully, install transport lock components and paint. Be certain right rear chain is pin and secure with hitch pies. Pins are stored in clear of hydraulic filter.

-

Page 45: General Considerations

The site should afford sufficient space to allow the you can take to protect the machine. unit to be exercised periodically. Because Gradall cannot anticipate all storage situations, • Apply Boeshield* T9 (GFradall Part No. 1440-4645) we do not provide a step-by-step procedure for short to exposed cylinder rods. - Page 46 EXCAVATOR HAND SIGNALS Standard Signals - When excavator work conditions require hand signals, they shall be provided or posted conspicuously for the use of both signalman and operator. No excavator motions shall be made unless signals are clearly understood by both signalman and operator.

- Page 47 CLOSE BUCKET - Hold one hand closed and MOVE SLOWLY - Place one hand motionless in THIS FAR TO GO - With hands raised and open stationary. Rotate other hand in small vertical circle front of hand giving motion signal. (Raise load inward, move hands laterally, indicating distance to with forefinger pointing horizontally at closed hand.

Need help?

Do you have a question about the XL2200 and is the answer not in the manual?

Questions and answers