Table of Contents

Advertisement

Quick Links

We bring better air to life

USER'S MANUAL

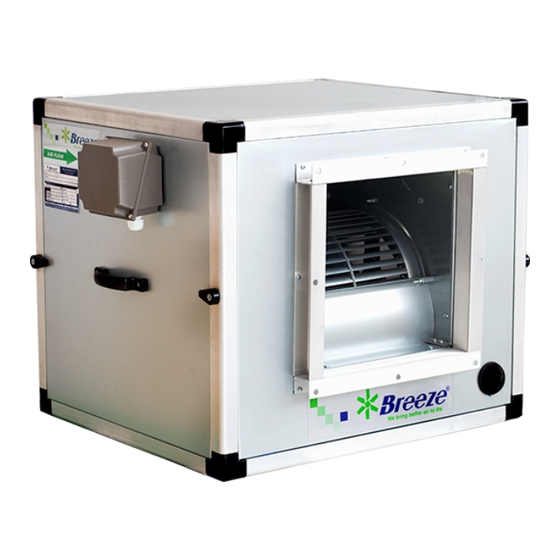

CDF / CDFS Series

CDF/CDFS 200-4 | CDF/CDFS 355-4

CDF/CDFS 225-4 | CDF/CDFS 355-6

CDF/CDFS 250-4 | CDF/CDFS 400-6

CDF/CDFS 280-4 | CDF/CDFS 450-6

CDF/CDFS 315-4 | CDF/CDFS 500-6

INLINE CENTRIFUGAL FAN

Thank you for choosing

save this user's manual for future reference. Read carefully before

attempting to assemble, install, operate or maintain the product

described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in

personal injury and property damage.

inline centrifugal fan. Please read and

2020

Advertisement

Table of Contents

Summary of Contents for Breeze CDF Series

- Page 1 We bring better air to life USER’S MANUAL CDF / CDFS Series CDF/CDFS 200-4 | CDF/CDFS 355-4 CDF/CDFS 225-4 | CDF/CDFS 355-6 CDF/CDFS 250-4 | CDF/CDFS 400-6 CDF/CDFS 280-4 | CDF/CDFS 450-6 CDF/CDFS 315-4 | CDF/CDFS 500-6 INLINE CENTRIFUGAL FAN Thank you for choosing inline centrifugal fan.

-

Page 2: General Safety Information

Should be firmly installed. Gradient installation Multiple bend at connecting part Outlet closed to crook forbidden. The product must be disposed separately at the end of its service life. Do not dispose the unit as unsorted municipal waste. www.breeze.com.vn | breezefans@breeze.com.vn... -

Page 3: Products Overview

100% speed controllable and are statically and dynamically balanced as a composite unit in our factory. The fans are also available with motor and impellers to be folded out for maintenance. Fan type: Ÿ CDF series: Standard fan. Ÿ CDFS series: Silencer box to meet the requirements of low noise. Material: •... - Page 4 7000 7500 8000 8500 9000 9500 10000 3500 4000 4500 5000 5500 6000 6500 7000 7500 CDF/CDFS 450-6 CDF/CDFS 500-6 m /h m /h 8000 8500 9000 9500 10000 10500 11000 11000 12000 13000 14000 15000 16000 www.breeze.com.vn | breezefans@breeze.com.vn...

-

Page 5: Performance Parameters

578 x 668 CDF/CDFS 355-4/6 CDF/CDFS 400-6 423 x 423 648 x 738 CDF/CDFS 450-6 1080 1030 473 x 473 728 x 858 CDF/CDFS 500-6 1019 1200 1100 1150 510 x 510 808 x 978 All dimensions in mm. www.breeze.com.vn | breezefans@breeze.com.vn... -

Page 6: Electric Installation

Spring Isolator Fig 01. Mounting type Building Construction Building Construction Spring Isolator Adjust nut to reach Adjust nut to reach Spring Isolator Stud Flexible Connection Inlet Duct Outlet Duct U-steel support U-steel support Fig 02. Hanging type www.breeze.com.vn | breezefans@breeze.com.vn... - Page 7 The equipment type and arrangement should be verified as ordered at once when it arrives at the jobsite. When a discrepancy is found, the local Breeze Sales Representative must be notified immediately so that corrective action may be investigated, also verify electrical conformance to specifications.

-

Page 8: Routine Maintenance

Too much bearing play? • Lubricant leaking from the bearings? • Surface protective coating damaged? • Attention: Conveyed medium too aggressive? • Unusual noises during operation • Fan output still sufficient for possibly extended or shortened ducting system? www.breeze.com.vn | breezefans@breeze.com.vn... - Page 9 Double speeds: 14000 20000 20000 2/4 Poles: 2880/1440 rpm 4/8 Poles: 1440/720 rpm 11000 20000 20000 4/6 Poles: 1440/960 rpm 20000 20000 6/8 Poles: 960/720 rpm 20000 20000 18000 20000 18000 20000 Service intervals for motor bearings. www.breeze.com.vn | breezefans@breeze.com.vn...

- Page 10 11. Examine motor, fan and ancillary are tight and are fully driven home in 5.8 fixing. If in doubt equipment fixings about the torque of a fixing contact Breeze Fan for advice 12. Check movement of vibration Check freedom of movement. Tighten fixings if necessary isolators (if fitted)

- Page 11 95% of their original setting to ensure no unnecessary disturbance of the fixing. See picture below for torque setting details. If in doubt about the torque of a particular fixing contact Breeze Fan for advice.

-

Page 12: Troubleshooting Table

• Weak support Strengthen base. • • Motor vibrates after • Coupling out of balance Balance coupling. corrections have been • made • Driven equipment unbalanced Rebalance driven equipment. • • Defective ball bearing Replace bearing. • www.breeze.com.vn | breezefans@breeze.com.vn... - Page 13 Rebalance the impeller o r replace the rotor. Irregular wear or corrosion o f • • the impeller Eliminate the causes of o v erheating. Impeller or shaft deformations • • Replace the roto r. due to overheating • www.breeze.com.vn | breezefans@breeze.com.vn...

- Page 14 Invert the installation of the i m peller on the shaft. • • • Performances not Excessive clearances between Adjust the clearances to c o mply with the instructions. • • obtained the impeller and the intake www.breeze.com.vn | breezefans@breeze.com.vn...

-

Page 15: Transport And Storage

• Wait until impeller is stationary. • Make sure that a restart is not possible. • Only use original spare parts manufactured and supplied by Breeze Fan. Change of motor or impeller: • Disconnect the wiring of the motor. •... - Page 16 Applied standard: BREEZE INDUSTRIAL VENTILATION JOINT STOCK COMPANY Vietnam Singapore Head Office: Office: 215D8 Nguyen Van Huong Street, Thao Dien Ward, No 15, Yishun Industrial Street District 2, Ho Chi Minh City, Vietnam. 1, #03-29, WIN5 Singapore Tel: +84 28 6651 8585 | Hotline: +84 931 920 368 S768091.

Need help?

Do you have a question about the CDF Series and is the answer not in the manual?

Questions and answers