Advertisement

Quick Links

Bendix

of Bendix

Prior to installation or performing service to ABS

controllers always perform the following steps:

1. Inspect the vehicle for damage, chafing, etc. to current

ABS unit, hoses or wiring and adjust routing of replacement

installation as necessary.

2. Turn power off.

3. Drain the air pressure from all reservoirs.

4. Remove as much contamination as possible prior to

disconnecting electrical connections and air lines.

5. Note the original controller assembly mounting position on

the vehicle.

6. Follow all General Maintenance Precautions as found

below in these instructions.

REMOVING THE ORIGINAl cONTROllER

1. Disconnect the ECU connector and any modulator

connector from the controller.

2. Remove all air lines connected to the unit. (Use spray

lubricant on the swivel fittings of the delivery lines where

necessary before attempting to remove them.)

3. Remove the controller assembly from the vehicle by

removing the mounting bracket nuts or by rotating the

entire assembly counterclockwise from the tank mount.

4. Disconnect the ABS sensors and remove the existing

harness. Bendix requires that only Bendix wheel speed

sensors be used for Bendix ABS systems.

wHEEl SPEEd SENSOR REPlAcEMENT

Due to the critical safety function provided by any ABS

product, Bendix does not assume responsibility for antilock

system reliability or performance issues in situations where

substitute non-Bendix

ABS components, not supplied by

®

Bendix (for example, substituting a non-Bendix

sensor or modulator valve) are used on a vehicle equipped

with Bendix

ABS. In addition, use of alternate components

®

in place of genuine Bendix components could lead to rejection

of ABS warranty claims. See Bulletin TCH-013-009 for more

details.

INSPEcTION

Inspect the location selected for installation and clean as

necessary.

NOTE: Inspect all components, including the replacement

trailer ABS module, for any external damage, such as

cracked valve ports, electronic housings, etc. Any

components found to be damaged should not be installed

on the vehicle and must be replaced.

INSTAllATION

1. Position and secure the ABS unit in the original mounting

orientation: (The exhaust port must point straight down.)

Tank (nipple) mount unit - Install the nipple fitting into the

ABS module supply port. Then rotate the entire assembly

into the tank port until secure. Over-torquing of the tank

nipple could cause damage to the Module.

Installation Instructions

Trailer ABS Service Replacement Kit Intended for Service Replacement

®

A-18 controller Assemblies for 2S/1M Through 4S/2M Trailer ABS

®

wheel speed

®

S-1489 ©2007 Bendix Commercial Vehicle Systems LLC 2/07 Printed in U.S.A. All Rights Reserved.

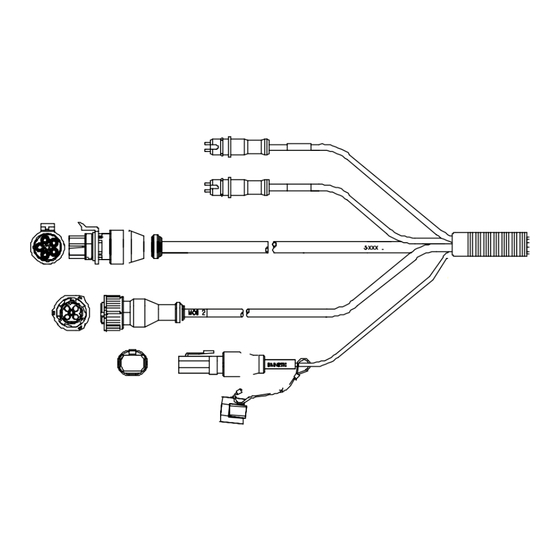

KIT cONTENTS

Item Description . . . . . . . . . . . . . . . . . . Qty.

1 . . ABS Power Harness (varies by kit). . . . . . . 1

2 . . Wheel Speed Sensor Harness . . . . . . . . . 2

3 . . Trailer ABS Module . . . . . . . . . . . . . . 1

4 . . Identification Label . . . . . . . . . . . . . . . 1

(not shown). . Service Data sheet. . . . . . . . . . 1

3

Cover

Release

Tab

FIGURE 1 - KIt (and optIonal dolly) componEnts

Frame (bracket) mount unit - Torque the mounting nuts to 180-

220 in-lbs.

2. Reconnect all air lines and plugs to the modulator-valve

assembly. Make certain that no thread sealing material enters

the valve. All air lines and fittings should be checked for leaks

prior to returning the vehicle to service.

3. Reconnect the ECU and sensor electrical connectors to the

unit. Slide the cover locking tab to gain access to the internal

connections. Apply a moderate amount of non-conductive

electrical grease to each connector pin before reconnecting.

1 (alt. style

harness)

1 (alt. style

harness)

B

A

D

2

4

E

C

Advertisement

Summary of Contents for BENDIX K019713

- Page 1 3. Reconnect the ECU and sensor electrical connectors to the Tank (nipple) mount unit - Install the nipple fitting into the unit. Slide the cover locking tab to gain access to the internal ABS module supply port. Then rotate the entire assembly connections. Apply a moderate amount of non-conductive into the tank port until secure. Over-torquing of the tank electrical grease to each connector pin before reconnecting. nipple could cause damage to the Module. S-1489 ©2007 Bendix Commercial Vehicle Systems LLC 2/07 Printed in U.S.A. All Rights Reserved.

- Page 2 5. following the vehicle manufacturer’s recommended procedures, deactivate the electrical system in a ABS wIRING manner that safely removes all electrical power from the The Bendix pigtail wiring harness and connectors are weather vehicle. resistant and sealed at the connector interface. 6. Never exceed manufacturer’s recommended pressures. 7. Never connect or disconnect a hose or line containing TROUBlESHOOTING pressure;...

- Page 3 Monday through Friday, 8:00 A.M. to 6:00 P.M. EST, and follow applications and systems. the instructions in the recorded message. 9. components with stripped threads or damaged parts Or, you may e-mail the Bendix technical assistance team at: should be replaced rather than repaired. do not attempt repairs requiring machining or welding unless specifically techteam@bendix.com.

- Page 4 • SAL & SAR (Additional Sensors) are connected to the 18-pin connector on the TABS6 ECU. • For lift axle applications, SAL & SAR (Additional Sensors) senses the wheels of the lift-able axle S-1489 ©2009 Bendix Commercial Vehicle Systems LLC 02/07 Printed in U.S.A. All Rights Reserved.

Need help?

Do you have a question about the K019713 and is the answer not in the manual?

Questions and answers