Advertisement

Advertisement

Table of Contents

Summary of Contents for Ryobi RAPS151

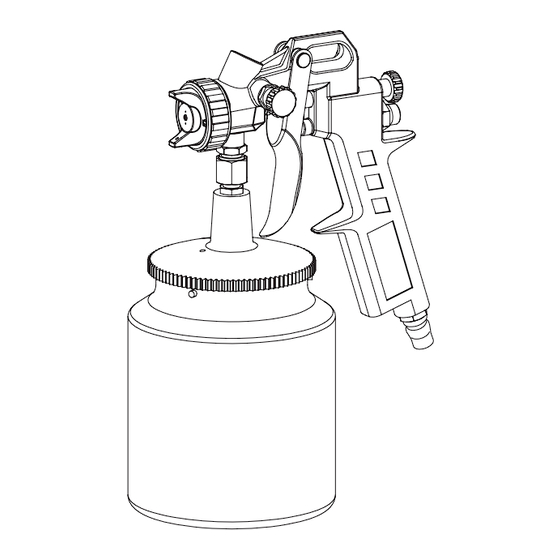

- Page 1 RAPS151 750ML SUCTION SPRAY GUN OPERATOR'S MANUAL ORIGINAL INSTRUCTIONS...

- Page 2 Important! It is essential that you read the instructions in this manual before assembling, operating, and maintaining the product. Subject to technical modifications.

- Page 3 DESCRIPTION 1. Air cap 6. NITTO style plug 11. Paint (not included) 16. Needle 2. Air cap nut 7. Paint pot 12. Quick coupler (not included) 17. Washer 3. Pattern adjustment dial 8. Wrench 13. Air hose (not included) 18. Nozzle 4.

-

Page 4: General Safety Warnings

Fig.7 Fig.6 ■ Operators and maintenance personnel shall be GENERAL SAFETY WARNINGS physically able to handle the bulk, weight and power Quick Quick of the product. ■ For multiple hazards, read and understand the safety connector connector Filter instructions before installing, operating, repairing, ■... -

Page 5: Additional Safety Instructions For Pneumatic Power Tools

■ Ensure that there are no electrical cables, gas pipes, ■ Air under pressure can cause severe injury. etc., which can cause a hazard if damaged by use of ■ Always shut off air supply, drain hose of air pressure the tool. -

Page 6: Specifications

Respiratory mask appropriate work – performed 750 ml suction spray gun Heavy-duty work gloves – Model RAPS151 Non-skid safety shoes – Hard hat – Average air consumption 230 L/min @ Safety goggles – 3 bar (43.5 psi) Hearing protection; exposure to noise can cause –... -

Page 7: Operation

Packing list WARNING! Prior to spraying, protect other people – Spray gun and property in the work area from flying debris by – Wrench providing barriers or shields. Wear appropriate personal protective equipment. – Cleaning brush – Operator’s manual WARNING! The sprayer is a precise instrument. Do not drop or expose unit to impact. - Page 8 the product's life due to excessive wear, and may be ■ Use a cardboard as a shield to catch overspray at the edges of the work to protect other surfaces. dangerous causing damage and/or personal injury. CHANGING NOZZLE AND NEEDLE ADJUSTMENT The desired pattern and volume of paint output can be See figure 6 - 7.

-

Page 9: Maintenance

■ Store the product in a dry, secure location out of reach of children. Wear ear protection. MAINTENANCE WARNING! Maintenance tasks not explained in this Wear a safety mask. manual must be carried out by qualified personnel. WARNING! To prevent serious personal injury from accidental operation, disconnect the product from the air supply and discharge any residual air pressure in the product before carrying out any inspection, maintenance... -

Page 10: Troubleshooting

TROUBLESHOOTING PROBLEM CAUSE SOLUTION The product will not start. 1. Compressor is not turned on. 1. Turn compressor on. 2. Air line is not connected properly. 2. Check that air line is connected 3. Fluid control is not open enough. properly. -

Page 11: Parts List

PARTS LIST Description Description Description Description NITTO style plug Needle spring Trigger pin Fluid inlet joint O-ring 8.5x1.8 Fluid needle set Director screw Gun body Needle Washer Container cap O-ring 3.3x2.3 Sealing screw O-ring 9x1.8 Washer Rectangle washer Sealing knob Fluid nozzle Straw Switch valve... - Page 12 31 Gilby Road, Mount Waverley VIC, 3149, Australia Techtronic Industries N.Z. Limited RYOBI is a trade mark of Ryobi Limited, and is used under license. Unit C, 70 Business Parade South NITTO is a registered trade mark owned by Nitto Kohki Co., Ltd.

Need help?

Do you have a question about the RAPS151 and is the answer not in the manual?

Questions and answers