Subscribe to Our Youtube Channel

Summary of Contents for First 24-240 SHW

- Page 1 Installation, Operation, & Maintenance IOM 8802 Rev. A 02/24 24 -240 SHW / SVW Blower Coil Units ATTENTION Read all instructions thoroughly and retain all manuals for future reference.

- Page 2 24 - 240 SHW / SVW IOM COPYRIGHT The Manufacturer works to continually improve its products and as a result, it reserves the right to change design and specifications without notice. ***WARNING TO INSTALLER, SERVICE PERSONNEL AND OWNER*** Altering the product or replacing parts with non-authorized factory parts voids all warranty or implied warranty and may result in adverse operational performance and/or a possible hazardous condition to service personnel and occupants.

-

Page 3: Table Of Contents

24 - 240 SHW / SVW IOM TABLE OF CONTENTS SAFETY CONSIDERATIONS GENERAL INFORMATION BLOWER COIL UNIT AIR DISTRIBUTION DUCTS ELECTRICAL PIPING GENERAL PIPING PRECAUTIONS 8-15 WIRING DIAGRAMS MOTOR DISCONNECT BOXES 16-17 PIPING INSULATION DUCT WORK NOISE MOUNTING INSTALLATION PRECAUTIONS START-UP OPERATION PRE-START CHECK BLOWER SPEED ADJUSTMENT... -

Page 4: Safety Considerations

24 - 240 SHW / SVW IOM SAFETY CONSIDERATIONS 1. READ THE ENTIRE MANUAL BEFORE STARTING THE INSTALLATION. 2. Improper installation, adjustment, alteration, service, maintenance, or use can cause explosion, fire, electrical shock, or other conditions which may cause personal injury damage. 3. -

Page 5: General Information

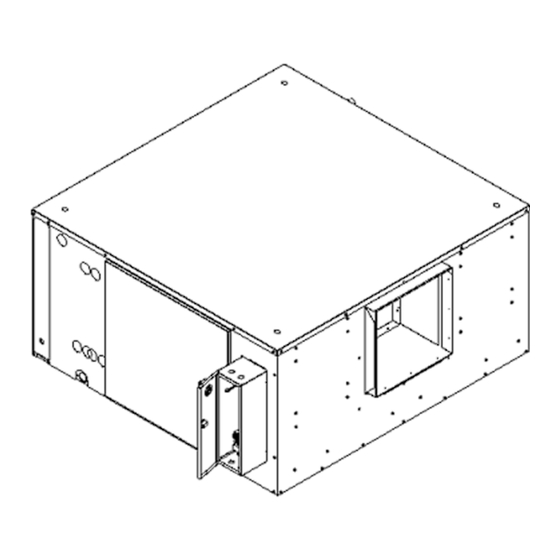

24 - 240 SHW / SVW IOM Sufficient clearance must be provided on the side of the GENERAL INFORMATION blower coil to allow access to electrical controls and to The manufactures assumes no responsibility for service the motor blower assembly. equipment installed in violation of any code Standard unit configuration is right hand looking with requirement. -

Page 6: Piping

24 - 240 SHW / SVW IOM Condensate drain lines must be installed with adequate PIPING slope away from the unit to assure positive drainage. A These units employ a hydronic coil designed for use with minimum slope of 1/4 “per foot is recommended. Field either hot or chilled water. -

Page 7: General Piping Precautions

24 - 240 SHW / SVW IOM GENERAL PIPING PRECAUTIONS 1. Flush all field piping prior to connection to remove all debris. 2. Use wet cotton rags to cool valve bodies, if present, when soldering. 3. Open all valves (mid-way for hand valves, manually open on motorized valves) prior to soldering. -

Page 8: Wiring Diagrams

24 - 240 SHW / SVW IOM WIRING DIAGRAMS Figure 2- Standard Unit Wiring Diagram Figure 3 - BAS 1-Phase WD88P001 24 - 240 SHW / SVW – IOM (Rev. A 2/24) - Page 9 24 - 240 SHW / SVW IOM WIRING DIAGRAMS (Continued) Figure 4 - BAS 3-Phase WD88P002 Figure 5 - EMS 3-Phase WD88P003 24 - 240 SHW / SVW – IOM (Rev. A 2/24)

- Page 10 24 - 240 SHW / SVW IOM WIRING DIAGRAMS (Continued) Figure 6 - SHW 120V-1Ph-60Hz Figure 7 - SHW 115/208-230V-1Ph-60Hz 24 - 240 SHW / SVW – IOM (Rev. A 2/24)

- Page 11 24 - 240 SHW / SVW IOM WIRING DIAGRAMS (Continued) Figure 8 - 277V-1Ph-60Hz Figure 9 - 575V-3Ph-60Hz 24 - 240 SHW / SVW – IOM (Rev. A 2/24)

- Page 12 24 - 240 SHW / SVW IOM WIRING DIAGRAMS (Continued) Figure 10 - 208-230/460V-3Ph-60Hz Figure 11 - 115/208-230V-1Ph-60Hz (2 Speed) 24 - 240 SHW / SVW – IOM (Rev. A 2/24)

- Page 13 24 - 240 SHW / SVW IOM WIRING DIAGRAMS (Continued) Figure 12- 110/220V-1Ph-50Hz Figure 13 - 208-230/460V-3Ph-60Hz (2 Speed) 24 - 240 SHW / SVW – IOM (Rev. A 2/24)

- Page 14 24 - 240 SHW / SVW IOM WIRING DIAGRAMS (Continued) Figure 14 - 460V-3Ph-60Hz (2 Speed) Figure 15 - 220/380/440V-3Ph-50Hz 24 - 240 SHW / SVW – IOM (Rev. A 2/24)

- Page 15 24 - 240 SHW / SVW IOM WIRING DIAGRAMS (Continued) Figure 16 - 208V-1Ph-60Hz Figure 17 - 208V-3Ph-60Hz 24 - 240 SHW / SVW – IOM (Rev. A 2/24)

-

Page 16: Motor Disconnect Boxes

24 - 240 SHW / SVW IOM MOTOR DISCONNECT BOXES Figure 18 - L3331 Figure 19 - Disconnect 240V 1PH 24 - 240 SHW / SVW – IOM (Rev. A 2/24) - Page 17 24 - 240 SHW / SVW IOM MOTOR DISCONNECT BOXES (Continued) Figure 20 - Disconnect 240/460 3PH 24 - 240 SHW / SVW – IOM (Rev. A 2/24)

-

Page 18: Piping Insulation

24 - 240 SHW / SVW IOM PIPING INSULATION After the system has been proven leak free, all lines and valve control packages must be insulated to prevent condensate drippage or insulated as specified on the building plans. NOTE Many valve packages will not physically allow all components to fit over an auxiliary drain pan. -

Page 19: Installation Precautions

2. No wiring or other work should be attempted damage. without first ensuring that the blower coil is completely disconnected from the power source and locked out. Always verify that a good ground connection exists prior to energizing any power sources. -

Page 20: Start-Up Operation

24 - 240 SHW / SVW IOM START-UP OPERATION PRE – START CHECK INSPECTION AND CLEANING 1. Check that supply voltage matches nameplate Before start-up all of the components should be given a data. thorough check. Optimal operation of this equipment 2. -

Page 21: Maintenance

24 - 240 SHW / SVW IOM MAINTENANCE To achieve maximum performance and service life of MOTOR each piece of equipment a formal schedule of regular Check motor connections to ensure that they are secure maintenance should be established and maintained by a and made in accordance with the wiring diagram. -

Page 22: Coil

24 - 240 SHW / SVW IOM MAINTENANCE (Continued) COIL Any dust or other contaminants which accumulate on the heat transfer surfaces interferes with the air flow and impairs heat transfer. The coil must be kept clean by any of the following methods. 1. -

Page 23: Notes

24 - 240 SHW / SVW IOM NOTES 24 - 240 SHW / SVW – IOM (Rev. A 2/24) - Page 24 P.O. Box 270969 Dallas, TX 75227 www.firstco.com or www.ae-air.com The manufacturer works to continually improve its products. It reserves the right to change design and specifications without notice. ©2022 First Co., Applied Environmental Air...

Need help?

Do you have a question about the 24-240 SHW and is the answer not in the manual?

Questions and answers