Table of Contents

Advertisement

Quick Links

USER AND SERVICE INSTRUCTION

USER AND SERVICE INSTRUCTION

MANUAL

SPARE PART LIST

- translation of the original instructions

translation of the original instructions -

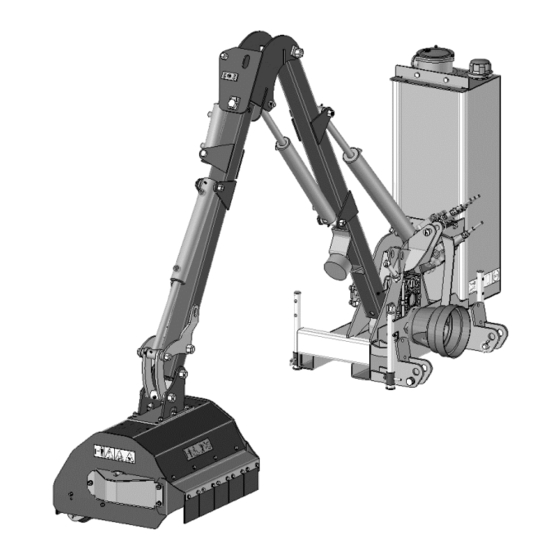

Mower with hydraulic Arm

Mower with hydraulic Arm

RBEP30L60 - L80

Please read the following instructions carefully before operating the machine and refer to them

Please read the following instructions carefully before operating the machine

Please read the following instructions carefully before operating the machine

as needed. If you do not understand a part of the user manual, please contact your MAJAR

If you do not understand a part of the user manual, please contact your MAJAR

If you do not understand a part of the user manual, please contact your MAJAR

reseller or :

MAJAR S.A

1 Route de Montréal - CS30074

11890 CARCASSONNE Cedex 9

Phone: 0033 4 68 25 38 16

FRANCE

1

04/2020

Advertisement

Table of Contents

Summary of Contents for MAJAR RBEP30L60

- Page 1 Please read the following instructions carefully before operating the machine and refer to them as needed. If you do not understand a part of the user manual, please contact your MAJAR If you do not understand a part of the user manual, please contact your MAJAR...

-

Page 2: Table Of Contents

TABLE OF CONTENTS TABLE OF CONTENTS ..........................2 FOREWORD .............................. 3 GENERAL CHARACTERISTICS ......................4 INSPECTION CHECKLIST ........................5 SUMMARY DESCRIPTION OF THE MACHINE .................. 6 HANDLING OF THE MACHINE ......................7 SAFETY REGULATIONS ......................... 8 SAFETY STICKERS ..........................9 PROTECTION DEVICE .......................... -

Page 3: Foreword

In line with the goals of continuous improvement MAJAR reserves the right to change the mac In line with the goals of continuous improvement MAJAR reserves the right to change the machines without changing the sold machines. The illustrations et characteristics of this manual may vary slightly on your due changing the sold machines. -

Page 4: General Characteristics

PTO speed Weight TRACTOR width Tr/min Tr/min Weight Weight Width (mini) (mini ini) Kg exterior tires RBEP30L60 540* 10 x 2 20/30 1.20 m RBEP30L80 540* 14 x 2 25/35 1000 1000 1.30 m *Rotation direction of joint shaft of the tractor: clockwise when standing in front of tractor output shaft... -

Page 5: Inspection Checklist

AU CONCESSIONNAIRE REVENDEUR RE REVENDEUR The assembly, installation and commissioning of the The assembly, installation and commissioning of the machine is the MAJAR reseller’s responsibility. is the MAJAR reseller’s responsibility. Please read carefully the use and care manua carefully the use and care manual and the safety regulations. Make sure that the indicated points of... -

Page 6: Summary Description Of The Machine

SUMMARY DESCRIPTION DESCRIPTION OF THE MACHINE MACHINE *This is a simplified representation without hoses and cables without hoses and cables, to simplify the presentation the presentation. Filing plug tank PTO reducer Return filter tank Frame Hydraulic tank Crusher head Cylinder distributor Hydraulic motor c motor Flow divider... -

Page 7: Handling Of The Machine

HANDLING OF THE HANDLING OF THE MACHINE MACHINE DANGER The operator who carries out the lifting operations of the machine must be competent to use The operator who carries out the lifting operations of the machine must be competent to use The operator who carries out the lifting operations of the machine must be competent to use devices for mechanical/electric lifts (bridge crane, forklifts, cranes, ..). -

Page 8: Safety Regulations

SAFETY REGULATIONS SAFETY REGULATIONS WARNING Some illustrations may show the machine without protective screen or shield. Never use the machine without Some illustrations may show the machine without protective screen or shield. Never use the machine without Some illustrations may show the machine without protective screen or shield. Never use the machine without these devices. -

Page 9: Safety Stickers

Missing or damaged stickers must be replaced immediately stickers must be replaced immediately. Contact your MAJAR reseller. The information illustrated by these symbols must be necessarily respected. The noncompliance with The information illustrated by these symbols must be necessarily respected. The noncompliance with The information illustrated by these symbols must be necessarily respected. - Page 10 EMPLACEMENT OF THE SAFETY STICKERS AND THE IDENTIFICATION PLATE...

-

Page 11: Protection Device

The protection devices must be maintained in good operating conditions and immediatly replaced if damaged. immediatly replaced if damaged. Only use original MAJAR spare part pieces y use original MAJAR spare part pieces 1 – Front shield: The machine is equipped with a protection... -

Page 12: Installation And Commissioning

AND COMMISSIONING The installation and commissioning of the to The installation and commissioning of the tool are the responsibility of the MAJAR reseller. MAJAR reseller. The machine must be delivered fully mounted, lubricated and adjusted to the normal operating conditions ricated and adjusted to the normal operating conditions ricated and adjusted to the normal operating conditions. -

Page 13: Uncoupling And Storage Of The Machine

With the machine on support stand • First remove the two included shafts on the two included shafts on the drawbar coupling. • Move back the tractor until the lower ctor until the lower arms are only a few cm of each sid a few cm of each side of the linkage axles. -

Page 14: Cardan Shaft Setting Up

CARDAN SHAFT SETTING UP SHAFT SETTING UP • DANGER More detailed information in the specific manual of the cardan More detailed information in the specific manual of the cardan More detailed information in the specific manual of the cardan which is an initial part of the safety n initial part of the safety documentation to read carefully to read carefully. -

Page 15: Setting Up Cable Control In The Cabin

• SETTING UP CABLE CONTROL IN THE SETTING UP CABLE CONTROL IN THE CABIN • The control levers must be fixed at the driver’s right hand side must be fixed at the driver’s right hand side • Fix the control block so that it does not hinder the so that it does not hinder the access to the driver’s cabine or to the other control s to the driver’s cabine or to the other control remotes of the tractor. -

Page 16: Cable Control Remote

• Cable control remote: Remember: to avoid abrupt and uncontrollable and uncontrollable movements, the oil flow rate in the cylinder system is low an cylinder system is low and the cylinder speeds are slow. This means a longer reaction time and and can give the impression of remote dysfunction when the cylinders when the cylinders are not yet purged or that the... -

Page 17: Before Starting

• BEFORE STARTING DANGER The following operations must be done exclusively with The following operations must be done exclusively with the motor stopped the motor stopped, pto disconnected, hand brake applied. If necessary lift the If necessary lift the machine, place supports to avoid falling or supports to avoid falling or failure of the tractor lifting. -

Page 18: Utilisation

• USE Never start the machine if the rotation remote of the cutting rotor is not on Never start the machine if the rotation remote of the cutting rotor is not on Never start the machine if the rotation remote of the cutting rotor is not on «... -

Page 19: Utilisation Sur Arbustes, Haies

• USE ON BUSHES, HEDGE DGES WARNING Ensure the cabine door is secured Ensure the cabine door is secured, install an adequat protection to protect you from projections. Be particularly careful with the projections and ensure Be particularly careful with the projections and ensure nobody is in the safety perimeter. - Page 20 • SECURITY OF THE ARM The machine is equipped with a security cylinder that allows the outside arms and the crushing head to release when a collision with an obstacle occurs (roots, trees, etc.) The cylinder movement allows the arms to pivot about 50°...

-

Page 21: Securite Du Bras

• SENSE OF ROTOR ROTATION ROTATION The motor of the machine can turn in the two directions turn in the two directions, we recommend a rotation in opposition to the running way of to the running way of the machine (image), corresponding to the ing to the position «... -

Page 22: Periodicité

MAINTENANCE BY USER MAINTENANCE BY USER MAINTENANCE BY USER DANGER Prior to maintenance or repair work on the machine, stop the engin, Prior to maintenance or repair work on the machine, stop the engin, Prior to maintenance or repair work on the machine, stop the engin, apply the handbrake and remove the key. -

Page 23: Niveaux - Filtres - Vidanges

LEVELS – FILTERS – DRAINING DRAINING • WARNING Do not throw away in natural environment atural environment: waste oil, mineral grease and cloths, dusters or paper , dusters or paper impregnated with these substances. Drop them into adequate containers or send them to collection centres Drop them into adequate containers or send them to collection centres Drop them into adequate containers or send them to collection centres. - Page 24 Return filter Filtering quality 25 micrometers Remove the cover maintaining it pressed on the spring Remove the cover maintaining it pressed on the spring (5) Remove the cartridge (1) and the spring and the spring (5) Remove the cup (2), clean it, check the conditions of the check the conditions of the seals (3) and (4) Oil ant replace the seals (3) and and (4), replace them if they are worn or if provided...

-

Page 25: Remplacement Of Knives

Stop the engin, apply the handbrake and remove the key. DANGER When you replace the blades, you are required to change the locknuts. Contact your MAJAR reseller to When you replace the blades, you are required to change the locknuts. Contact your MAJAR reseller to When you replace the blades, you are required to change the locknuts. -

Page 26: Declaration Of Conformity

C.E. DECLARATION OF CONFORMITY The letters CE on the identification plate of this machine certify that it is conforming to EC machine directive 2006/42/CE The Director, Jean-Luc Checa... -

Page 27: Guarantee

This guarantee does not oblige MAJAR or representative to reimburse labor costs or transport costs of the machine for reparation. -

Page 28: Spare Part List

SPARE PART LIST According to Article L.111-3 of the Consumer Code and of the Decree implementing the Code N°2014-1482 of 9th of December 2014, the availability duration of indispensable spare parts for use of MAJAR material is 7 years... - Page 34 Rep. Référence Désignation 082875 BAGUE CO1/8 Z15 186898 BANDE PROTECT AR EP800 186900 BANDE PROTECT AR EP600 186897 BANDE PROTECT AV EP800 186899 BANDE PROTECT AV EP600 582723 BOUCLIER EP800 582724 BOUCLIER EP600 582718 BRAS DROIT ROULEAU EP 582719 BRAS GAUCHE ROULEAU EP 582730 CACHE MOTEUR EP 582729...

- Page 35 Rep. Référence Désignation 9961919 VIS H 8X50/22 9960703 VIS TETE BOMBÉE CC Ø10x25 9962004 VIS H 10X35/35 082768 BAGUE ACIER 9961918 VIS H 10X40/26 9960700 VIS TETE BOMBÉE CC 10x35 9960706 VIS TETE BOMBÉE CC 8x25 9900208 ECROU H M8 9908010 RONDELLE MN 0 1O 9908073...

- Page 36 Rep. Référence Désignation 082867 LIMITEUR PRESSION 582711 CHAPE LIAISON DE BRAS 9960515 VIS CHC M5 X 20 9961972 VIS H 8X60/22 082601 GOUPILLE ANNEAU Ø8 9960514 VIS CHC M5 X 70/22 9908013 RONDELLE RESSORT 9900215 ECROU H M12 9962080 VIS H 12X35/35 9962011 VIS H 10X25/25 9962083...

- Page 37 Rep. Référence Désignation 082863 MANIPULATEUR DOUBLE 082861 MANIPULATEUR SIMPLE 082862 MANIPULATEUR SIMPLE A VERROU 9960511 VIS CHC M6 X 100 9908021 RONDELLE MN 6 9960513 VIS CHC M8 X 90/28 K11035 GAINE SPIRALE Ø30 L= 0,6m K11035 GAINE SPIRALE Ø30 L= 0,25m 082701 FLEXIBLE L0.35m 082882...

- Page 38 Rep. Référence Désignation 082902 UNION MALE 21G 1/2 CYL 082903 UNION MALE BSP 3/4"-1"CYL 082933 COLLIER DOUBLE Ø12 082346 UNION MALE 13G-3/8 NU 082354 BARRE EF540 CAT.1 582733 MULTICHAPE...

- Page 40 1 Route de Montréal - CS30074 11890 CARCASSONNE Cedex 9 Phone: 0033 4 68 25 38 16 FRANCE...

Need help?

Do you have a question about the RBEP30L60 and is the answer not in the manual?

Questions and answers