Advertisement

Quick Links

115DG30

115DG30 –130DG30 – 155DG30

Please read the following instructions carefully before operating the machine and refer to them

Please read the following instructions carefully before operating the machine and refer to them

Please read the following instructions carefully before operating the machine and refer to them

as needed. If you do not understand a part of the user manual, please contact your MAJAR

u do not understand a part of the user manual, please contact your MAJAR

u do not understand a part of the user manual, please contact your MAJAR

reseller or:

USER AND SERVICE INSTRUCTION

USER AND SERVICE INSTRUCTION

USER AND SERVICE INSTRUCTION

SPARE PART LIST

SPARE PART LIST

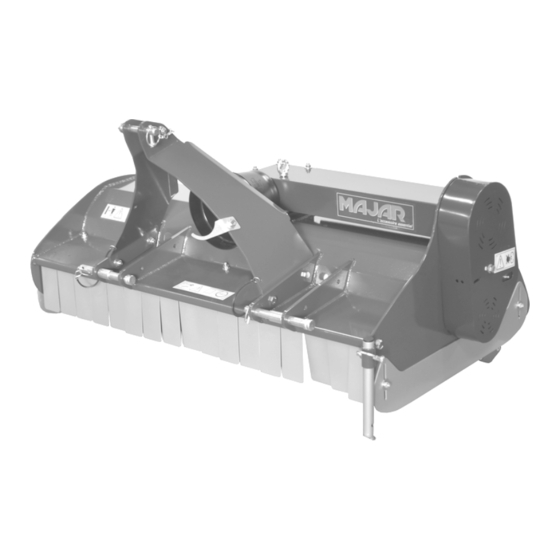

FLAIL MOWER

FLAIL MOWER

RBML - RBRM

RBML

100 – 115 – 130 – 155

100

1 Route de Montréal - CS30074

11890 CARCASSONNE Cedex 9

Phone 0033 / 4 68 25 38 16

MANUAL

MAJAR S.A

FRANCE

10/2018

Advertisement

Need help?

Do you have a question about the RBML100 and is the answer not in the manual?

Questions and answers