KRAL K Series Operating Instructions Manual

Screw pumps

Hide thumbs

Also See for K Series:

- Operating instructions manual (88 pages) ,

- Operating instructions manual (56 pages) ,

- Operating instructions manual (60 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for KRAL K Series

- Page 1 KRAL Screw Pumps – K Series. Operating Instructions OIK 08en Edition 06/2007...

-

Page 2: Table Of Contents

Table of Contents About this document Safety information for disposal General information Disposing of the pump Target groups Installation, removal and connection Symbols used Installation Danger levels Installing the pump Further applicable documents Installing the pump General safety instructions Aligning and checking the shaft coupling 23 Electrical connection Connecting the pump Labelling... -

Page 3: General Information

General information About this document General information The operating instructions form part of the pump or pump unit. The operating instructions have to be kept for future use and reference. Furthermore observe the operating instructions of the drive motor. Target groups Target group Tasks Operator-owner... -

Page 4: General Safety Instructions

Installation, removal and installation work may only be carried out by specialist personnel. Do not use KRAL pumps outside the performance limitations specified on the rating plate and in the "Technical data" section. In the case of operating data that do not agree with the specifications on the rating plate, contact the manufacturer. -

Page 5: Type Code

Type code Labelling Type code 1 Model 2 Size 3 Seal type 4 Pressure stage KF - 1300.AAA.000372 5 Heating system 6 Version index Fig. 1 Type code Item Designation Type Model Pump with free shaft end Pump casing with flanges inline Pump unit with or without foot at the pump bracket KFA: Pump with free shaft end... -

Page 6: Rating Plate

Rating plate Item Designation Type Heating system A: Without ancillary heating B: With electrical heating system C: With medium heating system X: Special heating system Version index For internal administration Rating plate 1 Nominal delivery rate 2 Nominal pressure 3 Operating temperature 4 Serial number 5 Type 6 Construction year... -

Page 7: Intended Use

Technical data Intended use KRAL screw pumps of the K series are designed solely to deliver lubricating fluids that are chemically neutral and do not contain any gas or solids content. The pumps may only be used within the operatio- nal limits described within this chapter. -

Page 8: Requisite Npsh Values

Requisite NPSH values Requisite NPSH values The following table shows the requisite NPSH values to ensure that the various pump sizes can be ope- rated without cavitation. These values are derived from the pump kinematics during operation with a low-volatility pump medium such as lubricating oil or hydraulic fluid. The following examples indicate that when pumped media have a readily volatile component content the NPSH values notably increase: Fuel oil requires an NPSH value of at least 6 mWC. -

Page 9: Noise Levels

Noise levels Pump Viscosity Rotating speed [1/min] Pump Viscosity Rotating speed [1/min] size 1450 1750 2900 3500 size 1450 1750 2900 3500 NPSH value [mWC] NPSH value [mWC] K 74 K 1101 — — — — K 85 K 1301 —... -

Page 10: Weight Table For Types Kf / Kfa / Kfn / Kft

Weight table for Types KF / KFA / KFN / KFT Weight table for Types KF / KFA / KFN / KFT Pump size K 15 K 32 K 55 K 105 K 160 K 235 K 370 K 550 K 851 K 1101 K 1501... -

Page 11: Weight Table For Type Kh

Weight table for Type KH Pump size K 15 K 32 K 55 K 105 K 160 K 235 K 370 K 550 K 851 K 1101 K 1501 K 2200 K 7.5 K 20 K 42 K 74 K 118 K 210 K 275 K 450... -

Page 12: General

General Heating system General The pumps can be equipped optionally with a heating system. This is advisable in the case of very vis- cous media that do not flow sufficiently, possibly causing increased power input or problems through cavitation or sealing. The type code provides information about the type, see Fig. -

Page 13: Medium Heating System

Medium heating system Medium heating system Operating data: Maximum pressure: 16 bar Maximum medium temperature: 200 °C 1 Heating cover 2 Piping connections Fig. 2 Medium heating system The medium heating system consists of a heating cover 1 attached additionally to the end cover through which a heating medium (vapor, thermal oil, etc.). -

Page 14: General Drawing Of A Screw Pump

General drawing of a screw pump Function description General drawing of a screw pump Fig. 1 Structure of a screw pump 1 Screw plug 8 Ball bearing, lifetime lubricated 2 Overflow valve 9 Flange cover 3 Pump casing 10 Thrust pin 4 Balancing cylinder 11 Vent hole 5 Sealing space vent... -

Page 15: Casing Variants

Casing variants Casing variants Casing Type Description KF / KH / KV Pump casing with flanges inline KFN / KFT / KVT Pump casing with DIN-flan- ges overhead, PN6 / PN16 Pump casing with special flanges overhead Tab. 1 Casing variants Function description Screw pumps belong to the group of rotating displacement pumps. -

Page 16: Mechanical Seal

Shaft seal Mechanical seal Mechanical seals require constant lubrication. The inevitable minimal leakage caused by the lubrication of the mechanical seal only amounts to a few cubic centimeters per hour and is imperative for proper functioning of the seal. Generally this leakage will evaporate and not even be noticeable. However, with low-volatility media such as heavy oil, the leakage will be visible. -

Page 17: Overflow Valve

These pumps must therefore be fitted with an overflow valve to protect them against this type of malfunction during operation. KRAL screw pumps of the K series have an integrated valve of this type. The valve is accessible via a screw plug 1 in the end cover and can be adjusted from the outside (opening pressure set in the factory: 110% of the nominal pres- sure). -

Page 18: Unpacking And Checking The State Of Delivery

Unpacking and checking the state of delivery Transportation, storage and disposal Unpacking and checking the state of delivery 1. On delivery unpack the pump/pump unit and check for damage during transportation. 2. Report damage during transportation immediately to the manufacturer. 3. -

Page 19: Storage

Storage 1. Pump: Screw eye bolts into two opposing holes at the flange cover. Pump unit: Fasten the slinging devices at the pump unit at an angle between 60° and 90°. Ensure that the center of gravity of the pump unit lies between and below the attachment points. If this is not possible, take other suitable measures to prevent the pump unit from tilting. -

Page 20: Safety Information For Disposal

Safety information for disposal Safety information for disposal WARNING! Danger of poisoning and damage to the environment through pumped medium or oil! ➤ Wear protective clothing during all the work on the pump ➤ Before disposing of the pump collect the discharging pumped medium and oil or grease and dis- pose of in accordance with the locally applicable regulations. -

Page 21: Installation

Installation Installation, removal and connection Installation Installing the pump Screw pumps can be operated in any installation position. However, we recommend that the pump not be mounted above the motor since pumped medium can ingress the motor if a leak occurs. Types: Fig. - Page 22 Installation Pump size Medium Max. mesh width Up to K 275 Light fuel oil 0.025 mm Heavy fuel oil 0.050 mm From K 370 Light fuel oil 0.035 mm Heavy fuel oil 0.070 mm Tab. 1 Mesh width of the start-up filter The pump connections to the piping system must be stress-free, as otherwise there is no guarantee that the pump will operate safely.

-

Page 23: Aligning And Checking The Shaft Coupling

Installation WARNING! Danger of damage to the device or impaired functionality through mechanical stresses. ➤ Ensure that the pump mounting on the piping system is free of mechanical stress. 1. Turn the pump shaft or the fan impeller of the motor. This tests that the pump runs smoothly. If the pump cannot be turned by hand, remedy the fault before installing the pump, see "Troubleshooting", page 51. -

Page 24: Electrical Connection

Electrical connection 1. Check the linear offset c of the coupling using a slide gauge or feeler gauge. If the limits of the above table are exceeded, loosen the fastening of the pump or motor and move the device in order to adjust the linear offset c. 2. - Page 25 Removing the pump DANGER! Risk of injury through emitted hot, poisonous or corrosive pumped medium when removing the pump. ➤ Observe the safety regulations for handling dangerous liquids. 1. In case of operation at higher temperatures wait until the unit has cooled down to the ambient tem- perature.

-

Page 26: Start-Up

Start-up Operation Start-up Filling the pump There are three possible ways to fill the pump: via the shut-off device on the suction side via the shut-off device on the pressure side via the vent holes 1 Seal vent hole 2 Suction-side vent hole 3 Pressure-side vent hole Fig. -

Page 27: Checking The Direction Of Rotation

Start-up Checking the direction of rotation The direction of rotation and the direction of flow are indicated by arrows on the pump. The direction of rotation of the motor gives the direction of rotation of the pump. That is to say, the fan impeller of the motor must rotate in the direction in which the arrow on the pump is pointing to indicate direction of rota- tion. -

Page 28: Commissioning The Pump

If the delivery pipe on the pressure side of the pump is blocked, extremely high pressure can build up which could possibly lead to the parts under pressure rupturing. KRAL screw pumps of the K series have an integrated overflow valve. The overflow valve prevents too high a pressure building up in the pump. -

Page 29: Switching Off The Pump

Switching off the pump Aids: Allen key for each pump size in accordance with the following table Pump size DIN 908 Hexagon socket K 5–20 R 1/4" SW 6 K 32–42 R 3/4" SW 8 K 55–118 R 3/4" SW 17 K 160–275 R 3/4"... -

Page 30: Resuming Pump Operation

Resuming pump operation Resuming pump operation Prerequisite: A return valve incorporated in the suction pipe, if it is possible to drain the suction pipe when the pump is at a standstill The requirements for commissioning are met, see "Commissioning the pump", page 28. WARNING! Dry running can damage pump equipment. -

Page 31: Maintenance

Maintenance Maintenance Maintenance Required maintenance The service life of the pump depends to a great extent on the operating conditions of the pump. If the operating limits are observed, see "Technical data", page 7, the pump has a service life of many years. The following table can be used to determine signs of progressive wear of the individual pump elements. -

Page 32: Maintaining The Mechanical Seal

Maintenance Maintaining the mechanical seal plastic, etc.). 3. Clean the line or hole, if it is not free. When operating the pump with low volatile liquids 4. Reconnect any drainage line that is connec- (e.g. heavy fuel oil) the regular small amounts of ted. -

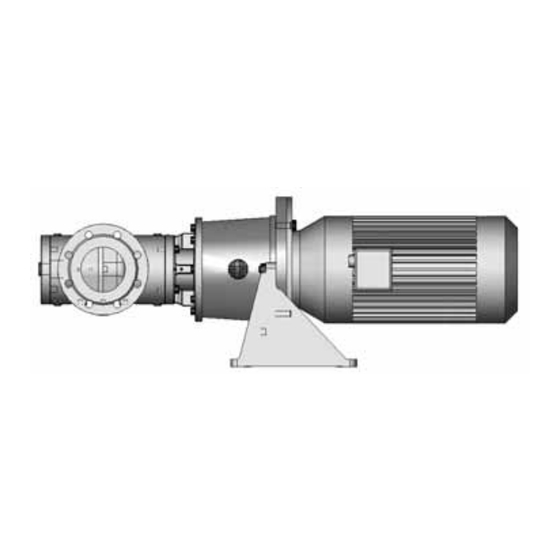

Page 33: Replacing The Coupling

Replacing the coupling Replacing the coupling General drawing 052,1 052,2 052,3 914,3 914,4 Fig. 1 Exploded view of a K-pump with completion and motor Pump Coupling intermediate ring Coupling complete Pump bracket foot 052,1 Pumpside coupling part Motor 052,2 Motorside coupling part Hexagon screws 052,3 Distance sleeve... -

Page 34: Removing The Coupling

Replacing the coupling Removing the coupling Prerequisite: Pump dismantled, see "Removing the pump", page 24 3. Loosen the fixation screw at the motor-side coupling part 052,2. 1. Before starting to disassemble, use suitable covers to protect the inlet and outlets opening of the pump against solid particles and soi- ling. -

Page 35: Mounting The Coupling

Replacing the coupling 1. Slide the distance sleeve 052,3 of the coup- 6. Loosen the fixation screw at the pump-side ling flush onto the circlip of the bearing. coupling part 052,1 and remove the coupling parts using suitable mounting levers. 2. - Page 36 Replacing the coupling 4. Measure the distance X between the face of 7. Insert the elastic coupling intermediate ring the coupling and the connecting surface of 525 and tighten the fixation screw at the cou- the pump bracket. pling part 052,2. 5.

-

Page 37: General Drawing For Mounting

General drawing for mounting General drawing for mounting Overview Balancing cylinder 457,2* Counter ring 729,4 Flat gasket 055**** Support ring 457,3* Rotating ring 729,5 Flat gasket Support ring 457,4* O-ring 729,7*** Flat gasket 062,1 Support ring 457,5* Thrust ring 729,8** Flat gasket End cover 457,6* Conical spring... -

Page 38: Replacing The Mechanical Seal

Replacing the mechanical seal Replacing the mechanical seal Removing the mechanical seal Prerequisite: Pump dismantled, see "Removing the pump", page 24. 3. Remove the circlip 471,2, remove the support ring 056. 1. Unscrew the four socket screws 914,1 at the flange cover 074 and loosen the flange cover using light "rebound"... -

Page 39: Mounting The Mechanical Seal

Replacing the mechanical seal Mounting the mechanical seal Prerequisite: Replacement seal available New flat gasket available 1. Carefully remove residue if the flat gasket 729,5 from the flange cover 074 and pump casing 131. 6. Push the counter ring 457,2* of the mechani- cal seal carefully out of the flange cover 074 using a soft rod. - Page 40 Replacing the mechanical seal 7. Clean the main screw around the mechanical 4. Insert the counter ring 457,2* of the replace- seal carefully and grease it. Place on the sup- ment part with the drawn-on o-ring 457,1* into port ring 062,1 . Turn the conical spring the flange cover.

- Page 41 Replacing the mechanical seal 12. Turn the premounted unit until the vent hole in 9. Press the main screw with the pushed-on the flange cover 074 is located at the same parts of the replacement seal into the ball position as the corresponding hole in the bearing 817 in the flange cover 074 until it pump casing 131.

-

Page 42: Exchanging The Domsel Type Radial Seal

Exchanging the Domsel type radial seal Exchanging the Domsel type radial seal Removing the radial seal Prerequisite: Pump dismantled, see "Removing the pump", page 24. 3. Remove the circlip 471,2, remove the support ring 056. 1. Unscrew the four socket screws 914,1 at the flange cover 074 and loosen the flange cover using light "rebound"... -

Page 43: Mounting The Radial Seal

Exchanging the Domsel type radial seal 3. Prepare a suitable rod for mounting the 6. Remove the support ring 745,2** and radial sealing ring. The rod must lie flat on the sup- seal 745,3**. Use a suitable rod if manual dis- port body of the sealing ring and may not mantling is not possible. - Page 44 Exchanging the Domsel type radial seal 6. Insert the support ring 745,2** and circlip 9. Insert the ball bearing 817. 745,1** that is used to axially secure the radial seal 745,3**. 10. Press the ball bearing until it stops in the flange cover 074.

-

Page 45: Replacing The Ball Bearing

Replacing the ball bearing screws 661,2. Rotate the main screw. Screw in the socket screws 914,1 at the flange cover and tighten it. Replacing the ball bearing Removing the ball bearing Prerequisite: Pump dismantled, see "Removing the pump", page 24. 12. -

Page 46: Mounting The Ball Bearing

Replacing the ball bearing 3. Remove the circlip 471,2, remove the support 6. Pull the ball bearing 817 out of the flange ring 056. cover 074 using a pulling-off device. Mounting the ball bearing Prerequisite: Replacement bearing available New flat gasket available 1. - Page 47 Replacing the ball bearing 6. Slide the support ring 056 and mount the cir- 3. Fasten the ball bearing 817 with the circlip clip 471,2 used to fasten the main screw 471,3 in the flange cover 074. 661,1. 4. Carefully clean the slide surfaces of the rota- 7.

-

Page 48: Replacing The Screw Set

Replacing the screw set 9. Slide the premounted unit consisting of flange 3. Pull the withdrawable unit consisting of main cover and main screw into the pump casing screw, bearing, seal and flange cover out of until the main screw 661,1 engages into the the pump casing 131. -

Page 49: Mounting The Screw Set

Replacing the screw set 1. Carefully remove residue if the flat gasket 729,5 from the flange cover 074 and pump casing 131. 6. Slide the rotating ring 457,3* with the conical spring 457,6*, thrust ring 457,5* and o-ring 457,1* from the main screw 661,1 with a slight rotating movement. - Page 50 Replacing the screw set 7. Remove the adhesive foil from the new flat 4. Carefully clean the slide surfaces of the rota- gasket 729,5. Place the flat gasket on the ting ring 457,3* and counter ring 457,2* using pump casing 131, press it on slightly. cleaning spirit and then administer a drop of Attention: Sealing surface must be clean and resin-free lubricating oil.

-

Page 51: Information About Faults

Information about faults Troubleshooting Information about faults Faults can have different causes. The following table lists the symptoms of a fault, the possible causes and measures for elimination. Possible faults Fault Cause / Elimination No pump suction 1, 2, 3, 4, 5, 6, 7, 8, 35 Delivery rate too low 2, 3, 4, 9, 10, 11, 12, 13, 14, 15, 16, 17 Pump runs noisily... - Page 52 Information about faults Cause Remedy ➤ Viscosity of the pumped medium too Increase the temperature of the medium high - or - ➤ Reduce the rotation speed. ➤ Viscosity of the pumped medium too Decrease the temperature of the medium - or - ➤...

- Page 53 Information about faults Cause Remedy ➤ Seal overload during To prevent thermal expansion of the media causing heating process a build-up of pressure, open the pressure- or suc- tion-side shut-off devices. ➤ Leaking return valve causes seal Clean the return valve and if necessary, replace it. overload when pump is at a standstill Foreign bodies in the pump 1.

-

Page 54: General Drawings

General drawings Appendix General drawings 052,1 052,2 052,3 914,3 914,4 Fig. 1 Exploded view of a K-pump with coupling and motor Fig. 2 Exploded view K 5 – 660 OIK 08en Edition 06/2007... - Page 55 General drawings Fig. 3 Exploded view K 851 – 1301 Fig. 4 Exploded view K 1500 – 1700 OIK 08en Edition 06/2007...

- Page 56 General drawings Fig. 5 Exploded view K 2200 – 2900 OIK 08en Edition 06/2007...

- Page 57 General drawings Fig. 6 Exploded view KFN 5 – 118 / KFT/KVT 5 – 210 OIK 08en Edition 06/2007...

-

Page 58: Spare Parts

Spare parts Spare parts Spare part Part Spare part Part Pump 471,3 Circlip Distance sleeve Spring Balancing cylinder Coupling intermediate ring Coupling complete Pump bracket foot 055**** Support ring Motor Support ring Valve casing Threaded ring Screw set 062,1 Support ring 729,1 Flat gasket 062,2++... - Page 59 Spare parts OIK 08en Edition 06/2007...

- Page 60 KRAL AG, Bildgasse 40, Industrie Nord, 6890 Lustenau, Austria,Tel.: +43 / 55 77 / 8 66 44 - 0 Fax: +43 / 55 77 / 8 84 33, www.kral.at, E-mail: kral@kral.at...

Need help?

Do you have a question about the K Series and is the answer not in the manual?

Questions and answers