Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for GUOZHI ARC-130

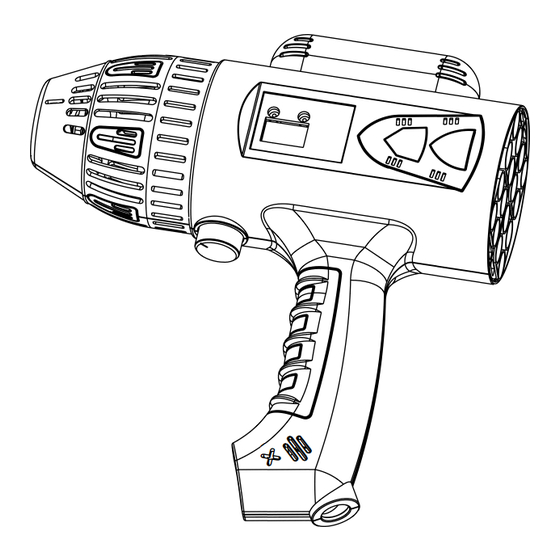

- Page 1 OWNER’S MANUAL -1 0 Welding Machine - STICK...

-

Page 2: Table Of Contents

Contents ............ 2 Contents & Explanation of Symbols ............ 3 Safety Warning ............ 5 Introduction and Specifications ...........7 Technical Specification Packing List Quick Setup And Use Guide Use ............8 Operation ........ 9 Trouble Shooting ........... 10 Operating Precautions ........... 11 Maintenance ........... -

Page 3: Safety Warning

Safety Warning IMPORTANT: BEFORE INSTALLING, OPERATING OR CARRYING OUT MAINTE- NANCE ON THE STICK WELDER, READ THE CONTENTS OF THIS MANUAL CAREFULLY, WHICH MUST BE STORED IN A PLACE FAMILIAR TO ALL USERS FOR THE ENTIRE OPERATIVE LIFE-SPAN OF THE MACHINE. PAY PARTICULAR ATTENTION TO THE SAFETY RULES.THIS EQUIPMENT MUST BE USED SOLELY FOR STICK WELDER. - Page 4 CE COMPLIANCE: This equipment complies with the European Community Directives. ARTIFICIAL OPTICAL RADIATION: According with the requirements in 2006/25/EC Directive and EN 12198 Standard, the equipment is a category 2. It makes mandatory the adoption of Personal Protective Equipments (PPE) having filter with a protection degree up to a maximum of 15, as required by EN169 Standard.

-

Page 5: Introduction And Specifications

Introduction And Specifications Do not direct metallic dust or any dirt intentionally General overview: -1 0 from is a DC toward the machine, particularly in grinding and stick purpose unit, designed for portable repair work welding operations. Make sure the panel is protected and small project use. - Page 6 Over Current. Over currents can occur if there is a This manual has been compiled to give an overview of operation and is designed to offer fault in the power supply system or inside the unit. If information centered around safe, practical this occurs, and the LED lights up, turn the unit off, use of the welder.

-

Page 7: Technical Specification Packing List

Technical Specification -1 0 STICK -120A Welding current Range(A) 115V Nominal DC Open Circuit Voltage (OCV) 1 0A/2 Welding output( STICK STICK 115V Rated Input Current(A) %@1 0A 100%@ Duty Cycle (%) STICK Efficiency Power factor 0. 3 Welder Type STICK WELDER Output Terminal Type Direct Wire... -

Page 8: Quick Setup And Use Guide Use

Quick Setup And Use Guide Stick Welding ( First determine the proper electrode polarity for the electrode to be used. Consult the electrode data for this information. Then connect the output cables to the output terminals of the machine for the selected polarity. -

Page 9: Operation

START STICK OPERATION Electrode holder connection Connect the to the (+) terminal and the the (-) terminal. Insert the connector with the key lining up with the keyway and rotate approximately ¼ Earth clamp connection turn clockwise. Do not over tighten. STICK OPERATION STARTING METHODS Tapping Method... -

Page 10: Trouble Shooting

Trouble Shooting Stick Trouble shooting: CAUSE/SOLUTION Check cords and wiring in the plug. Machine will not turn on. Check for sound work clamp and cable Machine runs, but will not weld in either connections. Make sure work cable are mode. securely fastened to the Dinse style connector. -

Page 11: Operating Precautions

Operating Precautions A. OperatingEnvironment 1. The machine can perform in environments where conditions are dry with a max humidity of 60%. 2. Ambient temperature should be between -10 to +40 degrees centigrade. 3. Avoid operating machine in direct sunshine, rain, or snow. 4. -

Page 12: Maintenance

Maintenance WARNING! Before maintenance and checking, power must be turned off, Before opening the cover disconnect the machine from electricity! DO NOT REPAIR OR MODIFY MACHINE IF STILL UNDER WARRANTY! 1. Remove dust with dry, machine is operated in an area where the air is polluted with smoke and dust, the machine needs to be cleaned regularly, remove dust monthly.

Need help?

Do you have a question about the ARC-130 and is the answer not in the manual?

Questions and answers