Summary of Contents for DICKOW PUMPEN SC

- Page 1 Oper at ion / I nst allat ion I nst r uct ions No. 44.SC.E3.09/ 17 Original Manual...

-

Page 2: Table Of Contents

Maintenance / Servicing / Inspection ....................29 7.1 Safety regulations ........................29 7.2 Operating surveillance .........................30 7.3 Drainage and Disposal .........................31 7.4 Disassembly of pump unit ......................31 7.5 Inspection ............................34 7.6 Assembly of pump unit .......................35 7.7 Bolt torques ..........................40 SC E3 09.17 2 of 50... - Page 3 Table of Cont ent s 8. Troubleshooting ..........................42 9. Interchangeability ..........................44 10. Sectional drawings ..........................45 10.1 Pump ............................45 10.2 Mechanical Seals .........................47 11. Certificates ............................49 11.1 EC-Declaration of Conformity .......................49 11.2 Document of Compliance ......................50 SC E3 09.17 3 of 50...

-

Page 4: General

The serial number is a precise description of the pump unit and serves as identification for all following procedures. In the event of damage the Customer Service of Dickow Pumpen must immediately be informed in order to maintain guarantee claims. -

Page 5: Safety

Together with a signal word, it signifies dangers in connection with death or injury. Dangerous voltage Together with a signal word, it signifies dangers in connection with voltage. Warning from magnetic field Together with a signal word, it signifies dangers in connection with magnetic fields. SC E3 09.17 5 of 50... -

Page 6: Intended Use

Consider and adhere to all safety instructions and other notices mentioned in the operating manual. Qualificat ion of per sonnel The personnel must possess the relevant qualification for assembly, operation, maintenance and inspection of the pump unit. Responsibility, competence and supervision must be strictly regulated by the owner. SC E3 09.17 6 of 50... -

Page 7: Additional Safety Regulations

Saf et y inst r uct ions f or m aint enance, inspect ion and assem bly Alteration works or modifications on the pump are only allowed after consulting Dickow Pumpen. Only original parts or parts approved by Dickow shall be used. -

Page 8: Notices On Explosion Protection

The pump may only be operated within the limits given in the pump data sheet and on the name tag. In case the owner cannot maintain the operating limits, monitoring devices are required. More information about monitoring devices can be inquired at DICKOW Pumpen. 2.9.3... -

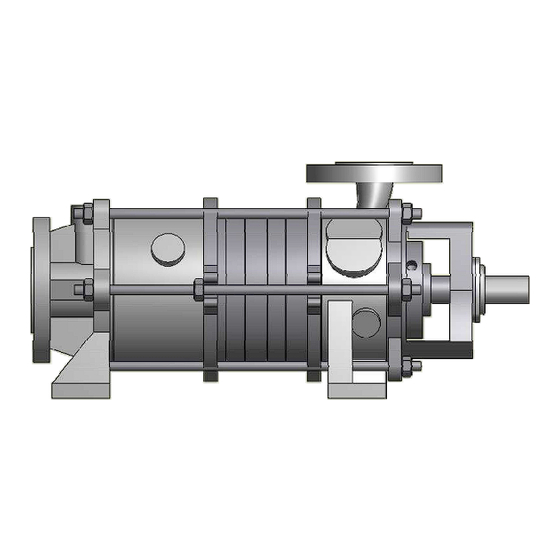

Page 9: Description

The pumps are not suitable for handling solid containing liquids. Design code Example: SC h 3562 A Ge Pump code Pump type Material execution; e.g. h = 1.4408 / 1.4571 Pump size;... -

Page 10: Identification

T-area or temperature range as well as the symbol “X” (behind the reference number of technical documentation) for special operating conditions regarding the temperature. Chapter 2.9.1 refers to the arising surface temperatures. Space permitting, this Ex-marking is integrated in the name plate as per chapter 3.4.1. SC E3 09.17 10 of 50... -

Page 11: Design

Shaft sealing gland packing single or double mechanical seal cartridge seal 3.5.1 Flange arrangements Fig. 3: end suction flange Fig. 4: vertical suction flange – clockwise rotation – design variant: 3 SC E3 09.17 11 of 50... -

Page 12: Scope Of Supply

Casted baseplate respectively welded baseframe of sturdy design Drive motor Special accessories if required Dim ensions and Weight s Dimensions and weights can be taken from the foundation plan / dimensional drawing. SC E3 09.17 12 of 50... -

Page 13: Handling / Storage / Disposal

Observe the local accident prevention regulations. Use suitable and approved lifting accessories. Fig. 5: lifting the pump Fig. 6: lifting the complete pump unit Fig. 7: lifting the pump mounted on baseplate SC E3 09.17 13 of 50... -

Page 14: Storage / Preservation

New pumps of material GGG (ductile iron) and ferritic cast steel are covered inside with anti-corrosive agent and dewatering-fluid. The maximum inside storage period is 12 months. If the storage period will be longer than 12 months, Dickow Pumpen must be informed. The pumps need to be treated with a long-term preservation, e.g.nitrogen-preservation. -

Page 15: Disposal

Consider the legal regulations for disposal of liquids dangerous to health. 1. Disassemble pump / pump unit. 2. Collect grease and oil. 3. Separate pump materials 4. Dispose according to the local regulations. SC E3 09.17 15 of 50... -

Page 16: Installation / Mounting

8. Tighten the foundation bolts evenly. 9. Pour the base plate with vibration-free concrete of normal graining with a water-cement-value (W/Z-value) ≤ 0,5. Provide a pourable consistency by using a mobile solvent. Cure of concrete according to DIN 1045. SC E3 09.17 16 of 50... -

Page 17: Piping

Never connect a larger suction pipe direct to the pump. Flow eddies reduce the free flow area of the pump. Use an eccentric reducer. Consider the figures below. Abb. 8: Flow eddies Abb. 9: Reducer connection SC E3 09.17 17 of 50... - Page 18 630 1260 555 1110 510 1020 1980 1190 1560 1085 630 1260 555 1110 510 1020 1980 1190 1560 1085 750 1500 675 1350 615 1230 1185 2370 1295 555 1110 510 1020 630 1260 990 1980 1190 SC E3 09.17 18 of 50...

- Page 19 Σ / M / m a x . a l l o w a b l e m a x . a l l o w a b l e SC E3 09.17 19 of 50...

-

Page 20: Insulation

Coupling check has also to be performed at pump units supplied on common base plate. For higher operating temperatures a second alignment at operating temperature is absolutely necessary. Fig. 10: Angular and radial misalignment of couplings SC E3 09.17 20 of 50... -

Page 21: Alignment Of Pump And Motor

Use shims for height compensation. 1. Dismantle coupling guard. 2. Check coupling alignment. Consider chapter 5.6. 3. Loosen hold down bolts of motor. 4. Place shims under the motor feet for height compensation. SC E3 09.17 21 of 50... -

Page 22: Electrical Connection Of The Pump Unit

1. Check for compliance of the available supply voltage with the indications on the motor name tag. 2. Select suitable connection method. 3. Check for identical rotating direction of motor and pump. Consider the rotating direction arrow of the pump! NOTE Observe the instruction manual of the motor! SC E3 09.17 22 of 50... - Page 23 1. Start motor briefly. Note rotating direction of the motor. 2. Rotating direction of the motor must comply with the rotating direction arrow on the pump. 3. In case of wrong rotating direction, change the cables in the motor terminal box. SC E3 09.17 23 of 50...

-

Page 24: Commissioning / Decommissioning

In case of external flush, the pump must be flushed with the quantities and pressures as stated in the pump data sheet respectively in the dimensional drawing. SC E3 09.17 24 of 50... - Page 25 Danger of explosion! Leakage of hot or toxic liquid Never operate pump with closed shut-off valves in suction and/or discharge pipe. Start-up pump unit only against partially opened shut-off valve on discharge side. SC E3 09.17 25 of 50...

-

Page 26: Operating The Pump

Maintain the allowable service conditions specified in the pump data sheet. Avoid operation against closed shut-off valve. Never operate pump at a temperature higher than specified in the pump data sheet. SC E3 09.17 26 of 50... -

Page 27: Switching Off The Pump

Liquids which tend to polymerization, crystallization or solidification, must be drained completely. If required, rinse the pump with a suitable liquid. Close shut-off valve in the suction pipe. Flush connections must be closed. SC E3 09.17 27 of 50... -

Page 28: Decommissioning

Plug suction and discharge flanges, e.g. with plastic caps. Lubricate all unpainted outside surfaces of the pump with oil and grease free of silicone. Not required for stainless steel pumps. Pay attention to additional notes in chapter 4.2. SC E3 09.17 28 of 50... -

Page 29: Maintenance / Servicing / Inspection

The user must assure that maintenance, inspection and assembly is performed by qualified personnel. These persons must have studied this operating manual comprehensively. A maintenance schedule needs a minimum of effort and may avoid expensive repairs. Any use of force on the pump unit must be avoided. SC E3 09.17 29 of 50... -

Page 30: Operating Surveillance

7.2.2 Lubrication of sleeve bearings Sleeve bearings require a stable liquid film. Checking of wear must be done: after dry run or cavitation. when vibrations, noises and power consumption are increasing. SC E3 09.17 30 of 50... -

Page 31: Drainage And Disposal

7.4.2 Removal of driver 1. Disconnect the motor. 2. Remove coupling guard. 3. Remove the hold down bolts of the motor from the baseplate. 4. Decouple pump and motor by displacing the motor. SC E3 09.17 31 of 50... - Page 32 7. Loosen grub screw 904.1 and remove deflector 507. 8. Press the radial ball bearing out off the bearing bracket housing. 7.4.5 Replacement of antifriction bearings Pump size 25 - 40 6304 2ZR 45 + 50 6305 2ZR 6306 2ZR SC E3 09.17 32 of 50...

- Page 33 3. Loosen grub screws and pull off the complete seal unit 433 from pump shaft. 7.4.7 Disassembly of impellers Possibly available residues of pumped liquid WARNI NG Danger for individuals and environment! Wear protective clothing. SC E3 09.17 33 of 50...

-

Page 34: Inspection

Measure the inner diameters of ball bearing seats. Replace the bearing bracket housing if the following values are exceeded. → Pump size 25 – 40 52,009 mm → Pump size 45 + 50 62,009 mm → Pump size 65 72,009 mm SC E3 09.17 34 of 50... -

Page 35: Assembly Of Pump Unit

Surface of shaft sleeve must be clean and smooth. The edge has a chamfer. Gland packing 1. Slide the gland packings 461 into the discharge casing 107. Number of packing rings can be taken from the table below. SC E3 09.17 35 of 50... - Page 36 25 – 40 115,9 45 + 50 121,9 191,9 Fig. 12: Setting dimension L (1) 3. Slide the mechanical seal 433 together with shaft sleeve 527 onto the pump shaft up to dimension “L”. SC E3 09.17 36 of 50...

- Page 37 The setting dimensions listed in the table apply only to the seal design „Te“ (= balanced both-sided). For seal design “balanced/unbalanced” and “unbalanced/unbalanced” consult Dickow Pumpen. 2. Slide the mechanical seal 433.1 together with shaft sleeve 527 onto the pump shaft up to dimension „L ”.

- Page 38 6. Slide the bearing bracket housing together with ball bearing onto the pump shaft 211 until limit. 7. Slide on the spacer disk 551 and secure it with circlip 932. 8. Fit the bearing cover 360.1 and tighten hexagon head bolts 901.2. SC E3 09.17 38 of 50...

- Page 39 14. Slide on intermediate ring 509.1 together with distance ring 504. 15. Insert key 940.3. 16. Slide on suction impeller 231 and fasten it with inner hexagon cap screw 914.4 respectively impeller nut 922 (left hand thread). SC E3 09.17 39 of 50...

-

Page 40: Bolt Torques

80% Yield strength utilisation of screw material. Friction coefficient μ = 0,14 ; use screw lubricant for threads and head- / nut contact surface. Recommended: Klüber-paste HEL 46-450. Torque controlled tightening by torque wrench. SC E3 09.17 40 of 50... - Page 41 G 1/2 = 75 Nm Bolt torques for impeller nut 922 respectively inner hexagon cap screw 914.6 (independent of material): 922 resp. 914.6 Pump size Bolt torque [Nm] Wrench size 25 - 50 SC E3 09.17 41 of 50...

-

Page 42: Troubleshooting

Check piping connections and Pump stressed by piping pump mounting Ball bearing damage Renew antifriction bearings X Unbalance of rotating parts Balance the parts Tighten screws and plugs Casing screws and screwed plugs loose Renew gaskets SC E3 09.17 42 of 50... - Page 43 Enlarge cross section Replace elastomeres Damaged elastomeres on mechanical seal Check material consistency Boiling point of pumped liquid Use double mechanical seal at atmospheric pressure is below the operating Use seal with steam quench temperature SC E3 09.17 43 of 50...

-

Page 44: Interchangeability

9. I nt er changeabilit y 9. I nt er changeabilit y SC E3 09.17 44 of 50... -

Page 45: Sectional Drawings

10. Sect ional dr aw ings 10. Sect ional dr aw ings 10.1 Pum p Fig. 16: Sectional drawing – Standard design SC SC E3 09.17 45 of 50... - Page 46 10. Sect ional dr aw ings Fig. 17: Sectional drawing – vertical suction flange – design variant 3 Fig. 18: Impeller bolting SC 65 Abb. 19: wear resistant design SC E3 09.17 46 of 50...

-

Page 47: Mechanical Seals

10.2 Mechanical Seals Fig. 20: single acting Standard mechanical seal. Fig. 21: Tandem-Standard mechanical seal, Design “Ge” Design “Te” Fig. 22: double acting Standard mechanical seal, Fig. 23: Cartridge-mechanical seal Design „Gde“ Design “Cart” SC E3 09.17 47 of 50... - Page 48 10. Sect ional dr aw ings Fig. 24: Design with stuffing box SC E3 09.17 48 of 50...

-

Page 49: Certificates

11.1 EC-Declar at ion of Conf or m it y EC-Declaration of Conformity according to EC-Machinery Directive 2006/42/EG, Annex II, No. 1A DICKOW PUMPEN GmbH & Co. KG Siemensstraße 22 D-84478 Waldkraiburg Herewith we declare that the pump unit described in the data sheet... -

Page 50: Document Of Compliance

The following safety measures must be taken before opening/repairing the pump: Customer data Company: Phone: Fax: Address: E-Mail: Name: Position: (Block Letters) This is to certify that the above mentioned pump has been proper cleaned/flushed/breamed and repair can be performed without risk. Date: Signature: SC E3 09.17 50 of 50...

Need help?

Do you have a question about the SC and is the answer not in the manual?

Questions and answers