Summary of Contents for DICKOW PUMPEN GMB Series

- Page 1 Oper at ion / I nst allat ion I nst r uct ions No. 44.GMB.E0.09/ 16 Original Manual...

-

Page 2: Table Of Contents

Table of Cont ent s Table of Cont ent s Table of Contents ............................2 1. General..............................4 2.1 Designation of Warning Notices ....................5 2.2 Intended use ..........................6 2.3 Avoidance of foreseeable operating errors ................... 6 2.4 Qualification of personnel ......................7 2.5 ... - Page 3 Table of Cont ent s 10. Certificates ............................40 10.1 EC-Declaration of Conformity ....................40 10.2 Document of Compliance ......................41 GMB E0 09.16 3 of 41...

-

Page 4: General

The serial number is a precise description of the pump unit and serves as identification for all following procedures. In the event of damage the Customer Service of Dickow Pumpen must immediately be informed in order to maintain guarantee claims. -

Page 5: Designation Of Warning Notices

2. Saf et y 2. Saf et y The manual includes basic instructions for installation, operation and maintenance. Only if these instructions are strictly observed, a safe handling of pump or pump unit is guaranteed and personal injury and material damage is avoided. All the safety instructions in this manual must be considered. -

Page 6: Intended Use

2. Saf et y Warning from magnetic field Together with a signal word, it signifies dangers in connection with magnetic fields. Hot surface Together with a signal word, it signifies dangers in connection with hot surfaces. Explosion protection Gives information on protection from explosion development in hazardous area according to EC-Directive 94/9/EG. -

Page 7: Qualification Of Personnel

Saf et y inst r uct ions f or m aint enance, inspect ion and assem bly Alteration works or modifications on the pump are only allowed after consulting Dickow Pumpen. Only original parts or parts approved by Dickow shall be used. -

Page 8: Non-Observance Of The Instruction Manual

2. Saf et y Non-obser vance of t he inst r uct ion m anual Non-observance of this manual leads to loss of warranty and damage claims. Non-observance will involve the following risks: Endangering of individuals through electrical, thermal, mechanical and chemical impacts. ... - Page 9 2. Saf et y Fig. 1: Containment shell temperature as a function of magnet losses P based on water. medium medium medium Inlet temperature of product at suction flange Refer to Figure 1 Specific heat capacity of water = 4,187 kJ / kgK Specific heat capacity of handled liquid [kJ / kgK] medium ...

- Page 10 2. Saf et y 2.9.2 Monitoring devices The pump may only be operated within the limits given in the pump data sheet and on the name tag. In case the owner cannot maintain the operating limits, monitoring devices are required. The following risks must be considered: ...

-

Page 11: Magnet Coupling

2. Saf et y 2.10 Magnet coupling Strong magnetic field from the area of the magnet coupling or from single DANGER magnets. Danger to life for individuals with pace maker! Disturbance of magnetic data media, electronic devices, components and instruments! Uncontrolled attractive force between magnetic components, tools etc.! ... -

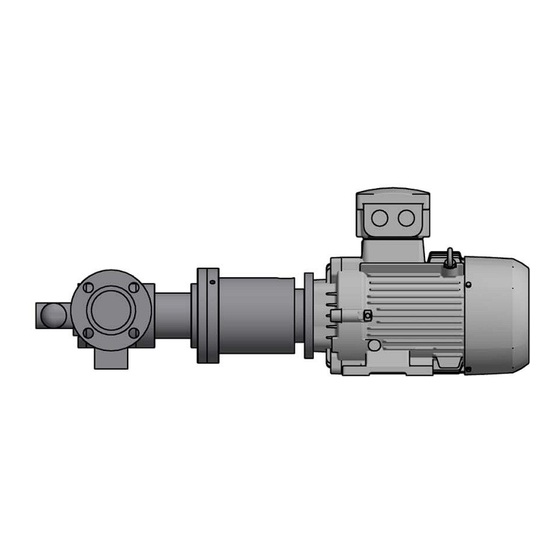

Page 12: Description

3. Descr ipt ion 3. Descr ipt ion Gener al descr ipt ion These gear pumps operate according to the internal gear principle in order to generate the desired displacing process. The pump has only two moving parts, the impeller and the rotor, whereas the impeller is carried by the driven rotor. -

Page 13: Application Limits

3. Descr ipt ion Applicat ion lim it s Steel Stainless steel Pump Max. speed Max. capacity Max. speed Max. capacity size Nominal flow Nominal flow [min [min 5,7 m /h @ 3,7 m /h @ 1800 1200 1450 min 920 min 10,9 m /h @... -

Page 14: Design

3. Descr ipt ion The surface temperature does not depend on the ignition source, but on the temperature of the pumped liquid. There is no identification with a temperature class or a temperature. The symbol "X" is integrated in the identification. Chapter 2.9.1 refers to the arising surface temperatures. Consider the notes on the pump data sheet. -

Page 15: Scope Of Supply

3. Descr ipt ion 3.5.3 Flange orientation / Rotation direction The following Figure shows the possible flange orientations of the connection flanges at angular and horizontal arrangement! Front view to the safety valve. Fig. 5: flange orientation / rotation direction Both rotation directions are possible without requiring change in design or replacing any components. -

Page 16: Handling / Storage / Disposal

4. Handling / St or age / Disposal 4. Handling / St orage / Disposal Handling DANGER Slipping of pump / pump unit from its suspension Danger of life through components falling down! Lift the pump / pump unit only in horizontal position. ... -

Page 17: Return Of Pump

New pumps of material GGG (ductile iron) and ferritic cast steel are covered inside with anti-corrosive agent and dewatering-fluid. The maximum inside storage period is 12 months. If the storage period will be longer than 12 months, Dickow Pumpen must be informed. The pumps need to be treated with a long-term preservation, e.g.nitrogen-preservation. -

Page 18: Disposal

4. Handling / St or age / Disposal Disposal WARNI NG Liquids dangerous to health Danger for individuals and environment! Collect and dispose rinsing water and residual liquid. Wear protective clothing and face mask. Consider the legal regulations for disposal of liquids dangerous to health. -

Page 19: Installation / Mounting

5. I nst allat ion / Mount ing 5. I nst allat ion / Mount ing Saf et y I nst r uct ions Improper installation in explosive area DANGER Danger of explosion! Consider the local applicable explosion proof regulations. ... -

Page 20: Piping

5. I nst allat ion / Mount ing 4. All shims must seat solidly. 5. Hook the foundation bolts into the provided bore. 6. Concrete the foundation bolts. 7. Align the base plate after concrete has hardened. 8. Tighten the foundation bolts evenly. 9. -

Page 21: Insulation

5. I nst allat ion / Mount ing 5.4.1 Allowable flange forces and moments Pump size Fx, Fy + Fz [N] Mx, My + Mz [Nm] 50 / 2" 50 / 2" 80 / 3" 1001 100 / 4" 1334 For casing designs of material EN-GJL, the above mentioned values must be multiplied by the factor 0,35. -

Page 22: Electrical Connection Of The Pump Unit

5. I nst allat ion / Mount ing Elect r ical connect ion of t he pum p unit Improper electrical installation DANGER Danger of explosion! Electrical installation requires additionally observance of IEC 60079-14 or NEC 505. Explosion proof motors shall be connected through motor protection switch only. - Page 23 5. I nst allat ion / Mount ing 5.6.1 Checking rotating direction Temperature rise through parts touching each other DANGER Danger of explosion! Never check rotoating direction with dry pump. Disconnect the pump for checking rotating direction. Wrong rotating direction of motor and pump ATTENTI ON Damage of the pump! ...

-

Page 24: Commissioning / Decommissioning

6. Com m issioning / Decom m issioning 6. Com m issioning / Decom m issioning Com m issioning The following points must be checked prior to start-up: The pump unit is correctly electronically connected to all relevant protective devices. ... - Page 25 6. Com m issioning / Decom m issioning If the factory setting needs to be changed, proceed as follows: 1. Mount the gauge in the discharge pipe as near as possible to the pump. 2. Remove cover (1) and cover seal (2). 3.

-

Page 26: Operating The Pump

6. Com m issioning / Decom m issioning 6.1.3 Starting the pump Exceedance of allowable pressure- and temperature limits DANGER Danger of explosion! Leakage of hot or toxic liquid! Never operate pump with closed shut-off valves in suction and/or discharge pipe. -

Page 27: Operating Limits

6. Com m issioning / Decom m issioning Oper at ing lim it s Exceedance of operating limits regarding pressure, temperature and speed DANGER Danger of explosion! Leaking hot or toxic liquid! Maintain the allowable service conditions specified in the pump data sheet. ... -

Page 28: Switching Off The Pump

6. Com m issioning / Decom m issioning Sw it ching of f t he pum p 1. Keep shut-off valve in suction pipe open. 2. Close shut-off valve in discharge pipe. 3. Switch off the motor and watch for steady run down. NOTE In case a non-return valve is installed in the discharge pipe, the shut-off valve can remain open. -

Page 29: Maintenance / Servicing / Inspection

7. Maint enance / Ser vicing / I nspect ion 7. Maint enance / Ser vicing / I nspect ion Saf et y r egulat ions Improper maintained pump unit DANGER Danger of explosion! Maintain the pump unit regularly. ... -

Page 30: Operating Surveillance

7. Maint enance / Ser vicing / I nspect ion Oper at ing sur veillance Elevated surface temperature through hot running antifriction bearings DANGER Danger of explosion! Fire hazard! Check antifriction bearings regularly for running noise. Wear caused by dry run ATTENTI ON Damage of the pump! ... -

Page 31: Disassembly Of Pump Unit

7. Maint enance / Ser vicing / I nspect ion Drainage of pumped liquids through the drain plugs at the casing, through a connected shut-off valve or through a flange. Mode of drainage and position can be taken from the dimensional drawing ! Disassem bly of pum p unit 7.4.1 General instructions... - Page 32 7. Maint enance / Ser vicing / I nspect ion 7.4.3 Tools Wrong disassembly and assembly tools ATTENTI ON Damage of components! Use special tools. In order to facilitate disassembly and assembly as well as to improve protection of sensitive components, the following special tools shall be used: Dimensions / size / dwg.No.

-

Page 33: Inspection

7. Maint enance / Ser vicing / I nspect ion 7. Remove key 940.4. 8. Loosen inner hexagon cap screws 914.11. 9. Remove stationary sleeve bearing 310.2. 10. Pull off shaft sleeve 524 and intermediate ring 509.1 as well as start-up ring 500.1 from pump shaft. -

Page 34: Assembly Of Pump Unit

Rotor and impeller For highly viscous liquids (> 1650 cSt) and/or high temperature applications (> 100°C), the components rotor 818.3 and impeller 237 have no standard dimensions. In this case please contact Dickow Pumpen. Assem bly of pum p unit 7.6.1... - Page 35 7. Maint enance / Ser vicing / I nspect ion 7.6.2 Assembly of rotor, sleeve bearing and shaft sleeve 1. Slide start-up ring 500.5 and shaft sleeve 524 onto the pump shaft and insert key 940.5. 2. Secure the stationary sleeve bearings 310.1 with inner hexagon cap screws 914.10 to the bearing housing 350.

-

Page 36: Bolt Torques

7. Maint enance / Ser vicing / I nspect ion Bolt t or ques Bolt torque [Nm] A4-70 Standard bolt Standard bolt Calculation basis: 80% Yield strength utilisation of screw material. Friction coefficient μ = 0,14 ; use screw lubricant for threads and head / nut contact surface. Recommended: Klüber-paste HEL 46-450. -

Page 37: Troubleshooting

8. Tr oubleshoot ing 8. Tr oubleshoot ing Failure Number Pump delivers no or not enough liquid Motor is overloaded Pump is leaking Increased noises and vibrations Inadmissible temperature increase Sleeve bearing damage Failure number Problem Elimination Pump or piping not Venting respectively filling completely vented or filled Shut-off valve in suction line... -

Page 38: Sectional Drawings

9. Sect ional dr aw ings 9. Sect ional dr aw ings GMB 030 GMB E0 09.16 38 of 41... -

Page 39: Gmb 080

9. Sect ional dr aw ings GMB 080 GMB E0 09.16 39 of 41... - Page 40 10.1 EC-Declar at ion of Conf or m it y EX-Declaration of Conformity According to EC-Machinery Directive 2006/42/EG, Annex II, No. 1A DICKOW PUMPEN GmbH & Co. KG Siemensstraße 22 D-84478 Waldkraiburg Herewith we declare that the pump unit described in the data sheet...

- Page 41 10. Cer t if icat es 10.2 Docum ent of Com pliance Document of Compliance Please fill in this statement for health innocuousness completely and attach it to the pump to be returned to the factory. Pump data Type: Serial No.: PB Reason for shipment Contamination of the pump Hazardous liquids were not handled...

Need help?

Do you have a question about the GMB Series and is the answer not in the manual?

Questions and answers