Summary of Contents for IEF Werner euroLINE 200

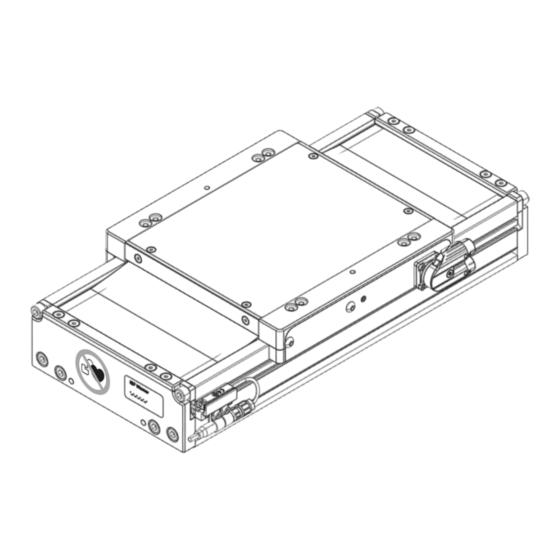

- Page 1 Assembly Instructions Product name: euroLINE 200 Product ID: 1433427 Werner GmbH | Wendelhofstraße 6 | 78120 Furtwangen - Germany | www.ief.de...

- Page 2 200 Mounting Instructions (Translation) (EN) 2 - 76 IEF-Werner GmbH | Wendelhofstraße 6 | DE-78120 Furtwangen | www.ief.de...

- Page 3 200 3 - 76 Translation (EN) of the original instructions (DE) ■ The assembly instructions must always be available near the component / device. The assembly instructions are considered part of the component / device. ■ ■ Always use the complete original (or the translation) of these assembly instructions.

- Page 4 200 Translation (EN) of the original instructions (DE) 4 - 76 Change history Document code Date Change Translation of the German document (“MAN_DE_1433425_ MAN_EN_1433427_euroLINE200_R1a.docx November 2023 euroLINE200_R2b.docx”) from November 2021 Trademarks and trade names are used without guarantee of free usability. Great care was taken in the preparation of the texts and examples.

-

Page 5: Table Of Contents

Temperature sensor ....................... 22 Technical data ........................23 4.5.1 Tightening torques for screw connections [Nm]............23 4.5.2 Technical data of euroLINE 200 linear unit ..............23 4.5.3 Type plates ........................25 4.5.4 Load information ......................26 Support points / support distances ..................28 Determine commutation angle ................ - Page 6 Encoder/motor connector assignment 200-S2-TTK70, L = 330 mm, art. no.: 1308745 ..........................68 euroLINE 200, slide type: 200-S1-LIC 211, L = 230 mm, art. no.: 1308743 ....69 9.4.1 Encoder/motor connector assignment 200-S1-LIC 211, L = 230 mm, art. no.: 1308743 ..........................

-

Page 7: Declaration Of Incorporation

Manufacturer: IEF-Werner GmbH Wendelhofstr. 6 78120 Furtwangen, Germany Incomplete machine (designation): euroLINE 200 (1800082) Authorised person responsible for the IEF-Werner GmbH documentation: The manufacturer hereby confirms that the incomplete machine named above complies with the following essential requirements of the Machinery Directive 2006/42/EC. -

Page 8: Annex To The Declaration Of Incorporation

200 Translation (EN) of the original instructions (DE) 8 - 76 1.1 Annex to the Declaration of Incorporation Essential health and safety requirements according to the Machinery Directive 2006/42/EC, Annex I Request is relevant Request has been fulfilled Request is not relevant... - Page 9 200 9 - 76 Translation (EN) of the original instructions (DE) ful- relevant filled Risks due to other hazards 1.5.1 Electricity supply 1.5.2 Static electricity 1.5.3 Energy supply other than electricity 1.5.4 Errors of fitting 1.5.5 Extreme temperatures 1.5.6 Fire 1.5.7...

- Page 10 200 Mounting Instructions (Translation) (EN) 10 - 76 IEF-Werner GmbH | Wendelhofstraße 6 | DE-78120 Furtwangen | www.ief.de...

-

Page 11: Safety

200 11 - 76 Translation (EN) of the original instructions (DE) 2 Safety 2.1 Definition of the warnings DANGER Indicates a dangerous situation. Failure to observe the safety regulations will result in death. WARNING Indicates a possibly dangerous situation. -

Page 12: General Warnings

12 - 76 2.2 General warnings The euroLINE 200 linear unit may only be commissioned by qualified personnel who have received safety training and who can assess potential hazards. In addition, all chapters of these assembly instructions must have been read and understood completely. -

Page 13: Special Hazard Warnings

200 13 - 76 Translation (EN) of the original instructions (DE) 2.3 Special hazard warnings In these assembly instructions, you will also find the following special hazard warnings: DANGER Danger for persons with pacemakers. Poses considerable risk to persons with pacemakers or other electronic implants. Due to strong magnetic fields, implants can be disturbed. - Page 14 The base body contains strong permanent magnets that can damage magnetic data carriers (e.g. credit cards). NOTE The euroLINE 200 linear unit may not be used in the vicinity of magnetic dusts and small parts! Figure 1 Dangers on the euroLINE 200...

-

Page 15: Intended Use

Translation (EN) of the original instructions (DE) 3 Intended use The euroLINE 200 linear unit is a precise, linear adjustment unit with an iron-core linear motor which is used as an add-on part in conjunction with other components in the commercial sector. Complex, multi-axis positioning systems can also be set up in combination with a variety of standardised assembly elements and with the other linear units from IEF-Werner GmbH. - Page 16 200 16 - 76 Mounting Instructions (Translation) (EN) Werner GmbH | Wendelhofstraße 6 | DE-78120 Furtwangen | www.ief.de...

-

Page 17: Assembly Instructions

4.1 Installation position The euroLINE 200 linear unit is primarily intended for use in the horizontal position. Vertical use is not possible without additional measures (such as a brake). -

Page 18: Fixing

200 Translation (EN) of the original instructions (DE) 18 - 76 4.3 Fixing The linear unit can be attached to the base body using clamping elements or to the slide via the threaded holes (see Figure 4). Figure 4 Fastening to the base body using clamping elements, example X/Y system A Clamping element, type 190 (art. -

Page 19: Actuator Holder

Translation (EN) of the original instructions (DE) 4.3.1 Actuator holder The actuators (cylinders, gripper modules, and the like) to be attached to the euroLINE 200 linear unit can be attached using the drilling pattern located on the slide. Corresponding drilling patterns are available for the two possible slide sizes. -

Page 20: Wiring

200 Translation (EN) of the original instructions (DE) 20 - 76 4.4 Wiring The connection options for the motor, encoder and temperature sensor are located on the angled receptacle of the slide. The exact pin assignment is shown in the parts lists and drawings. -

Page 21: Connection Cable For Optional Reference Switch

200 21 - 76 Translation (EN) of the original instructions (DE) 4.4.2 Connection cable for optional reference switch The reference switch (1311798) is designed with a 3-pin standard plug (M8). The cables of the plug are colour-coded (black, brown, blue). -

Page 22: Temperature Sensor

200 Translation (EN) of the original instructions (DE) 22 - 76 4.4.4 Temperature sensor A PTC 1000 is used as the temperature sensor. The temperature sensor has the following characteristics: Figure 9 PTC 1000 diagram The resistance increases exponentially from approx. 100°C. This means that the temperature sensor can also be connected to non-sensitive evaluation units such as a power output stage. -

Page 23: Technical Data

2.97 6.03 10.25 24.93 12.9 2.16 5.02 10.18 17.29 42.07 4.5.2 Technical data of euroLINE 200 linear unit Slide type (slide length) Type: Standard slide Type: Long slide Designation Unit 230 mm 330 mm Length of the linear unit [mm]... - Page 24 200 Translation (EN) of the original instructions (DE) 24 - 76 Slide type (slide length) Type: Standard slide Type: Long slide Designation Unit 230 mm 330 mm Motor constant [N²/W] Counter-EMF Phase-Phase [V/m/s] peak Resistance per phase [Ω] 1.21...

-

Page 25: Type Plates

200 25 - 76 Translation (EN) of the original instructions (DE) 4.5.3 Type plates The type plates are attached at the following positions (linear unit, slide): Figure 10 Positions of the type plates A Type plate on the slide... -

Page 26: Load Information

200 Translation (EN) of the original instructions (DE) 26 - 76 4.5.4 Load information Components (gripper modules, cylinders, etc.) are attached to the product via the drilling pattern on the slide (see Figure 5 and Figure 6, page 19). - Page 27 200 27 - 76 Translation (EN) of the original instructions (DE) Example projection / deflection: Figure 13 Tilt moment A Projection B Deflection (M Figure 14 Guide rigidity Werner GmbH | Wendelhofstraße 6 | 78120 Furtwangen - Germany | www.ief.de...

-

Page 28: Support Points / Support Distances

200 Translation (EN) of the original instructions (DE) 28 - 76 4.6 Support points / support distances NOTE Material damage Depending on the load and length of the axis, additional support elements are required to prevent deflection of the axis. -

Page 29: Determine Commutation Angle

200 29 - 76 Translation (EN) of the original instructions (DE) 5 Determine commutation angle When you start up a slide with a built-in measuring head for the first time with the scale tape attached to the base body, the commutation angle must be determined (encoder calibration). - Page 30 200 Translation (EN) of the original instructions (DE) 30 - 76 Select the "Auto detect" button ( Figure 17 Selecting the "Auto detect" button Select the "OK" button in the Motor identification window. Note: The slide must be able to move freely by at least 50 mm in both directions! Figure 18 Selecting the "OK"...

- Page 31 200 31 - 76 Translation (EN) of the original instructions (DE) The following is displayed after successful commutation: Figure 19 "Identification successful!" notification Select the "OK" button in the Motor identification window (identification successful). Figure 20 Selecting the "OK" button...

- Page 32 200 Translation (EN) of the original instructions (DE) 32 - 76 Select the Basic parameters button in the "SAVE" encoder in the Angle transmitter settings window. Figure 21 Selecting the "Save" button Select the "OK" button in the Save in encoder window.

- Page 33 200 33 - 76 Translation (EN) of the original instructions (DE) Select the "OK" button in the Information window to confirm that the parameters have been saved. Figure 23 Selecting the "OK" button Werner GmbH | Wendelhofstraße 6 | 78120 Furtwangen - Germany | www.ief.de...

-

Page 34: Carrying Out A Reference Run

200 Translation (EN) of the original instructions (DE) 34 - 76 5.2 Carrying out a reference run Select the "REF" reference position button ( ) in the icon bar of the S2 Commander. Figure 24 Selecting the "REF" button ... - Page 35 200 35 - 76 Translation (EN) of the original instructions (DE) After a successful reference run: Select the "Settings" tab ( ) and select the "Save in encoder" button ( ) to save the basic parameters/reference position in the encoder.

- Page 36 200 Translation (EN) of the original instructions (DE) 36 - 76 Select the "OK" button in the Information window to confirm that the parameters have been saved. Figure 29 Selecting the "OK" button IEF-Werner GmbH | Wendelhofstraße 6 | 78120 Furtwangen - Germany | www.ief.de...

-

Page 37: Maintenance

200 37 - 76 Translation (EN) of the original instructions (DE) 6 Maintenance WARNING Serious risk of injury due to electrical voltage. For all assembly, disassembly or repair work, the system must be de-energised. Failure to observe the safety regulations can result in death. -

Page 38: Maintenance Of The Corresponding Measuring System

Translation (EN) of the original instructions (DE) 38 - 76 6.1 Maintenance of the corresponding measuring system The euroLINE 200 linear unit can be equipped with one of the following two measuring systems: ■ TTK70 magnetic measuring system (absolute, non-contact linear measuring system) LIC optical measuring system (absolute, non-contact [optical/photoelectric scanning] linear ■... - Page 39 200 39 - 76 Translation (EN) of the original instructions (DE) To clean the measuring head, remove the measuring head [B] together with the measuring head holder [C] (see Abbildung 31, below). The measuring head holder is centred with the slide, by means of centring sleeves, and the slide position is maintained as far as possible.

-

Page 40: Guide Carriage Lubrication

200 Translation (EN) of the original instructions (DE) 40 - 76 6.2 Guide carriage lubrication The guide carriages are factory-fitted with long-term lubrication for a service life of 10,000 km. To achieve a longer service life, we recommend that you regularly re-grease the guide carriage. Under normal ambient conditions, relubrication should be carried out after a service life of 10,000 km or, if this is not reached, after approx. -

Page 41: Error Analysis

200 41 - 76 Translation (EN) of the original instructions (DE) 7 Error analysis Fault Reason Fault rectification Increased running noise Nominal service life of the guide Complete replacement of the guide carriages exceeded. carriages and, if necessary, the guide rails (ball rail guides). - Page 42 200 Translation (EN) of the original instructions (DE) 42 - 76 Fault Reason Fault rectification Linear unit does not move Motor coil defective. Replace the complete slide unit. (continuation) Guide carriage defective Replace the guide carriages and, if (sluggishness, blockage).

-

Page 43: Repair

200 43 - 76 Translation (EN) of the original instructions (DE) 8 Repair WARNING Warning against crushing of limbs. Due to the strong magnetic forces of attraction, there is a risk of crushing limbs (fingers) when replacing the slide. -

Page 44: Aligning Metal Strip

200 Translation (EN) of the original instructions (DE) 44 - 76 8.1 Aligning metal strip CAUTION Warning of sharp objects / risk of cuts. If inattentive, you could cut yourself on the metal strip cover during assembly, disassembly or repair work, for example. -

Page 45: Distance Of Metal Strip ↔ End Plates

200 45 - 76 Translation (EN) of the original instructions (DE) 8.1.1 Distance of metal strip ↔ end plates The distance (a) between the clamping of the metal strip and the end plates should be the same on both sides. The nominal dimension is 4 mm (dimension a → see Figure 33, below). -

Page 46: Distance Of Metal Strip ↔ Profile Edge

200 Translation (EN) of the original instructions (DE) 46 - 76 8.1.2 Distance of metal strip ↔ profile edge The position of the metal strip in relation to the profile edge (dimension b) should be even/parallel. Slide the carriage – with the metal strip screwed tight on both sides – up to approx. 30 mm to an end plate. -

Page 47: Replacing The Metal Strip/Outer Sliding Elements On The Slide

200 47 - 76 Translation (EN) of the original instructions (DE) 8.2 Replacing the metal strip/outer sliding elements on the slide Depending on the application and ambient conditions, it may be necessary to replace the metal strip and the outer sliding elements (sliding plates, IEF item no.: 1419649) on the slide. The outer sliding elements (sliding plates) are symmetrical and can be turned once (by 180°... -

Page 48: Ttk70 Magnetic Measuring System

200 Translation (EN) of the original instructions (DE) 48 - 76 8.3 TTK70 magnetic measuring system 8.3.1 Setting absolute, magnetic measuring head The measuring head only functions correctly at the correct mounting distance. If faults occur, the mounting distance must be checked first. -

Page 49: Replacement Absolute Magnetic Tape (Scale Tape) Ttk70

200 49 - 76 Translation (EN) of the original instructions (DE) 8.3.2 Replacement absolute magnetic tape (scale tape) TTK70 If the absolute magnetic tape (scale tape) has been damaged mechanically or by a strong magnetic field, the magnetic tape (scale tape) must be replaced. -

Page 50: Lic Optical Measuring System

200 Translation (EN) of the original instructions (DE) 50 - 76 8.4 LIC optical measuring system With the optical measuring system, the measuring head is integrated in the slide. The measuring head has stop surfaces and does not need to be aligned. -

Page 51: Replacing Slide

200 51 - 76 Translation (EN) of the original instructions (DE) 8.5 Replacing slide WARNING Warning against crushing of limbs. Due to the strong magnetic forces of attraction, there is a risk of crushing limbs (fingers) when replacing the slide. -

Page 52: Replacement Of Inner Sliding Elements

200 Translation (EN) of the original instructions (DE) 52 - 76 8.6 Replacement of inner sliding elements Under normal conditions, the inner sliding elements (see [B] in Abbildung 39) have a longer service life than the guide carriages [D], but preventive replacement is recommended when replacing the guide carriages. -

Page 53: Guide Carriage Replacement

200 53 - 76 Translation (EN) of the original instructions (DE) 8.7 Guide carriage replacement To replace the guide carriages, slide the carriage off the guide rails. Please follow the instructions in the sections: 8.5: Replacing slide, page 51 ■... - Page 54 200 Translation (EN) of the original instructions (DE) 54 - 76 The reference surface on the guide carriages must be observed during installation. This can be recognised by the polished surface. When tightening the screws, the guide carriages must be pressed against the stop surface of the intermediate plate.

-

Page 55: Guide Rail Replacement

200 55 - 76 Translation (EN) of the original instructions (DE) 8.8 Guide rail replacement To be able to replace the guide rail, the metal strip [A], the slide [B], an end plate [C] and the magnetic plate [D] on the side on which the slide is to be removed must be removed. - Page 56 200 Translation (EN) of the original instructions (DE) 56 - 76 One of the two guide rails [A] is attached to one side of the base body. This guide rail is the master rail [A]. This guide rail has a reference side. The reference side is marked with a notch in the contact surface.

-

Page 57: Procedure For Replacing Guide Rail

200 57 - 76 Translation (EN) of the original instructions (DE) 8.8.1 Procedure for replacing guide rail Proceed as follows to replace the guide rails: Dismantling old guide rails Remove the metal strip. Remove one end plate. - Page 58 200 58 - 76 Mounting Instructions (Translation) (EN) Werner GmbH | Wendelhofstraße 6 | DE-78120 Furtwangen | www.ief.de...

-

Page 59: Parts Lists And Drawings

200 59 - 76 Translation (EN) of the original instructions (DE) 9 Parts lists and drawings 9.1 euroLINE 200, parts list 1800082 E=Spare part; Z pos. Art. no.: Designation V=Wearing part 1419682 Base body, euroLINE 200 1419683 Ball rail guide... - Page 60 Cheese head screw; type: DIN 7984 - M5 x 12 - 8.8 galv. Cylinder pin with internal thread; type: DIN 7979 / ISO 8735 - 6 x 626930 20 - A 1419873 Stopper, euroLINE 200 734758 Thermal transfer label; type: EET-2551P-8A Prohibition sign ∅ 50 mm; No access for people with 1603154 pacemakers IEF-Werner GmbH | Wendelhofstraße 6 | 78120 Furtwangen - Germany | www.ief.de...

- Page 61 200 61 - 76 Translation (EN) of the original instructions (DE) Figure 45 Exploded-view, art. no.: 1800082 (page 1) Werner GmbH | Wendelhofstraße 6 | 78120 Furtwangen - Germany | www.ief.de...

- Page 62 200 Translation (EN) of the original instructions (DE) 62 - 76 Figure 46 Exploded-view, art. no.: 1800082 (page 2) IEF-Werner GmbH | Wendelhofstraße 6 | 78120 Furtwangen - Germany | www.ief.de...

-

Page 63: Euroline 200, Slide Type: 200-S1-Ttk70, L = 230 Mm, Art. No.: 1308614

200 63 - 76 Translation (EN) of the original instructions (DE) 9.2 euroLINE 200, slide type: 200-S1-TTK70, L = 230 mm, art. no.: 1308614 E=Spare part; Z pos. Art. no.: Designation V=Wearing part 1423605 Slide plate 1423607 Intermediate plate 1419645 Tunnel cover;... - Page 64 Cheese head screw; type: DIN 912 / ISO 4762 - M3 x 8 - 8.8 galv. Figure 47 euroLINE 200, slide type: 200-S1-TTK70, L = 230 mm, art. no.: 1308614 IEF-Werner GmbH | Wendelhofstraße 6 | 78120 Furtwangen - Germany | www.ief.de...

-

Page 65: Encoder/Motor Connector Assignment 200-S1-Ttk70, L = 230 Mm, Art. No.: 1308614

Translation (EN) of the original instructions (DE) 9.2.1 Encoder/motor connector assignment 200-S1-TTK70, L = 230 mm, art. no.: 1308614 Figure 48 Encoder/motor connector assignment euroLINE 200, slide type: 200-S1-TTK70 Werner GmbH | Wendelhofstraße 6 | 78120 Furtwangen - Germany | www.ief.de... -

Page 66: Euroline 200, Slide Type: 200-S2-Ttk70, L = 330 Mm, Art. No.: 1308745

200 Translation (EN) of the original instructions (DE) 66 - 76 9.3 euroLINE 200, slide type: 200-S2-TTK70, L = 330 mm, art. no.: 1308745 E=Spare part; Z pos. Art. no.: Designation V=Wearing part 1423606 Long slide plate 1423608 Long intermediate plate 1419645 Tunnel cover;... - Page 67 Cheese head screw; type: DIN 912 / ISO 4762 - M3 x 8 - 8.8 galv. Figure 49 euroLINE 200, slide type: 200-S2-TTK70, L = 330 mm, art. no.: 1308745 Werner GmbH | Wendelhofstraße 6 | 78120 Furtwangen - Germany | www.ief.de...

-

Page 68: Encoder/Motor Connector Assignment 200-S2-Ttk70, L = 330 Mm, Art. No.: 1308745

Translation (EN) of the original instructions (DE) 68 - 76 9.3.1 Encoder/motor connector assignment 200-S2-TTK70, L = 330 mm, art. no.: 1308745 Figure 50 Encoder/motor connector assignment euroLINE 200, slide type: 200-S2-TTK70 IEF-Werner GmbH | Wendelhofstraße 6 | 78120 Furtwangen - Germany | www.ief.de... -

Page 69: Euroline 200, Slide Type: 200-S1-Lic 211, L = 230 Mm, Art. No.: 1308743

200 69 - 76 Translation (EN) of the original instructions (DE) 9.4 euroLINE 200, slide type: 200-S1-LIC 211, L = 230 mm, art. no.: 1308743 E=Spare part; Z pos. Art. no.: Designation V=Wearing part 1423605 Slide plate 1423607 Intermediate plate 1419645 Tunnel cover;... - Page 70 Cheese head screw; type: DIN 912 / ISO 4762 - M3 x 8 - 8.8 galv. Figure 51 euroLINE 200, slide type: 200-S1-LIC 211, L = 230 mm, art. no.: 1308743 IEF-Werner GmbH | Wendelhofstraße 6 | 78120 Furtwangen - Germany | www.ief.de...

-

Page 71: Encoder/Motor Connector Assignment 200-S1-Lic 211, L = 230 Mm, Art. No.: 1308743

Translation (EN) of the original instructions (DE) 9.4.1 Encoder/motor connector assignment 200-S1-LIC 211, L = 230 mm, art. no.: 1308743 Figure 52 Encoder/motor connector assignment euroLINE 200, slide type: 200-S1-LIC 211 Werner GmbH | Wendelhofstraße 6 | 78120 Furtwangen - Germany | www.ief.de... -

Page 72: Euroline 200, Slide Type: 200-S2-Lic 211, L = 330 Mm, Art. No.: 1308746

200 Translation (EN) of the original instructions (DE) 72 - 76 9.5 euroLINE 200, slide type: 200-S2-LIC 211, L = 330 mm, art. no.: 1308746 E=Spare part; Z pos. Art. no.: Designation V=Wearing part 1423606 Long slide plate 1423608... - Page 73 Cheese head screw; type: DIN 912 / ISO 4762 - M3 x 8 - 8.8 galv. Figure 53 euroLINE 200, slide type: 200-S2-LIC 211, L = 330 mm, art. no.: 1308746 Werner GmbH | Wendelhofstraße 6 | 78120 Furtwangen - Germany | www.ief.de...

-

Page 74: Encoder/Motor Connector Assignment 200-S2-Lic 211, L = 330 Mm, Art. No.: 1308746

Translation (EN) of the original instructions (DE) 74 - 76 9.5.1 Encoder/motor connector assignment 200-S2-LIC 211, L = 330 mm, art. no.: 1308746 Figure 54 Encoder/motor connector assignment euroLINE 200, slide type: 200-S2-LIC 211 IEF-Werner GmbH | Wendelhofstraße 6 | 78120 Furtwangen - Germany | www.ief.de... -

Page 75: Accessory Drawings

200 75 - 76 Translation (EN) of the original instructions (DE) 9.6 Accessory drawings 9.6.1 Clamping elements Figure 55 Clamping elements type: 230-Z M8 (art. no.: 1309021) / M6 (art. no.: 1309034) Figure 56 Clamping element, type 190 (art. no.: 221702) -

Page 76: Centring Ring

200 Translation (EN) of the original instructions (DE) 76 - 76 9.6.2 Centring ring Figure 57 Centring ring (art. no.: 1024021) IEF-Werner GmbH | Wendelhofstraße 6 | 78120 Furtwangen - Germany | www.ief.de...

Need help?

Do you have a question about the euroLINE 200 and is the answer not in the manual?

Questions and answers