Summary of Contents for Gema OptiSpray AP02

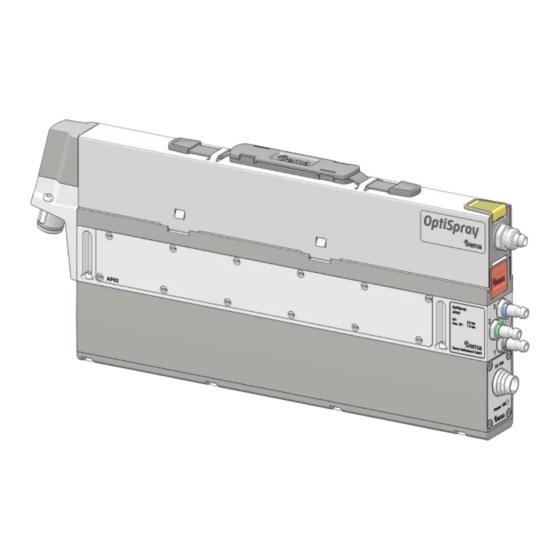

- Page 1 Rev. 00 1024 626 Operating instructions and Spare parts list Application pump OptiSpray AP02 Translation of the original operating instructions...

- Page 2 To the best of our knowledge and belief, the information contained in this publication was correct and valid on the date of publication. Gema Switzerland GmbH makes no representations or warranties with respect to the contents or use of this publication, and reserves the right to revise this publication and make changes to its content without prior notice.

-

Page 3: Table Of Contents

Powder hose rinsing ................18 Maintenance interval monitoring .............. 19 Assembly / Connection Assembly guide ..................... 21 Connection instructions ..................22 Start-up Preparation for start-up ..................25 Basic conditions ..................25 Basic information ..................25 Table of contents • 3 OptiSpray AP02... - Page 4 Materials ....................47 Disassembly of component groups ..............47 Spare parts list Ordering spare parts ..................... 49 OptiSpray AP02 Application pump ............... 50 Enclosure ......................52 Valve assembly B ....................53 Quick change system ................... 54 Pump head ......................55 Connecting material ....................

-

Page 5: About These Instructions

General information This operating manual contains all the important information that is needed to operate the OptiSpray AP02. It will safely guide you through the start-up process and give you references and tips for the optimal use when working with your powder coating system. -

Page 6: Structure Of Safety Notes

Presentation of the contents Figure references in the text Figure references are used as cross references in the descriptive text. Example: "The high voltage (H) created in the gun cascade is guided through the center electrode." 6 • About these instructions OptiSpray AP02... -

Page 7: Safety

If this product is to be used for other purposes or other substances outside of our guidelines then Gema Switzerland GmbH should be consulted. - Page 8 ► Before working with the device, organize the required documents and read the section "Safety regulations". ► Work should only be carried out in accordance with the instructions of the relevant documents. ► Always work with the complete original document. 8 • Safety OptiSpray AP02...

-

Page 9: Product Description

CG23-P or CG11-P control unit (manual equipment). The application pump will only operate in combination with the OptiGun GA04-P automatic gun or with other Gema models with a suitable diffuser (spraying air adapter). Please contact Gema if you have any further queries. -

Page 10: A Summary Of The Directives And Standards

Operation without the proper training – Use with insufficient compressed air quality – Use in connection with unauthorized coating equipment or components – Input pressure too low – Use of moist powder – Incorrectly assembled individual parts 10 • Product description OptiSpray AP02... -

Page 11: Technical Data

1.3 g/m³ 4 (dew point ≤ 3 °C) or Class 5 (dew point ≤ 7 °C) Residual content 0.1 mg/m³ Class Gema Switzerland GmbH recommends compressed air quality according to ISO 8573-1 class 3.4.2. Product description • 11 OptiSpray AP02... -

Page 12: Powder Output (Reference Values)

Rev. 00 12/23 Powder output (reference values) OptiSpray AP02 In OptiCenter: Conveying hose till 20 m – 50-300 g/min internal Ø 7 mm Suction tube/hose up to 30 cm- internal Ø 4.5 mm In manual equipment: Conveying hose till 20 m –... -

Page 13: Sound Pressure Level

The specified value is applicable only for this product itself and does not take into account external noise sources or cleaning impulses. The sound pressure level may vary, depending on the product configuration and space constraints. Product description • 13 OptiSpray AP02... -

Page 14: Rating Plate

Rev. 00 12/23 Rating plate Fig. 2 14 • Product description OptiSpray AP02... -

Page 15: Design And Function

Other hose diameters can also be used for certain applications. – Only use other hose diameters with the explicit recommendation of Gema! – On the transport side, a powder hose with conductive strip must be used (electrically conductive)! Product description • 15 OptiSpray AP02... -

Page 16: Spraying Air Function / Diffusers

Spraying air The OptiGun GA02 automatic gun and the OptiSelect GM03 manual gun must also be equipped with an appropriate diffuser adapter. The diffuser is grounded through the powder transport hose with conductive strips! 16 • Product description OptiSpray AP02... -

Page 17: Connections

Pinch valve air connection Transport air connection External signal connection Pin assignment Connection 2.5 Ext., 12-pins Control signal +24 VDC Body – grounding PE Scope of delivery – Mains cable – Quick-start guide and operating manual Product description • 17 OptiSpray AP02... -

Page 18: Typical Characteristics - Properties Of The Functions

Powder chamber emptying combined with hose cleaning in both directions – Cleaning the hose to the gun only – Cleaning the hose on the suction side only (For details, see the operating instructions of the corresponding gun control unit) 18 • Product description OptiSpray AP02... -

Page 19: Maintenance Interval Monitoring

► Only the original lid (without any sieve insert) must be assembled and closed on the OptiSpeeder! The pump is to be cleaned as a component of the entire system. Maintenance interval monitoring This function is provided by the superordinated control unit. Product description • 19 OptiSpray AP02... - Page 20 Rev. 00 12/23 20 • Product description OptiSpray AP02...

-

Page 21: Assembly / Connection

The application pump can be used in an OptiCenter OC10 Powder management center. The application pump is mounted into place using 2 M4 screws on the front side. Please contact Gema for other installation possibilities. Fig. 6 ATTENTION Ambient temperature too high –... -

Page 22: Connection Instructions

Gun cable Compressed air hose Control unit Pinch valve air hose Automatic gun with diffuser 2.5 Control signal cable Application pump no. 1 Transport air hose 9.1 Application pump no. 2 Spraying air hose 22 • Assembly / Connection OptiSpray AP02... - Page 23 ► Check ground connections with Ohm meter and ensure 1 MOhm or less. The compressed air must be free of oil and water! Close the unused connections with the provided dust protection caps! Assembly / Connection • 23 OptiSpray AP02...

- Page 24 Rev. 00 12/23 24 • Assembly / Connection OptiSpray AP02...

-

Page 25: Start-Up

– At the suction area, a homogeneous fluidization must be ensured, so that no air ducts (craters) can be formed Start-up • 25 OptiSpray AP02... - Page 26 Rev. 00 12/23 26 • Start-up OptiSpray AP02...

-

Page 27: Operation

For a better understanding of the interrelationships in powder coating, it is recommended to read completely the operating instructions of the control unit and the powder gun, so as to be familiar with their functions too. Operation • 27 OptiSpray AP02... - Page 28 Rev. 00 12/23 28 • Operation OptiSpray AP02...

-

Page 29: Decommissioning / Storage

If the physical conditions are maintained, the unit can be stored indefinitely. Space requirements The space requirements correspond to the size of the product. There are no special requirements concerning distance to neighboring equipment. Decommissioning / Storage • 29 OptiSpray AP02... -

Page 30: Physical Requirements

Storage must be inside a dry building at a temperature between +5 and +50 °C. Do not expose to direct sunlight! Maintenance during storage Maintenance schedule No maintenance schedule is necessary. Maintenance works During long-term storage, periodically perform a visual check. 30 • Decommissioning / Storage OptiSpray AP02... -

Page 31: Maintenance / Repairs

The main assembly with the valve and electrical equipment remains in place. To avoid downtime, it is recommended to keep the following assembly in stock. – see Spare parts list "Pump head" Fig. 8: Maintenance / Repairs • 31 OptiSpray AP02... -

Page 32: Maintenance Of The Dense Phase Pump

– see below. Wear parts The wear parts to be replaced during maintenance work are available separately. See chapter "Spare parts list" on page 49. 32 • Maintenance / Repairs OptiSpray AP02... -

Page 33: Cleaning

Periodic checks The periodic checks include examining all connecting cables and hoses. The corresponding parts should be replaced immediately if any damage to cables or hoses is discovered. All plugs must be properly tightened. Maintenance / Repairs • 33 OptiSpray AP02... -

Page 34: Repair Work

Repair work In the event of malfunctions or faults, the product must be checked and repaired at an authorized Gema service location. The repairs must only be performed by an authorized specialist. Improper interventions can result in serious danger for user or the... -

Page 35: Pump Disassembly

Torx L-key size 10 Needle nose pliers ATTENTION Incorrectly assembled parts may cause malfunctions or defects ► Observe the tightening torques when assembling! ► Use the appropriate torque wrench! Pump disassembly Remove hoses and cables Maintenance / Repairs • 35 OptiSpray AP02... - Page 36 Rev. 00 12/23 36 • Maintenance / Repairs OptiSpray AP02...

- Page 37 Rev. 00 12/23 Maintenance / Repairs • 37 OptiSpray AP02...

- Page 38 Rev. 00 12/23 38 • Maintenance / Repairs OptiSpray AP02...

-

Page 39: Replacing The Pinch Valves

Rev. 00 12/23 Replacing the pinch valves Maintenance / Repairs • 39 OptiSpray AP02... - Page 40 Rev. 00 12/23 ATTENTION Defective pinch valve causes blockage of the filter elements ► Clean or replace the corresponding filter element! 40 • Maintenance / Repairs OptiSpray AP02...

-

Page 41: Replacing The Filter Elements

► When cleaning the pinch valve bodies, do not use alcohol, acetone, benzol or other solvents! ► For cleaning, use benzine, light lye or acid or a cleaning agent! Maintenance / Repairs • 41 OptiSpray AP02... -

Page 42: Replacing The Application Pump In An Opticenter

Replacing the Application pump in an OptiCenter Remove the powder from the system Start the cleaning program, rinse in both directions Depressurize/vent OptiCenter Next steps are described in the corresponding OptiCenters operating manual 42 • Maintenance / Repairs OptiSpray AP02... -

Page 43: Fault Clearance

Powder hoses tend to clogging Clean or replace the powder hoses due to sintering Oil or water in the system Ensure that oil or water will be separated before entering into the Application pump Fault clearance • 43 OptiSpray AP02... - Page 44 Rev. 00 12/23 Incident Causes Corrective action Transport air offset C3 not Adapt transport air offset C3 (see adapted to powder output operating manual OptiStar CG24-CP, CG23-P, CG12-CP oder CG11-P, section "Correction values") 44 • Fault clearance OptiSpray AP02...

- Page 45 Start the pinch valve diagnostic Diagnosis OK? Use a replacement pump Start the pinch valve diagnostic Send in the defective Diagnosis OK? pump for repair Failure in the control unit or outside of the pump Fault clearance • 45 OptiSpray AP02...

- Page 46 Rev. 00 12/23 46 • Fault clearance OptiSpray AP02...

-

Page 47: Disposal

Requirements on personnel carrying out the work The disposal of the product is to be carried out by the owner or operator. When disposing of components that are not manufactured by Gema, the instructions in the respective manufacturer’s documentation must be observed. - Page 48 Rev. 00 12/23 48 • Disposal OptiSpray AP02...

-

Page 49: Spare Parts List

Ø 8/6 mm, 8 mm outside diameter (o/d) / 6 mm inside diameter (i/d) WARNING Use of non-original Gema spare parts Use of Non-Gema replacement spare parts may invalidate some or all approval certificates and accreditations; and the user assumes all explosion risks associated with use of these parts. Use of these replacement spare parts may void any and all warranty claims. -

Page 50: Optispray Ap02 Application Pump

Rev. 00 12/23 OptiSpray AP02 Application pump 1027 000 OptiSpray AP02 Application pump – complete Pump head cover – complete Pump head – complete, see corresponding spare parts list Tube connection – complete, incl. pos. 3.1 1023 559 O-ring – Ø 10x1.5 mm (not shown) 1026 358 # Quick change system –... - Page 51 Rev. 00 12/23 OptiSpray AP02 Application pump Fig. 11 Spare parts list • 51 OptiSpray AP02...

-

Page 52: Enclosure

Enclosure Front connection – complete, incl. pos. 2 1026 984 Screw – 4x8 mm 1016 664 Ventilation module – complete, incl. pos. 4 1026 986 Screw – M4x10 mm 1026 379 Fig. 12: 52 • Spare parts list OptiSpray AP02... -

Page 53: Valve Assembly B

1026 335 Injector unit – complete (incl. pos. 13, 14, 15) 1023 851 Angular connection 1023 893 Filter 1023 894 O-Ring – Ø 7x1.5 mm 1026 355 # # Wear part Fig. 13: Spare parts list • 53 OptiSpray AP02... -

Page 54: Quick Change System

Rev. 00 12/23 Quick change system Screw – M4x30 mm 1026 372 Powder stop filter 1023 230 Fig. 14: 54 • Spare parts list OptiSpray AP02... -

Page 55: Pump Head

1023 828 # O-ring – Ø 16x2 mm 1026 359 # Pump connection 1026 781 Screw – M4x10 mm 1026 379 O-ring – Ø 15.1x1.6 mm 1026 916 # # Wear part Fig. 15: Spare parts list • 55 OptiSpray AP02... -

Page 56: Connecting Material

Connecting cable – 12 pins, 10 m 1000 976 Connecting cable – 12 pins, 15 m 1000 977 Connecting cable – 12 pins, 20 m 1000 978 * Please indicate length Fig. 16: 56 • Spare parts list OptiSpray AP02... -

Page 57: Index

Fault clearance ..........43 Pinch valves ........... 34, 39 Figure references in the text ......6 Replacing the Application pump in an OptiCenter ..............42 Required spare parts ........34 Required tools..........35 Guidelines, European ........10 Index • 57 OptiSpray AP02... - Page 58 Technical Data ..........11 Spare parts list ..........49 Typical characteristics ........18 Spraying air function / diffusers ....... 16 Standards, European ........10 Start-up ............25 Wear parts ............32 Storage ............29 58 • Table of contents OptiSpray AP02...

- Page 60 Rev. 00...

Need help?

Do you have a question about the OptiSpray AP02 and is the answer not in the manual?

Questions and answers