Summary of Contents for Pro Mach Wexxar WF 30T

- Page 1 WF30T Case Former Wexxar Packaging Inc Richmond, BC Canada 1 888 565 3219 6136 1 604 930 9300 parts@wexxar.com service@wexxar.com...

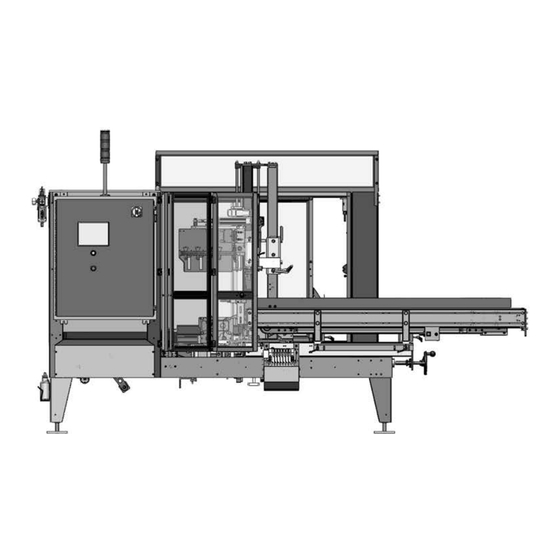

- Page 2 WF30T Case Former...

- Page 3 WF30T Case Former WEXXAR WF-30T CASE FORMER Operation and Service Manual Serial Number: 6136 Built For: Rubbermaid 3415 E. 12th Ave Plant 1087 - Winfield MFG Winfield KS 67156 United States Notice of Registered Patents Be advised that the following patents apply to our WF-20T and WF-30T machines: US Patent Numbers: 7,192,393 7,311,650...

- Page 4 WF30T Case Former...

-

Page 5: Table Of Contents

WF30T Automatic Case Former TABLE OF CONTENTS ABOUT THIS MANUAL C U . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 ONTACT S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 ARTS ERVICE , C , W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 OTES AUTIONS ARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 ISCLAIMER SAFETY C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 AFETY ONSIDERATIONS S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 AFETY TANDARDS ... - Page 6 WF30T Automatic Case Former Loading the Magazine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 C R C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 TARTING ONTINUOUS YCLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 ONITORING Monitoring WF30T Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 C W M R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 OADING ASES HILE ACHINE UNNING ...

- Page 7 WF30T Automatic Case Former Magazine Pusher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49 Injector Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49 Mast Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49 Forming Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49 Discharge Pusher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 Conveyor Belt Tension and Tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 Proximity Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 Flap Folder Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 S M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 NEUMATIC YSTEM AINTENANCE Pneumatic Supply Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 Filter‐Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 General Pneumatics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52 ...

- Page 8 WF30T Automatic Case Former OPTIONS M S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89 ACHINE ANAGEMENT YSTEM Magazine Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89 C ™ V P . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89 RACE HECK OLTAGE ORTAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89 EACON ‐V F C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90 IBRATION RICTION LAMPS ...

-

Page 9: About This Manual

WF30T Automatic Case Former About this Manual ABOUT THIS MANUAL This Operation and Service Manual was written to assist you in installing, operating, troubleshooting, maintaining, and repairing your Wexxar WF30T. Please read the manual carefully, as it contains the necessary information required to extend the service life of this machine to its fullest. A Supplementary Manual is located at the back of this book. The Supplementary Manual includes information specific to your Wexxar machine, such as mechanical settings and part drawings. -

Page 10: Notes , Cautions , And Warnings

WF30T Automatic Case Former About this Manual Notes, Cautions, and Warnings Explanation on the use of cautions and warning messages. NOTE Notes highlight important information or helpful tips. CAUTION Cautions alert you to the possibility that taking a specific action, or failing to take a specific action, could cause equipment or product damage. WARNING Warnings alert you to the possibility that taking a specific action, or failing to take a specific action, could cause injury. -

Page 11: Safety

WF30T Automatic Case Former Safety SAFETY READ THIS SECTION BEFORE OPERATING THE WF30T NOTE The instructions in this manual are not intended to cover all of the details or variations in equipment, or to provide for every possible contingency to be met in connection with installation, operation, or maintenance. Should further information be desired, or should particular problems arise which are not covered sufficiently for the purchaser's purposes, the matter should be referred directly to WEXXAR. WARNING Any electrical or mechanical modifications to this equipment without the prior written consent of WEXXAR may void your warranty. Unauthorized modifications can also result in personal injury, death, or destruction of the equipment. The WF30T has safety features to protect you while the machine is operating. Sliding and bi‐folding guard doors equipped with interlock switches prevent you from entering the work cell while the case formation is in progress; the WF30T will not run if these doors are open. The electrical enclosure access door must also be closed in order for the machine to operate. The perimeter guarding system surrounds the area known as the restrictive envelope and covers the entire range of possible machine motion. For your safety, you should never try to bypass the perimeter guarding system or enter the restrictive envelope while the machine is in operation. ... -

Page 12: General Precautions

WF30T Automatic Case Former Safety • CSA C22.2 No. 14‐95 Industrial Control Equipment. • ANSI Z535.4‐2002 Product Safety Signs & Labels. • ANSI B155.1‐2000 for Packaging Machinery. • NEMA 12 UL listed standard electrical control. General Precautions Your WF30T is a rugged piece of industrial machinery. It is equipped with various guards and other safety features, but it must be treated with respect at all times to avoid the possibility of personal injury. • Do not operate the WF30T until it is completely set up and installed properly, and you are familiar with its operation. • Do not operate the machine without guards and safety mechanisms in place and functioning. • Do not attempt to enter the machine for any reason while it is powered or the air pressure is still • Do not wear neckties, jewelry, loose clothing, or other items that can get caught in moving parts or mechanisms near the machine. • Do not operate, troubleshoot, or maintain the machine while under the influence of any type of drug or alcohol. • Always observe all safety warnings and notices on the WF30T and in this manual. • Do not use solvents when cleaning or maintaining the machine. • All installation wiring must comply with applicable local codes. Lock‐out Compliance • The WF30T is lock‐out / tag‐out compliant on both the electrical and pneumatic main shut‐offs. • Ensure that you lock out the WF30T and adhere strictly to the safety precautions listed in this chap‐ ter before performing any repairs or maintenance. Compressed Air • Make sure that the WF30T's main air solenoid valve is shut off before attempting to clear jams or make minor adjustments which require you to get close to the moving parts of the machine. ... -

Page 13: Electrical Power

WF30T Automatic Case Former Safety Electrical Power • Switch off the main power disconnect switch on the control panel, and lock it out before starting service or repair work. • Before performing service work inside of the electrical enclosure, disconnect all electrical power to the WF30T. Conveyor Drivebelts • Keep fingers well clear of all moving parts, as the gearmotors develop substantial torque, and do not stop easily. • Do not wear loose clothing or accessories when operating WEXXAR packaging machines. Interlock Guard Doors • The interlock guard doors are meant to keep per‐ sonnel out of contact of moving parts while the WF30T is operating. Do not operate the machine with these safety devices removed or disabled. • Opening any of the guard doors on the WF30T dis‐ ables all machine functions. Wexxar offers additional safety guarding packages. If your machine includes the PHSR Option (Pre‐start Health and Safety Review) see ’Pre‐Start Health and Safety Review (PHSR Option)’ on page 91, for more information. - Page 14 WF30T Automatic Case Former Safety...

-

Page 15: Installation

WF30T Automatic Case Former Installation INSTALLATION Prerequisites To install the WEXXAR WF30T Case Former you will require: • A spirit level to level the machine. • Compressed air and electrical power supplies. The preferred method to remove the machine from the base is by means of a forklift. Use appropriate wood blocking (i.e.: 4 pieces of 4” x 4” x 12” timber) to avoid fork contact with protruding parts Site Environment Consideration Before receiving the WF30T, consider the physical environment that the machine will operate in. Consider the following factors before transporting, unpacking, installing, or setting up the machine. • This machine is intended for use in a controlled indoor environment free of conductive contami‐ nants. • Do not let any electrical components come in contact with water. • This system is not intended for external use unless it has been specifically modified for that pur‐ pose. • This unit is rated in accordance with national and local electrical codes. Make sure that the power connection is also wired to these specifications. • The power supply for this unit: ○ Must be rated in accordance with the equipment data plate. ○ Must be suitably grounded. • Do not place the machine near any heat source or machinery which may produce metallic particles, dust or powder. Do not place the machine near equipment that will produce corrosive substances or vapor. • Do not locate in an area where unauthorized personnel may have access to the unit. • Install the unit in a well‐ventilated area away from flammable liquids, gases, and explosives. Location, Leveling and Conveyors Location When selecting the machine location, carefully consider the following points: •... -

Page 16: Leveling

WF30T Automatic Case Former Installation • Sufficient clearance for magazine width increases that occur when the machine is set up for large cases. • Easy lift‐truck access. • Good access for magazine loading and nearby space for pallet loads of flat cases. NOTE Note that the bi‐fold doors jut out further when the ‘C’ adjustment is shortened for shorter cases. This increase in machine width should be taken into consideration while ensuring easy access for magazine loading. Leveling To level the WF30T: Set the WF30T for maximum Dimension ‘C’ (with the magazine in the maximum rearward position). -

Page 17: Service Connections

WF30T Automatic Case Former Installation Service Connections WARNING Service connections (electrical and pneumatic) should ONLY be undertaken by qualified personnel. Observe proper lock‐out procedures and recommended sequence to avoid personal injury or damage to the machine. Compressed Air Connect the compressed air supply to the inlet end of the manual shutoff valve on the Filter‐Regulator unit mounted on the discharge end of the WF30T. The air supply should be clean and dry, and the air‐line should have a minimum inside diameter of 3/4” (for flexible tubes) or 1” (for steel tubes). With the electrical power Off, open the manual shutoff valve and check that the regulator is set to a pressure of 90 PSI. After connecting the electrical power (see Electrical Power on page 9), switch the electrical power On; all cylinders should revert to their HOME positions, and there should be no evidence of air leaks. Non‐Lube Pneumatic System A coalescing‐type mist separator that effectively removes 99.9% of oil mist from incoming air. Combined with pre‐lubricated air cylinders and valves, this system provides reliable pneumatic operation. Electrical Power Electrical connection should be performed by a qualified electrician. Before attempting any electrical connections check the WF30T’s set‐up voltage, which is listed on the inside ... - Page 18 WF30T Automatic Case Former Installation...

-

Page 19: Theory Of Operation

WF30T Automatic Case Former Theory of Operation THEORY OF OPERATION All motions of the WF30T Case Former are controlled by the PLC (Programmable Logic Controller), which is located in the main electrical control enclosure. Inductive and optical proximity sensors are used to detect the position of the machine's components and the cases being formed. Interlock switches are used to ensure that the doors are closed while the machine is in operation. The touchscreen and switches on the control panel form the user interface. The sensors, switches, and panel provide the input signals to the PLC. The PLC then decides upon the next stage of machine operation, and sends electrical signals to the pneumatic solenoid valves. These valves control the flow of the compressed air to the pneumatic cylinders that move the different machine components. Pneumatic & Servo System Sequence of Operations Loading and Case Supply A case magazine holds the folded cases ready for erecting, and feeds them into the WF30T. The cases stand edgewise on two feedbelts which steadily move them towards the case forming section, where they are selected one at a time for processing. The magazine pusher is also part of the feed system. It applies constant pressure to the top rear of the case stack to ensure proper operation of the case separator and case injector. Case Separation The case separator, located above the case blanks, selects the first case from the magazine stack. It moves downwards, causing a small step on its rear surface to catch the case edge and drive it down into a slot at the inward end of the magazine feedbelts. This slot is formed by the calipers and the injector, and its width is set to suit the thickness of the flat corrugated case blank. When the case is securely pushed... -

Page 20: Case Injection

WF30T Automatic Case Former Theory of Operation Case Injection The case injector pushes upwards on the bottom edge of the separated case to impale the top edges of the corrugated case onto a series of sharp pins mounted on the inner surfaces of the jawplates of the forming head assembly that penetrate into case corrugation flutes. When the injector returns to the Down position, it leaves the case securely held by these pins of the Pin and Dome mechanical gripping system developed by WEXXAR. Case Opening: The case opening action now occurs, which opens the case 90° to the fully Open position while still held securely by the pins. WEXXAR does not use a vacuum system on its case formers. Minor Flap Folding: After opening the case, the forming head moves it to the Down position. During this descent, the case bottom's minor (widthwise) flaps contact a pair of angled minor flap folders, causing them to begin to fold inwards. As the descent continues to the bottom position, the angled minor flap folders simultaneously move to a horizontal position, completing the folding of the case's minor flaps. Major Flap Folding: A pair of major flap folders receives the bottom major flaps into slots as the forming head descends to the fully Down position. When the case is fully Down, the major flap folders rotate to fold the case's major flaps about half way, and secures the case from vertical movement. The forming head now moves to the UP position, pulling the pins out of the top edges of the flaps, and leaving the partially formed case ready to be sealed with the bottom flaps folded. Case Sealing and Discharge: The conveyors transport the case over the tape head, which applies tape to the bottom flaps as the case moves towards the discharge end of the machine. After ... -

Page 21: Sensors

WF30T Automatic Case Former Theory of Operation Sensors Optical Proximity Sensor s These infrared sensors are used to detect the position of the cases being formed as they proceed through the WF30T. They help in timing the machine, and detect any faults in the process. Sensor # Sensor Name Home Status Part # CASE DOWN 02‐1026 LS21 CASE SEPARATED 01‐280 Remote Demand Sensor The Remote Demand sensor optically detects if there is a jam at the discharge end, and halts production of additional cases until the jam has been cleared. It can also be used to control 'case on demand' production with more manual fill lines. Sensor # Sensor Name Home Status Part # LS11 REMOTE DEMAND... -

Page 22: Sensor Cables

WF30T Automatic Case Former Theory of Operation Sensor # Sensor Name Home Status Part # PUSHER FORWARD 02‐1004 LS18 INJECTOR UP 01‐276 LS22 TAPEHEAD 01‐276 DISENGAGED Sensor Cables The WF30T is equipped with the following sensor cables. Refer to the part numbers below when ordering replacement parts. Cable Description Part # Sensor Cable 0.6M 01‐257 Sensor Cable 1.5M 01‐258 Sensor Cable 3.0M 01‐259 Sensor Cable 10.0M 01‐260 Injector LS Cable 1.5M 01‐288 Injector LS Cable 2.0m 01‐340 Interlock Switches The interlock switches are used to ensure that all doors are CLOSED while the WF30T is operating. Sensor # Sensor Name Magazine Slide Door Bi‐fold Door DS3–DS7 Guard Doors... -

Page 23: Pressure Switches

WF30T Automatic Case Former Theory of Operation Pressure Switches The pressure switches are used to gauge the pressure applied by the stack of case blanks on the injector plate. Sensor # Sensor Name Home Status Part # LS102 Magazine Pressure 01‐354 Switch (LH) LS103 Magazine Pressure 01‐354 Switch (RH) Tape Management System This optional system on the WF30T monitors the pressure‐sensitive adhesive tape application, and detects faulty conditions. A set of optical and inductive sensors monitors the condition of the tape applicator. -

Page 24: Factors Influencing Pneumatic Speeds

WF30T Automatic Case Former Theory of Operation Factors Influencing Pneumatic Speeds Case height, width, weight, corrugate thickness, flute size and scoring all affect the optimum speed of the pneumatic cylinders. A significant increase in case size or weight makes it more difficult to lift, rotate and fold the cases. Flat Case Height (Dimension 'B') The height of the case being formed is a major determinant of machine throughput. Machines running shorter cases can operate faster because the mast movements can achieve higher speeds. Taller cases also add weight, so that more energy is required to lift, rotate and fold the cases. Case Thickness (Dimension 'F') Case corrugate thickness (especially double or triple wall corrugate) will add weight and make the case less pliable. It will therefore cause cycle times to change, as the pneumatic cylinders require more energy to fold the flaps correctly and to perform other pneumatically driven functions. Non‐Lube Pneumatic System Wexxar's non‐lube pneumatic system features a coalescing‐type mist separator that effectively removes 99.9% of oil mist from incoming air. Combined with pre‐lubricated air cylinders and valves, this option will provide reliable pneumatic operation. Maintenance • Drain the mist separator bowl frequently. • As the mist separator becomes contaminated, the pressure drop across the filter will increase. Replace the element when the pressure drop reaches 15 PSI, or once per year, whichever comes first. • The rate at which the filter element is contaminated will be greatly affected by the quality of the incoming air. If the air is wet and contaminated with lubricant, the filter element will need more fre‐ quent replacement. CAUTION Do not attempt to change the factory‐set minimum low pressure setting on the low pressure switch. Any changes to the low pressure setting may be hazardous, and may void the machine's warranty. ... - Page 25 WF30T Automatic Case Former Theory of Operation Press the Emergency Stop button. This will shut off the electrical and air power to the machine mechanisms. It may take a few moments for the system air pressure to decline to zero; wait until air pressure has fully exhausted and all mechanisms are stationary before proceeding. If required by local regulations or company policy, lock out the electrical power and air supply before proceeding. If the WF30T has stopped mid‐cycle, open a guard door and remove any case corrugate in the case forming section of the machine. Inspect the machine for air leaks. Make sure that the air compressor is operating properly and that the pneumatic supply hoses are not leaking. Rotate the Emergency Stop clockwise, close the guard door (if applicable), and press Reset to re‐ energize the machine. Verify that the FRC is set to 90 PSI. To adjust the pressure settings, pull down the black knob on the bottom of the pressure gauge. To increase the pressure, turn the knob clockwise. To decrease the pressure, turn the knob counter‐ clockwise. Press Start on the touchscreen to restart the WF30T.

- Page 26 WF30T Automatic Case Former Theory of Operation...

-

Page 27: Operating Procedures

WF30T Automatic Case Former Operating Procedures OPERATING PROCEDURES NOTE Read Safety on page 3 before continuing. Controls Overview Control panel disconnect switch Disconnects power to the case former. Used to start or stop the tray former cycle, select a preset tray recipe, monitor tray former production, and change tray former settings. Reset Used to reset the tray former after an emergency stop or fault. E‐STOP Editing HMI Value Fields Most of the HMI screens include several value fields. Some of these fields can be edited, while some are for displaying data only. Generally, a field with blue text can be edited. A field with white text cannot. Blue text can be edited. White text cannot. -

Page 28: To Edit A Value Field

WF30T Automatic Case Former Operating Procedures To Edit a Value Field: HMI Screen Navigation... -

Page 29: Start-Up

WF30T Automatic Case Former Operating Procedures Start‐up Preliminary Checks Before placing the WEXXAR Model WF30T Automatic Case Former into operation, check the following points: Preliminary Start‐up Checklist □ Check that the WF30T is set for the right case size. (See Size Change on page Check that the WF30T is properly loaded, with the first case pushed into the caliper □ slot. See Loading the Magazine on page With the manual shutoff valve Open, verify that the air pressure at the main regulator □ is set to 90 PSI. □ Verify that all guard doors are closed and that all personnel are clear. Verify that the electrical power disconnect switch is turned On and that the Emergency □ Stop button is in the Out position. Check if the tape applicator is properly installed, loaded with a tape roll, and ready to □ □ Check if the Remote Demand sensor is clear. - Page 30 WF30T Automatic Case Former Operating Procedures • Always load cases in the magazine standing vertically upright. If cases sit at an angle in the maga‐ zine, a jam may occur. To Load Cases into the Magazine: NOTE: Cases can be loaded while the WF30T is running (see Loading Cases While the Machine is Running on page 24 ) but the following procedure assumes that you have stopped the machine. Turn the pusher air valve, located at the center of the magazine, to Off. Positioning the Magazine Feedbelts Pull back the magazine push arm. Make sure that the magazine feedbelts are properly positioned and then place a stack of case blanks, upright, into the magazine. Push the stack of cases as far forward in the magazine as ...

-

Page 31: Starting The Continuous Run Cycle

WF30T Automatic Case Former Operating Procedures Starting the Continuous Run Cycle After completing the procedures outlined in 'Preliminary Checks' and loading the magazine, start the WF30T as follows: Press the Reset button once. Ready appears on the display and air pressure will now be applied to the various machine mechanism cylinders and they move to their respective Home positions. On the HMI, touch the Start button once. Check that the conveyor side‐belts are tracking properly. They should be centered on the drive pulley, properly tensioned, and in reasonably good condition. Monitoring Monitoring WF30T Operation The WEXXAR WF30T is completely automated. It requires very little monitoring once it is running. Monitoring the machine involves: •... -

Page 32: Loading Cases While The Machine Is Running

WF30T Automatic Case Former Operating Procedures Loading Cases While the Machine is Running The magazine can be reloaded without stopping the machine, if desired. WARNING Use extreme caution when loading the machine while it is running. Make sure that your hands and arms are clear of any moving parts. If in doubt, we recommend stopping the machine before reloading the magazine. To Load Cases While the WF30T is Running: Position fresh cases in the magazine behind the magazine pusher arm. While applying modest pressure to the stacked cases to maintain contact, switch the pusher air valve at the center of the magazine Off. Lift the magazine pusher arm up to clear the stacked cases, pull it back behind the new cases, and reposition it to push on the last case. Switch the magazine pusher valve back to On. Remove any banding straps that may be around the case bundles. Resolving Tray Backups in the Discharge Area The WF30T is equipped with a Remote Demand sensor that, when active, pauses tray former operation when it detects a backup of trays in the discharge area. Once the discharge area is clear, the tray former automatically resumes operation. The operator is not required to restart or reset the tray former. To Turn On the Remote Demand: On the HMI’s Main Control screen, touch Setup. Touch the Remote Demand toggle switch. The toggle switch turns green, and a Remote Demand On message appears at the bottom of the ... -

Page 33: Clearing A Case Jam

WF30T Automatic Case Former Operating Procedures Clearing a Case Jam WEXXAR Case Formers will provide reliable, trouble‐free performance on a wide variety of case sizes. Occasional jams are not uncommon, but frequent jamming can usually be traced to a particular reason, such as incorrectly set machine adjustment, and corrected. Refer to Size Change on page 27 for further information. To place the WF30T back into service as quickly as possible after a jam, proceed as follows: Press the Reset button. This will return the machine's mechanisms to their HOME positions so that it is easier to clear the case jam. Press the Emergency Stop button. This will shut off the electrical and air power to the machine mechanisms. It may take a few moments for the system air pressure to decline to zero; wait until air pressure has fully exhausted and all mechanisms are stationary before proceeding. If required by local regulations or company policy, lock out the electrical power and air supply before proceeding. -

Page 34: Viewing Case Production And Speed

WF30T Automatic Case Former Operating Procedures Viewing Case Production and Speed On the Case Record Summary screen, you can view the number of cases that the machine has formed (lifetime), the total number of cases formed in the current “shift”, as well as the current speed in cases per minute. To View Case Production and Speed: From the Main Control screen, touch Setup. Touch Case Record Summary. Stopping the WF30T NOTE Normal stopping of the machine should be accomplished by using the Stop button. There are several options to stop the machine: • Stop Button: Pushing the Stop button is the proper way to stop the machine in a non‐emergency situation. When the Stop button is pressed in Cycle mode operation, the case in process is com‐ pleted, and the mechanisms return to their HOME positions unless the machine is in Remote Demand pause. If the machine is in Remote Demand pause or Jog step cycle when the Stop button is pressed, the mechanisms remain where they are. The air pressure and power remain on. When the Remote Demand sensor is cleared, the machine will finish the present cycle and then stop. • Emergency Stop Button (E‐STOP): Pushing the E‐STOP button stops the machine rapidly regardless of where the machine is in its operating cycle. Air and electrical power is removed from the machine mechanisms. Restarting the machine after an emergency stop is more complex. Most likely the case that was being formed will be wasted and have to be removed manually. Refer to Loading Cases While the Machine is Running on page • Open a Guard Door: Opening a guard door will stop the machine rapidly regardless of where the machine is in its operating cycle, similar to actuating the E‐STOP button. • Disconnect Switch: Turning off the disconnect switch or any other means of removing the electri‐ cal power will cause the machine to stop rapidly, similar to actuating the E‐STOP button. • Turning Off Pneumatic/Air Supply: Cutting off the compressed air supply to the machine will cause it to halt operation. -

Page 35: Size Change

WF30T Automatic Case Former Size Change SIZE CHANGE NOTE Read Safety on page 3 before continuing. Adjustments made to the machine for different case sizes are based on the dimensions of the actual case. You will need to measure each case dimension and adjust the machine components accordingly. The WF30T features “tool‐less” adjustment components and includes measurement scales to assist you with the case size change procedure. Size Change Parts (‘Zone Changes’) Most case size modifications do not require change parts; however, exceptionally short or long case dimensions may require you to complete ‘zone changes’. -

Page 36: Case Size Change Procedure

WF30T Automatic Case Former Size Change Case Size Change Procedure You will need: • A flattened case • ‘Zone Setup Table’ (found in the Supplementary Manual) • Size change parts and tools (if required) The case size change follows this procedure: Select case recipe and record the case dimensions. Remove power and air and perform lock‐out/tag‐out procedure. Remove cases from the magazine. Adjust case dimension B. Adjust case dimension D. Adjust case dimension C. Adjust case dimension A1 and A2. Adjust case dimension F (case thickness). Load cases into the magazine. Adjust case dimension A3. Attach size change parts and adjust Jaw Plate pins (optional). Remove lock‐out/tag‐out and restore power and air. Test size change and begin production. -

Page 37: Select Case Recipe And Record Case Dimensions

WF30T Automatic Case Former Size Change Select Case Recipe and Record Case Dimensions On the HMI, touch the Case Selected button. Touch the button that matches the case you are changing to. Record the B, D, and C dimensions on a case blank for easy reference. ... -

Page 38: Remove Power And Air And Perform Lock - Out /Tag - Out Remove Cases From The Magazine

WF30T Automatic Case Former Size Change Remove Power and Air and Perform Lock‐out/Tag‐out Remove Cases from the Magazine WARNING Failure to remove power and air from the case former before attempting to perform a size change may result in serious injury. Press an E‐STOP. Turn off the air at the main regulator, and the power at the main disconnect switch. Follow your company lock‐out/tag‐out procedure. Remove the cases from the magazine and set them aside. -

Page 39: Adjust Case Dimension B1

WF30T Automatic Case Former Size Change Adjust Case Dimension B1 Loosen the two light‐blue quick‐adjust handles located on the collar assembly. Use the hand crank to raise or lower the collar assembly. Reading the Scale: Read the scale according to the ‘zone’ of the case you want are changing to. The zone numbers correspond with the amount of holes punched into the jawplates. • If the jawplate is punched with 1 or 2 holes: Read the bottom edge of the scale at the pointer that is labelled ‘Zones 1 & 2’ • If the jawplate is punched with 3, 4 or 5 holes: Read the top edge of the scale at the pointer that is labelled ‘Zones 3, 4, 5’.For more informa‐ tion, refer to the ‘Zone Setup Table’ located in the Supplementary Manual. Tighten the quick‐adjust handles. -

Page 40: Adjust Case Dimensiond

WF30T Automatic Case Former Size Change Adjust Case Dimension D Use the blue handwheel located at the base of the mast (‘D1’) to position the magazine guide, the mast assembly, and the major flap folders. The scale is on the discharge pusher alongside the nearest major flap folder. Note: Check the adjustment with an actual case, held open, with the bottom minor flaps folded. The bot‐ tom major flaps should pass centrally between the bars of the major flap folders with difficulty, with the case resting on the minor flap folders. Use the blue handwheel located at the discharge end (‘D2’) to position the width of the outfeed conveyor assembly. Adjust Case Dimension C Use the green handwheel located at the infeed end to set the length of the forming section. -

Page 41: Adjust Case Dimension A1 And A2

WF30T Automatic Case Former Size Change Adjust Case Dimension A1 and A2 Place a single case blank in the magazine. Loosen the A1 adjustment handles (x2) and then slide the guide rail up against the edge of the case blank. Make sure that there is a 1/8” gap between the case edges and the guide rails. Tighten the adjustment handles. Loosen the A2 adjustment handles (x4) and then position the feedbelts so that they are centered underneath the minor flaps. Tighten the adjustment handles. Adjust Case Dimension F NOTE Don’t adjust Dimension ‘F’ (case wall thickness) unless there is a significant change in case blank thickness (for example, from single‐wall to double‐wall corrugate material). Loosen the F adjustment handles (x2). Adjust the calipers vertically so that a case that is three corrugate panels thick could fit between them and the case separator plate. Tighten the adjustment handles Note: An easy way to measure Dimension F is to fold over one of the case flaps and slide the case between the calipers and the case separator plate. -

Page 42: Load Cases Into The Magazine

WF30T Automatic Case Former Size Change Load Cases into the Magazine Load cases into the magazine. Make sure that are all correctly oriented (right‐way up), and that the first case is pushed down into the caliper slot against the injector drive bar. Position the pusher arm as shown. Adjust Case Dimension A3 Loosen the two quick‐adjust handles located on top of the case separator. Slide the separator along the channel until it is centered on the case blanks. Tighten the quick‐adjust handles. Note: For larger cases, it may not be possible to center the case separator above the case centerline. -

Page 43: Attach Size Change Parts And Adjust Jaw Plate Pins ( Optional )

WF30T Automatic Case Former Size Change Attach Size Change Parts and Adjust Jaw Plate Pins (optional) If your machine includes change parts, you may need to install some or all of them when changing to certain case sizes. Refer to the ‘Zone Setup Table’ included in the Supplementary Manual for information on which change parts you need to attach for each case size. For help with common size change parts, see page If necessary, lower or raise the pin blocks. Pin blocks should be lowered (engaged) at the inside and outside ... -

Page 44: Remove Lock - Out /Tag - Out And Restore Power And Air Test Size Change And Begin Production

WF30T Automatic Case Former Size Change Remove Lock‐out/Tag‐out and Restore Power and Air Test Size Change and Begin Production Remove lock‐out/tag‐out. Turn on the air supply and electrical power. Turn the E‐STOP button to disengage it. Verify that there are no Warning or Alarms on the HMI and that you have selected the correct case recipe. We recommend to test the size change first before starting the production run. Navigate to the Jog screen and jog a case through the case former to verify that the case is forming correctly. For additional information and instructions on testing the size change, see page 42 When you’ve successfully jogged a case through the forming process, touch Start to begin the automatic production cycle. -

Page 45: Additional Wf30T Adjustments

WF30T Automatic Case Former Size Change Additional WF30T Adjustments WARNING Before making any machine adjustments, ensure that you discharge the air from the pneumatic lines by pressing an E‐Stop button or opening any guard door. The machine’s mechanisms will stop immediately without the mechanisms reverting to their Home positions. Then lock out the pneumatic and electrical supplies to ensure that the machine cannot be accidentally activated while maintenance is being performed. Tape Head WF30T case formers that are built to accommodate 6” tape heads can switch between 6”, 3” and 2” tape heads by adding or removing the tape deck adapter plate. To change from a 2" or 3" tape head to a 6" tape head: On the tape deck, from the adapter plate, loosen the thumbscrew. Push the adapter plate forward and then pull the adapter plate out from the tape deck. -

Page 46: Stabilizer Bars And Pinblocks

WF30T Automatic Case Former Size Change Stabilizer Bars and Pinblocks Pinblock Orientation The stabilizer bars are used to support the outside corner of the case as it descends into the minor and major flap folders. A standard set of 3 fixed bars will cover most case sizes. The bars are most useful on medium to large sized cases, where the inherent stability of the case is lower, and on machines running at higher speeds. Adjust the number of pins penetrating the case flaps to best suit the case. Lower the pins in the pin blocks mounted on the jawplates where they should penetrate into the case flaps; raise pins where they should not penetrate. It may be necessary to raise pins to avoid engaging the wrong flap when the case is opened. It is not necessary (and is often not possible) to have pins down at the outer ends of the case dimensions. This is especially true with smaller cases. With longer, heavier cases, the pins should be down towards the outer corners. But, it is not usually necessary to have all of the pins down along each case dimension. Lowering two pins for each side is sufficient. Lowering more pins may be necessary to lessen case wobble with unusually long or heavy cases. Engage as many pins as necessary to get a good grip on the case, but be aware that having too many pins will make injecting them into the flaps (and extracting them) more difficult, and can also interfere with raising of the forming head after folding the bottom major flaps. If there are too many pins lowered, the... -

Page 47: Sensor Ls7 Adjustment

WF30T Automatic Case Former Size Change Pinblock Mounting Orientation The pinblocks have been designed with the pins slightly off‐center so that reversing the block will increase or decrease the distance between the pins and their adjacent domes on the jawplate. Using this adjustment makes it possible to overcome many hard‐to‐run case‐forming conditions. When the pins are set closer to the domes, they exert more pressure (more of a pinching effect) to grip the corrugate more tightly. This tighter grip is desirable in handling larger heavier cases. A lighter grip is desirable in handling smaller, lighter cases. Pinblock side view showing offset Sensor LS7 Adjustment Sensor LS7 signals the presence of the major flap through or below the major flap folders. It mounts on a bracket and senses the arrival of the major flap. The sensor can be adjusted slightly, but is usually unnecessary. If the case size change involves a significantly different length of the flap, then you may need to adjust the position of the LS7 sensor. When running cases with small bottom flaps, ensure that the sensor ... -

Page 48: Discharge Pusher

WF30T Automatic Case Former Size Change Discharge Pusher The front plate on the discharge pusher is fastened to the pusher body using four adjustable bolts. These bolts are mounted in slider channels such that the horizontal angle of the pusher plate can be altered in order to ensure that it pushes with equal force across the rear wall of the case being formed. As the machine components wear in, machine operators may need to make small adjustments to the pusher plate in order to ensure that the leading corners of the case are gripped by the side‐belt conveyors at precisely the same Discharge Pusher Adjustment Plate time, ensuring predictable case squaring. Limit Switch Actuators As the limit switch actuators regulate the flow of case blanks into the machine, it is important that they are adjusted correctly. Different case sizes and weights of corrugate can cause the need for adjustment to these switch actuators. To determine whether your machine’s Limit Switch Actuators need to be adjusted, review Troubleshooting Case Flow Issues on page 78. Definition: The limit switch actuators are ... - Page 49 WF30T Automatic Case Former Size Change Adjusting Once these other possible causes have been the Limit discarded, (Case Feeding Issues, previous Switch page) review the following to adjust the limit Actuators: switch actuators. Guideline Initial setup position: At the standard factory set‐up, the switches are activated when the tabs are pushed back to the position shown. At this calibration, the edge of the tab goes no further than the center of the thickness of the injector plate, when pulled back (towards the out‐feed end of the machine). Important: Adjust to apply the minimum amount of force necessary to trip the switches. This practice will extend the life of both the machine's separator and injector functions Accessing To gain access to the actuators for calibration: the limit • Press the E‐Stop button & lock out air & power to the pneumatic system. switch actu‐ • Open the bi‐folding door and push the discharge pusher toward the out‐ ators: feed end of the machine to gain unobstructed access to the limit switch actuators, (shown below). How to Calibration steps: adjust/set Decide: Are the tabs too sensitive or up the Limit ...

-

Page 50: Testing The Size Change

WF30T Automatic Case Former Size Change Testing the Size Change After making all of the necessary size adjustments, test the machine to check that they are correct. To test the size adjustments set up the WF30T and then test the adjustments in Jog mode. Set‐up the WF30T To set‐up the WF30T: Ensure that the magazine is loaded with cases that are all correctly oriented (right‐way up), and that the first case is pushed fully Down into the caliper slot against the injector drive bar. Close all guards. Check that the Remote Demand sensor is clear and that the Remote Demand toggle button on the Setup screen of the touchscreen displays the text Remote Demand Off. Turn On the manual pneumatic shutoff valve and ensure that pressure is 90 PSI on the main regulator. Turn the electrical disconnect switch On. Ensure that the E‐Stop is disengaged (rotate clockwise if not). Press the Reset to turn On the main air. The other mechanisms will be in the their Home positions, as follows: Mechanism Home Positions Forming Head Jaws... - Page 51 WF30T Automatic Case Former Size Change Touch Machine Cycle Jog consecutively to step the machine through the full cycle sequence as follows: Full Cycle Sequence STEP 1 Forming Head Jaws Close STEP 2 Injector Case pushed into jaw pins STEP 3 Injector Down Case stays in jaws STEP 4 Forming Head Jaws Open Case opens STEP 5 Forming Head Assembly Down Case in major flap folders STEP 6 Major Flap Folders Close Major flaps turned in STEP 7 Former Head Assembly Case stays down. STEP 8 Discharge Pusher Case moves into side‐belt conveyor The machine should form the case successfully in a step‐by step manner. If a problem should occur ...

-

Page 52: Adding A Case Recipe

WF30T Automatic Case Former Size Change Adding a Case Recipe Step 1 ‐ Create a New Recipe On the HMI, on the Main Control screen, touch the Case Selected Input Field. The Case Selection screen appears. On the Case Selection screen, touch an empty case button, and then touch Recipe Setup. A Keypad appears. On the Keypad, enter the User Name and Password. The Recipe Setup screen appears. NOTE The default user for the HMI is: engineer. The default password for the HMI is: 9300. On the Recipe Setup screen, touch Recipe Selected. This is the Recipe Name Button. Enter a name for your new recipe. -

Page 53: Step 2 - Enter Case Dimensions

WF30T Automatic Case Former Size Change Touch the Recipe Enabled Input Field to enable the recipe. (When the recipe is enabled, a 1 appears in the button display. Touch the Jawplate Zone No Input Field and enter the correct jaw plate zone for your case size. Refer to the Zone Setup Table in the Supplementary Manual. ... -

Page 54: Step 4 - Save The Recipe

WF30T Automatic Case Former Size Change To Enter the Target CPM: Touch the Target CPM Input Field. Enter the target speed in cases per minute (min. 11; max 30. Maximum amount depends on case and jaw plate size). Step 4 ‐ Save the Recipe • Touch Save Recipe. Your new recipe is saved with the name you gave it in Step 1. NOTES • Your recipe won’t save if any of the dimensions values are outside the minimum or maximum value allowed. • You must enable the recipe before it can be used. Touch Recipe Enabled until the number 1 appears in the button display. -

Page 55: Machine Maintenance

WF30T Automatic Case Former Machine Maintenance MACHINE MAINTENANCE NOTE Read Safety on page 3 before continuing. Maintenance WARNING The tape knife blade is sharp, and can cause serious injury. Inspections On a daily basis, the operators should inspect for: • Leaks in the pneumatic system • Drain bottle overflow • Loose fasteners • Belt condition, tracking, and tension • Irregular noise and signs of wear. Cleaning Tools and Materials • Soapy water • Rag or paper towel • Filter replacements (if necessary) CAUTION Do not use solvents for cleaning. Instructions • Inspect the WF30T daily and remove any corrugated fragment deposits that may have accumu‐ lated. • Regularly check the pneumatic filter bowl and filter for debris; replace the filter at suitable inter‐ vals, depending on the cleanliness level of the incoming air supply. ... -

Page 56: Preventive Maintenance Schedule

WF30T Automatic Case Former Machine Maintenance Preventive Maintenance Schedule CAUTION Do not lubricate the adjustment leadscrews. The leadscrews are self‐lubricating and do not need additional lubrication. Applying lubricant may cause damage to the leadscrews. Daily • Visually inspect the WF30T for loose fasteners, and leaks in the pneumatic system, and drain bottle overflow. • Clean the tape knife on the Tape Head with WD‐40 or a similar low‐toxicity cleaner and lubricate the blade guard pad with silicone. Weekly • Check conveyor belt condition, tracking, and tension. Monthly* • Thoroughly clean all adjustment screws, sprockets, chain, and sliding components, and then lightly grease.** • Grease guide wheels on mast.** Every 3 Months* • Grease guide wheels on mast and discharge pusher.** *Timeframes are based on a WF30T running 30 cycles per minute, 8 hours per day, and 22 days/month, or 1,000,000 cycles. Adjust your schedule according to your machine use. ... -

Page 57: Magazine Pusher

WF30T Automatic Case Former Machine Maintenance Magazine Pusher The magazine pusher is fitted with a pressure regulator, a shutoff valve, and a flow control. The flow control is set to almost fully CLOSED, as the speed is very slow. Magazine Pusher Maintenance: • Verify that all parts are there (i.e., pusher arm, knob, spacer, etc). Check these parts for proper function and any excessive wear or damage. • Inspect magazine pusher cylinder for leaks and proper function. Verify that the on/off switch for this cylinder is working and that its pressure is correctly regulated as per service manual recom‐ mendations. • Examine magazine pusher bar pivot point at drive carriage for wear. • Examine drive carriage rollers for damage or wear. Injector Assembly Verify the following items on the magazine injector assembly: •... -

Page 58: Discharge Pusher

WF30T Automatic Case Former Machine Maintenance Discharge Pusher It is important that the discharge pusher speed matches the conveyor speed. Verify the following items on the discharge pusher: • Inspect discharge pusher cylinder for leaks. • Check the overall condition of this assembly (that is, the guide wheels, rod ends, welds, etc.) Conveyor Belt Tension and Tracking The correct belt tension is factory‐set on new machines, but the tension will decrease when the machine is in service, particularly in the first few months, and will require regular adjustment to maintain correct case transfer. ... -

Page 59: Proximity Sensors

WF30T Automatic Case Former Machine Maintenance Proximity Sensors Two types of proximity sensors are used on the WF30HT case former: inductive and infrared photo‐type. The majority is of the inductive type; they sense the presence of a steel component by magnetic effects and are mostly used to sense the position of the machine mechanisms. It is important that these sensors be the correct ... -

Page 60: General Pneumatics

WF30T Automatic Case Former Machine Maintenance General Pneumatics Check the following pneumatic item: • Tubings and fittings for damage and leaks. Electrical System Maintenance Safety Circuit Check the following general electrical conditions: • E‐STOP and door switches are functioning. Electrical Enclosure Verify that the electrical enclosure meets the following criteria: • The HMI screen displays information and is functioning properly. • There are no loose or damaged connections and wires. Mechanical Maintenance • Observe the WF30T in operation, looking particularly for any uneven or excessively noisy motions and abnormal air leaks. • With the WF30T stopped and the air OFF, check for smooth action without excessive bearing wear or abnormal looseness of all moving parts. Special attention should be given to the head Up/Down motion, which is guided by the grooved wheels on the bevel bar. Any looseness in this subassem‐ bly can be corrected by adjustment of the eccentric bushings. See Mast Assembly on page 49 for further details. • Inspect the machine for signs of abnormal wear, such as debris caused by scraping or grinding together of parts. All piston rods on the air cylinders should be smooth and shiny; black, crumbly deposits are signs of seal deterioration. • Watch for signs of improper belt tensioning, such as the belts slipping when transporting a heavy case. Correct belt tension is one percent stretch from the no‐load position ‐ if in doubt, slacken the belt to no‐load, make marks on the belt 25" apart, and re‐tension to produce a distance of 25¼" between the marks. Always tighten tension bolts equally to maintain correct tracking. -

Page 61: Maintenance Parts List & Schedule

WF30T Automatic Case Former Machine Maintenance Maintenance Parts List & Schedule At/Frequency Related Part Action Every Compression cylinder Replace cylinder seals using 2,000,000 cycles PN 15‐409 repair kit PN 16‐1218 Approx. every 6 months* Replace all shock absorbers. Example, for injector cylinder Every PN 15‐414 and Compression cyl‐ 4,000,000 cycles All shock absorbers inder PN 16‐1256 (SHock Approx. every year absorber part numbers vary by related part. See drawings and confirm when ordering). Every Discharge pusher cylinders 10,000,000 cycles Replace cylinders PN 15‐387 PN 15‐387 Approx. every 2.5 years* Injector cylinder Replace side bearing w/body PN 15‐414 PN 16‐1302 Every Replace cylinder PN 15‐414 12,000,000 cycles Injector cylinder ‐or‐... -

Page 62: Lubrication

WF30T Automatic Case Former Machine Maintenance Lubrication Frequency Parts Suggested Lubricant Volume Moderately oil along Fuchs Geralyn RO Chains the entire chain with 15 Food Grade Oil an oil feeder. Every 230,000 cycles 0.12 ounces (two Purity FG Food Case Injector strokes of a 6 ounces/ Approx. every 3 weeks Grade Machinery Cylinder 100 stroke grease gun) Grease Guide Rods for each lubricant 650‐105 PFG2 point. 0.6 ounces Every 1,000,000 cycles Guide wheel (Forming (ten strokes of a 6 head and discharge Fuchs Geralyn FMG 387 ounce/100 stroke Approx. every 3 pusher roller) casings grease gun) for each ... -

Page 63: Machine Sanitation

WF30T Automatic Case Former Machine Maintenance Chains Moderately oil along the entire length of all chains using an oil feeder as shown. Machine Sanitation WARNING Lock out the machine before cleaning. NOTE The following guidelines should serve only as a reference. They are intended to help develop a cleaning procedure that will meet the specific needs of your operation. Purpose To ensure the cleanliness of your WF30T is maintained to an acceptable standard. Frequency Clean at regular intervals such as between changeovers, after a product spill, and as required. Responsibility The operator and sanitation crew are typically responsible for conducting cleaning tasks. Materials The following are examples of some materials you may need for your cleanup: • Long/short handled brushes and dust pans • Cleaning cloths •... -

Page 64: Procedure

WF30T Automatic Case Former Machine Maintenance Procedure Standard WF30T’s are not designed for a full washdown. Rather, a dry cleaning or spot cleaning method is recommended. • Dry cleaning employs the use of brushes, vacuums, or other tools to collect and remove debris. Ensure that all tools are clean so that they do not introduce new contaminants. • Spot cleaning involves the use of a cleaner or sanitizer to clean a specific area. Be sure to follow the manufacturer’s recommendations when preparing and using any cleaner or sanitizer. Also, ensure that your cleaners and sanitizers are compatible and will not damage equipment surfaces. Lastly, ensure that your cleaning cloths are clean, and used solely for this purpose—refer to Cleaners and Sanitizers on page 69 for more details. Critical Areas Although your WF30T may not have any direct food contact surfaces, this does not exclude it from having any food safety risks. A big concern for indirect food contact surfaces is cross contamination. The pictures in the following pages identify critical areas that have a high potential for cross contamination. In particular, all frequently touched surfaces (handles, knobs, touch screens, and buttons), and hard‐to‐access surfaces are identified. -

Page 65: Overview Of Critical Areas

WF30T Automatic Case Former Machine Maintenance Overview of Critical Areas View of all critical areas... -

Page 66: Frequently Touched Surfaces

WF30T Automatic Case Former Machine Maintenance Frequently Touched Surfaces Daily operations require frequent touching of the surfaces shown in the following pictures. Failing to clean or sanitize these surfaces regularly may result in the spread of harmful contaminants to other equipment surfaces and, in the worst case, to your food products. Thus, you should clean these surfaces regularly. If using a cleaning cloth for sanitizing, ensure that it remains in a sanitizer solution between uses and that it is solely used for this purpose. Refer to Cleaners and Sanitizers on page 69 ... - Page 67 WF30T Automatic Case Former Machine Maintenance . WF30T Back/Outfeed End...

- Page 68 WF30T Automatic Case Former Machine Maintenance WF30H LH Machine / Outfeed ...

- Page 69 WF30T Automatic Case Former Machine Maintenance Front/Infeed End Mast Assembly Magazine Pusher Mast Assembly...

- Page 70 WF30T Automatic Case Former Machine Maintenance WF30H LH Machine / Infeed...

- Page 71 WF30T Automatic Case Former Machine Maintenance Feed‐belt Area...

- Page 72 WF30T Automatic Case Former Machine Maintenance WF30H LH Machine / Feedbelt Area...

-

Page 73: Hard-To-Access Surfaces

WF30T Automatic Case Former Machine Maintenance Hard‐to‐Access Surfaces Hard‐to‐access surfaces can easily go ignored. As a result, the accumulation of debris can become airborne contaminants, which can find their way onto clean surfaces. The contaminants may be harmful chemicals, physical materials, or microbes. Thus, the use of air hoses for cleaning is not recommended. Rather, we recommend the use of clean brushes and vacuums to remove loose debris. Finally, it is important ... - Page 74 WF30T Automatic Case Former Machine Maintenance WF30 LH Machine / Hard‐to‐access surfaces (highlighted in red)

- Page 75 WF30T Automatic Case Former Machine Maintenance WF30 LH Machine / Hard‐to‐access surfaces (highlighted in red)

-

Page 76: Other Areas: Lexan™ Windows

WF30T Automatic Case Former Machine Maintenance Other Areas: Lexan™ Windows Different areas of your Lexan™ windows will accumulate with different types of filth. The following are recommendations based on these different types of filth. Light filth such as fingerprints, water splash residues, and dust: • Use a compatible cleaner and nonabrasive cloth to wipe off any light filth • DO NOT use any abrasive or alkaline cleaners, benzene, acetone, or carbon tet‐ rachloride as this can cause dulling or hazing • Please consult your chemical supplier for further details regarding other chemi‐ cal compatibilities Lexan™ Heavy filth such as product residues that have sprayed onto the windows: Window • Many types of heavy filth can be removed with a simple wipe as outlined in the above Light filth section • Certain filth that adheres to the Lexan™ surface may require additional soaking with an appropriate cleaner. Once softened, use a nonabrasive cloth to wipe the filth off • Some filth may not soften with soaking. A strong tape, such as duct tape, may remove the filth. Alter‐ natively, you can try scraping the filth with a plastic scraper fitted with a clean soft cloth around its scraper blade • A hot cloth may help soften certain residues. Other heating methods may be used. However, we do not recommend any temperatures above the boiling point of water. This being said, Wexxar will not assume any responsibilities or liabilities, directly or indirectly, for any damage or loss caused by any alternate heating methods • DO NOT use any sharp scraping tools such as metal scrapers or razor blades • DO NOT clean the Lexan™ windows in the hot sun or at elevated temperatures... -

Page 77: Cleaners And Sanitizers

WF30T Automatic Case Former Machine Maintenance Cleaners and Sanitizers Poor cleaning and sanitizing techniques can contribute to undesired microbial contamination. Therefore, it is important to adopt the proper techniques. Before you start, we recommend designating buckets for specific uses such as for cleaning and sanitizer solutions, and discarded cleaning cloths. Sanitizer solution Used/dirty cloths Cleaning solution Suggested cleaning steps: • Remove any loose debris from the surface with a brush and dust pan, or vacuum. • Prepare a fresh bucket of cleaning solution with hot water. Refer to the manufacturer’s recommenda‐ tion for specific details. Note: if the surface is not significantly dirty, you may skip the cleaning step and only do a sanitizing step. • Apply the cleaning solution with a clean cloth to remove any stubborn debris. Discard any used/dirty cloths in a designated bucket. • Before you start sanitizing, wipe off all cleaning solution residues with a clean wet cloth. pH test the wiped surface with litmus paper. If thoroughly wiped, the pH of the surface will match the pH of your potable water. Suggested sanitizing steps: Option 1 • Prepare the sanitizing solution in a color coded bucket if it has not been previously prepared. Follow the manufacturer’s recommendation. • Dip a clean cloth into the solution and apply the saturated cloth onto the equipment surface. Refer to the manufacturer’s documentation for working temperature ranges, contact times, and rinse instruc‐ tions (if applicable). • Sanitizers may be lightly sprayed if this is an approved method by the manufacturer. • Keep any sanitizing cloths in the sanitizing solution when not in use. - Page 78 WF30T Automatic Case Former Machine Maintenance Option 2 • Alternatively you may wish to use a suitable sanitizer wipe such as the Ecolab Eco‐Wipe™ FCS Sanitizing wipes. Other recommendations: • Replace the sanitizing solution when it becomes cloudy or when it no longer meets its effective concentration. Concentrations can be verified with a sani‐ tizer‐specific testing kit such as the Hydrion® (QT‐10) quat test paper kit. • Keep sanitizers for raw meats (or other high risk materials) separate from other sanitizers. Use color coding or signage to ensure sanitizers are used for their sole purposes. Ecolab Eco‐ • Use color coded buckets to avoid potential contamination of cleaning and san‐ wipes™ itizing solutions. • Designate a bucket for dirty/used cloths. • Avoid using dirty/used cloths. • Have a plentiful supply of clean cloths to prevent the use of dirty/used cloths. • Use color coded cloths to avoid confusion between cleaning and sanitizing cloths. Quat test paper • Avoid contaminating the sanitizing solution with dirty cloths; the sanitizing solution can be inactivated if it becomes too dirty. • Cleaning solutions should be freshly prepared with hot water each time a clean is conducted.

-

Page 79: Troubleshooting And Repairs

WF30T Automatic Case Former Troubleshooting and Repairs TROUBLESHOOTING AND REPAIRS WARNING Prior to referencing the troubleshooting guide, ensure that you have properly read and Safety on page 3 understand All troubleshooting steps that require working inside the electrical panel or removing guarding should only be performed by certified maintenance personnel. About Warnings and Alarms Machine warnings and alarms are displayed on most HMI screen at the top of the screen. Alarm Messages Warning Messages • Warning Messages: Displayed in yellow text on the HMI. Warning messages are meant to alert the operator to certain machine conditions (for example, the magazine is running low). The triggering of a warning message does not stop or prevent machine operation. • Alarm Messages: Displayed in red text on the HMI. An alarm is typically triggered to alert the oper‐ ator of a machine error (for example, a case jam). When an alarm is triggered, the machine stops operation. The machine can not start operation again until the alarm condition is resolved and the Restarting the Case Former After an Emergency Stop or Alarm on page 25 machine is reset. (See ... -

Page 80: Viewing The Alarm History

WF30T Automatic Case Former Troubleshooting and Repairs Viewing the Alarm History The Alarm History screen displays the date, time, and identity of each alarm condition that the machine has experienced. This screen is useful in determining common problems, which can assist the operator in troubleshooting or making machine adjustments. To View the Alarm History: From the Main Control Screen, touch Setup. Touch Alarm History. The Alarm History screen opens. NOTE To ... -

Page 81: Identifying Problems With Plc Outputs

WF30T Automatic Case Former Troubleshooting and Repairs The PLC Inputs screens display an indicator button for each of the machine’s PLC Inputs. The current status of an input can be identified from these indicators. (Touch the Next button to cycle through all of the PLC Input screens.) Indicator Dark: The sensor is not on or does not have an active target. Indicator Lit: The sensor is on or has an active target. Indicator Blinking: There is a problem with the sensor. NOTE If there is a problem with a sensor, touch the PLC Input button to view the sensor’s location in the machine. Shutdown and lock out the machine. Inspect the area for any visible ... -

Page 82: To Test A Plc Output

WF30T Automatic Case Former Troubleshooting and Repairs WARNING Before touching a PLC Output button, stop the machine, close all guard doors, and keep personnel clear of the machine. To Test a PLC Output: Locate the PLC Output that you want to test. (Touch the Next button to cycle through all of the PLC Output screens.) Touch the PLC Output button. If the output is working correctly, it activates and runs through its cycle. NOTE If the output fails to activate, shutdown and lock out the machine. Inspect the area for any visible problems and begin troubleshooting procedures (refer to pages — ). For help, contact the Wexxar Service Department toll free +1 (888) 565‐3219. General Troubleshooting The most common error in troubleshooting packaging machinery problems is an incorrect diagnosis of the problem. Errors cause much lost time and needless expense and are avoided by a careful analytical approach before attempting corrective action. Always start by ensuring that all case size adjustments Size Change on page 27 have been made correctly (see ... -

Page 83: Jogging " The Wf30T (Jog Cycle )

WF30T Automatic Case Former Troubleshooting and Repairs • If the mechanism moves normally when the valve is actuated manually, then the pneumatic system is working and the problem is electrical in nature. It may be that the solenoid coil on the valve has failed, or it may be that there is a problem with the signal reaching the valve. Continue this diagnostic systematic approach until the exact malfunctioning component has been isolated; corrective action will then usually be obvious. The following is a list of some common mechanical problems that can occur, and suggestions for dealing with them. More advanced troubleshooting may require special training. CAUTION Some of the advanced troubleshooting steps contained in this section may need to be carried out by trained technicians. “Jogging” the WF30T (Jog Cycle) Machine Sequence Troubleshooting Use the Jog cycle for training purposes or for troubleshooting. (See ' on page 81 for more information on troubleshooting.) To Jog the WF30T: From the Main Control screen, touch the Jog Control button on the bottom left of the screen. The machine enters JOG cycle. - Page 84 WF30T Automatic Case Former Troubleshooting and Repairs NOTE The Sensor status indicators show which sensors are activated at each step as the machine is jogged forward. A blinking Sensor status indicator means that there is no response from a particular sensor. Touching the Sensor status indicator brings up the Error Identification screen with a photo of the sensor and its location on the machine.

- Page 85 WF30T Automatic Case Former Troubleshooting and Repairs General Troubleshooting Problem Possible Cause Solution Insufficient pins and/or pin‐ Increase number of pins & pin‐ blocks on jawplate blocks. Reverse pinblocks to the mini‐ Pins too far from domes mum gap position. Case falls or slips from pins Check injector stroke. Poor injector stroke, case not Injector Assembly on Refer to fully UP onto pins page 49 Readjust Dimension ‘C’ by Case length adjustment Dimen‐ adjusting the case recipe page 39 sion ‘C’ incorrect ), or using the Auto‐ Case kicks towards discharge page 63 Adjust offset ( end at bottom of descent Rear minor flap folder too slow ...

-

Page 86: Troubleshooting Case Flow Issues

WF30T Automatic Case Former Troubleshooting and Repairs General Troubleshooting Problem Possible Cause Solution Damp, soft cases Discard damp cases. Case partly pulls up out of major Lightweight corrugate Reduce pins to minimum. flap folders when forming head rises Reposition the secondary Major flap folders gap too large straight bar Troubleshooting Case Flow Issues Case Flow Troubleshooting Problem Possible Cause Solution Fill the magazine with case blanks. Machine has stopped; The 'Empty Magazine' sensor, Not enough pressure on a limit conveyors have stopped, cases not detecting blanks will stop switch actuator, switch not acti‐ not advancing. the machine. vated. Stack the blanks evenly, elimi‐ nating any gaps. - Page 87 WF30T Automatic Case Former Troubleshooting and Repairs Case Flow Troubleshooting Problem Possible Cause Solution The magazine belt(s) keep(s) Not enough pressure on a limit Adjust the limit switch actuators Limit Switch Actuators on running, but the cases are not switch actuator, switch not acti‐ (see page 36 being separated or loaded into vated. the caliper correctly. The distance between the con‐ Each conveyor belt should be veyor belts is not adequate. aligned as much as possible beneath the center position of its corresponding minor case flap. If not, adjust the spacing between the conveyors. Note: When this is not possible, due to very large case sizes, align one of the belts to ride under the center of one minor flap, and adjust the width between the belts to the widest possible position. ...

- Page 88 WF30T Automatic Case Former Troubleshooting and Repairs Case Flow Troubleshooting Problem Possible Cause Solution The blanks jam up into the injec‐ Too much pressure on a limit Adjust the limit switch actua‐ Limit Switch Actuators tor and separator area, prevent‐ switch actuator. tor. See on page 36 ing these from working . properly. Too much pressure on the Reduce the amount of pressure pusher arm. being applied.* * Note: Pressure should be between 20‐35; less for light‐ weight blanks and more for heavier ones. The blanks have been pushed or Avoid using any additional kicked forward. physical force on the stack of blanks. The pneumatic tubes are not Make sure the pneumatic tubes ...

-

Page 89: Machine Sequence Troubleshooting

WF30T Automatic Case Former Troubleshooting and Repairs Machine Sequence Troubleshooting The machine sequence is controlled by a PLC located inside the electrical enclosure. The controller responds to inputs from the panel buttons and various sensors on the machine mechanisms, and it provides outputs that control the solenoid valves in the pneumatic system. The most common reason for machine sequence malfunction is incorrect sensor operation. The following series of 'quick checks' can be carried out by simply observing the rear of the sensor to see if it is illuminated when it should be. ... -

Page 90: Error Codes

WF30T Automatic Case Former Troubleshooting and Repairs Error Codes Error Code Condition Error Code Condition F001 E‐Stop Activated F014 Reserved F002 Guard Door Open F020 Injector DOWN Sensor Fault Major Flap Folded Sensor F003 Control Power if OFF F025 Fault F004 Jaw E‐Drive Fault F026 Pusher Forward Sensor Fault F005 Jaw AOI/LCL Fault F006 Reserved F036 Injector UP Sensor Fault F007 Head E‐Drive Fault F039 Case Separated Sensor Fault LH Outfeed Belt E‐Drive F010 Fault LH Outfeed Belt AOI/LCL ... - Page 91 WF30T Automatic Case Former Troubleshooting and Repairs If the Run LED is Off, use the Disconnect switch to turn Off the electrical power to the machine, and then turn it back On. NOTE Many of the input signals to the PLC originate from inductive or optical sensors as noted on the electrical control circuit. Without a target, they are similar to a normally open ('NO') switch. With a target in their sensing range, they turn ON and connect the load to positive through a PNP output transistor. These sensors are equipped with an LED on the wire lead end of their housing. These LEDs are turned ON when the target is in their sensing range. WARNING PROCEED WITH EXTREME CAUTION. STAY CLEAR OF ALL MECHANISMS. In the unlikely event that these LEDs are still illuminated improperly, and you do not have the appropriate PLC interface, or training, contact WEXXAR's service department. Without the appropriate equipment and training to correct this status, there is nothing else that you can do. If the LEDs are illuminated as described above: Press the Reset button once. Ready appears on the display and air pressure will now be applied to the various machine mechanism cylinders and they move to their respective Home positions as follows: From here, you can choose to go either into Automatic Cycle mode or into Jog mode. Press Start. The feedbelts should start oscillating. Check that the conveyor side‐belts are tracking properly. They should be centered on the drive pulley, properly tensioned, and in reasonably good condition. Check that the magazine pusher valve is On and the pressure is set to between 20 and 35 PSI. Note that a pressure lower than 20 PSI places a lesser load on the pneumatic system. However, if you have magazine feed problems, increase the pressure to ensure smooth operation. For very large case sizes, the pressure should be set slightly higher, but should not exceed 50 PSI.

-

Page 92: Pneumatic Troubleshooting

WF30T Automatic Case Former Troubleshooting and Repairs Pneumatic Troubleshooting WARNING Turn off the manual air valve and electrical power before proceeding. The pneumatic system of your WEXXAR Case Former is designed to give long, trouble‐free service. Most pneumatic problems can be avoided by ensuring that the machine receives a supply of clean, dry air. The following tables demonstrate the potential issues associated with the pneumatic components incorporated into the WF30T. Some common problems are as follows: General Pneumatic Troubleshooting Problem Possible Cause Solution Verify that main regulator is set at 90 PSI. Check the inlet filter Machine becomes sluggish in Inadequate air supply to the cyl‐ and replace it if necessary. operation inders Check settings of flow controls on solenoid valves. Refer to Compressed Air on page 4 Replace or repair cylinder. Seal ... - Page 93 WF30T Automatic Case Former Troubleshooting and Repairs Both Forming Head and Jaw Too Slow Troubleshooting Problem Possible Cause Solution Adjust the regulator’s set point. Regulator set point too low Main regulator: 90 PSI Insufficient air compressor Increase the capacity of the air capacity compressor. The supply air pressure regula‐ tor should be set to 110 PSI (7.6 bar). Depending on the length and the inside diameter of the Low Air Pressure Supply air pressure set too low hose between the machine and the regulator, the pressure may have to be adjusted. The maxi‐ mum supply air pressure should be 150 PSI. The minimum inside diameter of the hose between the supply Improper supply air‐line design regulator and the machine is ¾" (for flexible hoses) or 1" (for steel tubes). Auto drain of the Filter‐Regula‐ Drain the water in the filter cup tor is not working; water accu‐ and fix the auto drain valve or mulated in the cup is not replace the filter cup.

-

Page 94: Repair Procedures

WF30T Automatic Case Former Troubleshooting and Repairs Jaw Too Slow / Forming Head Speed Normal Troubleshooting Problem Possible Cause Solution Auto drain of the Filter‐ Drain the water in the filter cup Regulator is not working; and fix the auto drain valve or water accumulated in the cup Water replace the filter cup. is not discharged Condensation Dry the air before it enters the Too much water in air supply machine. Forming Head Not Moving Troubleshooting Problem Possible Cause Solution Compressed air not connected Connect air supply. Mechanical Jam Clear mechanical jam. Socket loose Tighten socket. Open Circuit Cable broken Replace cable. Auto drain of the Filter‐Regula‐ Drain the water in the filter cup tor is snot working; water accu‐ and fix the auto drain valve or mulated in the cup is not ... -

Page 95: Pneumatic Cylinder Repairs

WF30T Automatic Case Former Troubleshooting and Repairs Pneumatic Cylinder Repairs Tie‐rod Type A tie‐rod type NFPA‐style cylinder is used to drive the separator motions. Repair kits to replace all wear components in this cylinder are available. When ordering repair kits, ensure that the correct cylinder is specified. Band‐type (Rodless) A rodless cylinder is used to drive the magazine pusher mechanism. This cylinder can be overhauled to replace all wear components. Non‐repairable Type Non‐repairable cylinders are used to drive the flap folders (major and minor). These cylinders must be replaced when worn out. High Power Type High power cylinders are used for the mast and discharge pusher. Repair kits are available from your Wexxar representative. Magazine Repairs Remove all cases from the magazine before commencing any repair work. Feedbelt Repairs All feedbelts run on sealed ball bearings, which are lubricated for life. Should bearing failure occur, the entire bearing and housing should be replaced. -

Page 96: Conveyor Drivebelt Repairs