Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Miller Big Blue 400 PX

- Page 1 OM-223 037 C March 2005 Processes Stick (SMAW) Welding TIG (GTAW) Welding MIG (GMAW) Welding Flux Cored (FCAW) Welding Air Carbon Arc (CAC-A) Cutting and Gouging Description Engine Driven Welding Generator Big Blue 400 PX (50/60 Hz) Visit our website at www.MillerWelds.com...

- Page 2 We know you don’t have time to do it any other way. That’s why when Niels Miller first started building arc welders in 1929, he made sure his products offered long-lasting value and superior quality.

-

Page 3: Table Of Contents

TABLE OF CONTENTS SECTION 1 − SAFETY PRECAUTIONS − READ BEFORE USING ........1-1. - Page 4 TABLE OF CONTENTS SECTION 8 − MAINTENANCE & TROUBLESHOOTING ......... . . 8-1.

- Page 5 Miller Electric Mfg. Co. Manufacturer’s Name: 1635 W. Spencer Street Manufacturer’s Address: Appleton, WI 54914 USA Big Blue 400 PX Declares that the product: conforms to the following Directives and Standards: Directives Low Voltage Directive: 73/23/EEC Electromagnetic compatibility Directives: 89/336/EEC, 92/31/EEC...

- Page 6 Cheadle Heath 20098 San Giuliano Stockport, Chesire SK30XU Milanese, Italy Phone: 39(02)98290-1 Fax: 39(02)98290203 European Contact Signature: Big Blue 400 PX The Manufacturer Declares the: Conforms to Directive: 2000/14/EC, Noise Level of Welding Generators Effective Date: 7/2004 Sound Level Information...

-

Page 7: Section 1 − Safety Precautions − Read Before Using

SECTION 1 − SAFETY PRECAUTIONS − READ BEFORE USING rom _nd_8/03 Y Warning: Protect yourself and others from injury — read and follow these precautions. 1-1. Symbol Usage Means Warning! Watch Out! There are possible hazards with this procedure! The possible hazards are shown in the adjoining symbols. -

Page 8: Engine Hazards

WELDING can cause fire or explosion. HOT PARTS can cause severe burns. D Allow cooling period before maintaining. Welding on closed containers, such as tanks, drums, or D Wear protective gloves and clothing when working on pipes, can cause them to blow up. Sparks can fly off from the welding arc. -

Page 9: Compressed Air Hazards

STEAM AND HOT COOLANT can burn. BATTERY ACID can BURN SKIN and EYES. D Do not tip battery. D If possible, check coolant level when engine is cold to avoid scalding. D Replace damaged battery. D Always check coolant level at overflow tank, if pres- D Flush eyes and skin immediately with water. -

Page 10: California Proposition 65 Warnings

READ INSTRUCTIONS. ARC WELDING can cause interference. D Use only genuine MILLER/Hobart replacement D Electromagnetic energy can interfere with sensitive parts. electronic equipment such as microprocessors, computers, and computer-driven equipment such as D Perform engine and air compressor (if applicable) robots. -

Page 11: Section 2 − Consignes De Sécurité − Lire Avant Utilisation

SECTION 2 − CONSIGNES DE SÉCURITÉ − LIRE AVANT UTILISATION rom_fre 8/03 Y Avertissement: Protégez vous et les autres des blessures − lisez et suivez ces précautions. 2-1. Signification des symboles Signifie Mise en garde ! Soyez vigilant ! Cette procédure Ce groupe de symboles si- présente des risques de danger ! Ceux-ci sont identifiés par gnifie Mise en garde ! -

Page 12: Dangers Existant En Relation Avec Le Moteur

Suivre les recommandations dans OSHA 1910.252(a)(2)(iv) et NFPA 51B LES ACCUMULATIONS DE GAZ ris- pour les travaux à chaud et avoir de la surveillance et un extincteur à proxi- quent de provoquer des blessures ou mité. même la mort. DES PARTICULES VOLANTES peuvent blesser les yeux. -

Page 13: Dangers Liés À L'air Comprimé

D Pour empêcher tout démarrage accidentel pendant les travaux d’entretien, L’EXPLOSION DE LA BATTERIE peut débrancher le câble négatif (−) de batterie de la borne. RENDRE AVEUGLE. D Ne pas approcher les mains, cheveux, vêtements lâches et outils des orga- nes mobiles. -

Page 14: Principales Normes De Sécurité

LE SURCHAUFFEMENT peut endom- LIRE LES INSTRUCTIONS. mager le moteur électrique. D Utiliser seulement les pièces de rechange d’origine. D Effectuer la maintenance du moteur et du compres- D Arrêter ou déconnecter l’équipement avant de dé- seur (si applicable) suivant ce manuel et le manuel du marrer ou d’arrêter le moteur. -

Page 15: Section 3 − Definitions

SECTION 3 − DEFINITIONS 3-1. Warning Label Definitions Warning! Watch Out! There are possible hazards as shown by the symbols. Do not smoke and keep matches and flames away from battery. Sparks can cause battery gases to explode. Battery explosion can blind and injure. Wear a face shield. - Page 16 Warning! Watch Out! There are possible hazards as shown by the symbols. Hot muffler and exhaust pipes can cause severe burns. Do not touch hot muffler or pipes. S-176 230 3/96 Warning! Watch Out! There are possible hazards as shown by the symbols. Engine fuel plus flames or sparks can cause fire.

- Page 17 Warning! Watch Out! There are possible hazards as shown by the symbols. Fire hazard from leaking engine fuel. Fire can result from welding base non-designated areas causing a possible fuel leak. Fuel tank is located inside base. Do not weld on base of unit. Weld only on supplied brackets or bolt unit down.

- Page 18 Remove unit from shipping S-177 571 crate. Remove Owner’s Manual from unit. Follow instructions to install muffler. Read Owner’s Manual. Read labels on unit. Use Diesel Fuel only, and fill fuel tank. Leave room for expansion. Warning! Watch Out! There are possible hazards as shown by the symbols.

-

Page 19: Manufacturer's Rating Label

3-2. Manufacturer’s Rating Label 223 081-A OM-223 037 Page 13... -

Page 20: Symbols And Definitions

3-3. Symbols And Definitions NOTE Some symbols are found only on CE products. Fast (Run, Weld/ Stop Engine Slow (Idle) Start Engine Power) Starting Aid Engine Oil Battery (Engine) Engine Oil (Preheat) Pressure Check Injectors/ Check Valve Protective Earth Fuel Pump Clearance (Ground) -

Page 21: Section 4 − Specifications

SECTION 4 − SPECIFICATIONS 4-1. Weld And Power Specifications Weld Output Weld Output Maximum Rated Welding Rated Welding Welding Range At Range At Open- Generator Power Output At 60 Hz Output At 50 Hz Mode 60 Hz 50 Hz Circuit Rating (1800 rpm) (1500 rpm) -

Page 22: Volt-Ampere Curves − 50 Hz Operation

4-4. Volt-Ampere Curves − 50 Hz Operation A. Stick Mode The volt-ampere curves show the minimum and maximum voltage and amperage output capabilities of the welding generator. Curves of all other settings fall between the curves shown. 2 0 0 30 0 2 00 DC AMPERES... -

Page 23: Volt-Ampere Curves − 60 Hz Operation

4-5. Volt-Ampere Curves − 60 Hz Operation A. Stick Mode The volt-ampere curves show the minimum and maximum voltage and amperage output capabilities of the welding generator. Curves of all other settings fall between the curves shown. DC AMPERES B. MIG Mode DC AMPERES C. -

Page 24: Fuel Consumption

4-6. Fuel Consumption The curve shows typical fuel use under weld or power loads. 2.00 1.75 1.50 1.25 1.00 0.75 0.50 ID LE 0.25 0.00 DC WELD AMPERES AT 100% DUTY CYCLE − 60 HZ 217 509 Notes Work like a Pro! Pros weld and cut safely. -

Page 25: Duty Cycle And Overheating − 50 Hz Operation

4-7. Duty Cycle And Overheating − 50 Hz Operation Duty Cycle is percentage of 10 min- 100% Duty Cycle At 250 Amperes utes that unit can weld at rated load without overheating. Y Exceeding duty cycle can damage unit void warranty. -

Page 26: Ac Generator Power Curve

4-9. AC Generator Power Curve The ac power curve shows the gen- erator power in amperes. 2 40 2 00 1 60 1 20 AC AMPERES IN 110 V MODE A C A MPERES IN 22 0V MODE 223 185-A Notes MATERIAL THICKNESS REFERENCE CHART 24 Gauge (.025 in) -

Page 27: Section 5 − Installation

SECTION 5 − INSTALLATION 5-1. Installing Welding Generator Y Always securely fasten weld- ing generator onto transport vehicle or trailer and comply with all DOT and other applica- Movement ble codes. Y Always ground generator frame to vehicle frame to pre- vent electric shock and static electricity hazards. -

Page 28: Mounting Welding Generator

5-2. Mounting Welding Generator Y Do not weld on base. Weld- ing on base can cause fuel tank fire or explosion. Weld only on the four mounting brackets or bolt unit down. Supporting The Unit Y Do not mount unit by sup- porting the base only at the four mounting brackets. -

Page 29: Installing Exhaust Pipe

5-3. Installing Exhaust Pipe Y Stop engine and let cool. Point exhaust pipe in desired di- rection but always away from front panel and direction of travel. Tools Needed: 1/2 in 803 582−B / Ref. 222 875-A Notes Work like a Pro! Pros weld and cut safely. -

Page 30: Activating The Dry Charge Battery (If Applicable)

5-4. Activating The Dry Charge Battery (If Applicable) Remove battery from unit. Eye Protection − Safety Glasses Or Face Shield Rubber Gloves Vent Caps Sulfuric Acid Electrolyte (1.265 Specific Gravity) Well Fill each cell with electrolyte to bottom of well (maximum). Y Do not overfill battery cells. -

Page 31: Connecting The Battery

5-5. Connecting The Battery Close door after connecting battery. The engine will not run if engine access door is open. Y Connect Negative (−) Cable Last. − Tools Needed: 1/2 in Ref. 804 009 / Ref. 222 875 / S-0756-C Notes OM-223 037 Page 25... -

Page 32: Engine Prestart Checks

5-6. Engine Prestart Checks Check radiator coolant level when fluid is low in recovery tank. Full Full Diesel Capacity: 6 qt (5.7 L) Coolant Recovery Tank Hot Full Cold Full Full Ref. 804 009−A Do not run out of fuel or air will enter fuel sys- Keep radiator and air intake clean and free Check all engine fluids daily. -

Page 33: Connecting To Weld Output Terminals

5-7. Connecting To Weld Output Terminals Y Stop engine. Work (−) Weld Output Terminal CV (Wire) Weld Output Terminal CC (Stick/TIG) Weld Output Terminal Stick and TIG Welding For Stick and TIG welding Direct Current Elec- trode Positive (DCEP), connect electrode holder cable to CC (Stick/TIG) terminal on right and work cable to Negative (−) terminal on left. -

Page 34: Connecting To Remote 14 Receptacle Rc14

5-9. Connecting To Remote 14 Receptacle RC14 Socket* Socket Information 24 volts ac. Protected by circuit breaker CB8. 24 VOLTS AC 24 VOLTS AC Contact closure to A completes 24 volt ac contactor control circuit. Output to remote control:+10 volts dc in MIG mode; 0 to +10 volts dc in Stick or TIG mode. -

Page 35: Gas Connections

5-10. Gas Connections Gas Fitting Fittings have 5/8-18 right-hand threads. Cylinder Valve Open valve slightly to blow dirt from valve. Close valve. Regulator/Flowmeter Flow Adjust Typical flow rate is 15 cfh (cubic feet per hour). Connect gas hose between regula- tor/flowmeter and gas fitting on front of unit. -

Page 36: Section 6 − Operating Welding Generator

SECTION 6 − OPERATING WELDING GENERATOR 6-1. Front Panel Controls (See Section 6-2) Stop 218 379−A / 804 009−A OM-223 037 Page 30... -

Page 37: Description Of Front Panel Controls (See Section 6-1)

6-2. Description Of Front Panel Controls (See Section 6-1) Engine Controls Engine Gauges, Meters, And Lights Process/Contactor Switch See Section 6-3 for Process/Contactor The engine will not run if engine access switch information. Fuel Gauge/Hourmeter door is open or Emergency Stop switch has been pressed. -

Page 38: Process/Contactor Switch

6-3. Process/Contactor Switch Process/Contactor Switch Y Weld output terminals are ener- gized when Process/Contactor switch is in a Weld Terminals Al- ways On position and the engine is running. Use switch to select weld process and weld output on/off control (see table be- low). -

Page 39: Remote Voltage/Amperage Control

6-4. Remote Voltage/Amperage Control Remote 14 Receptacle RC14 Connect optional remote control to RC14 (see Section 5-9). When a remote control is connected to the Remote receptacle, the Auto Sense Re- mote feature automatically switches volt- age/amperage control to the remote con- trol. -

Page 40: Section 7 − Operating Auxiliary Equipment

SECTION 7 − OPERATING AUXILIARY EQUIPMENT 7-1. 110 Volt Receptacles 222 975 110 V 32 A AC Receptacle RC11 Circuit breaker CB5 protects receptacle ther circuit breaker opens the correspond- RC12 from overload. CB6 protects RC13 ing receptacle does not work. Place circuit 110 V 16A AC Receptacle RC12 from overload. - Page 41 Notes Work like a Pro! Pros weld and cut safely. Read the safety rules at the beginning of this manual. OM-223 037 Page 35...

-

Page 42: Section 8 − Maintenance & Troubleshooting

SECTION 8 − MAINTENANCE & TROUBLESHOOTING 8-1. Routine Maintenance Note The engine will not run if engine access door is open or Emergency Stop switch has been pressed (see Section 6-1). Note Follow the storage procedure in the engine owner’s manual if the unit will not be used for an extended period. -

Page 43: Perkins Customer Assistance

Every 500 h Replace primary (in-line) Replace Secondary fuel filter. See Section (Canister) Fuel Filter. 8-7. See Section 8-7. Repair Or Replace Damaged Cables. Every 1000 h Check Radiator Drain Sludge FUEL Fluid Level. See From Fuel Section 5-6. SLUDGE Tank. -

Page 44: Maintenance Label

8-3. Maintenance Label OM-223 037 Page 38... -

Page 45: Servicing Air Cleaner

8-4. Servicing Air Cleaner Y Stop engine. Y Do not run engine without air cleaner or with dirty element. En- gine damage caused by using a damaged element is not covered by the warranty. The air cleaner primary element can be cleaned but the dirt holding capac- ity of the filter is reduced with each cleaning. -

Page 46: Inspecting And Cleaning Spark Arrestor Muffler

8-5. Inspecting And Cleaning Spark Arrestor Muffler Y Stop engine and let cool. Spark Arrestor Muffler Cleanout Plug Remove plug and remove any dirt covering cleanout hole. Exhaust Pipe Start engine and run at idle speed to blow out cleanout hole. If nothing blows out of hole, briefly cover end of exhaust pipe with fireproof material. -

Page 47: Servicing Fuel And Lubrication Systems

8-7. Servicing Fuel And Lubrication Systems Y Stop engine and let cool. Y After servicing, start engine and check for fuel leaks. Stop engine, tighten connec- tions as necessary, and wipe up spilled fuel. Oil Filter Oil Drain Valve And Hose Oil Fill Cap Primary (Canister) Fuel Filter Secondary (In-Line) Fuel... -

Page 48: Overload Protection

8-8. Overload Protection Y Stop engine. When a circuit breaker or fuse opens, it usually indicates a more serious problem exists. Contact Factory Authorized Service Agent. Fuse F1 F1 protects the stator exciter wind- ing from overload. If F1 opens, weld and generator power is low or stops entirely. -

Page 49: Checking Generator Brushes

8-9. Checking Generator Brushes Y Stop engine and let cool. Generator Brush With Spring Mark and disconnect leads at brush hold- er cap. Remove brushes. Replace brushes if damaged or if brush material is at or near minimum length. 5/16 in. (8 mm) Minimum Length 9/16 in. -

Page 50: Optional Voltmeter/Ammeter Help Displays

8-10. Optional Voltmeter/Ammeter Help Displays Use the Voltmeter/Ammeter help displays to diagnose and correct fault conditions. When a help code is displayed HL.P normally weld output has stopped but generator power output may be okay. To reset help displays, stop unit and then restart. -

Page 51: Troubleshooting

8-11. Troubleshooting Note Also see Voltmeter/Ammeter help displays to assist in troubleshooting weld problems (see Section 8-10). Engine speed is controlled by an electronic governor and throttle actuator. Governor adjustment should only be done by a Factory Authorized Service Agent. A. - Page 52 B. Standard Generator Power Trouble Remedy No generator power output at ac recep- Reset receptacle circuit breakers (see Section 7-1). tacles; weld output okay. No generator power or weld output. Disconnect equipment from generator power receptacles during start-up. Check fuse F1, and replace if open (see Section 8-8). Have Factory Authorized Service Agent check vol- tage regulator module PC3.

- Page 53 Trouble Remedy Engine suddenly stops. Close engine access door. Engine access door switch LS1 prevents engine from starting or running if door is open Check oil and coolant levels. Automatic shutdown system stops engine if oil pressure is too low or coolant temperature is too high (see Section 5-6).

-

Page 54: Section 9 − Electrical Diagrams

SECTION 9 − ELECTRICAL DIAGRAMS Figure 9-1. Circuit Diagram For Welding Generator OM-223 037 Page 48... - Page 55 222 966--C OM-223 037 Page 49...

-

Page 56: Section 10 − Run-In Procedure

SECTION 10 − RUN-IN PROCEDURE run_in1 8/01 10-1. Wetstacking Y Do perform run-in procedure at less than 20 volts weld output and do not exceed duty cycle or equip- ment damage may occur. Welding Generator Run diesel engines near rated volt- age and current during run-in period to properly seat piston rings and prevent wetstacking. -

Page 57: Run-In Procedure Using Load Bank

10-2. Run-In Procedure Using Load Bank Y Stop engine. Y Do not touch hot exhaust pipe, engine parts, or load bank/grid. Y Keep exhaust and pipe away from flammables. Y Do perform run-in procedure at less than 20 volts weld output and do not exceed duty cycle or equip- ment damage may occur. -

Page 58: Run-In Procedure Using Resistance Grid

10-3. Run-In Procedure Using Resistance Grid Y Stop engine. Y Do not touch hot exhaust pipe, engine parts, or load bank/grid. Y Keep exhaust and pipe away from flammables. Y Do perform run-in procedure at less than 20 volts weld output and do not exceed duty cycle or equip- ment damage may occur. -

Page 59: Section 11 − Generator Power Guidelines

SECTION 11 − GENERATOR POWER GUIDELINES NOTE The views in this section are intended to be representative of all engine-driven welding generators. Your unit may differ from those shown. 11-1. Selecting Equipment Generator Power Receptacles − Neutral Bonded To Frame 3-Prong Plug From Case Grounded Equipment 2-Prong Plug From Double... - Page 60 11-3. Grounding When Supplying Building Systems Equipment Grounding Terminal Grounding Cable GND/PE Use #10 AWG or larger insulated copper wire. Ground Device Y Ground generator to system earth ground if supplying power to a premises (home, shop, farm) wiring system. Use ground device as stated in electrical codes.

- Page 61 11-5. Approximate Power Requirements For Industrial Motors Industrial Motors Rating Starting Watts Running Watts Split Phase 1/8 HP 1/6 HP 1225 1/4 HP 1600 1/3 HP 2100 1/2 HP 3175 Capacitor Start-Induction Run 1/3 HP 2020 1/2 HP 3075 3/4 HP 4500 1400 1 HP...

- Page 62 11-7. Approximate Power Requirements For Contractor Equipment Contractor Rating Starting Watts Running Watts Hand Drill 1/4 in 3/8 in 1/2 in Circular Saw 6-1/2 in 7-1/4 in 8-1/4 in 1400 1400 Table Saw 9 in 4500 1500 10 in 6300 1800 Band Saw 14 in...

- Page 63 11-8. Power Required To Start Motor Motor Start Code AC MOTOR Running Amperage VOLTS AMPS Motor HP CODE Motor Voltage PHASE To find starting amperage: Step 1: Find code and use table to find kVA/HP. If code is not listed, multiply running amperage by six to find starting amperage.

- Page 64 11-10. Typical Connections To Supply Standby Power Y Properly install and ground this equipment according to its Owner’s Manual and national, state, and local codes. Fused Utility Welding Disconnect Electrical Generator Transfer Switch Switch Service Output (If Required) Essential Loads Y Have only qualified persons perform Switch transfers the electrical load from Connect generator with temporary or perma-...

- Page 65 11-11. Selecting Extension Cord (Use Shortest Cord Possible) Cord Lengths for 120 Volt Loads Y If unit does not have GFCI receptacles, use GFCI-protected extension cord. Maximum Allowable Cord Length in ft (m) for Conductor Size (AWG)* Current Load (Watts) (Amperes) 350 (106) 225 (68)

-

Page 66: Section 12 − Parts List

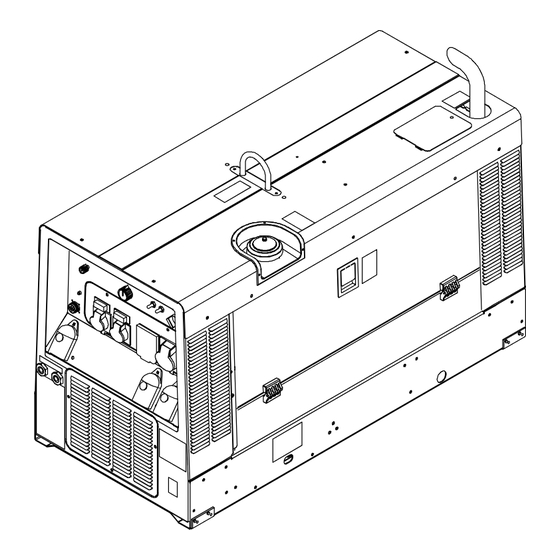

SECTION 12 − PARTS LIST Hardware is common and not available unless listed. Wiring harnesses are listed at the end of parts section. 4−Fig.12−5 2−Fig.12−3 100−Fig.12−2 Figure 12-1. Main Assembly OM-223 037 Page 60... - Page 67 Fig.12-4 804 069-B OM-223 037 Page 61...

- Page 68 Item Dia. Part Mkgs. Description Quantity Figure 12-1. Main Assembly ... 168829 Transducer, Current 1000a Module Max Open Loop ....

- Page 69 Item Dia. Part Mkgs. Description Quantity Figure 12-1. Main Assembly (Continued) ....+213487 Door, Engine Access ..........

- Page 70 Item Dia. Part Mkgs. Description Quantity Figure 12-1. Main Assembly (Continued) ....213460 Crossmember, Generator ........

- Page 71 Hardware is common and not available unless listed. Wiring harnesses are listed at the end of parts section. 804 070-A Figure 12-2. Panel, Front w/Components Item Dia. Part Mkgs. Description Quantity Figure 12-2. Panel, Front w/Components (Figure 12-1 Item 100) .

- Page 72 Item Dia. Part Mkgs. Description Quantity Figure 12-2. Panel, Front w/Components (Continued) ... . . 212436 Switch, Ignition 4 Position (Includes Knob) ......

- Page 73 Hardware is common and not available unless listed. Wiring harnesses are listed at the end of parts section. 804 071-A Figure 12-3. Control Panel Item Dia. Part Mkgs. Description Quantity Figure 12-3. Control Panel (Figure 12-1 Item 2) ..

- Page 74 Hardware is common and not available unless listed. Wiring harnesses are listed at the end of parts section. 17 16 803 686 Figure 12-4. Generator Item Dia. Part Mkgs. Description Quantity Figure 12-4. Generator (Figure 12-1 Item 73) ..

- Page 75 Hardware is common and not available unless listed. Wirng harnesses are listed at the end of parts section. 803 685-A Figure 12-5. Rectifier Assembly Item Dia. Part Mkgs. Description Quantity Figure 12-5. Rectifier Assembly (Figure 12-1 Item 4) ....217081 Rectifier, Assembly (Includes) .

- Page 76 Note Some wiring harness components (switches, relays, circuit breakers) are also referenced elsewhere in this parts list. Purchase components separately or as part of the associated wiring harness. Item Dia. Part Mkgs. Description Quantity Wiring Harnesses ....223030 Harness, Engine Perkins (Includes) .

- Page 77 Effective January 1, 2005 (Equipment with a serial number preface of “LF” or newer) This limited warranty supersedes all previous Miller warranties and is exclusive with no other Warranty Questions? guarantees or warranties expressed or implied. Call LIMITED WARRANTY − Subject to the terms and conditions Induction Heating Coils and Blankets below, Miller Electric Mfg.

-

Page 78: Options And Accessories

Contact the Delivering Carrier to: File a claim for loss or damage during shipment. For assistance in filing or settling claims, contact your distributor and/or equipment manufacturer’s Transportation Department. © PRINTED IN USA 2005 Miller Electric Mfg. Co. 1/05...

Need help?

Do you have a question about the Big Blue 400 PX and is the answer not in the manual?

Questions and answers