Summary of Contents for Hobart HR100

- Page 1 OM-285376C 2023-04 Processes Flux Cored (FCAW) Welding MIG (GMAW) Welding Description Semi-Automatic, Air-Cooled Flux Cored (FCAW) And MIG (GMAW) Welding Gun HR100 Gun OWNER’S MANUAL www.HobartWelders.com...

- Page 2 From Hobart to You Thank you and congratulations on choosing Hobart. Now you can get the job done and get it done right. We know you don’t have time to do it any other way. This Owner’s Manual is designed to help you get the most out of your Hobart products.

-

Page 3: Table Of Contents

TABLE OF CONTENTS SECTION 1 – SAFETY PRECAUTIONS – READ BEFORE USING..............1 Symbol Usage . -

Page 5: Section 1 - Safety Precautions - Read Before Using

SECTION 1 – SAFETY PRECAUTIONS – READ BEFORE USING Protect yourself and others from injury—read, follow, and save these important safety precautions and operating instructions. 1-1. Symbol Usage DANGER! – Indicates a hazardous situation which, if not avoided, will result in death or serious injury. The possible hazards are shown in the adjoining symbols or explained in the text. -

Page 6: California Proposition 65 Warnings

NOISE can damage hearing. READ INSTRUCTIONS. Noise from some processes or equipment can � Read and follow all labels and the Owner’s Manual damage hearing. carefully before installing, operating, or servicing unit. Read the safety information at the beginning � Check for noise level limits exceeding those speci- of the manual and in each section. -

Page 7: Section 2 - Consignes De Sécurité - Lire Avant Utilisation

SECTION 2 – CONSIGNES DE SÉCURITÉ - LIRE AVANT UTILISATION Pour écarter les risques de blessure pour vous-même et pour autrui — lire, appliquer et ranger en lieu sûr ces consignes relatives aux précautions de sécurité et au mode opératoire. 2-1. -

Page 8: Proposition Californienne 65 Avertissements

� Avoir recours à des écrans protecteurs ou à des rideaux pour pro- � Utiliser des bouche-oreilles ou des serre-tête antibruit approuvés téger les autres contre les rayonnements les éblouissements et si le niveau de bruit est élevé. les étincelles ; prévenir toute personne sur les lieux de ne pas re- �... -

Page 9: Section 3 - Installation

SECTION 3 – INSTALLATION 3-1. Specifications Wire Diameter Range Cooling Method Duty Cycle Rating Weight 60%: 100 A With Flux Cored Wire Flux Cored Wire: .023–.045 in. Air Cooled Welding Gun For (0.6–1.1 mm) GMAW And FCAW Welding With 10 ft (3.0 m) Power Cable: 100%: 100 A With CO Shielding 3.8 lb (1.6 kg) -

Page 10: Installing Gun With Four Pin Connector

3-3. Installing Gun With Four Pin Connector tools/ allen_wrench allen_set flathead philips head wrench Turn off and disconnect input crescent wrench power. 1 Gun Securing Knob 2 Gun End Loosen knob. Insert gun end until it bottoms against drive assembly. Tighten knob. pliers needlenose 3 Gun Trigger Plug... -

Page 11: Section 4 - Operation

SECTION 4 – OPERATION 4-1. Operating The Gun 1 Trigger Switch Press and hold switch to feed energized wire and start flow of shielding gas. Ref. 284545-A OM-285376 Page 7... -

Page 12: Section 5 - Maintenance And Troubleshooting

SECTION 5 – MAINTENANCE AND TROUBLESHOOTING 5-1. Removing Nozzle, Contact Tip, And Adapter, Changing Liner, And Cleaning Gun Casing tools/ 5/8 in. (16 mm) allen_wrench allen_set flathead philips head wrench crescent wrench Liner Stickout pliers needlenose knife steelbrush nutdriver chippinghammer Ref.284972-A allen_wrench allen_set... -

Page 13: Replacing Switch And/Or Neck Assembly

5-2. Replacing Switch And/Or Neck Assembly tools/ allen_wrench allen_set flathead philips head wrench crescent wrench If replacing the head tube continue with the 10 Trigger switch Turn off welding power source/wire following instructions. feeder. 11 Locking Cap � 5 Head Tube Wire size stamped on tip, check and 12 Handle Hardware 6 Jam Nut... -

Page 14: Routine Maintenance

5-3. Routine Maintenance Complete Parts List is available at www.MillerWelds.com Disconnect power before maintaining. A complete Parts List is available at www.MillerWelds.com � Maintain more often during severe conditions. SECTION 6 MAINTENANCE AND TROUBLESHOOT � = Check ◇ = Change �... -

Page 15: Section 6 - Parts List

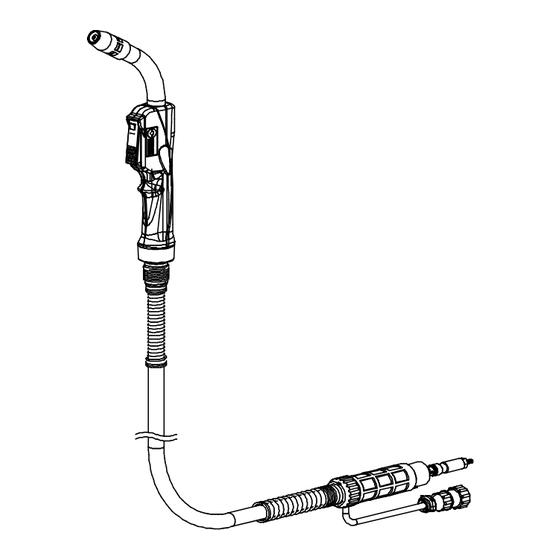

SECTION 6 – PARTS LIST Figure 6-1. Complete Assembly For HR–100 MIG Gun OM-285376 Page 11... - Page 16 1 (5 per pack) ♦770183 Tip, Contact Scr .045 Wire x 1.125 1 (5 per pack) 770402 Adapter, Contact Tip 771002 Kit, Neck Assy HR100 Includes ..Assembly, Neck ..Nut, Lock 771004 Kit,Handle Assy HR100 Includes ..Handle, Right ..Handle, Left ..

- Page 17 Ref 285032-A Figure 6-2. Complete Assembly For HR–100 MIG Gun With Friction Lugs OM-285376 Page 13...

- Page 18 1 (5 per pack) ♦770183 Tip, Contact Scr .045 Wire x 1.125 1 (5 per pack) 770402 Adapter, Contact Tip 771002 Kit, Neck Assy HR100 Includes ..Assembly, Neck ..Nut, Lock 771004 Kit,Handle Assy HR100 Includes ..Handle, Right ..Handle, Left ..

- Page 19 Effective January 1, 2023 5/3/1 WARRANTY applies to all Hobart welding equipment, plasma cutters and spot welders with a serial num- ber preface of ND or newer. This limited warranty supersedes all previous Hobart warranties and is exclusive with no other guarantees or warranties expressed or implied.

- Page 20 Distributor Address City State Thank you for purchasing Hobart. Our trained technical support team is dedicated to your satisfaction. For questions regarding performance, operation, or service, contact us! Resources Available Always provide Model Name and Serial/Style Number. To locate a Service Center:...

Need help?

Do you have a question about the HR100 and is the answer not in the manual?

Questions and answers