Summary of Contents for Wallenstein W4180

- Page 1 INSTALLATION INSTRUCTIONS W 4180 Hydraulic Pump Kit Rev Apr-2024 Part Number: Z97820_En...

-

Page 2: Table Of Contents

4. Prepare the Gearbox ..........6 5. Install a W4180 Kit ..........8 The W4180 hydraulic pump kit is necessary to connect a 5.1 Preparation ............... 8 WX310 or WX370 log splitter to a tractor that has a limited or nonexistent hydraulic system. -

Page 3: Safety

W4180 Hydraulic Pump Kit 2. Safety 2.2 Signal Words WARNING! The signal words DANGER, WARNING and CAUTION identify Read the machine Operator’s Manual before you the severity of a hazard to anyone who uses the machine. The install or use this accessory. Carefully read all... -

Page 4: Accessory Components

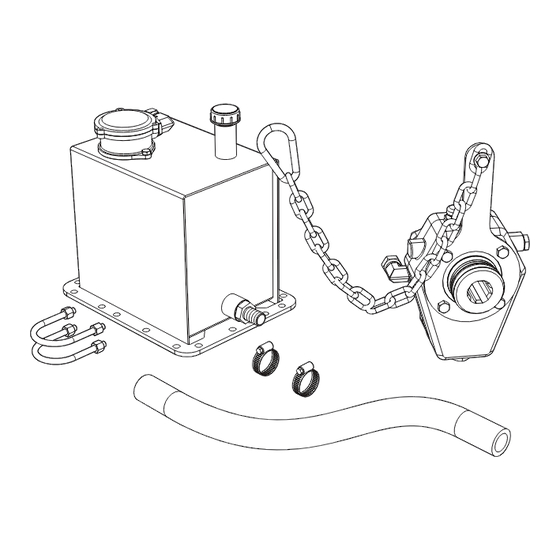

W4180 Hydraulic Pump Kit 3. Accessory Components Figure 1 – Gearbox and pump assembly components Item Part Number Description Quantity Item Part Number Description Quantity 2081L104 Connector plate Z71307 Hex bolt, 3/8" NC x 3/4" Z43102 Gearbox Z71310 Hex bolt, 3/8" NC x 1"... - Page 5 W4180 Hydraulic Pump Kit Figure 2 – Hydraulic-fluid reservoir components Item Part Number Description Quantity Item Part Number Description Quantity 2081W102 Hydraulic-fluid reservoir Hydraulic-fluid filter, FP12 Z55201 (includes the gasket) 2081S102 U-bolt, 3/8" x 3-1/2" Z55402 Cap and dipstick, 5"...

-

Page 6: Prepare The Gearbox

4. Prepare the Gearbox IMPORTANT! Keep the work area clean to prevent internal gearbox and oil contamination. Before you can install the W4180 kit, you must fill the gearbox with gear oil. Do the following to prepare the gearbox: Step 1 Assemble the gearbox and gear pump: a. - Page 7 W4180 Hydraulic Pump Kit Step 3 Add gear oil to the gearbox: a. Put the end of a clean funnel in the gearbox fill hole. b. Put 0.22 L (7.4 US oz) of 85W-140 gear oil into the gearbox. c. Remove the funnel.

-

Page 8: Install A W4180 Kit

Incorrect installation or changes to the equipment can cause serious injury or damage the machine. The W4180 kit comes partially assembled. Illustrations in this document show the typical installation method. This procedure is one-time only; it is not necessary to do it again. After the pump kit is assembled, only minor maintenance is necessary. -

Page 9: Procedure

W4180 Hydraulic Pump Kit 5.3 Procedure Do the following to install the W4180 kit on your tractor and log splitter: Step 1 It helps to have two people to do this step. Install the hydraulic fluid reservoir on the right side of the log splitter: a. - Page 10 W4180 Hydraulic Pump Kit Step 3 WARNING! Make sure that all hydraulic hose connections are tight and torqued to the correct specifications before you operate the machine. Put on heavy gloves and use a piece of cardboard, wood, or plastic to check for leaks.

- Page 11 W4180 Hydraulic Pump Kit Step 6 WARNING! Hydraulic- Make sure that all hydraulic hose connections fluid reservoir are tight and torqued to the correct return fitting specifications before you operate the machine. Put on heavy gloves and use a piece of cardboard, wood, or plastic to check for leaks.

-

Page 12: Service And Maintenance

W4180 Hydraulic Pump Kit 6. Service and Maintenance Regular preventive maintenance can improve performance and Put the machine in a safe condition before you start any prolong the life of the machine. Machine maintenance is your service or maintenance: responsibility. -

Page 13: Accessory Break-In

W4180 Hydraulic Pump Kit 6.2 Accessory Break-In • Before you apply pressure to the hydraulic system, make sure that all the connections are tight, and the hoses, tubes, and fittings are not damaged. After 60 to 80 hours of operation, change the gearbox oil. - Page 14 W4180 Hydraulic Pump Kit 6.4.2 Change the Hydraulic Fluid CAUTION! Risk of burns to exposed skin. Hydraulic fluid gets hot during operation, which makes hoses, tubes, and other parts hot as well. Wait for the fluid and components to cool before you start maintenance or service.

- Page 15 W4180 Hydraulic Pump Kit Step 5 Flush the hydraulic system with pressurized fluid: a. Start the machine. For instructions, see the log splitter Operator's Manual. b. Operate the hydraulic controls for 1 to 2 minutes to remove air from the hydraulic system.

- Page 16 W4180 Hydraulic Pump Kit 6.4.3 Clean the Hydraulic Fluid Filter CAUTION! Risk of burns to exposed skin. Hydraulic fluid gets hot during operation, which makes hoses, tubes, and other parts hot as well. Wait for the fluid and components to cool before you start maintenance or service.

- Page 17 W4180 Hydraulic Pump Kit Step 5 Install the hydraulic-fluid filter: a. Put the hydraulic-fluid filter in the hole in the hydraulic- fluid reservoir. b. Align the hydraulic-fluid filter cover with the filter. c. Install the three fasteners.

-

Page 18: Gearbox Maintenance

W4180 Hydraulic Pump Kit 6.5 Gearbox Maintenance CAUTION! Do not remove the gearbox or the gear pump while the tractor is on or the PTO shaft is turning. Put the machine and tractor in a safe condition before you do any maintenance. Your hands,... - Page 19 W4180 Hydraulic Pump Kit Step 4 Fill the gearbox with the correct type and quantity of gear oil. For instructions, see Step 2 on page 6 and Step 3 on page 7. Step 5 Use an environmentally safe method to discard the used gear...

-

Page 20: Torque Specifications

W4180 Hydraulic Pump Kit 7. Torque Specifications This section provides general torque specifications for your reference. 7.1 Bolt Torque Imperial Bolt Torque Specifications Torque IMPORTANT! If you replace hardware, use fasteners Bolt of the same grade. SAE Gr. 2 SAE Gr. 5 SAE Gr. -

Page 21: Hydraulic Fitting Torque

W4180 Hydraulic Pump Kit 7.2 Hydraulic Fitting Torque Hydraulic Fitting Torque Specifications Tighten flare-type tube fittings: Hex size Tube size across Flats from finger a. Check the flare and flare seat for defects that might flats Torque tight cause leaks. -

Page 22: Warranty

W4180 Hydraulic Pump Kit 8. Warranty LIMITED WARRANTY Wallenstein products are warranted to be free of defects in materials and workmanship under normal use and service, for a period of Five Years for Consumer Use Two Years for Commercial/Rental Use from the date of purchase, when operated and maintained in accordance with the opera�ng... - Page 23 WallensteinEquipment.com...

Need help?

Do you have a question about the W4180 and is the answer not in the manual?

Questions and answers