Subscribe to Our Youtube Channel

Summary of Contents for Sicor SH110B

- Page 1 OPERATION AND MAINTENANCE MANUAL SH110B COD.: MUM0138_REV. 04 SICOR S.R.L. Head Office and Production Centre Viale Caproni 32 (Industrial Area) 38068 Rovereto (TN) Italy...

-

Page 2: Table Of Contents

SH110B INDEX LETTER PROVIDED TO THE CUSTOMER ON DELIVERY ..........2 MACHINE IDENTIFICATION ..................3 WARRANTY ......................4 GENERAL DELIVERY NOTES ..................5 SAFETY PRECAUTIONS ..................... 6 SAFETY REQUIREMENTS ..................7 TECHNICAL FEATURES ..................... 10 MOVING THE WINCH ....................11 NOTES FOR INSTALLATION ..................14 9.1. -

Page 3: Letter Provided To The Customer On Delivery

SH110B LETTER PROVIDED TO THE CUSTOMER ON DELIVERY Dear Customer, SICOR S.R.L. -

Page 4: Machine Identification

SH110B MACHINE IDENTIFICATION ber. -

Page 5: Warranty

SH110B WARRANTY • governed by the following clauses: faulty. Labour, travel and board and lodging costs must be met by the Customer. • • ings, electric windings. • • Customer under warranty or will send its own technicians. reliability of its machines. -

Page 6: General Delivery Notes

SH110B GENERAL DELIVERY NOTES there is no visible damage to the winch or its accessories necessary). Machine data... -

Page 7: Safety Precautions

SH110B SAFETY PRECAUTIONS similar). WHEN THESE WARNINGS APPEAR, PROCEED WITH THE UTMOST CAUTION. -

Page 8: Safety Requirements

SH110B SAFETY REQUIREMENTS WARNING LIFT MACHINERY HAZARD ACCESS FORBIDDEN UNAUTHORISED PERSONS dangers associated with the machine and must have read and Before installing the winch, the customer must verify that the concrete in the country where the winch will be installed. - Page 9 SH110B EXCLUSION OF POWER SOURCES WARNING WARNING...

- Page 10 SH110B intended. etc...).

-

Page 11: Technical Features

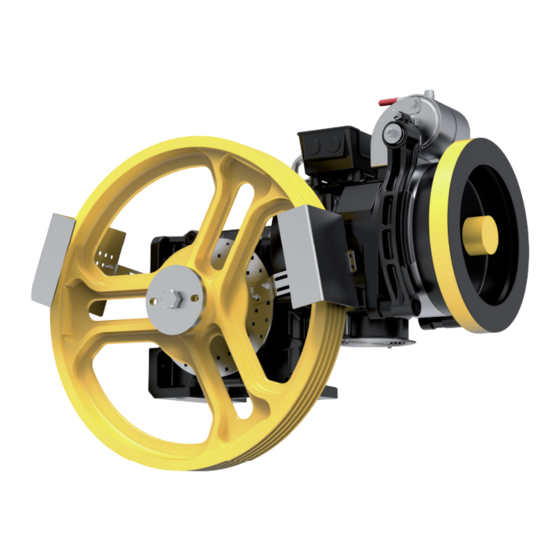

SH110B TECHNICAL FEATURES found in the SICOR technical catalogue. 360÷600... -

Page 12: Moving The Winch

SH110B MOVING THE WINCH WARNING RISK OF CRUSHING, IMPACT AND ABRASION WARNING... - Page 13 SH110B WARNING lay the crate on the ground slowly PACKAGING IN THE ENVIRONMENT, but rather reuse it or send...

- Page 14 SH110B WARNING 20°...

-

Page 15: Notes For Installation

SH110B NOTES FOR INSTALLATION WARNING (clean the machine room before installing the machine). 40°c 5°c... -

Page 16: Motor Rotation Instructions

SH110B 9.1. MOTOR ROTATION INSTRUCTIONS the motor. -

Page 17: Encoder Installation Instructions

SH110B 9.2. ENCODER INSTALLATION INSTRUCTIONS Before installing the encoder, you must: winch. If machines are ordered with the Detail of winch with encoder Remove two of the 4 M6 fastening screws on ing dowel. M6 screw... -

Page 18: Vent Plug Positioning (Code:tap0025)

SH110B 9.3. VENT PLUG POSITIONING (CODE:TAP0025) -

Page 19: Winch Lubrication

SH110B WINCH LUBRICATION Shell Omala S4 WE with mineral oils and with most 10.1. CHANGING THE OIL be changed every 2 years. The oil must also be changed if it is unrecommended oil). To change the oil: down. -

Page 20: Checking The Oil Level

SH110B machine fasten. damage to the machine. gauge is reached. 10.2. CHECKING THE OIL LEVEL WARNING Do not release into the environment. Oil level gauge... -

Page 21: Electrical Connections

SH110B ELECTRICAL CONNECTIONS If they match, connect the electric motor. 1 ELECTRIC MOTOR Using the wiring diagram (which can be found in the motor terminal COLLEGAMENTO MOTORE IMPORTANT NOTE - WHITE TACHOMETER - RED - WHITE THERMISTORS MAX 3V BROWN... -

Page 22: Electrical Wiring Diagram

SH110B ELECTRICAL WIRING DIAGRAM HIGH BRAKE THERMISTOR SPEED SUPPLY SUPPLY SPEED SUPPLY VVVF SUPPLY TERMOCONTACTS Vmax 250 V(AC) 50/60 Hz Imax 2,0 A cosφ 0,95 THERMISTORS RESISTANCE T<150°C ≤ 300 Ohm T>150°C ≥ 4 KOhm Do not apply voltages > 2,5 V... -

Page 23: Starting The Winch

SH110B STARTING THE WINCH enclosed with the winch. about anything, contact SICOR. overload the winch and the motor. WARNING... -

Page 24: Disposal Of The Winch At The End Of Its Service Life

SH110B IMPORTANT NEVER USE THE WINCH FOR PERFORMANCES ABOVE THOSE INDICATED IN THE TECHNICAL CATALOGUE. DISPOSAL OF THE WINCH AT THE END OF ITS SERVICE LIFE... -

Page 25: Maintenance

SH110B MAINTENANCE WARNING gloves, safety shoes). General cleaning of the winch absorbers and that the cab cannot be accessed. - Page 26 SH110B 15.1. L=55mm 15.2. BRAKE ON POS 1 BRAKE OFF BRAKE OFF POS 2 POS 2 1 2 5 15.2.1. 15.2.2.

- Page 27 SH110B 15.2.3. This brake must be capable of stopping by itself the machinery with cab travelling downhill at a nominal speed and with a loading capacity on the braking surface must be installed in pairs. If one of said elements speed with a load equal to the nominal load capacity and uphill without a load (empty).

-

Page 28: Checking The Stroke

SH110B 15.3. CHECKING THE STROKE BRAKE ON POS 1 BRAKE OFF BRAKE OFF POS 2 POS 2 1 2 5 — C nom. (minimum) SH110B 0.44... -

Page 29: Compulsory Maintenance Operations

SH110B 15.4. COMPULSORY MAINTENANCE OPERATIONS Oil level 6 months 6 months 6 months 6 months 6 months 12 months 15.5. CHECKING THE GEAR BACKLASH... -

Page 30: Checking The Gear Backlash On The Input Shaft

SH110B CHECKING THE GEAR BACKLASH ON THE INPUT SHAFT 1. Put the elevator out of order 2. Put the counterweight on 4. Turn the resistance... - Page 31 SH110B 9. If Table 1 Warning Distance Limit measured Model measured on the on the 17 – 22 mm SH110 33 – 46 mm...

-

Page 32: Checking The Gear Backlash On The Output Shaft

SH110B CHECKING THE GEAR BACKLASH ON THE OUTPUT SHAFT... - Page 33 SH110B dial indicator. Table 2 Model Distance A 0,6 mm SH110 100 mm 0,8 mm...

-

Page 34: Manual Emergency Operating

SH110B 18. MANUAL EMERGENCY OPERATING 18.1. WARNINGS if necessary. • • • • • • • 18.2. INSTRUCTIONS FOR AN EMERGENCY MANUAL MANOEUVRE • • • •... - Page 35 SH110B Never loosen the cab doors or try to get out of the cab. manual emergency • winch are safe for moving the cab. BRAKE ON BRAKE OFF POS 1 POS 2 limits the contact surface uniform • manoeuvre. •...

- Page 36 SICOR S.R.L. Head Office and Production Centre Viale Caproni 32 (Industrial Area) 38068 Rovereto (TN) Italy...

Need help?

Do you have a question about the SH110B and is the answer not in the manual?

Questions and answers