Summary of Contents for Secoh JDK-60

- Page 1 INSTRUCTION MANUAL LINEAR COMPRESSORS : JDK-60 MODEL JDK-80 JDK-100 JDK-120 READ AND FOLLOW ALL SAFETY INSTRUCTIONS. KEEP THIS MANUAL FOR FUTURE REFERENCE. SECOH SHANGHAI MEC LTD...

-

Page 2: Table Of Contents

CONTENTS ・・・・・ 1. Parts name ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 2. Instructions 2-1 Prior To Operation ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 2-2 Storage and Transfer ・・・・・・・・・・・・・・・・・・・・・・・・・・・ 2-3 Installation・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 1) Location ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 2) Grounding ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 3) Mounting ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 4) Plumbing・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 5) Operation ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 3. Periodic maintenance 3-1 Filter element cleaning・・・・・・・・・・・・・・・・・・・・・・・・・・ 3-2 Replacement of filter element, ・・・・・・・・・・・・・・・・・・・... -

Page 3: Parts Name

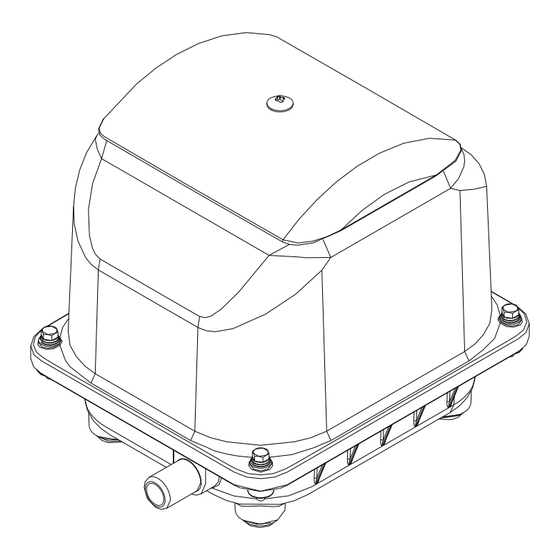

Parts name Truss head screw Filter cover Filter cover packing Filter element Inlet Overall Cover Outlet L-joint Hose Hose Clamp (2pcs) Power supply cord... -

Page 4: Instructions

2. Instructions ○ Read information carefully to ensure that this product operates correctly. ○ Follow the safety instructions. ○ Any servicing other than that recommended in this manual should be performed by an authorized service facility. The following is an explanation of the three different types of hazards. Severe personal injury or death will occur if hazard is ignored. -

Page 5: Installation

○ Do not store this product in temperatures below 14° F ( -10℃ ). Failure to do so could result in decrease of air flow due to magnet deterioration. ○ Store this product indoors out of the weather to avoid the deterioration of rubber parts. -

Page 6: Grounding

2) Grounding ○ Improper installation of the grounding plug can result in a risk of electric shock. If repair or replacement of the cord or plug is necessary, do not connect the grounding wire to either flat blade terminal. The wire with insulation having an outer surface that is green, with or without yellow stripes, is the grounding wire. -

Page 7: Plumbing

○ The ambient temperature should not be over 104° F (40℃). ● Cooling fan is recommended to be installed when mounting in an area of higher temperature. ○ This product should be mounted on a horizontal, stable and rigid surface for appropriate operation. -

Page 8: Periodic Maintenance

3. Periodic maintenance ○ Always disconnect power before servicing. Failure to do so could result in electrical shock, personal injury or death. ○ Clean the filter element quarterly. A clogged filter element can cause overheating or pump failure. 3-1 Filter element cleaning Truss head screw Filter cover... - Page 9 ○ Remove the shock absorber.Undo the screws Screw Holder cover and remove the holder cover. (Ref.: Fig 2-E) Shock absorber ○ Undo the screws and loosen up the hose band. Remove the valve box. (Ref.: Fig 2-F) Fig 2-E Screw ○...

-

Page 10: Reset Of Auto Stopper

○ If the magnet contacts the solenoids during operation, it will cause damage on parts, abnormal heat, and short circuiting. ○ Do not touch live parts. Touching live parts will result in electric shock. ○ Improper setting of the rubber bush can result in electric shock, air leakage. -

Page 11: Automatically Reset Thermal Protector

3-4 Automatically reset thermal protector An automatically reset thermal protector installed on the solenoid stops pump operation if solenoid temperature becomes over 130 ± 5 ℃. When the solenoid temperature cools down to 85 ± 15 ℃, the protector is reset automatically and pump operation restarts. -

Page 12: Specifications

DISTRIBUTED BY FPZ , Inc. 150 N. Progress Dr. Saukville, W I 5308 0 Tel: 262-268-0180 email: usa@fpz.com MANUFACTURED BY SECOH SHANGHAI MEC LTD. Head Office : No.160 Xuanchun Road, Xuanqiao Town, Pudong New Area, Shanghai,China Tel: +86-21-58039273 Fax: +81-21-58039265 201508-01...

Need help?

Do you have a question about the JDK-60 and is the answer not in the manual?

Questions and answers