Advertisement

Quick Links

OWNER' S GUIDE & INSTALLATION INSTRUCTIONS

Retractable, Thru-Hull

Depth/Temperature Sensor

Models: D800 and DT800

IMPORTANT : Please read the instructions completely

before proceeding with the installation. These

instructions supersede any other instructions in your

instrument manual if they differ.

CAUTION : NEVER USE SOLVENTS

Cleaners, fuel, paint, sealants, and other products may

contain strong solvents, such as acetone, which attack

many plastics greatly reducing their strength.

Applications

• Plastic housings recommended for fiberglass or metal hulls only.

Never install a plastic housing in a wood hull since swelling of the

wood may overstress the plastic causing a fracture.

• Bronze housings recommended for fiberglass or wood hulls.

Never mount a bronze housing in an aluminum hull because

electrolytic corrosion will occur.

• Stainless steel housing compatible with all hull materials.

Recommended for metal hulls to prevent electrolytic corrosion.

A stainless steel housing must be isolated from a metal hull.

• Never install a metal housing in a vessel with a positive ground

system.

Tools and Materials

Water-based antifouling paint ( mandatory in salt water )

Safety goggles

Dust mask

Electric drill with 10mm (3/8") or larger chuck capacity

Drill bit

3mm or 1/8"

51mm or 2" (plastic or bronze housing)

Hole saw:

57mm or 2-1/4"

Countersink tool (installing a flush housing)

Sandpaper

Mild household detergent or weak solvent (such as alcohol)

File (installation in a metal hull)

Marine sealant

Additional washer [for aluminum hull less than 6mm (1/4") thick]

Slip-joint pliers (installing a bronze housing)

Zip-ties

Installation in a cored fiberglass hull (see page 3):

Hole saw for hull interior

Fiberglass cloth and resin

or Cylinder, wax, tape, and casting epoxy

(stainless steel housing in a metal hull)

60mm or 2-3/8"

Record the information found on the cable tag for future reference.

Part No._________________Date___________Frequency________kHz

Antifouling Paint

Marine growth can accumulate rapidly on the sensor's surface

reducing its performance within weeks. Surfaces exposed to salt

water must be coated with antifouling paint. Use water - based

antifouling paint only. Never use ketone-based paint, since

ketones can attack many plastics possibly damaging the sensor.

It is easier to apply antifouling paint before installation, but allow

sufficient drying time. Reapply paint every 6 months or at the

beginning of each boating season. Paint the following surfaces

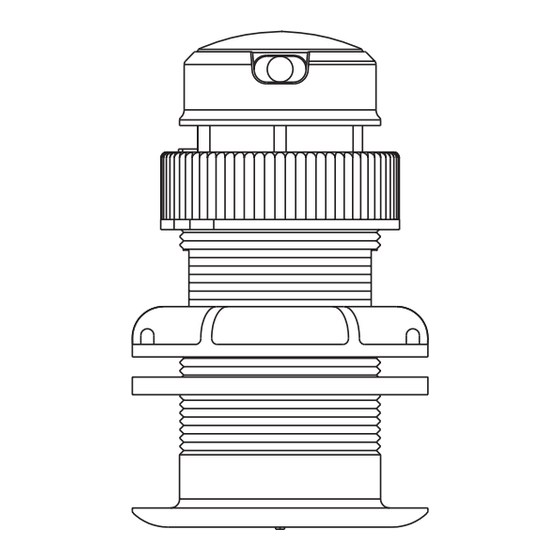

(see Figure 1):

• Outside wall of the

insert below the lower

O-ring

• Exposed end of the

insert

• Bore of the housing up

30mm (1-1/4")

• Exterior lip of the

housing

• Blanking plug below the

lower O-ring including

the exposed end

P17

Plastic

Low profile housing

insert

outside wall

below lower

O-ring

housing

exposed end

exterior lip

of housing

bore of housing

up 30mm (1-1/4")

Figure 1. Antifouling paint

Advertisement

Summary of Contents for Airmar D800

- Page 1 Retractable, Thru-Hull Record the information found on the cable tag for future reference. Part No._________________Date___________Frequency________kHz Depth/Temperature Sensor Models: D800 and DT800 IMPORTANT : Please read the instructions completely before proceeding with the installation. These instructions supersede any other instructions in your instrument manual if they differ.

- Page 2 Inboard —Mount well ahead of the propeller(s) and shaft(s). Step-hull —Mount just ahead of the first step. pressure waves Boat capable of speeds above 25kn (29MPH)—Review the installation location and operating results of similar boats before proceeding. 1/3 aft • Fin keel sailboats —Mount on or as close as possible to the 150-300mm centerline and forward of the fin keel 300–600mm (1–2').

- Page 3 Cutting the cable or removing the Plastic housing — Do not clamp tightly on the wrenching flats, connector, except when using Airmar’s junction box, will void the possibly causing the housing to fracture. warranty. Plastic hull nut — Hand - tighten only. Do not over tighten.

- Page 4 Airmar metal housing. If you have purchased a low profile housing and prefer a flush housing, 5. If you are skilled with fiberglass, saturate a layer of fiberglass see below.

Need help?

Do you have a question about the D800 and is the answer not in the manual?

Questions and answers