Summary of Contents for Puhui T-890i

- Page 1 BGA IRDA-WELDER USER MANUAL MODEL: T-890i SHANDONG PUHUI ELECTRIC TECHNOLOGY CO., LTD https://www.te168.com...

-

Page 2: Technical Parameters

IRDA-WELDER T-890i 用户使用手册 Features 1.This machine has the powerful and perfect function selection, with eight temperature waves in the memory software, users can select the right temperature wave according to the solder/unsolder request. 2.Intelligent temperature wave heating, achieve solder/unsolder automatically,scientifically. -

Page 3: Description Of The Main Parts

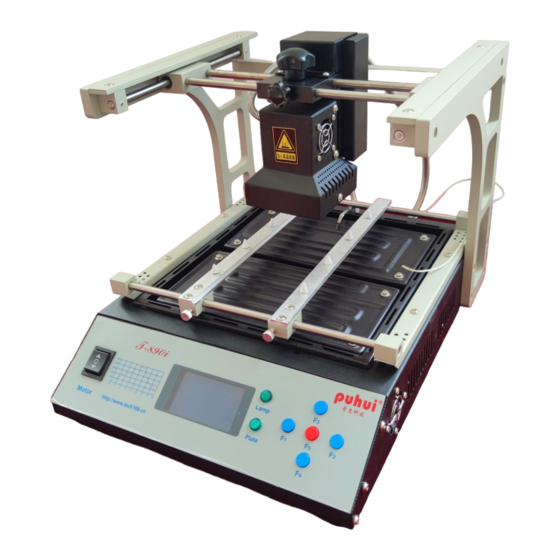

IRDA-WELDER T-890i 用户使用手册 Preheating chassis preheating size 245 X 260 mm Preheating chassis temperature range 0 ℃-350 ℃ Size 316mm X 410mm X 330mm Net weight 9.4 kg Main parts Welding table main body Infrared lamp body Portal frame Power line... -

Page 4: Front Panel

IRDA-WELDER T-890i 用户使用手册 Front Panel Display Screen Motor Control Button Indicator Light Press Button Lamp body installation instructions 1.Unpack the package,take out the main parts . 2.Take out the left/right portal frames and fix them to the corresponding mounting holes on both sides of the main body using M5x12 hex socket cylindrical head screws. - Page 5 IRDA-WELDER T-890i 用户使用手册 3.Fix the connecting rod on the portal frames with 2 pcs M5x12 cross round head screws. (The bolt cannot be tightened) Connecting Rod 4.Loosen the M4 screws which fix guide rods on the left and right portal frames, and pull the two guide rods away from the front fixing blocks.Take out the lamp body...

- Page 6 IRDA-WELDER T-890i 用户使用手册 2).Press “F1” button,with 2-click sound, the preheating chassis starts to work, press “F1” button again,with 2-click sound,to stop. 3).Press “F2” button,with 1-click sound,the infrared lamp starts to work, press “F2” button again with 4-click sound,to stop. 2. The wave selection and setting 1).

- Page 7 IRDA-WELDER T-890i 用户使用手册 3).Press “F2” button to select wave,eight different waves provided, please choose one according to your request, press “F1” to save the wave you choose, come to the Main Menu page by press “F3”. 4).Press “F2” button, the lamp starts heating up according to the chose wave.

- Page 8 IRDA-WELDER T-890i 用户使用手册 3) .Press “F2” button to select wave,eight different waves provided 4) .If reset the wave, press “F4” button to select the point you will set , press “F5” button, when it flickers the grid, you can set. Press “F3/F4” buttons up and down the temperature, press “F1/F2”...

- Page 9 IRDA-WELDER T-890i 用户使用手册 Wave three: for soldering the more lead paste, like 63Sn/37Pb 60Sn/40Pb. Wave four: for unsoldering the more lead paste, like 63Sn/37Pb 60Sn/40Pb. Wave five: for soldering high-melting-point lead-free paste, like Sn/Ag3.5;Sn/Cu.75 Sn/Ag4.0/Cu.5 Sn95.5/Ag3.8/Cu0.7 https://www.tech168.cn...

- Page 10 IRDA-WELDER T-890i 用户使用手册 Wave six: for unsoldering high-melting-point lead-free paste, like Sn/Ag3.5 ; Sn/Cu.75 Sn/Ag4.0/Cu.5 Sn95.5/Ag3.8/Cu0.7 Wave seven: for soldering lead-free solder in melting point, like Sn/Ag2.5/Cu.8/Sb.5; Sn/Bi3.0/Ag3.0 Wave eight:for unsoldering lead-free solder melting point, like Sn/Ag2.5/Cu.8/Sb.5;Sn/Bi3.0/Ag3.0 Attentions: 1.According to the chips size and welding technological requirements, select the right wave to unsolder the chips, use tweezer or vacuum nozzle to remove the chips.

- Page 11 IRDA-WELDER T-890i 用户使用手册 greater than 1.5℃/ S, each segment time setting value cannot exceed 250 seconds. 3.If need to reset to Factory Default, press “F1” and “F2” at the same time, then power on the machine ,“continuous buzzers” indicates the set is done.

- Page 12 IRDA-WELDER T-890i 用户使用手册 will affect the welding quality, and serious is causing the solder paste does not melt. If the peak temperature is high or the reflow time is long, the metal power will be oxidized and affect the welding quality and serious is causing the component and PCB damaged.

- Page 13 IRDA-WELDER T-890i 用户使用手册 Adjust the infrared lamp temperature sensor: Put the infrared lamp temperature sensor on or around the chip. Then adjust the place of PCB preheat temperature sensor, letting the sensor contacts the preheat plate well. In order to let the temperature measurement exact, put some flux around the chip and the head of sensor.

- Page 14 IRDA-WELDER T-890i 用户使用手册 You can seal off when the component is equally heated. Specially, should turn on the upper infrared lamp to heat up, which can seal off quickly. For the double side board, you can choose low temperature to preheat up the PCB and then use the upper lamp to heat up.

-

Page 15: Daily Maintenance

IRDA-WELDER T-890i 用户使用手册 4). Clean and dry the PCB after reflow and dry it, the check it; if it is not good, can reflow again. If it is still not good enough, please operate the whole process again. Daily maintenance: 1.

Need help?

Do you have a question about the T-890i and is the answer not in the manual?

Questions and answers