Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for AES EPIC 3D

- Page 1 MADE IN ITALY EPIC 3 D Installation ad use manual 0,37÷15 RANGE 0,50÷20...

- Page 2 2.1 WARNINGS pag. 4 2.2 CAUTION pag. 4 Installation 3.1 ASSEMBLING pag. 5 3.2 ELECTRICAL CONNECTIONS pag. 6 EPIC 3D 3.3 ADJUSTMENTS AND SETTINGS pag. 8 (INITIALIZATION) 3.4 ADJUSTMENTS AND SETTINGS pag. 10 (ADVANCED MENU) 3.5 TRIMMER SETTINGS pag. 27 3.6 CONTACT ALARM OUTPUTS...

- Page 3 For instructions, use and maintenance of EPIC 3D. situations and events not considered in this The user should read this manual before operating manual or in the sale documents, please contact the unit.

-

Page 4: Safety Information

• (400V ± 10% 50/60Hz x il EPIC 3D -400/...) protected. The line must be protected with an • (230V ± 10% 50/60Hz x il EPIC 3D -230) Earth leackage and magnetic switch measured in accordance with the regulations locally in force. -

Page 5: Installation

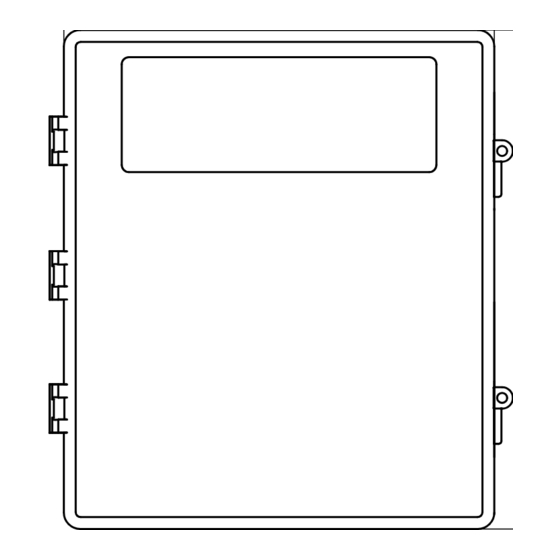

Installation EPIC 3 D 3.1 ASSEMBLING Fix the control panel for a stable support with If use an electric screwier pay attention not to screws and screw anchor using the holes spoil the thread or the screws. arranged in the box. After the fixing, remove every plastic or metallic To fix the cables in their terminals use a tool surplus (ex. -

Page 6: Electrical Connections

Installation EPIC 3 D 3.2 ELECTRICAL CONNECTIONS EPIC 3D 230 ELETRONIC BOARD 2 3 C ELETRONIC BOARD... - Page 7 Installation EPIC 3 D EPIC 3D 400 ELETRONIC BOARD 2 3 C ELETRONIC BOARD...

- Page 8 Installation EPIC 3 D 3.3 ADJUSTMENTS AND SETTINGS (INITIALIZATION) CONTROL PANEL TURN ON >LANGUAGE >ITA After making all the electrical connections, initial message to appear on the display. switch on the control panel and wait for the LANGUAGE SETTING (OBLIGATORY) Step 1 Step 2 Step 3...

-

Page 9: Preset Parameters

Installation EPIC 3 D AUTOTUNING (OBLIGATORY) Step 5 Step 6 Step 7 AUTOTUNING: P1 AUTOTUNING: P1 CONFIRM DATA? PUSH CONFIRM xxxV To start the self-learning of the pump 1 data, Before starting the self-learning type reply (step 5). procedure, it is necessary to check with a tester that the For the final confirmation of the data (step 7) type mains voltage corresponds to... - Page 10 Installation EPIC 3 D 3.4 ADJUSTMENTS AND SETTINGS (ADVANCED MENU) ACCESS TO ADVANCED MENU DIP-SWITCH 2 The control panel is set as standard with the dip-switch 2 in the “OFF” position. To access the “ADVANCED MENU” and modify the various parameters, switch off the control panel and set dip-switch 2 to “ON”.

- Page 11 Installation EPIC 3 D M01 UTILITY ACCESS TO FUNCTION MODIFIED PARAMETERS LANGUAGE Language selection >M01 UTILITY START DELAY M02 GENERAL Control panel switch-on delay after restart (in sec.) MANUAL KEYPAD Possibility of operating the “MAN” button in stable or unstable mode (ON: stable / OFF: unstable) MAX LEVEL ALARM DELAY Possibility to delay 15 minutes.

- Page 12 Installation EPIC 3 D CHANGE “MAN” BUTTON (STABLE/UNSTABILE) M01 UTILITY >MAN. MODALITY MAN. MODALITY >MAN. MODALITY >OFF MAN. MODALITY M01 UTILITY >EXIT >ON >MAN. MODALITY CHANGE MAX LEVEL ALARM DELAY M01 UTILITY >MAX LEV ALL.DEL MAX LEV ALL.DEL >MAX LEV ALL.DEL >OFF MAX LEV ALL.DEL M01 UTILITY...

- Page 13 Installation EPIC 3 D M02 GENERAL ACCESS TO FUNCTION MODIFIED PARAMETERS PUMP START DELAY M01 UTILITY Set the pump start delay >M02 GENERAL PUMP STOP DELAY Set the pump stop delay PUMPS ALTERNATION Set the pumps alternation TIME ON MAX Max continuous operation of the pump.

- Page 14 Installation EPIC 3 D CHANGE PUMPS ALTERNATION M02 GENERAL >ALTERNATION ALTERNATION >ALTERNATION >ON ALTERNATION M02 GENERAL >EXIT >OFF >ALTERNATION CHANGE TIME ON MAX M02 GENERAL >TIME ON MAX TIME ON MAX >TIME ON MAX >001 TIME ON MAX M02 GENERAL >EXIT >001 >TIME ON MAX...

- Page 15 Installation EPIC 3 D M03 NET CONTROL ACCESS TO FUNCTION MODIFIED PARAMETERS NOMINAL VOLTAGE M02 GENERAL Set the nominal voltage >M03 NET CONTROL MINIMUM VOLTAGE Set the minimum voltage MAXIMUM VOLTAGE Set the maximum voltage NOMINAL FREQUENCY Set the nominal frequency FREQUENCY RANGE Set the frequency range CHANGE NOMINAL VOLTAGE...

- Page 16 Installation EPIC 3 D CHANGE MAXIMUM VOLTAGE M03 NET CONTROL >MAX VOLTAGE MAX VOLTAGE >MAX VOLTAGE >110 MAX VOLTAGE M03 NET CONTROL >EXIT >110 >MAX VOLTAGE CHANGE NOMINAL FREQUENCY M03 NET CONTROL >NOM. FREQUENCY NOM. FREQUENCY >NOM. FREQUENCY >50 NOM. FREQUENCY M03 NET CONTROL >EXIT >50...

-

Page 17: Auto Tuning

Installation EPIC 3 D M04 PUMP 1 / M05 PUMP 2 / M09 PUMP 3 ACCESS TO FUNCTION MODIFIED PARAMETERS AUTOTUNING It allows the self-learning of the data to be carried out again >M04 PUMP 1 NOMINAL CURRENT M05 PUMP 2 Set nominal/operating current of the pump MINIMUM AMPERAGE Current setting min. - Page 18 Installation EPIC 3 D CHANGE MINIMUM AMPERAGE M04 PUMP 1 >MIN AMPERAGE MIN AMPERAGE >MIN AMPERAGE >085 MIN AMPERAGE M04 PUMP 1 >EXIT >XXX >MIN AMPERAGE CHANGE MAXIMUM AMPERAGE M04 PUMP 1 >MAX AMPERAGE MAX AMPERAGE >MAX AMPERAGE >130 MAX AMPERAGE M04 PUMP 1 >EXIT >XXX...

- Page 19 Installation EPIC 3 D φ CHANGE MIN COS φ φ >MIN. COS M04 PUMP 1 MIN. COS φ >x.xx >MIN. COS >x.xx φ MIN. COS M04 PUMP 1 >EXIT φ >X.Xx >MIN. COS...

- Page 20 Installation EPIC 3 D M06 PROGRAM ACCESS TO FUNCTION MODIFIED PARAMETERS OPERATION Emptying selection “EMPTY” or filling ”FILL“ TYPE M05 PUMP 2 Selection of clear or dirty* water types >M06 PROGRAM SELF HOLDING Mostly used for waste water applications: 4 floating switches has been used (G1 stop the pump, G2 start pump 1, G4 max level alarm and start the pump) BMS (remote emergency start/stop)

- Page 21 Installation EPIC 3 D SELF HOLDING M06 PROGRAM >SELF HOLDING SELF HOLDING >SELF HOLDING >ON SELF HOLDING M06 PROGRAM >EXIT >OFF >SELF HOLDING BMS SETTING M06 PROGRAM >BMS >BMS >OFF M06 PROGRAM >EXIT >ON >BMS MULTI TANK SETTING M06 PROGRAM >MULTI TANK MULTI TANK >MULTI TANK...

- Page 22 Installation EPIC 3 D M07 SENSOR (sensor/trasducer 4÷20 mA) ACCESS TO FUNCTION MODIFIED PARAMETERS PARAMETERS M06 PROGRAM Setting unit of measure (mt*/bar/celsius) >M07 SENSOR FULL SCALE Set the full scale value specified by the manufacturer of the sensor used (serial value 160.0) MINIMUM LEVEL Parameter active only with unit of measure in mt The “SENSOR ”...

-

Page 23: Set Minimum Level

Installation EPIC 3 D SET MINIMUM LEVEL M07 SENSOR >MIN LEVEL MIN LEVEL >MIN LEVEL 005.5 >005.0 MIN LEVEL M07 SENSOR >EXIT >005.0 >MIN LEVEL SET MAXIMUM LEVEL M07 SENSOR >MAX LEVEL MAX LEVEL >MAX LEVEL 100.0 >100.0 MAX LEVEL M07 SENSOR >EXIT >100.0... - Page 24 Installation EPIC 3 D PUMP 1 STOP M07 SENSOR >P1 STOP P1 STOP >P1 STOP 020.0 >020.0 P1 STOP M07 SENSOR >EXIT >XXX.X >P1 STOP PUMP START / STOP PUMPS 2, 3 It is necessary to carry out the same procedure to set the values of the “START PUMP 2 / PUMP3”...

- Page 25 Installation EPIC 3 D M08 TIMER ACCESS TO FUNCTION MODIFIED PARAMETERS ENGAGE TIMER T1 TIMER T1 ON M07 SENSOR Setting the working minutes of the pump 1 TIMER T1 OFF >M08 TIMER Setting the pause minutes of the pump 1 ENGAGE TIMER T2 TIMER T2 ON Setting the working minutes of the pump 2...

- Page 26 Installation EPIC 3 D TIMER T1 OFF M08 TIMER >timer t1 off timer t1 off >timer t1 off 0000 >0000 timer t1 off M08 TIMER >USCITA >xxxx >timer t1 off TIMER SETTING T2/T3 ON / TIMER T2/T3 OFF The same procedure must be followed to set the values of the “TIMER T2/T3 ON” and “TIMER T2/T3 OFF”...

- Page 27 Installation EPIC 3 D 3.5 TRIMMER SETTINGS To change manually the threshold protections, PROTECTION DELAY interrupt the power supply to the control The pump protection switching panel and work on the trimmers, please delay has been set at 5 sec. following the below instructions: TRIMMER SETTING TRIMMER 1: PROBE SENSITIVITY CHANGE...

- Page 28 EPIC 3 D...

-

Page 29: General Use

General use EPIC 3 D 4.1 KEYPAD AND LIGHTS INDICATIONS CONTROL PANEL blue light indicating power network presence and powered panel. ALARM red light to indicate a general alarm and pump stop. (min e max Amp, min e max V, min e max level, motor klixon, water in oil chamber, phase failure). START green light to indicate pump start;... - Page 30 General use EPIC 3 D 4.2 ALARMS The control panel signals a series of alarms that All alarms are displayed on the panel (red LED may occur during operation. Some of these stop flashing), while the display shows the code/alarms the pumps, while others are only displayed.

-

Page 31: Delete Alarm

General use EPIC 3 D ALARM WITH STOP PUMP Following the detection of an alarm and the consequent blocking of the pump, the control panel provides the following operations: • Try the first restart after 5 min. • In case of a negative result, make another attempt after 30 min. and 3 other attempts with intervals of 60 min. -

Page 32: Typical Installations

General use EPIC 3 D 4.3 TYPICAL INSTALLATIONS 4÷20 input for 4÷20 mA sensor or pressure transducer pressure transducer 2/3/C input for level probes float switch for clear water input for water in oil chamber sensor/water leakage float switch for waste water input for motor klixon level probes pressure switch... - Page 33 General use EPIC 2D 4÷20 input for 4÷20 mA sensor or pressure transducer pressure transducer 2/3/C input for level probes float switch for clear water input for water in oil chamber sensor/water leakage float switch for waste water input for motor klixon level probes pressure switch pump...

-

Page 34: Maintenance

5.2 SERVICE EPIC 3 D does not require any routine DANGER! maintenance provided that their working limits Make sure that EPIC 3D is are observed . Any maintenance operations disconnected from the power must be performed qualified supply before... -

Page 35: Certificate Of Conformity

Atlantic Power Control S.r.l.s Via E. Fermi, 10 - 35020 Polverara (PD) - ITALIA DECLARES UNDER IS OWN RESPONSIBILITY THAT THE FOLLOWINGS CONTROL PANELS: EPIC 3D -230 e EPIC 3D -400 ARE IN CONFORMITY WITH COMMUNITY DIRECTIVES REGARDING: • European •... - Page 36 Tel: 01284 658700 Email: sales@automatedenvironmentalsystems.co.uk www.automatedenvironmentalsystems.co.uk...

Need help?

Do you have a question about the EPIC 3D and is the answer not in the manual?

Questions and answers