Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Doheny's Pool Pro Ultra VS

- Page 1 Pool Pro Ultra VS Item #s 90950 & 90951 INSTALLATION, OPERATION & PARTS...

-

Page 2: Important Safety Instructions

IMPORTANT SAFETY INSTRUCTIONS General Warnings • Never open the inside of the drive or motor enclosure. There is a capacitor IMPORTANT NOTICE bank that holds a 230 VAC charge even when there is no power to the This guide provides installation and operation instructions for this pump.Co unit. - Page 3 IMPORTANT SAFETY INSTRUCTIONS TO MINIMIZE THE RISK OF INJURY DUE TO HAZARDOUS PRESSURE: STANDCLEAR OF PUMP SUCTION ENTRAPMENT HAZARD: AND FILTER DURING START UP. Circulation systems operate under high pressure. • A properly installed and secured ANSI/ASME A112.19.8 approved anti- When any part of the circulating system (i.e.

-

Page 4: Table Of Contents

TABLE OF CONTENTS Important Safety Instructions........... i Introduction..............1 Maintenance..............11 Pump Features Cleaning the Pump Strainer Basket Motor Features Motor Care Drive Features Pump Disassembly Pump Reassembly Using the Drive Keypad............ 2 Restarting the Pump Installation................4 Winterizing Location Troubleshooting...............14 Piping Troubleshooting Chart Fitting and Valves Alarms and Fault Codes Electrical Installation... -

Page 5: Introduction

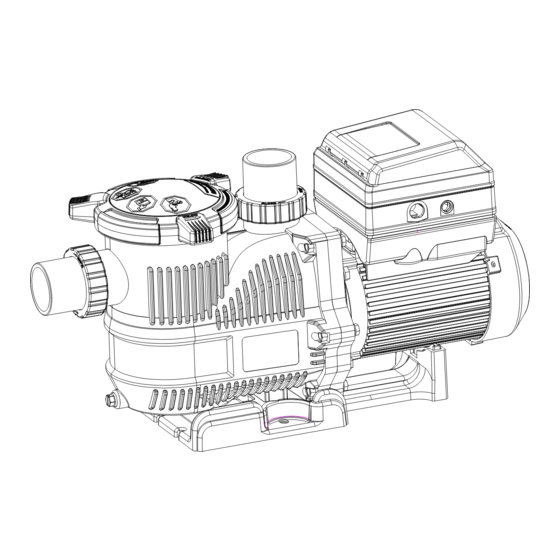

INTRODUCTION Drive Features Pump Features The pump features a premium efficiency variable • Extremely quiet operation frequency drive that provides flexibility in terms of motor • 2 in. Plumbing for simple replacement speed and duration settings. • See-through strainer pot lid allows easy inspection This pump is for use with 230 Vrms nominal, and of strainer basket in pool pump applications ONLY. -

Page 6: Using The Drive Keypad

USING THE DRIVE KEYPAD Before operating the pump for the first time, the pump’s internal clock and operational schedules must be programmed. Refer to Setting the Clock, page 6 and Programming Custom Schedules, page 7 for instructions regarding the programming of this pump for scheduled operation. The pump can be programmed and controlled from the drive keypad. - Page 7 ①Control panel digital tube: used to view the current speed, time, duration, power consumption, Bluetooth connection prompt and other functions. ②Display mode LED indicator light: with the display button to display the corresponding LED, the information displayed on the digital tube corresponds to a specific point. Blinking indicates the current editable parameter.

-

Page 8: Installation

INSTALLATION Only a qualified plumbing professional should install the pump. Refer to IMPORTANT SAFETY INSTRUCTIONS on page i-ii for additional installation and safety information. Location Figure Note: Do not install this pump within an outer enclosure or beneath the skirt of a hot tub or spa. Note: Ensure that the pump is mechanically secured to the equipment pad. -

Page 9: Electrical Installation

Electrical Installation RISK OF ELECTRICAL SHOCK OR ELECTROCUTION. The pump must be installed by a licensed or certified electrician or a qualified service professional in accordance with the National Electrical Code and all applicable local codes and ordinances. Improper installation will create an electrical hazard which could result in death or serious injury to users, installers, or others due to electrical shock, and may also cause damage to property. -

Page 10: Setting The Clock

OPERATION Before operating the pump for the first time, the pump’s internal clock and operational schedules must be programmed by following the steps in this manual. Refer to Setting the Clock below and Programming Custom Schedules on page 7, for instructions regarding the programming of this pump for scheduled operation. Using the Default Schedule NOTE The default schedule is designed to provide sufficient... -

Page 11: Programming A Custom Schedule

5. Use “+” and “-” to adjust the SPEED 1 start time. Programming Custom Schedules use the “<” and “>” move the cursor. To customize your pump’s schedule, the pump must Note: The start time adjustment Stepping be stopped. Ensure that the Start/Stop LED is not is 1hour/10min/1min illuminated. -

Page 12: Speed Priorities (Non-External Control)

Operating the Pump While Running Speed Priorities (Non-External Control) For schedule duration settings, SPEEDs are If power is connected to the pump, pressing any prioritized as follows: SPEED 1 -> SPEED 2 -> of the following buttons referred to in this section SPEED 3 ->... -

Page 13: Priming

Priming This pump is shipped with Priming mode ENABLED. The pump will ramp up to 3200 RPM when the pump is initially started. Before turning the pump ON: 1. Open filter air relief valve. 2. Open necessary valves. 3. Ensure return line is completely open and clear of any blockages. 4. -

Page 14: Programming Quick Clean

Factory Reset Programming Quick Clean The drive can be reset to factory settings if The pump is equipped with a Quick Clean feature, which necessary.A Factory Reset will erase all can be engaged to temporarily run at higher or lower programmed settings and schedules, except for speeds ranging from 1700 to 3450 RPM. -

Page 15: Maintenance

MAINTENANCE DO NOT open the strainer pot if pump fails to prime or if pump has been operating without water in the strainer pot. Pumps operated inthese circumstances may experience a build up of vapor pressure and may contain scalding hot water. Opening the pump may cause serious personal injury. -

Page 16: Pump Disassembly

Refer to the Motor/Hydraulics Assembly Diagram, on the next page, for a parts breakdown of the pump. Always disconnect power to the pump at the circuit breaker before servicing the pump. Failure to do so could result in death or serious injury to service people, users or others due to electric shock. -

Page 17: Restarting The Pump

Restarting the Pump Winterizing You are responsible for determining when freezing If pump is installed below the water level of the pool, conditions may occur. If freezing conditions are close return and suction lines prior to opening the expected, take the following steps to reduce the risk of strainer pot on pump. -

Page 18: Troubleshooting

TROUBLESHOOTING Diagnosing certain symptoms may require interaction with, or close proximity to, components that are energized with electricity. All servicing should be performed by a qualified service professional. Contact with electricity can cause death,personal injury, or property damage. Troubleshooting Chart Problem Possible Cause Corrective Action... -

Page 19: Alarms And Fault Codes

Troubleshooting Chart (cont.) Problem Possible Cause Corrective Action Pump runs without flow. Impeller is loose Ensure fan at the rear of pump is spinning. If so, disassemble pump (Pump Disassembly, page 12) and ensure impeller is correctly installed. Air in suction line or pump 1. -

Page 20: Replacement Parts

REPLACEMENT PARTS Item Part. No. Description Item Part. No. Description 47259401080 Pump housing 5225008000 Screw 47259404080 Lid Clamp 5232001106 5221008000 Screw 47259405089 Drain Plug O-ring, Lid 48860105080 5431032080 Mounting foot 47276803001 Strainer Basket 47259403080 O-ring 5231002106 Nut, Motor Foot 5431032080 5221008000 Screw Gasket... -

Page 21: Technical Data

TECHNICAL DATA Technical Specifications (1.5 HP Models) Environmental NEMA Type 3 / IPX5 Input Voltage Nominal 230 VAC Enclosure Rating Input Current 5 Amps Ambient Condition Range Input Frequency 1PH,L1-L2 or L-N,50 or 60 Hz Storage -40°C to +60°C (-40°F to 140°F) Max Input Watts 1150 W Operating... - Page 22 Technical Specifications (2 HP Models) Environmental NEMA Type 3 / IPX5 Input Voltage Nominal 230 VAC Enclosure Rating Input Current 7.5 Amps Ambient Condition Range Input Frequency 1PH,L1-L2 or L-N,50 or 60 Hz Storage -40°C to +60°C (-40°F to 140°F) Max Input Watts 1700 W Operating...

- Page 23 Technical Specifications (3 HP Models) Environmental NEMA Type 3 / IPX5 Input Voltage Nominal 230 VAC Enclosure Rating Input Current 11 Amps Ambient Condition Range Input Frequency 1PH,L1-L2 or L-N,50 or 60 Hz Storage -40°C to +60°C (-40°F to 140°F) Max Input Watts 2500 W Operating...

-

Page 24: Pump Dimensions

Pump Dimensions (1.5 HP 2 HP 3 HP Models)

Need help?

Do you have a question about the Pool Pro Ultra VS and is the answer not in the manual?

Questions and answers

How do you get inside to wire? It looks as if you remove the four corner screws of the keypad?

To access the wiring inside the Doheny's Ultra VS pump, you must first stop the pump by pressing "Start/Stop" and then disconnect all power to the pump at the circuit breaker. This is necessary to prevent electric shock or injury. After ensuring the power is off, you can proceed with servicing, which may include accessing the wiring. Always follow servicing instructions and safety precautions before opening the pump.

This answer is automatically generated