Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Excillum NanoTube N3

- Page 1 NanoTube N3 Operation manual Content NanoTube N3 Operating manual...

- Page 2 NanoTube, NanoTube N1, NanoTube N2, and NanoTube N3 are registered trademarks or trademarks of Excillum AB. Excillum’s X-ray sources and technology are protected by several patents including, but not limited to, US Patents Nos. US 6 711 233, US 8 170 179, US 8 681 943, US 8 837 679, US 9 171 693, US 9 245 707, US 9 380 690, US 9 530 607, US 9 564 283, US 9 947 502, US 10 784 069, US 10 818 468, US 10 825 642, US 10 930 464, US 10 971 323, and Chinese Patents Nos.

-

Page 3: Table Of Contents

NanoTube N3 Operation manual Content Introduction ............................ 1 1.1 Instructions and conventions ....................1 1.2 Basic X-ray source functionality ..................... 3 1.3 System components ....................... 3 Safety precautions .......................... 6 2.1 Qualified personnel ......................... 6 2.2 Proper use ..........................6 2.3 Partly completed machinery .................... - Page 4 NanoTube N3 Operation manual Content 6.2 Capabilities of software ......................34 6.3 Start the system ........................34 6.4 Generate vacuum ........................36 6.5 Preparation..........................36 6.6 Select e-beam properties ...................... 38 6.7 Select a workpoint ........................ 40 6.8 Turn on X-rays ........................41 6.9 Turn off X-rays ........................

-

Page 5: Introduction

This operating manual is for customers of Excillum. It contains important information regarding installation, operation, maintenance, and safety of the NanoTube N3 source. All persons involved in installation, operation and service must have thoroughly read and understood the relevant parts in operating manual beforehand. - Page 6 NanoTube N3 Operation manual Introduction This table lists the symbols that can be found on the source, generator, chiller and power module. Number Symbol Reference Description IEC 60417-5031 (2002-10) Direct current IEC 60417-5032 (2002-10) Alternating current IEC 60417-5019 (2006-08) Protective conductor terminal...

-

Page 7: Basic X-Ray Source Functionality

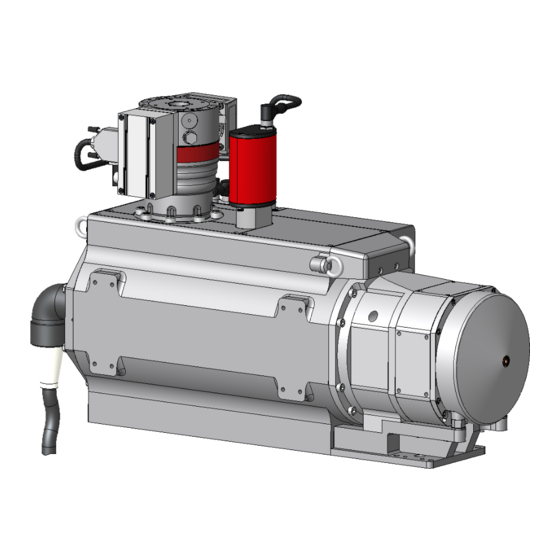

Figure 1: X-ray basics in an image System components The NanoTube N3 is a system component, not a stand-alone X-ray source. For more information, see Section 2.3 and 4.1. The standard delivery consists of the following parts but can vary depending on customer configuration. - Page 8 NanoTube N3 Operation manual Introduction 1.3.1 X-ray head parts The X-ray head consists of the following parts: Part High-vacuum pump (turbo pump) High-vacuum gauge Lens cooling block Target Roughing pump hose connection Venting valve Cooling water outlet High-voltage cable connected to high-voltage feedthrough...

- Page 9 Fabric may get tangled in the fans, use caution when working near the ventilation. 1.3.3 Generator The NanoTube N3 is designed and closely integrated with the high-voltage generator for optimal performance. For more information, read the separate generator manual. 1.3.4 Water chiller The NanoTube N3 is designed and closely integrated with the water chiller for optimal performance.

-

Page 10: Safety Precautions

NanoTube N3 Operation manual Safety precautions 2 Safety precautions Qualified personnel Installation work, commissioning, and operation of the NanoTube N3 source shall only be done by personnel who are qualified and skilled in the following: • Safety regulations • X-ray radiation •... -

Page 11: Handling The Source

The NanoTube N3 source provides no specific protection from X-ray radiation. Therefore, the NanoTube N3 must e.g. be placed in a radiation enclosure where the opening of doors and hatches are strictly controlled and monitored by a safety system to prevent the user from getting exposed to X-rays. -

Page 12: Electricity And High Voltage

The high- voltage decay time when power is shut down can be significant. In the case of NanoTube N3, the table below shows the decay times that have been measured (initial conditions from 60 kV-160 kV, 0 mA). -

Page 13: Safety Enclosure Requirements

The generator provides signal for X-rays warning lamps that can be used by the enclosure if required. These signals are functions but not a safety signal. Excillum recommends delayed entry and/or preventive measured to prevent short radiation exposure. -

Page 14: Heat

Possible damage to the target could risk in system venting and must be replaced 2.11 Hazardous metals The NanoTube N3 source contains metals such as nickel, lead, and brass which have known allergic reactions to human contact. The X-ray source contains metal elements such as brass, nickel, and lead which have known allergic reactions. -

Page 15: Transport, Handling, And Storage

The NanoTube N3 source shall only be transported and stored in an upright position. • The NanoTube N3 is delivered with lifting hooks attached on 4 sides of the X-ray head. It provides necessary lifting options to maneuver the X-ray head with a crane, straps, chains, or hooks. -

Page 16: System Design Considerations

System design considerations 4 System design considerations It is important to install the NanoTube N3 source according to this manual and local regulations. Check off this list to make sure the obligations are prepared prior installation day. Excillum does not provide these obligations. - Page 17 NanoTube N3 Operation manual System design considerations 4.1.1 Input to high-voltage generator The input to the high-voltage generator is through the JE1 connector on the generator (see Appendix B for more details). The power to the generator should be supplied only when the safety relays are activated when the customers safety requirements are fulfilled.

-

Page 18: Operating Conditions

Ambient conditions o See section 9 for technical information about NanoTube N3. o The NanoTube N3 source should not be placed in a space where it may be exposed to direct sunlight, atmospheric agents (rain, snow, ice, etc.), dust, or aggressive gases. -

Page 19: System Accessibility

System design considerations • Magentic fields o The X-ray head of the NanoTube N3 source is sensitive to external magnetic fields, which may cause severe loss of X-ray output performance since the electron beam may be affected. o The NanoTube N3 source may also be sensitive to ferromagnetic materials (and other materials with a high relative magnetic permeability) close to the X-ray head. -

Page 20: Checklist

System design considerations Checklist This checklist is intended as an assistance before installation of the Excillum NanoTube N3 source to minimize potential complications. Before installation day, perform step 1-4 to save time. If these conditions are not fulfilled, do not proceed with the installation. Contact Excillum if needed. -

Page 21: Installation

(Image 7), the side mount (Image 8) or a combination of both. For the NanoTube N3 center of mass, see Image 9. Refer to this before lifting and mounting the source. The X-ray head should be properly fastened using the 12 M6-threaded holes on the base/side of the source. - Page 22 NanoTube N3 Operation manual Installation Image 7: X-ray base mount Image 8: X-ray side mount January - 2023...

- Page 23 Image 9: Center of mass 2. It is recommended to mount the sub-assembly racks in suitable places (see Image 10). The rack is not provided by Excillum. Table 10 summarizes which sub-modules are rack mounted and indicates space requirements within the rack.

- Page 24 Operation manual Installation 3. Connect the water hoses from the chiller unit directly on the NanoTube N3 water fittings. Image 11: Water fittings located in the back of the NanoTube N3 4. Connect the vacuum hose to the KF16 ports on the turbopump on the X-ray head, and the roughing pump in the power module box using KF16 O-rings and stainless steel KF16 clamps.

- Page 25 NanoTube N3 Operation manual Installation 6. Connect all interconnecting cables according to the table below. For clarification, see appendix A. It is important that the COM ports are connected as specified below. Generator JE5 has C-00172 as the interconnect loop back pre-installed.

- Page 26 NanoTube N3 Operation manual Installation 8. Remove transportation cover and inspect the conical isolator. Before connecting it, always clean the isolator with lint-free tissues and isopropanol. Recommend to save the transportation covers in a safe place for use during future maintenance and storage.

- Page 27 NanoTube N3 Operation manual Installation 11. Tighten the three M6x20 screws evenly until fully fastened. The two first rings should be visible but not the third one (Image 16). If necessary, adjust by removing the four screws and rotating the cable flange.

- Page 28 NanoTube N3 Operation manual Installation 13. Remove transportation cover on the other end of the HV cable and inspect the conical isolator. Before connecting it, always clean the isolator with lint-free tissues and isopropanol. Image 18: Conical isolator to insert in the HV generator 14.

- Page 29 High voltage is potentially lethal. Make sure to check following list: • All sub-assembly units must be properly grounded, and all cables must be securely attached before turning on the NanoTube N3 source. • Ensure that all interlocks are connected before energizing the NanoTube N3 source.

-

Page 30: Software Set-Up

NanoTube N3 Operation manual Installation Software set-up This section explains how to integrate the system controller in the system IT infrastructure. This set-up demands being on site. 1. Connect a screen to the source computer using a VGA cable. 2. Start up the computer and wait until the desktop is shown. - Page 31 NanoTube N3 Operation manual Installation 5.3.2 Change the time zone Change the time zone to match the time zone at the installation site. 1. Open a window by right clicking on the lower panel of the GUI and select “Settings.”...

- Page 32 NanoTube N3 Operation manual Installation 3. Select between DHCP or static as suitable for the application. Image 22: Select ʻDCHPʼ or ʻStaticʼ 4. Apply and close the settings window. The default setting is DHCP. A router with a DHCP server is preferred but a switch can also be used if the X-ray system controller is configured to use a static IP address.

- Page 33 Excillum provides the latest available software version for the source. Download here or type: https://www.excillum.com/operational-support-nanotube/ Connect the computer being used to the same network as Nanotube N3 computer. • Open any browser on the same network. • Type in n3-XXXXX:8080 in the browser (XXXXX=the source number If your source •...

- Page 34 NanoTube N3 Operation manual Installation Image 25: Select ʻRunmodeʼ Image 26: Select ʻRestart Runmodeʼ • The system will restart, and the user can see the updated version information in the bottom left corner. (e.g., if you receive Version 2.6.1 in the update file, after...

-

Page 35: Installation Checklist

Before proceeding the startup of the source, ensure all these steps are completed as mentioned in earlier sections. If there are any questions about this checklist, contact Excillum for advice. If this checklist is not completed, do not start up the source. -

Page 36: Operation

NanoTube N3 Operation manual Operation 6 Operation Source startup The instructions and screenshots assume that XCS 3.0 or later is installed, including a custom desktop for the Debian Linux distribution that the X-ray system controller is running. If there is an older version, most of the instructions are still valid. - Page 37 NanoTube N3 Operation manual Operation Figure 2: Flowchart showing the decision process when starting the NanoTube source. January - 2023...

-

Page 38: Capabilities Of Software

4. If ‘connection error’ occurs, refer to section 5.4 and ensure all cables are properly installed. 5. Right click on the desktop and select ‘User interface’ to bring up the GUI for user control of the NanoTube N3 source. January - 2023... - Page 39 NanoTube N3 Operation manual Operation 6. The user interface with system overview will open as shown below: Image 29: User Interface start-up screen The User interface has multiple sections. • Vacuum: The current vacuum pressure of the system is displayed •...

-

Page 40: Generate Vacuum

NanoTube N3 Operation manual Operation 7. Set the water temperature under the climate system at start up. Click on ‘Enable cooling’ for changes to take effect and check water circulation for leaks. Refer to section 8.7. Recommended temperature for the best performance of the cooling system is +/- 1 C°... - Page 41 NanoTube N3 Operation manual Operation When the preparation is completed, the source is ready for use and the status bar will display ‘Ready’. It also marks the preparation as done on the GUI. In this state the generator will be started and X-rays generated.

-

Page 42: Select E-Beam Properties

NanoTube N3 Operation manual Operation Select e-beam properties To get the required e-beam properties, change setpoints by hovering the mouse pointer over the desired section. See example and explanation below. Image 33: E-beam spotsize selection options for user with highlighted example. - Page 43 NanoTube N3 Operation manual Operation 1. Selecting energy: The energy range depends on the model of generator purchased. This value can be set from 40 keV up to maximum available by the generator. Hover mouse pointer above or below value to choose desired value by clicking on the shaded gray box.

-

Page 44: Select A Workpoint

NanoTube N3 Operation manual Operation Select a workpoint Selecting workpoint: The available workpoints are highlighted with a blue dot. A selected workpoint will have a blue circle around the blue dot. Hover the mouse pointer over desired workpoint and a short description will be shown. This describes the time spent, energy absorbed, index of workpoint, and positioning of each workpoint. -

Page 45: Turn On X-Rays

NanoTube N3 Operation manual Operation Turn on X-rays Select ʻX-rays onʼ to start generating X-rays. Image 35: ʻX-rays onʼ is selected • X-rays on: Turns on X-rays with current keV and power selected in ‘Beam section’ There is no focus applied. This action will apply the last calibration settings of the e-optics and power by the user. -

Page 46: Turn Off X-Rays

10 minutes. The system will be put in ‘ready’ state when selecting ‘X-rays off’ after operation. It is strongly recommended that the NanoTube N3 system is always in the ‘ready’ state where vacuum is maintained. Refer to Section 7.1 for more information. -

Page 47: Shut Down

Shut down for shorter periods If the NanoTube N3 source is not going to be used for a short time period (less than three months) it is preferred to leave it in the ‘ready’ state, i.e. with the vacuum pumps running, but with the high voltage generator turned off. -

Page 48: Maintenance And Service

Article number • Serial number The article number of the NanoTube N3 source is G-200-0022. The source consists of five sub- assembly units and the article numbers is located at the back of each unit, close to the electrical power connector. -

Page 49: Support And Troubleshooting

Maintenance and service Support and troubleshooting In case of NanoTube N3 source malfunction, find possible causes and instructions for repair in the table below. If the malfunction is not listed, contact Excillum for assistance. See section 1.3 for product identification. -

Page 50: Remote Support

XCS computer, is connected to the Internet. TeamViewer comes preinstalled on the X-ray system controller, but it can be downloaded for free from www.teamviewer.com. When TeamViewer is started an ID number and a password is shown which can be used to invite Excillum support to assist with troubleshooting. -

Page 51: Venting Source For Service

NanoTube N3 Operation manual Maintenance and service Venting source for service System must be vented before opening the vacuum chamber to perform any service. This process takes an estimated time of 15-45 minutes, depending on cathode temperature. It is recommended to shut down the system entirely for services after the source has been vented. -

Page 52: Cathode Replacement

NanoTube N3 Operation manual Maintenance and service Cathode replacement 8.6.1 Remove the HV assembly Ensure that the power module is turned off and disconnected from the electric mains before servicing HV parts. Remove pull wire from the back of the source head. - Page 53 NanoTube N3 Operation manual Maintenance and service 2. Use a 5 mm hex key to remove the HV cable from the HV feedthrough. Loosen the three(one not visible in image) screws (A) in a circular pattern to minimize stress on the cable assembly.

- Page 54 NanoTube N3 Operation manual Maintenance and service 5. Use a 5 mm hex key to remove the HV feedthrough from the chamber. Loosen the screws in a star pattern to minimize stress on the cable assembly. Carefully remove the flange straight backwards without dropping or scratching the outside of the...

- Page 55 NanoTube N3 Operation manual Maintenance and service 8.6.2 Remove the firing assembly 1. Remove the top section of the emitter cover by gently pulling it upwards. Make sure to pull it straight upwards to avoid it getting stuck. Image 45: Remove top section of emitter cover mount 2.

- Page 56 NanoTube N3 Operation manual Maintenance and service 8.6.3 Install a new firing unit 1. Use clean room gloves to remove the new firing unit from the shipping container. 2. Record the serial number of the new firing unit and update it in the GUI (section 8.6.5).

- Page 57 NanoTube N3 Operation manual Maintenance and service 5. Tighten both hex screws with a 2 mm UHV hex key and tighten firmly. Image 50: Tighten and loosen screws to install the firing unit 6. Measure with a digital multimeter (DMM) and confirm between ≈ 5- 8ohm resistance between copper blocks.

- Page 58 NanoTube N3 Operation manual Maintenance and service 8. Measure with DMM between firing unit shell and copper blocks (B). One copper block should show an open circuit, e.g., no connection. The other copper block will be short. Example ≤ 1 ohm.

- Page 59 NanoTube N3 Operation manual Maintenance and service 8.6.4 Re-install HV assembly 1. Inspect the HV feedthrough for loose particles. If necessary, use compressed air to gently remove dust from the feedthrough. O-rings have been vacuum-baked to reduce outgassing. Do not use isopropanol to clean.

-

Page 60: Climate System

Therefore, no inspection interval is necessary when water cooling is provided by Excillum. We recommend an anti-algicide that is shipped with the source. Contact Excillum to replenish the cooling water. -

Page 61: Consumables

NanoTube N3 Operation manual Maintenance and service Consumables When receiving the source, a small items kit is included. Excillum recommend to stock the parts labeled with ʻSʼ since they are standard wear parts. Part # Group / Part Name Description... -

Page 62: Technical Data

NanoTube N3 Operation manual Technical data Technical data Parameter Value X-ray system Max acceleration voltage 160 kV Max electron-beam power 60 kV, 110 kV or 160 kV (depending on model) Best resolution 150 nm (lines and spaces e.g., JIMA) Target type Transmission Min. - Page 63 8 mm /AWG 8 Required PE Cable Balasubramanian PUW Interlock is Excillum internal safety system requirement to turn on generator, 6 mm /AWG 10 Required PE Cable Refer to Nano N3 control interface for information on safety system. 2.5 mm /AWG 13 Required PE Cable 3.Integrator responsible for power and ground connections...

- Page 64 EXCILLUM INTEGRATOR Ethernet for control/monitoring Integrator safety/control system NETWORK 8P8C jack CABINET INTERLOCKS COM PORT Radiation shield cabinet door/access panel/port (IEC 61010-2-091:2012) monitoring JE4 COMMUNICATION Optical Avago HFBR-1524/HFBR-2524 JE3 HV INTERLOCK 2 pin Phoenix MC 1,5/2-GF-3.81 HV PSU AC CONTACTOR A control/monitor...

Need help?

Do you have a question about the NanoTube N3 and is the answer not in the manual?

Questions and answers