Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

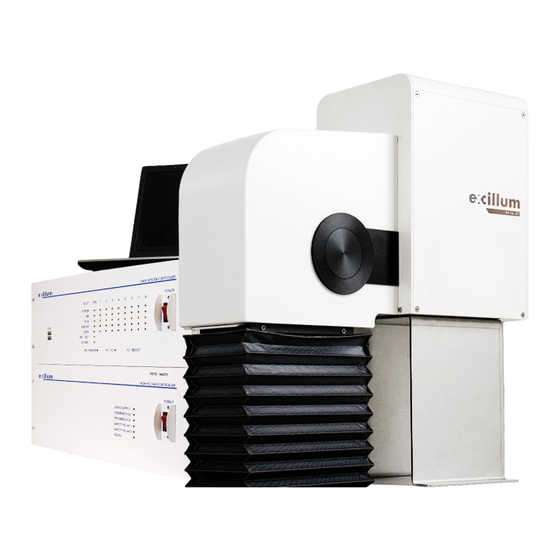

Summary of Contents for Excillum MetalJet D2+

- Page 1 MetalJet D2+ Operating manual Revision 19, November 2016...

- Page 2 Excillum reserves the right to alter this information at our own discretion at anytime. The warranty and product documentation remains valid as long as the customer does not make any changes to the product.

- Page 3 Please fill in the serial numbers and the manufacturing year for the sub-assembly units of your MetalJet D2+ x- ray source in the table below, and have them readily available when contacting Excillum for assistance, additional information, or purchase of spare parts.

-

Page 4: Table Of Contents

METALJET D2+ TABLE OF CONTENTS Table of Contents INTRODUCTION ..........................1-1 Validity ..............................1-1 Instructions and conventions ......................1-1 Product information ........................... 1-2 1.3.1 Product identification ........................1-2 1.3.2 Design and function ........................1-2 1.3.2.1 Liquid-metal circulation loop ....................1-2 1.3.2.2 Electron gun/x-ray head ...................... - Page 5 METALJET D2+ TABLE OF CONTENTS 4.3.1 Mounting of sub-assembly units ....................4-2 4.3.2 Connecting tubing and cables ......................4-8 4.3.2.1 Tighten inlet and outlet check valve housings ..............4-8 4.3.2.2 Flex-hose assembly and jet-exit port ..................4-8 4.3.2.3 Cooling water supply and return ................... 4-9 4.3.2.4 High-pressure tubing and nozzle assembly .................

- Page 6 METALJET D2+ TABLE OF CONTENTS User levels ............................5-8 Error messages ........................... 5-8 Parametrization ..........................5-9 5.8.1 Prepare system for parametrization ....................5-9 5.8.2 Align electron beam to optical axis ....................5-10 5.8.3 Determine jet size and position ....................5-10 5.8.4 Characterize focus lens and verify jet stability ................

- Page 7 METALJET D2+ TABLE OF CONTENTS Shutting down for shorter periods ..................... 7-1 Shutting down for longer periods ....................... 7-1 Restarting after longer shutdown ...................... 7-1 Disposal .............................. 7-1 MALFUNCTION AND TROUBLESHOOTING ..................8-1 CUSTOMER SUPPORT ........................9-1 System log files ........................... 9-1 Remote support ..........................

-

Page 8: Introduction

1 INTRODUCTION 1.1 Validity This operating manual is for customers of Excillum. It describes the functioning of the MetalJet D2+ source and provides the most important information for safe use of the unit. The description follows applicable EU guidelines. Up-to-date operating instructions may be obtained by contacting Excillum, see page ii for contact information. -

Page 9: Product Information

METALJET D2+ INTRODUCTION 1.3 Product information 1.3.1 Product identification To correctly identify the product when communicating with Excillum, always provide the following information from the identification tag(s): Model number Article number Serial number Manufacturing year ... - Page 10 METALJET D2+ INTRODUCTION The electron gun/x-ray head consists of the following parts, see Figure 1-1 below: 1. High-pressure tubing 2. Particle filter 3. Nozzle assembly 4. Lens cooling block 5. High-vacuum gauge 6. High-vacuum pump (turbopump) 7. Ventilation valve 8. Fore-vacuum hose 9.

- Page 11 METALJET D2+ INTRODUCTION The main components of the pump box are the following parts (see Figure 1-2): 1. High-pressure tubing 2. Upper cooling block 3. Jet brake 4. Flex-hose assembly 5. Fore-vacuum hose 6. Cooling water inlet 7. Cooling water outlet 8.

- Page 12 METALJET D2+ INTRODUCTION Revision 19, November 2016 Page 1-5...

-

Page 13: X-Ray Output Options

METALJET D2+ INTRODUCTION Figure 1-2. The main components inside the pump box. 1.3.3 X-ray output options MetalJet D2+ systems can be configured to operate with the x-ray output either on the left-hand side (left- handed), the right-hand side (right-handed) or both sides (dual port). The definition of left and right is indicated in Figure 1-3 using a red arrow for the left-handed system and a green arrow for the right-handed system. -

Page 14: With X-Ray Shutter

METALJET D2+ INTRODUCTION The system can also be configured to operate either with or without an x-ray shutter. When operated without a shutter it can be configured with a standard exit window or an exit window with an increased cone angle. The figures in Sections 1.3.3.1-1.3.3.3 show minimum source-to-object distance, exit window diameter and x-ray emission cone angle for each of these configurations. -

Page 15: Without X-Ray Shutter Using Standard Exit Window

METALJET D2+ INTRODUCTION 1.3.3.2 Without x-ray shutter using standard exit window Figure 1-5. Schematic of the x-ray head without x-ray shutter using standard exit window. Revision 19, November 2016 Page 1-8... -

Page 16: Without X-Ray Shutter Using Increased Cone Angle Exit Window

METALJET D2+ INTRODUCTION 1.3.3.3 Without x-ray shutter using increased cone angle exit window Figure 1-6. Schematic of the x-ray head without x-ray shutter using increased cone angle exit window. Revision 19, November 2016 Page 1-9... -

Page 17: Safety

Excillum is not responsible for the installation, use, or application of the MetalJet D2+ source. If the MetalJet D2+ source is used in a manner not specified by Excillum, then protection built into the MetalJet D2+ source may be impaired. -

Page 18: X-Ray Radiation

Therefore, do not modify, remove, or otherwise change any part of the MetalJet D2+ source unless this action has been approved of by Excillum beforehand. However, no practical design can provide complete protection nor prevent operators from exposing themselves or others to unnecessary radiation. -

Page 19: High Pressure

METALJET D2+ SAFETY DANGER High voltage is potentially lethal High voltage can cause electric shock or burn. All sub-units of the MetalJet D2+ source must be properly grounded before being energized. Use high voltage precautions. Always ensure complete discharge of the high-voltage cable when removing it from the system by letting the circled metal connectors touch ground, see Figure 2-1. -

Page 20: Heat

METALJET D2+ SAFETY 2.1.7 Heat During operation of the MetalJet D2+ source the surfaces of the x-ray head, the vacuum pumps, and the low- pressure tubing may become hot. Depending on the operating and ambient conditions these surfaces may reach temperatures above 50°C (122°F). Use suitable finger guards if necessary. CAUTION Hot surfaces The x-ray head, the vacuum pumps, and the low-pressure tubing may become hot during operation of the... -

Page 21: Poisoning Hazard

METALJET D2+ SAFETY 2.1.9 Poisoning hazard The x-ray exit window of the MetalJet D2+ source consists of a beryllium foil. Beryllium metal is highly toxic. Do not touch or otherwise handle the foil. Take care to read and follow the instructions below. WARNING Poisoning hazard –... -

Page 22: Proper Use

If permitted liquids (or similar) is not stated in the confirmation of the purchase order written approval from Excillum has to be acquired before exchanging liquids (or similar). Operating the MetalJet D2+ source in potentially explosive areas. -

Page 23: Transport And Storage

The MetalJet D2+ source should only be transported in an upright position. The MetalJet D2+ source may be considered to be dangerous goods when being transported. Contact Excillum for more information, see Section 1.3.4. Information regarding the overall dimensions and weight may be found in Section 11. -

Page 24: Storage

METALJET D2+ TRANSPORT AND STORAGE Figure 3-2. Pay special attention to the cooling-water connections and the jet-exit port when placing the electron gun/x-ray head on a table. They may be damaged unless positioned slightly outside the edge of the table. CAUTION Lifting of equipment Never attempt to lift the pump box or the electron gun/x-ray head alone. -

Page 25: Installation

It is highly recommended that at least steps 1-6 are performed by the customer prior to on-site installation and training by Excillum staff in order to save time. Should you feel uncertain about how to perform either of these steps please contact Excillum support for advice. -

Page 26: Unpacking

4.2 Unpacking Make sure to look for possible transportation damage to the container before unpacking. In case of transportation damage, immediately notify the carrier and contact Excillum. Check the material received against the packing list. Report any discrepancies immediately. - Page 27 METALJET D2+ INSTALLATION High-pressure tubing Flex-hose assembly Figure 4-1. The x-ray head is semi-rigidly connected to the pump box by the supply high-pressure tubing and the return bellow for the metal-jet loop. In addition, 6 mm outer diameter flexible hoses for cooling water supply and return run from the opening in the pump box towards the x-ray head.

- Page 28 METALJET D2+ INSTALLATION Figure 4-2. The minimum distance from the lid of the pump box and the base plate is 45 cm, and the maximum distance is 55 cm. Also, the jet-exit port should be placed straight above the rectangular hole in the pump-box lid.

- Page 29 METALJET D2+ INSTALLATION Figure 4-3. The jet-exit port should be placed straight above the hole in the pump-box lid. Revision 19, November 2016 Page 4-5...

- Page 30 METALJET D2+ INSTALLATION The electron gun/x-ray head and the pump box must be properly fastened in order to avoid dangerous situations where personnel may get injured or equipment may get damaged. The electron gun/x-ray head should be properly fastened using the six M6-threaded holes underneath the base plate, see Figure 4-5.

- Page 31 METALJET D2+ INSTALLATION Figure 4-5. The six M6-threaded holes are spaced according to this image (the electron gun/x-ray head seen from below). Mount the x-ray system controller and the x-ray high-voltage controller properly into a 19” rack located close to the electron gun/x-ray head and the pump box. Figure 4-6.

-

Page 32: Connecting Tubing And Cables

METALJET D2+ INSTALLATION 4.3.2 Connecting tubing and cables 4.3.2.1 Tighten inlet and outlet check valve housings Temperature cycling during transportation may reduce the preload of the sealing surfaces inside the check valve housings, which may cause liquid metal leaks. 1. Tighten the inlet and outlet check valve housings, circled in red in Figure 4-7, slightly using a crescent wrench. -

Page 33: Cooling Water Supply And Return

METALJET D2+ INSTALLATION interlock connector Figure 4-9. Upper cooling block held in position with four M6-screws around the straight section of the flex- hose assembly. 4. Locate the interlock cable coming out from the opening circled in red in Figure 4-9 and connect it to the interlock connector of the upper cooling block. - Page 34 METALJET D2+ INSTALLATION 1. Pump box inlet 2. Turbopump cooling block 3. Lens cooling block 4. Electron dump cooling block 5. Blank window cooling block (when present) 6. Target chamber cooling 7. Upper cooling block 8. Jet brake cooling block 9.

- Page 35 METALJET D2+ INSTALLATION Figure 4-11. X-ray head with right hand cover removed. Turbo pump cooling block circled in red. Revision 19, November 2016 Page 4-11...

- Page 36 METALJET D2+ INSTALLATION 2. Connect the return hose to the fitting on the upper cooling block circled in green in Connect the water To lower cooling block Figure 4-12. Upper cooling block with water hoses connected and flow direction indicated blue arrows. Revision 19, November 2016 Page 4-12...

-

Page 37: High-Pressure Tubing And Nozzle Assembly

METALJET D2+ INSTALLATION 4.3.2.4 High-pressure tubing and nozzle assembly 1. Carefully remove transportation seals from the high-pressure tubing and the nozzle assembly before connecting these to each other. NOTE: Some pressure can build up inside the high-pressure tubing, due to temperature and air pressure cycling, causing some liquid metal spillage. -

Page 38: Cooling Water

RS232 or USB. In addition, the water temperature has to be compatible with the melting point of the alloy used. Contact Excillum for further information about water chiller requirements if an external water cooling solution is preferred or required. -

Page 39: Interconnecting Cables

METALJET D2+ INSTALLATION 4.3.2.7 Interconnecting cables 1. Connect all interconnecting cables between x-ray head, x-ray system controller, x-ray high-voltage controller and pump box according to Table 4-1 below. Refer to Section 4.3.2.8 and Figure 4-15, Figure 4-16, and Figure 4-17 regarding connector locations for MetalJet D2+ 70 kV systems and Section 4.3.2.9 and Figure 4-15, Figure 4-21, and Figure 4-22 for MetalJet D2+ 160 kV systems. -

Page 40: Metaljet D2+ 70 Kv

METALJET D2+ INSTALLATION 4.3.2.8 MetalJet D2+ 70 kV The high-voltage generator is built into the x-ray high-voltage controller in MetalJet D2+ 70 kV systems, see Figure 4-17. Figure 4-16. X-ray head from behind showing connectors to x-ray system controller and x-ray high-voltage controller (left side). - Page 41 METALJET D2+ INSTALLATION 1. Connect the high-voltage cable to the electron gun (Figure 4-18). a) Remove the transportation cover and wipe the tapered end of the insulator on the connector of the high-voltage cable with a minor amount of isopropanol and lint-free tissue paper. b) Gently insert the tapered end into the high-voltage connector on the electron gun, being careful not to scrape the insulator.

- Page 42 METALJET D2+ INSTALLATION 3. Remove transportation cover and connect the high-voltage cable to the x-ray high-voltage controller (Figure 4-20). Insert the ribbed contact into the receptacle socket on the back of the x-ray high-voltage controller while paying attention to that the key mates with the bottom of the receptacle. - If the friction when inserting the ribbed contact is too high;...

-

Page 43: Metaljet D2+ 160 Kv

METALJET D2+ INSTALLATION 4.3.2.9 MetalJet D2+ 160 kV The high-voltage generator is external in MetalJet D2+ 160 kV systems and connect to the x-ray high-voltage controller, see Figure 4-22. Figure 4-21. X-ray head from behind showing connectors to x-ray system controller and x-ray high-voltage controller (left side). - Page 44 METALJET D2+ INSTALLATION 2. Connect the high-voltage cable to the electron gun (Figure 4-18). a) Remove the transportation cover and wipe the tapered end of the insulator on the connector of the high-voltage cable with a minor amount of isopropanol and lint-free tissue paper. b) Gently insert the tapered end into the high-voltage connector on the electron gun, being careful not to scrape the insulator.

- Page 45 METALJET D2+ INSTALLATION 4. Remove transportation cover and connect the high-voltage cable to the x-ray high-voltage controller (Figure 4-25). Insert the high-voltage contact into the receptacle socket in the back of the high-voltage generator. b. Tighten the four screws to holding the connector flange in position and check for correct HV cable compression by visual inspection on the side of the cable assembly.

- Page 46 METALJET D2+ INSTALLATION DANGER High voltage is potentially lethal All sub-assembly units must be properly grounded and all cables must be securely attached before turning on the MetalJet D2+ source. Ensure that all interlocks are connected before energizing the MetalJet D2+ source. Do not disconnect or bypass any interlocks.

-

Page 47: Mains Supply

The PE terminals are located in the back of each module. The uninterrupted power supply (UPS) offered with MetalJet D2+ system in Figure 4-27 is optional. Follow Excillum document “P-020- 0023 - MetalJet D2+ Security Plus” for detailed installation instructions if a UPS has been purchased together with the system. - Page 48 METALJET D2+ INSTALLATION 2. Connect electrical mains cables to the rear of the x-ray high-voltage controller, the x-ray system controller, the pump box and the water chiller. Mains cables are not included except when a UPS was purchased together with the system. Verify that all electrical mains cables connected to each sub- assembly are connected to a residual-current circuit breaker and that the supply voltage is within the specifications in Table 4-4.

-

Page 49: Safety System

Section 4.4.1 and 4.4.2 below explain the purpose and functionality coupled to the various connectors. Excillum document “P-029-0002 - Customer safety system example” is appended to this operating manual. It shows a system level diagram of how a customer safety system can be implemented. - Page 50 Note: The shutter that Excillum supplies only includes the actual actuator and sensors and does NOT include any drivers or adaption logic.

-

Page 51: Operating Conditions

METALJET D2+ INSTALLATION 4.5 Operating conditions The MetalJet D2+ source may only deliver optimum performance if the following operating conditions are respected. 4.5.1 Ambient conditions See Chapter 11 The MetalJet D2+ source should not be placed in a space where it may be exposed to direct sunlight, atmospheric agents (rain, snow, ice, etc.), dust, or aggressive gases. -

Page 52: System Integration

METALJET D2+ INSTALLATION 4.6 System integration This section gives recommendations regarding system integration and accessibility of system components to allow maintenance and service to the MetalJet D2+ system. It also explains how to integrate the system controller in the system IT infrastructure. 4.6.1 System accessibility Easy access to the system simplify regular maintenance and service and should be considered during the system design phase. - Page 53 METALJET D2+ INSTALLATION During cathode replacement, the high-voltage cable and the high-voltage flange need to be removed, see Figure 4-30. If possible, provide access to both front and back by removable radiation shielding covers. Figure 4-30. Allow for enough clearance to remove the high voltage cable and high voltage flange during cathode replacement.

-

Page 54: Network Connectivity

METALJET D2+ INSTALLATION 4.6.2 Network connectivity The x-ray system controller should be connected to a local network, see Figure 4-32. A router with a DNS server is preferred but a switch can also be used if the x-ray system controller is configured to use a static IP address. The x-ray system controller runs a VNC server and a SFTP server that can be used to remote control the machine and access files stored on the system controller. -

Page 55: Operation

MetalJet D2+ sources may be operated using two different anode alloys: ExAlloy-G1 and ExAlloy-I1. They have different compositions, which are tailored for different applications. Contact Excillum for further information about which alloy to choose for a specific application. The physical properties of the alloys are also different. -

Page 56: Electron Beam Power Vs. Spot Size

METALJET D2+ OPERATION 5.1.4 Electron beam power vs. spot size The MetalJet D2+ source is in principle capable of focusing 300 W of power into a sub ~5 µm spot. Such a high anode power loading will however generate significant amounts of metal vapor that can damage the source in various ways. -

Page 57: Starting The Metaljet D2+ System

5.2 Starting the MetalJet D2+ system The decision process when starting the MetalJet D2+ system is illustrated by a flowchart in Figure 5-1 below. Contact Excillum according to the instructions in Page ii in situations not covered by this flowchart. START... -

Page 58: Capabilities Of The Software

METALJET D2+ OPERATION 5.3 Capabilities of the software The XCS software and its corresponding HMI application can control all parameters in the system. The main functions of the software are: Performing parametrization (Section 5.8) Turning x-ray generation on and off (Sections 5.10.1 and 5.10.3) ... - Page 59 METALJET D2+ OPERATION Figure 5-3. The “Summary” tab is the start view of the GUI for control of the MetalJet D2+ source. Revision 19, November 2016 Page 5-5...

-

Page 60: Gui Layout

METALJET D2+ OPERATION 5.4.1 GUI layout The GUI has eleven tabs, each controlling specific parts of the MetalJet D2+ source. In each tab certain functions of the source may be controlled. Functions Summary Summary of source settings and system status States State machine controls Vacuum... -

Page 61: Advanced States

METALJET D2+ OPERATION Figure 5-4. The “States” tab from which regular operation of the MetalJet D2+ source is carried out through state requests from this tab. On. In this state, the system generates x-rays at the requested power, while the liquid-metal jet is running and the system maintains a good vacuum. -

Page 62: State Indicators

Changing the user level is done in the upper right corner using the drop down list under the Excillum logotype (see Figure 5-4 above). The default password is “jxs4944”. During normal operation it is recommended to always use the “user” level. -

Page 63: Parametrization

METALJET D2+ OPERATION Figure 5-5. The “Log” tab. Errors, warnings, and other relevant information regarding the operation of the MetalJet D2+ source may be found here. 5.8 Parametrization The first time the MetalJet D2+ source is set up, or when the cathode or the electron optics have been physically modified or adjusted, the system needs to be parametrized. -

Page 64: Align Electron Beam To Optical Axis

METALJET D2+ OPERATION This will ramp up the high voltage of the electron gun and the electron-beam power to the “Lowpower” setting. The actual value is determined by the minimum spot size achievable for the cathode installed and can be changed when the user level is set to “Service”. 4. -

Page 65: Characterize Focus Lens And Verify Jet Stability

METALJET D2+ OPERATION 9. Wait for the green button to indicate that the “Segment” state is reached. 10. Go to the “Results” tab, select “Segment” in the images list and inspect the image. If the system is ok the image of the jet should be fairly sharp, straight, and centered in the aperture (see Figure 5-7). 11. -

Page 66: Characterize Linefocus Coils

METALJET D2+ OPERATION 15. The software automatically checks the status of the jet stability, and changes the color of the “confirm stability jet” button in the “Service” tab if the jet is stable. In case the software does not confirm jet stability automatically, the customer has the option to analyze the image in figure 5-8 and determine if the jet is stable enough. -

Page 67: Set Emission Power And Spot Size

METALJET D2+ OPERATION 19. The result from “Linefocus” can also be found under the “Results” tab by selecting “Linefocus” in the images list. However, no inspection is necessary. 20. Go to the “Summary” tab, change the user level to “User” and follow the instructions under Section 5.9 to set and calibrate the spot size. -

Page 68: Recalibrate Spot Size

METALJET D2+ OPERATION The emission power will now be increased to the maximum power allowed for calibration using the current spot size settings, or to the requested power if it is lower than the maximum allowed power. The system will then use an iterative algorithm to find the correct focus- and linefocus-coil settings. - Page 69 METALJET D2+ OPERATION This will turn off the x-ray generation, high voltage, liquid-metal jet pump, turbo vacuum pump, and roughing pump. Note that the system will not be vented which means that no vacuum sealing surfaces should be opened. 2.

-

Page 70: System Settings

METALJET D2+ OPERATION 5.11 System Settings The system settings menu can be accessed by right clicking on the gray banner in the bottom of the screen and selecting “Settings”, see Figure 5-10. This menu can be used to change network settings as well as the time zone and keyboard layout. -

Page 71: Software Api

Controlling the XCS over TCP/IP from customer written software is easy. The XCS acts as a TCP server listening on port 4944. All commands are sent in clear-text and follow a request – reply pattern. Commands end with an end-line. Contact Excillum for a detailed description of the XCS API. Revision 19, November 2016 Page 5-17... -

Page 72: Maintenance And Service

NOTE Disclaimer of liability Excillum accepts no liability for personal injury or material damage, losses or operating malfunctions due to improperly performed maintenance. Table 6-1 summarizes which systems and components that will require maintenance and service in order for the MetalJet D2+ source to function normally. -

Page 73: Vacuum System

Excillum offer turbopump service through a replacement program. Excillum recommendation: Turbopump performance is monitored internally by the pump to shut it down in case current draw or temperature thresholds are exceeded. -

Page 74: Jet Pump Diaphragm

Excillum recommendation: We suggest that service is driven by when the jet pump shows symptoms of check valve wear and troubleshooting efforts indicate check valve malfunction, see Section 8. Excillum’s experience is that the check valve on the inlet side wears out more frequently than the one on the outlet side. -

Page 75: Nozzle Assembly

Section 6.2.5 below. If a new nozzle fails to start properly on the first attempt Excillum will replace it free of charge but will not replace more nozzles free of charge until the particle filter, see Section 6.2.5, has been replaced and Excillum support contacted. - Page 76 Stable jet? Section 5.8.4 Replace nozzle & restart source Stable jet? Section 5.8.4 First contact Excillum support. Replace liquid- metal particle filter and then nozzle as described in Section 6.2.5. Claim warranty for nozzle and filter. Stable jet? Section 5.8.4...

-

Page 77: Particle Filter

Excillum recommendation: The lifetime of the window has so far been limited by incidents related to jet instabilities or by customer requirements on beryllium window homogeneity. We therefore suggest that service is entirely driven by exit window failure or application requirements. -

Page 78: Liquid Metal Spillage

Background: During installation and service spillage may occur. Under normal conditions there should not be any leaks from the MetalJet D2+ source causing spillage of liquid metal. If liquid metal is leaking from any part of the system, immediately contact Excillum according to instructions in Section 1.3.1. - Page 79 As a reference, Excillum has significant experience operating the MetalJet D2+ source with an 80x20 μm spot size at 250 W and 70 kV acceleration voltage.

-

Page 80: Climate System

Background: The MetalJet D2+ source requires cooling water to maintain the correct operation temperature for the turbopump and the jet system. It comes with the option of using an Excillum supplied water cooler which is integrated into our software or an independent water cooler. -

Page 81: Shutdown

Visually inspect all sub-assembly units. If there is evidence of rust on any of the parts of the system, then do not take it into operation before having consulted Excillum (see Page ii). Depending on how long the system has been taken out of operation the o-rings may have to be replaced. - Page 82 METALJET D2+ SHUTDOWN WARNING Poisoning hazard – Beryllium window Fumes or dust from beryllium and its compounds can be hazardous if inhaled! Corrosion of the beryllium may occur during use. Beryllium must not be cut, machined, or handled in any way. The beryllium foil of the x-ray source is fragile and brittle.

-

Page 83: Malfunction And Troubleshooting

If there is no reference to a specific section in this operating manual or the service manual in the “remedy” column, please contact Excillum for further instructions. Additional and more detailed information regarding the jet pump, roughing pump, turbopump, fore-vacuum gauge, and high-vacuum gauge may be found in their respective operating manual. - Page 84 METALJET D2+ MALFUNCTION AND TROUBLESHOOTING Problem/Symptom Possible cause Remedy Follow service manual HV feedthrough insufficiently instructions to aligned Align HV feedthrough Follow service manual Electron-dump aperture Alignment procedure does not instructions to contaminated by liquid-metal Remove liquid-metal debris from converge debris electron-beam dump aperture No electron-dump signal...

-

Page 85: Customer Support

Excillum strives at offering first-class customer support. We’ll provide our customers with fast and reliable advice on the most cost-effective and quickest solution. Most replacement parts can be shipped immediately. To ensure a fast and smooth servicing process, contact Excillum according to instructions on page ii with the following information: ... -

Page 86: Remote Support

VNC, is connected to internet. TeamViewer comes preinstalled on the x-ray system controller, but it can be downloaded for free from www.teamviewer.com. When TeamViewer is started an ID number and a password is shown which can be used to invite Excillum support to assist with troubleshooting. -

Page 87: Spare Parts

METALJET D2+ SPARE PARTS 10 SPARE PARTS Below is a list of the most common spare parts needed for maintenance of the MetalJet D2+ source. We recommend that you stock the parts labeled with “S”, since these are standard wear parts. Part # Group / Part Name Description... - Page 88 METALJET D2+ SPARE PARTS Part # Group / Part Name Description Special Starters Kit S-010-0002 Special starters kit Contents: Kit of 4 x Cathode Assemblies (A200 or A100) Kit of 4 x Nozzle assemblies The Special Starters Kit contain a kit of the wear parts Exit window and consumables listed above, sold at a rebated price Alloy top off (ExAlloy G1 or ExAlloy I1)

-

Page 89: Technical Data

METALJET D2+ TECHNICAL DATA 11 TECHNICAL DATA Parameter Value Electron gun/x-ray head Max acceleration voltage & beam current 70 kV / 4.28 mA Max electron-beam power 300 W Min x-ray focal spot size 10 µm Jet alloy (target material) ExAlloy-G1/ ExAlloy-I1 Max x-ray leakage at full power 0.6 µSv/h X-ray window material... - Page 90 METALJET D2+ TECHNICAL DATA Parameter Value Cooling water specification Water specification According to water cooling system instructions Min pump flow rate capacity 3 l/min Min pump pressure capacity 5 bar Typical water flow rate 4 l/min at ΔP = 3 bar Water temperature Alloy dependent, typically 30 ±...

- Page 91 X-ray High Voltage Controller SIR 512 24V SIR 512 24V...

- Page 92 240 ohm 2015-03-16 13:02:26 C:\Users\Rickard\OneDrive - Excillum AB\electronics-Excillum\system wiring diagrams\Safety System interface\Electron Gun Safety System Interface\P-029-0001 Rev 02 - Electron gun safety system interface.sch (Sheet: 1/1)

- Page 93 P-029-0002 Rev 02...

- Page 94 Safety Data Sheet according to Regulation (EC) No. 1907/2006 Trading name: ExAlloy-G1 Revised on: 23 Sept. 2009 01. Identification of the substance or the preparation and the company Identification of the substance or preparation: ExAlloy-G1 Other identification REACH registration no.: indium 05-2114306912-55-0000, gallium 05-2114306905-50-0000 (Pre- registration no.) Use of the substance / preparation: Hg substitute, lubricant, reflection agent, electroconductive medium, heat transfer systems, thermal coding heating...

- Page 95 Safety Data Sheet according to Regulation (EC) No. 1907/2006 Trading name: ExAlloy-G1 Revised on: 23 Sept. 2009 04. First aid measures General information: No general information is necessary. Inhalation: No exposure by inhalation possible. Skin contact: Wash off with soap and water. Eye contact: Rinse with lukewarm water with the edge of the eyelid open;...

- Page 96 Safety Data Sheet according to Regulation (EC) No. 1907/2006 Trading name: ExAlloy-G1 Revised on: 23 Sept. 2009 Other information Storage information: Do not store with oxidising or acidic substances. 08. Exposure controls / personal protection Limits for exposure at workplace and/or biological thresholds Workplace limits in Germany: Ingredients with workplace-specific limits to be controlled: not applicable Personal protection...

- Page 97 Safety Data Sheet according to Regulation (EC) No. 1907/2006 Trading name: ExAlloy-G1 Revised on: 23 Sept. 2009 Other information: The product amalgamates with metals on the surface like copper, tin, lead, zinc, gold and silver jewellery, particularly also with light metals on the surface, especially if these are free of oxides.

- Page 98 Safety Data Sheet according to Regulation (EC) No. 1907/2006 Trading name: ExAlloy-G1 Revised on: 23 Sept. 2009 The alloy is not a hazardous working material in the meaning of this Directive. National regulations Water hazard class Class: not dangerous for water (self-assessment) 16.

- Page 99 Safety Data Sheet according to Regulation (EC) No. 1907/2006 Trading name: ExAlloy I 1 Revised on: 22.11.2011 01. Identification of the substance or the preparation and the company Identification of the substance or preparation: ExAlloy I 1 Other identification REACH registration no.: tin 05-2114306920-58-0000, indium 05-2114306912-55-0000, gallium 05-2114306905-50-0000 (Pre-registration no.) Use of the substance / preparation: Hg substitute, lubricant, reflection agent, electroconductive medium...

- Page 100 Safety Data Sheet according to Regulation (EC) No. 1907/2006 Trading name: ExAlloy I 1 Revised on: 22.11.2011 04. First aid measures General information: No general information is necessary. Inhalation: No exposure by inhalation possible. Skin contact: Wash off with soap and water. Eye contact: Rinse with lukewarm water with the edge of the eyelid open;...

- Page 101 Safety Data Sheet according to Regulation (EC) No. 1907/2006 Trading name: ExAlloy I 1 Revised on: 22.11.2011 Other information Storage information: Do not store with oxidising or acidic substances. 08. Exposure controls / personal protection Limits for exposure at workplace and/or biological thresholds Workplace limits in Germany: Ingredients with workplace-specific limits to be controlled: not applicable Personal protection...

- Page 102 Safety Data Sheet according to Regulation (EC) No. 1907/2006 Trading name: ExAlloy I 1 Revised on: 22.11.2011 Other information: The product amalgamates with metals on the surface like copper, tin, lead, zinc, gold and silver jewellery, particularly also with light metals on the surface, especially if these are free of oxides.

- Page 103 Safety Data Sheet according to Regulation (EC) No. 1907/2006 Trading name: ExAlloy I 1 Revised on: 22.11.2011 The alloy is not a hazardous working material in the meaning of this Directive. National regulations Water hazard class Class: not dangerous for water (self-assessment) 16.

Need help?

Do you have a question about the MetalJet D2+ and is the answer not in the manual?

Questions and answers