Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Taber 5750

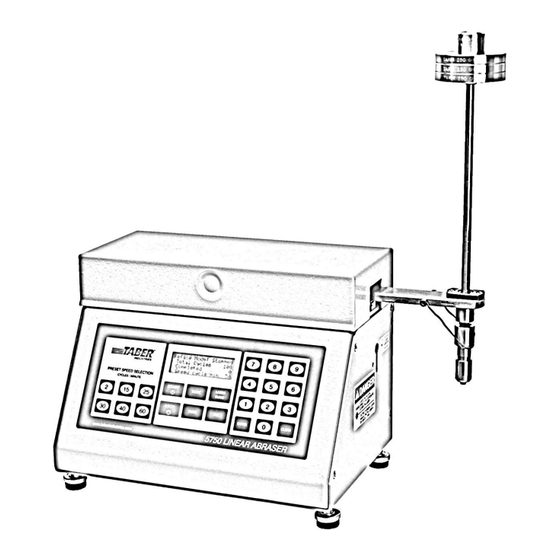

- Page 1 ® Taber Linear Abraser Model 5750 Operating Instructions...

-

Page 2: Safety Precautions

Contents of the shipping container should these components during testing as this may include the following: cause injury and/or damage the equipment. Linear Abraser – Model 5750 Do not place fingers/hands or WARNING: ... -

Page 3: Product Features

Using the same reliable INTRODUCTION abrasive material with the Linear Abraser as with the Taber Rotary Platform Abraser allows you to The Taber Linear Abraser offers tremendous maintain your testing standards. versatility and allows the operator to conduct numerous types of physical property tests. -

Page 4: Instrument Setup

Linear Abraser’s electronic components. NOTE: The bottom of the spline shaft is drilled and tapped to accommodate optional Scratch and Mar Model 5750 – Linear Abraser Operating Instructions ver 2.1 (p/n 132233) - Page 5 PRECAUTIONS oriented at the bottom. The Linear Abraser 5750 incorporates a Class NOTE: If the bubble in the Weight Holder circular level 3R Laser that will highlight the path of the test bubble is not aligned with the center of the circle, the instrument may not be level (see step 7).

-

Page 6: Setting The Test Parameters

The following instructions can be used for either the TEST or REFACE Modes. In both cases, the Linear Abraser must not be in operation in order to reprogram the speed (status displayed Figure 10 is Stopped). Model 5750 – Linear Abraser Operating Instructions ver 2.1 (p/n 132233) - Page 7 >Enter new speed 4” / 101.6mm 6.28 159.51 >CLEAR key to return Test speed set to 45 Cycles/Minute NOTE: If an incorrect speed is entered, press the CLEAR button. Model 5750 – Linear Abraser Operating Instructions ver 2.1 (p/n 132233)

- Page 8 This does NOT affect other speed calibrations. Model 5750 – Linear Abraser Operating Instructions ver 2.1 (p/n 132233)

- Page 9 350g. 4. Ensure that the Wearaser to be refaced is secured and is set to the proper 0.100” distance using the Wearaser Depth Gage. Model 5750 – Linear Abraser Operating Instructions ver 2.1 (p/n 132233)

- Page 10 To ensure Wearasers are refaced consistently, hand brush and reinsert into the Wearaser use a new S-14 refacing strip for each refacing. Collet. Use the Wearaser Depth Gage to ensure proper set-up. Model 5750 – Linear Abraser Operating Instructions ver 2.1 (p/n 132233)

-

Page 11: Specimen Preparation

If the product is allowed to move, shift or rock during testing, an inconsistent wear path may develop which will compromise your test Figure 18 results. Model 5750 – Linear Abraser Operating Instructions ver 2.1 (p/n 132233) - Page 12 Figure 19 may influence the test results. Used in conjunction with the T-Slot Universal Table, Taber also offers fixtures specific for the Specimen Positioning type of material you are testing. The Specimen Fixing Plate is ideal for flexible specimens It is recommended that specimens be tested as (figure 20).

-

Page 13: Testing Procedure

Trial and error is suggested to determine the best abradant/load combination. Figure 23 Taber Industries offers a variety of standardized abradants for the Linear Abraser made from the same high quality materials used in Genuine... - Page 14 25. NOTE: The laser guide will automatically shut off when the START button is pushed. Pressing the Laser Guide button will also shut off this feature. Model 5750 – Linear Abraser Operating Instructions ver 2.1 (p/n 132233)

-

Page 15: Data Sheet

‘bounce’ on the specimen surface, resulting in Data Sheet#: Indicate the sequential data sheet number additional impact force at landing points and here, for your records. additional damage to the surface. Model 5750 – Linear Abraser Operating Instructions ver 2.1 (p/n 132233) -

Page 16: Maintenance

Lubrication Taber recommends annual factory calibration at which time the unit will be thoroughly checked. The bearing assemblies are factory lubricated and do not require regular lubrication. Should... - Page 17 To check the tightness of the rod-end bearings, this problem. If the problem persists, contact Taber Industries. DO NOT continue to run the hold the crank arm securely with one hand and Linear Abraser in this condition as damage to the gently moving the load arm back and forth with instrument may occur.

- Page 18 (8 screws per set). driver responds to the software commands, and To secure the rail to the Linear Abraser, use the longer (16mm) of the M2.5mm screws. Model 5750 – Linear Abraser Operating Instructions ver 2.1 (p/n 132233)

- Page 19 Pressing ENTER will begin the Taber Industries recommends that you calibrate speed calibration, pressing CLEAR will return the Linear Abraser 5750 on an annual basis. the user to the main screen. Should your Linear Abraser require calibration; repair; or adjustment, carefully package it in a rugged container with plenty of cushioning material.

-

Page 20: Troubleshooting

Contact Taber Industries Should you require further assistance, please contact Taber Industries Customer Service Department. Before returning the Linear Abraser to Taber Industries for service / repair, you MUST contact us to obtain a Return Authorization Number. Model 5750 – Linear Abraser... -

Page 21: Optional Accessories

OPTIONAL ACCESSORIES The following pages list optional test attachments and accessories for the Linear Abraser that are sold separately. If you are interested in an attachment that is not listed, please contact Taber Industries. Wear & Abrasion Accessories Wire / Cable Scrape Accessories ... - Page 22 Wearaser Collet The Wearaser® Collet Kit supplied with the Taber Linear Abraser is stainless steel {98g} but is also available in Figure 29 aluminum {28g} (figure 28) or plastic {16g} if a lighter testing load is required.

- Page 23 Crockmeter Kit The Crockmeter Kit {166g} (figure 32) is used to convert the Taber Linear Abraser into a crockmeter allowing the instrument to be used for wet or dry crock testing (color transfer) or rub testing. The test piece is secured under the path of a 16mm diameter acrylic rubbing finger.

- Page 24 "everyday" cleaning. For applications when steel wool is the desired abradant, Taber offers either the 10mm Square Finger Attachment {27g} (figure 33) or the 20mm Square Finger Attachment {39g}. Both are designed with a flat square contact area, and include a compressible neoprene rubber pad.

- Page 25 (figure 36) has a radius (R5) with two faces 90 degrees apart, to which a small piece of sandpaper is affixed. This kit includes Taber’s Fixing Plate Kit which has an 11mm x 140mm opening and 8mm diameter rod. For...

- Page 26 With optional accessories, the Taber Linear Abraser can easily be converted to conduct scratch or mar tests. Many of the scratch tools...

- Page 27 3 to 5 increasing scratches (or what constitutes a Pass/Fail) may be established for each type of material and used solely for comparison to determine test end point. Model 5750 – Linear Abraser Operating Instructions ver 2.1 (p/n 132233)

- Page 28 0.5mm diameter radius point the Linear Abraser spline shaft. Taber’s diamond tool holder is offered with one of three conical diamond tools. 3 mil radius point with 90° angle (Model 139-55) ...

- Page 29 Hoffman Type Stylus (figure 50) - Made from tool steel heat treated to HRC 55-61 with a 0.275" diameter contact arc and 8 RMS surface finish. Figure 51 Model 5750 – Linear Abraser Operating Instructions ver 2.1 (p/n 132233)

- Page 30 9B - 6B - 5B - 4B - 3B - 2B - B - HB - F - H - 2H - 3H - 4H - 5H - 6H - 9H Figure 55 Figure 53 Model 5750 – Linear Abraser Operating Instructions ver 2.1 (p/n 132233)

- Page 31 NOTES: a) The standard load of the Taber Linear Abraser is 350g; includes spline shaft; weight support; and steel wearaser collet kit. b) If no accessory weight discs are required, it is possible to reduce the load by removing the weight support.

- Page 32 Taber will, at its option, repair or replace the defective product if Taber determines it is defective within the warranty period and if it is returned, freight prepaid, to Taber. Replacement parts will be shipped F.O.B. Taber’s plant. Taber is not obligated to furnish service under this Limited Warranty: a) to repair damage resulting from attempts by personnel other than Taber representatives to install, repair, or service the product;...

Need help?

Do you have a question about the 5750 and is the answer not in the manual?

Questions and answers